AMAZON multi-meters discounts AMAZON oscilloscope discounts

Variable-reluctance machines (often abbreviated as VRMs) are perhaps the simplest of electrical machines. They consist of a stator with excitation windings and a magnetic rotor with saliency. Rotor conductors are not required because torque is produced by the tendency of the rotor to align with the stator-produced flux wave in such a fashion as to maximize the stator flux linkages that result from a given applied stator current. Torque production in these machines can be evaluated by using the techniques of Section 3 and the fact that the stator winding inductances are functions of the angular position of the rotor.

Although the concept of the VRM has been around for a long time, only in the past few decades have these machines begun to see widespread use in engineering applications. This is due in large part to the fact that although they are simple in construction, they are somewhat complicated to control. For example, the position of the rotor must be known in order to properly energize the phase windings to produce torque. It is the widespread availability and low cost of micro and power electronics that has made the VRM competitive with other motor technologies in a wide range of applications.

[Variable-reluctance machines are often referred to as switched-reluctance machines (SRMs) to indicate the combination of a VRM and the switching inverter required to drive it. This term is popular in the technical literature. ]

1. BASICS OF VRM ANALYSIS

Common variable-reluctance machines can be categorized into two types: singly-salient and doubly-salient. In both cases, their most noticeable features are that there are no windings or permanent magnets on their rotors and that their only source of excitation consists of stator windings. This can be a significant feature because it means that all the resistive winding losses in the VRM occur on the stator. Because the stator can typically be cooled much more effectively and easily than the rotor, the result is often a smaller motor for a given rating and frame size.

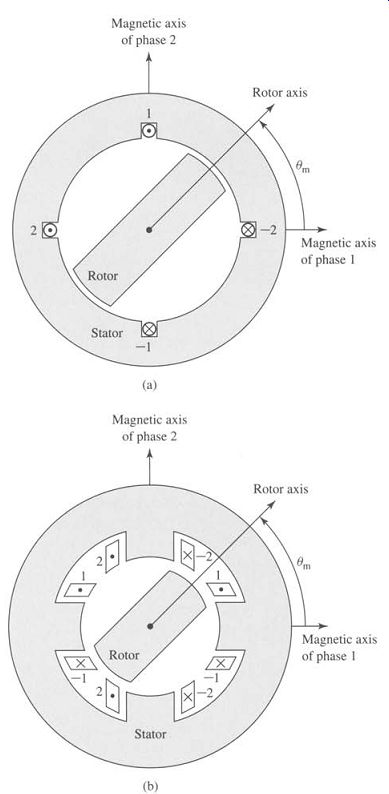

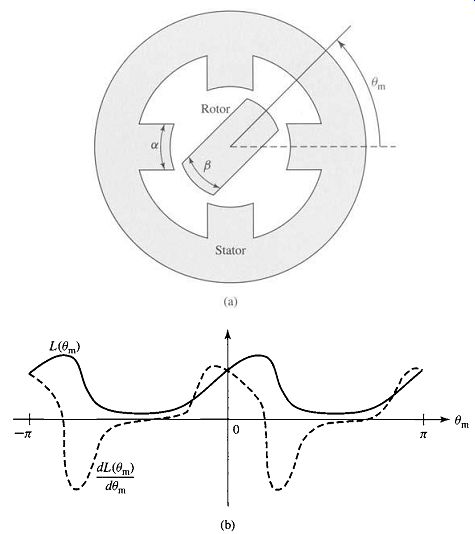

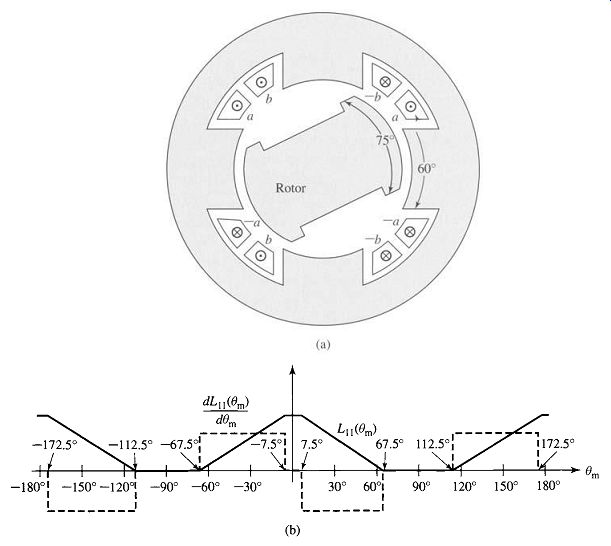

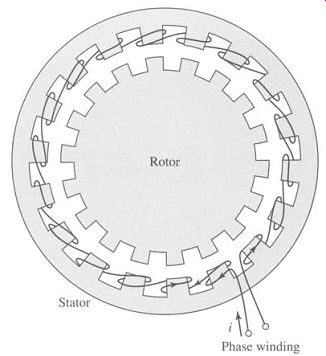

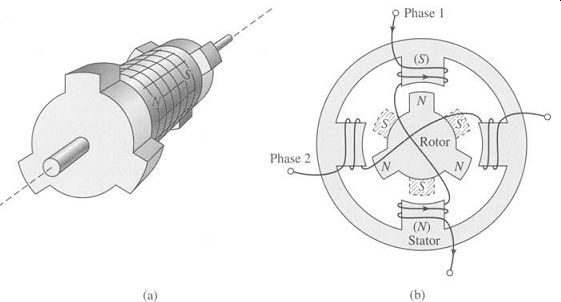

As is discussed in Section 3, to produce torque, VRMs must be designed such that the stator-winding inductances vary with the position of the rotor. FIG. 1a shows a cross-sectional view of a singly-salient VRM, which can be seen to consist of a nonsalient stator and a two-pole salient rotor, both constructed of high-permeability magnetic material. In the figure, a two-phase stator winding is shown although any number of phases are possible.

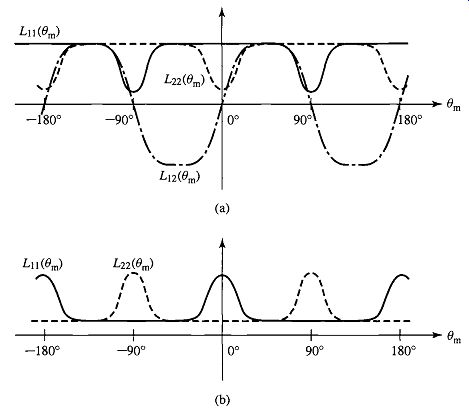

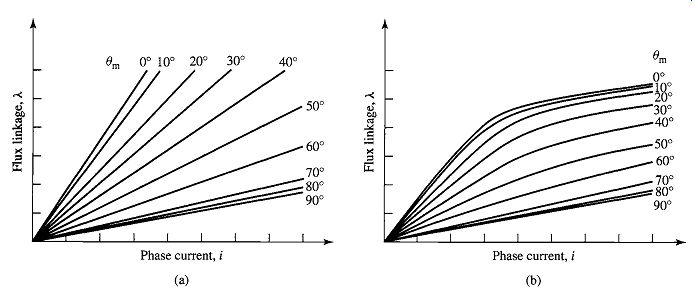

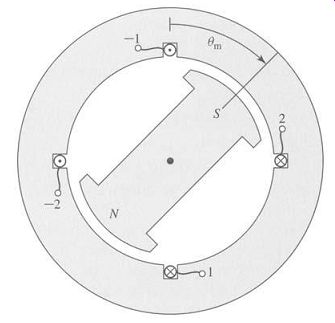

FIG. 2a shows the form of the variation of the stator inductances as a function of rotor angle 0m for a singly-salient VRM of the form of Fig. 1 a. Notice that the inductance of each stator phase winding varies with rotor position such that the inductance is maximum when the rotor axis is aligned with the magnetic axis of that phase and minimum when the two axes are perpendicular. The figure also shows that the mutual inductance between the phase windings is zero when the rotor is aligned with the magnetic axis of either phase but otherwise varies periodically with rotor position.

FIG. 1b shows the cross-sectional view of a two-phase doubly-salient VRM in which both the rotor and stator have salient poles. In this machine, the stator has four poles, each with a winding. However, the windings on opposite poles are of the same phase; they may be connected either in series or in parallel. Thus this machine is quite similar to that of Fig. 1a in that there is a two-phase stator winding and a two-pole salient rotor. Similarly, the phase inductance of this configuration varies from a maximum value when the rotor axis is aligned with the axis of that phase to a minimum when they are perpendicular.

Unlike the singly-salient machine of Fig. 1 a, under the assumption of negligible iron reluctance the mutual inductances between the phases of the doubly-salient VRM of Fig. 1 b will be zero, with the exception of a small, essentially-constant component associated with leakage flux. In addition, the saliency of the stator enhances the difference between the maximum and minimum inductances, which in turn enhances the torque-producing characteristics of the doubly-salient machine. FIG. 2b shows the form of the variation of the phase inductances for the doubly-salient VRM of Fig. 1b.

The relationship between flux linkage and current for the singly-salient VRM is of the form:

(Eq. 1)

Here L 11 (0m) and L 22 (0m) are the self-inductances of phases 1 and 2, respectively, and L l2(0m) is the mutual inductances. Note that, by symmetry:

(Eq. 2)

By sequentially exciting the phases of a VRM, the rotor will rotate in a stepwise fashion, rotating through a specific angle per step. Stepper motors are designed to take advantage of this characteristic. Such motors often combine the use of a variable-reluctance geometry with permanent magnets to produce increased torque and precision position accuracy.

FIG. 1 Basic two-phase VRMs: (a) singly-salient and (b) doubly-salient.

FIG. 2 Plots of inductance versus 0m for (a) the singly-salient VRM

of Fig. 1a and (b) the doubly-salient VRM of Fig. 1b.

Note also that all of these inductances are periodic with a period of 180° because rotation of the rotor through 180° from any given angular position results in no change in the magnetic circuit of the machine.

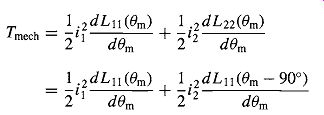

From Eq. 3.68 the electromagnetic torque of this system can be determined from the coenergy as [...]

Equations 6 and 7 illustrate an important characteristic of VRMs in which mutual-inductance effects are negligible. In such machines the torque expression consists of a sum of terms, each of which is proportional to the square of an individual phase current. As a result, the torque depends only on the magnitude of the phase currents and not on their polarity. Thus the electronics which supply the phase currents to these machines can be unidirectional; i.e., bidirectional currents are not required.

Since the phase currents are typically switched on and off by solid-state switches such as transistors or thyristors and since each switch need only handle currents in a single direction, this means that the motor drive requires only half the number of switches (as well as half the corresponding control electronics) that would be required in a corresponding bidirectional drive. The result is a drive system which is less complex and may be less expensive. Typical VRM motor drives are discussed in Section 11.4.

The assumption of negligible mutual inductance is valid for the doubly-salient VRM of Fig. 1b both due to symmetry of the machine geometry and due to the assumption of negligible iron reluctance. In practice, even in situations where symmetry might suggest that the mutual inductances are zero or can be ignored because they are independent of rotor position (e.g., the phases are coupled through leakage fluxes), significant nonlinear and mutual-inductance effects can arise due to saturation of the machine iron. In such cases, although the techniques of Section 3, and indeed torque expressions of the form of Eq. 3, remain valid, analytical expressions are often difficult to obtain. At the design and analysis stage, the winding flux-current relationships and the motor torque can be determined by using numerical-analysis packages which can account for the nonlinearity of the machine magnetic material. Once a machine has been constructed, measurements can be made, both to validate the various assumptions and approximations which were made as well as to obtain an accurate measure of actual machine performance.

From this point on, we shall use the symbol ps to indicate the number of stator poles and Pr to indicate the number of rotor poles, and the corresponding machine is called a Ps/Pr machine. Example 1 examines a 4/2 VRM.

Example 1 illustrates a number of important considerations for the design of VRMs. Clearly these machines must be designed to avoid the occurrence of rotor positions for which none of the phases can produce torque. This is of concern in the design of 4/2 machines which will always have such positions if they are constructed with uniform, symmetric air gaps.

It is also clear that to operate VRMs with specified torque characteristics, the phase currents must be applied in a fashion consistent with the rotor position. For example, positive torque production from each phase winding in Example 1 can be seen from Fig. 4c to occur only for specific values of 0m. Thus operation of VRMs must include some sort of rotor-position sensing as well as a controller which determines both the sequence and the waveform of the phase currents to achieve the desired operation. This is typically implemented by using electronic switching devices (transistors, thyristors, gate-turn-off devices, etc.) under the supervision of a microprocessor-based controller.

Although a 4/2 VRM such as in Example 1 can be made to work, as a practical matter it is not particularly useful because of undesirable characteristics such as its zero-torque positions and the fact that there are angular locations at which it is not possible to achieve a positive torque. For example, because of these limitations, this machine cannot be made to generate a constant torque independent of rotor angle; certainly no combination of phase currents can result in torque at the zero-torque positions or positive torque in the range of angular locations where only negative torque can be produced. As discussed in Section 8.2, these difficulties can be eliminated by 4/2 designs with asymmetric geometries, and so practical 4/2 machines can be constructed.

As has been seen in this section, the analysis of VRMs is conceptually straightforward. In the case of linear machine iron (no magnetic saturation), finding the torque is simply a matter of finding the stator-phase inductances (self and mutual) as a function of rotor position, expressing the coenergy in terms of these inductances, and then calculating the derivative of the coenergy with respect to angular position (holding the phase currents constant when taking the derivative). Similarly, as discussed in Section 3.8, the electric terminal voltage for each of the phases can be found from the sum of the time derivative of the phase flux linkage and the i R drop across the phase resistance.

In the case of nonlinear machine iron (where saturation effects are important)

as is discussed in Section 4, the coenergy can be found by appropriate integration of the phase flux linkages, and the torque can again be found from the derivative of the coenergy with respect to the angular position of the rotor. In either case, there are no rotor windings and typically no other rotor currents in a well-designed variable-reluctance motor; hence, unlike other ac machine types (synchronous and induction), there are no electrical dynamics associated with the machine rotor. This greatly simplifies their analysis.

Although VRMs are simple in concept and construction, their operation is somewhat complicated and requires sophisticated control and motor-drive electronics to achieve useful operating characteristics. These issues and others are discussed in Sections 2 to 5.

2. PRACTICAL VRM CONFIGURATIONS

Practical VRM drive systems (the motor and its inverter) are designed to meet operating criteria such as n Low cost.

Constant torque independent of rotor angular position.

A desired operating speed range.

High efficiency.

A large torque-to-mass ratio.

As in any engineering situation, the final design for a specific application will involve a compromise between the variety of options available to the designer. Because VRMs require some sort of electronics and control to operate, often the designer is concerned with optimizing a characteristic of the complete drive system, and this will impose additional constraints on the motor design.

VRMs can be built in a wide variety of configurations. In Fig. 1, two forms of a 4/2 machine are shown: a singly-salient machine in Fig. 1a and a doubly-salient machine in Fig. lb. Although both types of design can be made to work, a doubly-salient design is often the superior choice because it can generally produce a larger torque for a given frame size.

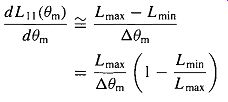

This can be seen qualitatively (under the assumption of a high-permeability, non-saturating magnetic structure) by reference to Eq. 7, which shows that the torque is a function of dLll (Om)/dOm, the derivative of the phase inductance with respect to angular position of the rotor. Clearly, all else being equal, the machine with the largest derivative will produce the largest torque.

This derivative can be thought of as being determined by the ratio of the maximum to minimum phase inductances Lmax/Lmin. In other words, we can write,

(Eq. 8)

where A0m is the angular displacement of the rotor between the positions of maximum and minimum phase inductance. From Eq. 8, we see that, for a given Lmax and A0m, the largest value of Lmax/Lmin will give the largest torque. Because of its geometry, a doubly-salient structure will typically have a lower minimum inductance and thus a larger value of Lmax/Lmin; hence it will produce a larger torque for the same rotor structure.

For this reason doubly-salient machines are the predominant type of VRM, and hence for the remainder of this section we consider only doubly-salient VRMs. In general, doubly-salient machines can be constructed with two or more poles on each of the stator and rotor. It should be pointed out that once the basic structure of a VRM is determined, Lmax is fairly well determined by such quantities as the number of turns, air-gap length, and basic pole dimensions. The challenge to the VRM designer is to achieve a small value of Lmi n. This is a difficult task because Lmin is dominated by leakage fluxes and other quantities which are difficult to calculate and analyze.

As shown in Example 1, the geometry of a symmetric 4/2 VRM with a uniform air gap gives rise to rotor positions for which no torque can be developed for any combination of excitation of the phase windings. These torque zeros can be seen to occur at rotor positions where all the stator phases are simultaneously at a position of either maximum or minimum inductance. Since the torque depends on the derivative of inductance with respect to angular position, this simultaneous alignment of maximum and minimum inductance points necessarily results in zero net torque.

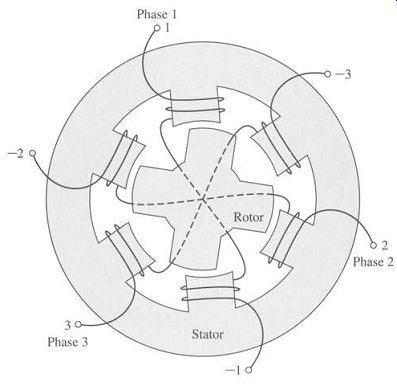

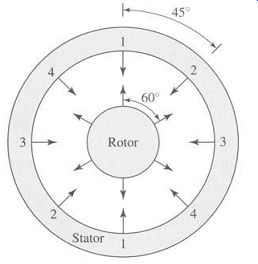

FIG. 5 Cross-sectional view of a 6/4 three-phase VRM.

FIG. 5 shows a 6/4 VRM from which we see that a fundamental feature of the 6/4 machine is that no such simultaneous alignment of phase inductances is possible. As a result, this machine does not have any zero-torque positions. This is a significant point because it eliminates the possibility that the rotor might get stuck in one of these positions at standstill, requiring that it be mechanically moved to a new position before it can be started. In addition to the fact that there are not positions of simultaneous alignment for the 6/4 VRM, it can be seen that there also are no rotor positions at which only a torque of a single sign (either positive or negative) can be produced. Hence by proper control of the phase currents, it should be possible to achieve constant-torque, independent of rotor position.

In the case of a symmetric VRM with Ps stator poles and Pr rotor poles, a simple test can be used to determine if zero-torque positions exist. If the ratio Ps/Pr (or alternatively Pr/Ps if Pr is larger than Ps) is an integer, there will be zero-torque positions. For example, for a 6/4 machine the ratio is 1.5, and there will be no zero torque positions. However, the ratio is 2.0 for a 6/3 machine, and there will be zero torque positions.

In some instances, design constraints may dictate that a machine with an integral pole ratio is desirable. In these cases, it is possible to eliminate the zero-torque positions by constructing a machine with an asymmetric rotor. For example, the rotor radius can be made to vary with angle as shown in grossly exaggerated fashion in Fig. 6a. This design, which also requires that the width of the rotor pole be wider than that of the stator, will not produce zero torque at positions of alignment because dL(Om)/dOm is not zero at these points, as can be seen with reference to Fig. 6b.

FIG. 6 A 4/2 VRM with nonuniform air gap: (a) exaggerated schematic

view and (b) plots of L(0m) and dL( Om)/dOm versus 0m.

An alternative procedure for constructing an integral-pole-ratio VRM without zero-torque positions is to construct a stack of two or more VRMs in series, aligned such that each of the VRMs is displaced in angle from the others and with all rotors sharing a common shaft. In this fashion, the zero-torque positions of the individual machines will not align, and thus the complete machine will not have any torque zeros.

For example, a series stack of two two-phase, 4/2 VRMs such as that of Example 1 (Fig. 3) with a 45 ° angular displacement between the individual VRMs will result in a four-phase VRM without zero-torque positions.

Generally VRMs are wound with a single coil on each pole. Although it is possible to control each of these windings separately as individual phases, it is common practice to combine them into groups of poles which are excited simultaneously. For example, the 4/2 VRM of Fig. 3 is shown connected as a two-phase machine. As shown in Fig. 5, a 6/4 VRM is commonly connected as a three-phase machine with opposite poles connected to the same phase and in such a fashion that the windings drive flux in the same direction through the rotor.

In some cases, VRMs are wound with a parallel set of windings on each phase.

This configuration, known as a bifilar winding, in some cases can result in a simple inverter configuration and thus a simple, inexpensive motor drive. The use of a bifilar winding in VRM drives is discussed in Section 11.4.

In general, when a given phase is excited, the torque is such that the rotor is pulled to the nearest position of maximum flux linkage. As excitation is removed from that phase and the next phase is excited, the rotor "follows" as it is then pulled to a new maximum flux-linkage position. Thus, the rotor speed is determined by the frequency of the phase currents. However, unlike the case of a synchronous machine, the relationship between the rotor speed and the frequency and sequence of the phase winding excitation can be quite complex, depending on the number of rotor poles and the number of stator poles and phases. This is illustrated in Example 2.

---------------

EXAMPLE 2

Consider a four-phase, 8/6 VRM. If the stator phases are excited sequentially, with a total time of To sec required to excite the four phases (i.e., each phase is excited for a time of To~4 sec), find the angular velocity of the stator flux wave and the corresponding angular velocity of the rotor. Neglect any system dynamics and assume that the rotor will instantaneously track the stator excitation.

Solution

FIG. 7 shows in schematic form an 8/6 VRM. The details of the pole shapes are not of importance for this example and thus the rotor and stator poles are shown simply as arrows indicating their locations. The figure shows the rotor aligned with the stator phase-1 poles.

-------------

This position corresponds to that which would occur if there were no load on the rotor and the stator phase-1 windings were excited, since it corresponds to a position of maximum phase-1 flux linkage.

FIG. 7 Schematic view of a four-phase 8/6 VRM. Pole locations are indicated

by arrows.

Consider next that the excitation on phase 1 is removed and phase 2 is excited. At this point, the stator flux wave has rotated 45 ° in the clockwise direction. Similarly, as the excitation on phase 2 is removed and phase 3 is excited, the stator flux wave will move an additional 45 ° clockwise. Thus the angular velocity Ogs of the stator flux wave can be calculated quite simply as pi/4 rad (45 °) divided by:

T0/4 sec, or omega s = pi/T0 rad/sec.

Note, however, that this is not the angular velocity of the rotor itself. As the phase-1 excitation is removed and phase 2 is excited, the rotor will move in such a fashion as to maximize the phase-2 flux linkages. In this case, Fig. 7 shows that the rotor will move 15 ° counterclockwise since the nearest rotor poles to phase 2 are actually 15 ° ahead of the phase-2 poles. Thus the angular velocity of the rotor can be calculated as -pi/12 rad (15 °, with the minus sign indicating counterclockwise rotation) divided by T0/4 see, or 09 m = - pi /(3T0) rad/sec.

In this case, the rotor travels at one-third the angular velocity of the stator excitation and in the opposite direction!

Example 2 illustrates the complex relationship that can exist between the excitation frequency of a VRM and the "synchronous" rotor frequency. This relationship is directly analogous to that between two mechanical gears for which the choice of different gear shapes and configurations gives rise to a wide range of speed ratios. It is difficult to derive a single rule which will describe this relationship for the immense variety of VRM configurations which can be envisioned. It is, however, a fairly simple matter to follow a procedure similar to that shown in Example 2 to investigate any particular configuration of interest.

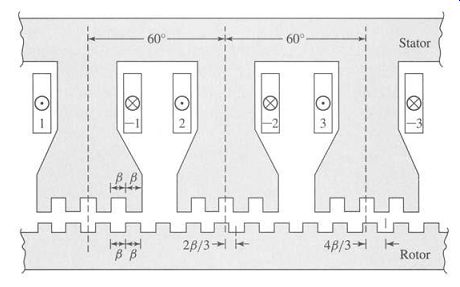

FIG. 8 Schematic view of a three-phase castleated VRM with six stator

poles and four teeth per pole and 28 rotor poles.

Further variations on VRM configurations are possible if the main stator and rotor poles are subdivided by the addition of individual teeth (which can be thought of as a set of small poles excited simultaneously by a single winding). The basic concept is illustrated in Fig. 8, which shows a schematic view of three poles of a three-phase VRM with a total of six main stator poles. Such a machine, with the stator and rotor poles subdivided into teeth, is known as a castleated VRM, the name resulting from the fact that the stator teeth appear much like the towers of a medieval castle.

In Fig. 8 each stator pole has been divided into four sub-poles by the addition 3 o (indicated by the angle/3 in the figure), with a slot of the of four teeth of width 6 7 same width between each tooth. The same tooth/slot spacing is chosen for the rotor, resulting in a total of 28 teeth on the rotor. Notice that this number of rotor teeth and the corresponding value of/3 were chosen so that when the rotor teeth are aligned with those of the phase 1 stator pole, they are not aligned with those of phases 2 and 3. In this fashion, successive excitation of the stator phases will result in a rotation of the rotor.

Castleation further complicates the relationship between the rotor speed and the frequency and sequence of the stator-winding excitation. For example, from Fig. 8 it can be seen that for this configuration, when the excitation of phase 1 is removed and phase 2 is excited (corresponding to a rotation of the stator flux wave by 60 ° 2 ° in the clockwise direction), the rotor will rotate by an angle of (2fl/3) = 4 7 in the counterclockwise direction.

From the preceding analysis, we see that the technique of castleation can be used to create VRMs capable of operating at low speeds (and hence producing high torque for a given stator power input) and with very precise rotor position accuracy.

For example, the machine of Fig. 8 can be rotated precisely by angular increments of (2fl/3). The use of more teeth can further increase the position resolution of these machines. Such machines can be found in applications where low speed, high torque, and precise angular resolution are required. This castleated configuration is one example of a class of VRMs commonly referred to as stepping motors because of their capability to produce small steps in angular resolution.

3. CURRENT WAVEFORMS FOR TORQUE PRODUCTION

As is seen in Section 1, the torque produced by a VRM in which saturation and mutual-inductance effects can be neglected is determined by the summation of terms consisting of the derivatives of the phase inductances with respect to the rotor angular position, each multiplied by the square of the corresponding phase current. For example, we see from Eqs. 8.6 and 8.7 that the torque of the two-phase, 4/2 VRM of Fig. 1b is given by:

(Eq. 9)

FIG. 9 Idealized inductance and dL/dern curves for a three-phase 6/4 VRM with 40 ° rotor and stator poles.

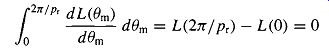

For each phase of a VRM, the phase inductance is periodic in rotor angular position, and thus the area under the curve of d L/dOm calculated over a complete period of L(0m) is zero, i.e.,

(Eq. 10)

....where Pr is the number of rotor poles.

The average torque produced by a VRM can be found by integrating the torque equation (Eq. 9) over a complete period of rotation. Clearly, if the stator currents are held constant, Eq. 10 shows that the average torque will be zero. Thus, to produce a time-averaged torque, the stator currents must vary with rotor position. The desired average output torque for a VRM depends on the nature of the application. For example, motor operation requires a positive time-averaged shaft torque. Similarly, braking or generator action requires negative time-averaged torque.

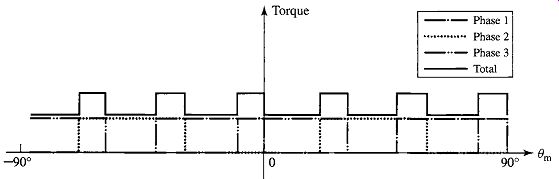

Positive torque is produced when a phase is excited at angular positions with positive d L/dOm for that phase, and negative torque is produced by excitation at positions at which dL/dOm is negative. Consider a three-phase, 6/4 VRM (similar to that shown in Fig. 5) with 40 ° rotor and stator poles. The inductance versus rotor position for this machine will be similar to the idealized representation shown in Fig. 9.

FIG. 10 Individual phase torques and total torque for the motor of

Fig. 9. Each phase is excited with a constant current/o only at positions

where dL/dOm > O.

Operation of this machine as a motor requires a net positive torque. Alternatively, it can be operated as a generator under conditions of net negative torque. Noting that positive torque is generated when excitation is applied at rotor positions at which d L/dOm is positive, we see that a control system is required that determines rotor position and applies the phase-winding excitations at the appropriate time. It is, in fact, the need for this sort of control that makes VRM drive systems more complex than might perhaps be thought, considering only the simplicity of the VRM itself.

One of the reasons that VRMs have found application in a wide variety of situations is because the widespread availability and low cost of microprocessors and power electronics have brought the cost of the sensing and control required to successfully operate VRM drive systems down to a level where these systems can be competitive with competing technologies. Although the control of VRM drives is more complex than that required for dc, induction, and permanent-magnet ac motor systems, in many applications the overall VRM drive system turns out to be less expensive and more flexible than the competition.

Assuming that the appropriate rotor-position sensor and control system is available, the question still remains as to how to excite the armature phases. From Fig. 9, one possible excitation scheme would be to apply a constant current to each phase at those angular positions at which dL/dOm is positive and zero current otherwise.

If this is done, the resultant torque waveform will be that of Fig. 10. Note that because the torque waveforms of the individual phases overlap, the resultant torque will not be constant but rather will have a pulsating component on top of its average value. In general, such pulsating torques are to be avoided both because they may produce damaging stresses in the VRM and because they may result in the generation of excessive vibration and noise.

Consideration of Fig. 9 shows that there are alternative excitation strategies which can reduce the torque pulsations of Fig. 10. Perhaps the simplest strategy is to excite each phase for only 30 ° of angular position instead of the 40 ° which resulted in Fig. 9. Thus, each phase would simply be turned off as the next phase is turned on, and there would be no torque overlap between phases.

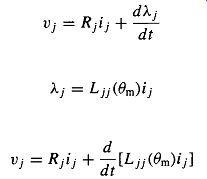

Although this strategy would be an ideal solution to the problem, as a practical matter it is not possible to implement. The problem is that because each phase winding has a self-inductance, it is not possible to instantaneously switch on or off the phase currents. Specifically, for a VRM with independent (uncoupled) phases, 2 the voltage-current relationship of the jth phase is given by

(Eq. 11)

(Eq. 12)

(Eq. 13)

(Eq. 14)

(Eq. 15)

Although Eqs. 13 through 15 are mathematically complex and often require numerical solution, they clearly indicate that some time is required to build up currents in the phase windings following application of voltage to that phase. A similar analysis can be done for conditions associated with removal of the phase currents. The delay time associated with current build up can limit the maximum achievable torque while the current decay time can result in negative torque if current is still flowing when dL(0m)/dOm reverses sign. These effects are illustrated in Example 3 which also shows that in cases where winding resistance can be neglected, an approximate solution to these equations can be found.

Reconsider Example 3 under the condition that a voltage of -250 V is applied to turn off the phase current. Use MATLAB to calculate the integral under the torque-versus-time plot and compare it to the integral under the torque-versus-time curve for the time period during which the torque is positive.

------------

Practice Problem 3

Solution

The current returns to zero at t = 3.5 msec. The integral under the torque curve is 3.67 × 10^-4 N. m. s while that under the positive portion of the torque curve corresponding to positive torque remains equal to 4.56 x 10 ^-4 N. m. s. In this case, the negative torque produces a 20 percent reduction in torque from that which would otherwise be available if the current could be reduced instantaneously to zero.

-------------

Example 3 illustrates important aspects of VRM performance which do not appear in an idealized analysis such as that of Example 1 but which play an extremely important role in practical applications. It is clear that it is not possible to readily apply phase currents of arbitrary waveshapes. Winding inductances (and their time derivatives) significantly affect the current waveforms that can be achieved for a given applied voltage.

In general, the problem becomes more severe as the rotor speed is increased.

Consideration of Example 3 shows, for a given applied voltage, (1) that as the speed is increased, the current will take a larger fraction of the available time during which dL( Om)/dOm is positive to achieve a given level and (2) that the steady-state current which can be achieved is progressively lowered. One common method for maximizing the available torque is to apply the phase voltage somewhat in advance of the time when dL( Om)/dOm begins to increase. This gives the current time to build up to a significant level before torque production begins.

Yet a more significant difficulty (also illustrated in Example 3) is that just as the currents require a significant amount of time to increase at the beginning of a turn-on cycle, they also require time to decrease at the end. As a result, if the phase excitation is removed at or near the end of the positive dL (0m)/dOm period, it is highly likely that there will be phase current remaining as dL(Om)/dOm becomes negative, so there will be a period of negative torque production, reducing the effective torque-producing capability of the VRM. One way to avoid such negative torque production would be to turn off the phase excitation sufficiently early in the cycle that the current will have decayed essentially to zero by the time that dL( Om)/dOm becomes negative. However, there is clearly a point of diminishing returns, because turning off the phase current while dL (0m)/dOm is positive also reduces positive torque production. As a result, it is often necessary to accept a certain amount of negative torque (to get the required positive torque) and to compensate for it by the production of additional positive torque from another phase.

Another possibility is illustrated in Fig. 12. FIG. 12a shows the cross-sectional view of a 4/2 VRM similar to that of Fig. 3 with the exception that the rotor pole angle has been increased from 60 ° to 75 °, with the result that the rotor pole overhangs that of the stator by 15 °. As can be seen from Fig. 12b, this results in a region of constant inductance separating the positive and negative dL(Om)/dOm regions, which in turn provides additional time for the phase current to be turned off before the region of negative torque production is reached.

Although Fig. 12 shows an example with 15 ° of rotor overhang, in any particular design the amount of overhang would be determined as part of the overall design process and would depend on such issues as the amount of time required for the phase current to decay and the operating speed of the VRM. Also included in this design process must be recognition that the use of wider rotor poles will result in a larger value of Lmin, which itself tends to reduce torque production (see the discussion of Eq. 8) and to increase the time for current buildup.

FIG. 12 A 4/2 VRM with 15 ° rotor overhang: (a) cross-sectional view

and (b) plots of L 11 (#m) and dL 11 (8m) / dern versus #rn.

Under conditions of constant-speed operation, it is often desirable to achieve constant torque independent of rotor position. Such operation will minimize pulsating torques which may cause excessive noise and vibration and perhaps ultimately lead to component failure due to material fatigue. This means that as the torque production of one phase begins to decrease, that of another phase must increase to compensate. As can be seen from torque waveforms such as those found in Fig. 11, this represents a complex control problem for the phase excitation, and totally ripple-free torque will be difficult to achieve in many cases.

4. NONLINEAR ANALYSIS

Like most electric machines, VRMs employ magnetic materials both to direct and shape the magnetic fields in the machine and to increase the magnetic flux density that can be achieved from a given amplitude of current. To obtain the maximum benefit from the magnetic material, practical VRMs are operated with the magnetic flux density high enough so that the magnetic material is in saturation under normal operating conditions.

As with the synchronous, induction, and dc machines discussed in Sections 7, the actual operating flux density is determined by trading off such quantities as cost, efficiency, and torque-to-mass ratio. However, because the VRM and its drive electronics are quite closely interrelated, VRMs design typically involves additional trade-offs that in turn affect the choice of operating flux density.

FIG. 13 Plots of ~. versus i for a VRM with (a)linear and (b) nonlinear

magnetics.

FIG. 14 (a) Flux-linkage-current trajectory for the (a) linear and

(b) nonlinear machines of Fig. 13.

FIG. 2 shows typical inductance-versus-angle curves for the VRMs of Fig. 1.

Such curves are characteristic of all VRMs. It must be recognized that the use of the concept of inductance is strictly valid only under the condition that the magnetic circuit in the machine is linear so that the flux density (and hence the winding flux linkage) is proportional to the winding current. This linear analysis is based on the assumption that the magnetic material in the motor has constant magnetic permeability.

This assumption was used for all the analyses earlier in this section.

An alternate representation of the flux-linkage versus current characteristic of a VRM is shown in Fig. 13. This representation consists of a series of plots of the flux linkage versus current at various rotor angles. In this figure, the curves correspond to a machine with a two-pole rotor such as in Fig. 1, and hence a plot of curves from 0 ° to 90 ° is sufficient to completely characterize the machine.

FIG. 13a shows the set of ~.-i characteristics which would be measured in a machine with linear magnetics, i.e., constant magnetic permeability and no magnetic saturation. For each rotor angle, the curve is a straight line whose slope corresponds to the inductance L(0m) at that angular position. In fact, a plot of L(0m) versus 0m such as in Fig. 2 is an equivalent representation to that of Fig. 13a.

In practice, VRMs do operate with their magnetic material in saturation and their ~.-i characteristics take on the form of Fig. 13b. Notice that for low current levels, the curves are linear, corresponding to the assumption of linear magnetics of Fig. 13a.

However, for higher current levels, saturation begins to occur and the curves bend over steeply, with the result that there is significantly less flux linkage for a given current level. Finally, note that saturation effects are maximum at 0m = 0 ° (for which the rotor and stator poles are aligned) and minimal for higher angles as the rotor approaches the nonaligned position.

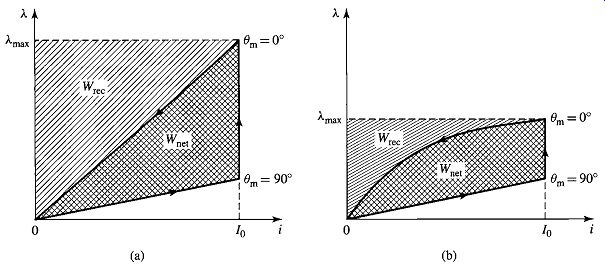

Saturation has two important, somewhat contradictory effects on VRM performance. On the one hand, saturation limits flux densities for a given current level and thus tends to limit the amount of torque available from the VRM. On the other hand, it can be shown that saturation tends to lower the required inverter volt-ampere rating for a given VRM output power and thus tends to make the inverter smaller and less costly. A well-designed VRM system will be based on a trade-off between the two effects. 3 These effects of saturation can be investigated by considering the two machines of Fig. 13a and b operating at the same rotational speed and under the same operating condition. For the sake of simplicity, we assume a somewhat idealized condition in which the phase-1 current is instantaneously switched on to a value I0 at 0m = -90 ° (the unaligned position for phase 1) and is instantaneously switched off at 0m = 0 ° (the aligned position). This operation is similar to that discussed in Example 1 in that we will neglect the complicating effects of the current buildup and decay transients which are illustrated in Example 3.

Because of rotor symmetry, the flux linkages for negative rotor angles are identical to those for positive angles. Thus, the flux linkage-current trajectories for one current cycle can be determined from Fig. 13a and b and are shown for the two machines in Fig. 14a and b.

As each trajectory is traversed, the power input to the winding is given by its volt-ampere product...

(Eq. 16)

The net electric energy input to the machine (the energy that is converted to mechanical work) in a cycle can be determined by integrating Eq. 16 around the trajectory

(Eq. 17)

This can be seen graphically as the area enclosed by the trajectory, labeled Wnet in Fig. 14a and b. Note that the saturated machine converts less useful work per cycle than the unsaturated machine. As a result, to get a machine of the same power output, the saturated machine will have to be larger than a corresponding (hypothetical)

unsaturated machine. This analysis demonstrates the effects of saturation in lowering torque and power output.

The peak energy input to the winding from the inverter can also be calculated. It is equal to the integral of the input power from the start of the trajectory to the point

(Eq. 18)

This is the total area under the )~-i curve, shown in Fig. 14a and b as the sum of the areas labeled Wrec and Wnet.

Since we have seen that the energy represented by the area Wnet corresponds to useful output energy, it is clear that the energy represented by the area Wrec corresponds to energy input that is required to make the VRM operate (i.e., it goes into creating the magnetic fields in the VRM). This energy produced no useful work; rather it must be recycled back into the inverter at the end of the trajectory.

The inverter volt-ampere rating is determined by the average power per phase processed by the inverter as the motor operates, equal to the peak energy input to the VRM divided by the time T between cycles. Similarly, the average output power per phase of the VRM is given by the net energy input per cycle divided by T. Thus the ratio of the inverter volt-ampere rating to power output is

(Eq. 19)

In general, the inverter volt-ampere rating determines its cost and size. Thus, for a given power output from a VRM, a smaller ratio of inverter volt-ampere rating to output power means that the inverter will be both smaller and cheaper. Comparison of Fig. 14a and b shows that this ratio is smaller in the machine which saturates; the effect of saturation is to lower the amount of energy which must be recycled each cycle and hence the volt-ampere rating of the inverter required to supply the VRM.

------------

Practice Problem 4

Consider a two-phase VRM which is identical to that of Example 4 with the exception of an additional 5 mH of leakage inductance in each phase. (a) Calculate the ratio of the inverter volt-ampere rating to the VRM net power output for the following idealized operating cycle:

(i) The current is instantaneously raised to 25 A when 0m ---90 °.

(ii) The current is then held constant as the rotor rotates to 0m = 10 °.

(iii) At 0 m = 10 °, the current is reduced to zero.

(b) Assuming the VRM to be operating as a motor using the cycle described in part (a) and rotating at a constant speed of 2500 r/min, calculate the net electromechanical power supplied to the rotor.

Solution

b. emech = 1467 W

Inverter volt-ampere rating = 1.75

Net output power

------------------

Saturation effects clearly play a significant role in the performance of most VRMs and must be taken into account. In addition, the idealized operating cycle illustrated in Example 4 cannot, of course, be achieved in practice since some rotor motion is likely to take place over the time scale over which current changes occur. As a result, it is often necessary to resort to numerical-analysis packages such as finite-element programs as part of the design process for practical VRM systems. Many of these programs incorporate the ability to model the nonlinear effects of magnetic saturation as well as mechanical (e.g., rotor motion) and electrical (e.g., current buildup) dynamic effects.

As we have seen, the design of a VRM drive system typically requires that a trade-off be made. On the one hand, saturation tends to increase the size of the VRM for a given power output. On the other hand, on comparing two VRM systems with the same power output, the system with the higher level of saturation will typically require an inverter with a lower volt-ampere rating. Thus the ultimate design will be determined by a trade-off between the size, cost, and efficiency of the VRM and of the inverter.

5. STEPPING MOTORS

As we have seen, when the phases of a VRM are energized sequentially in an appropriate step-wise fashion, the VRM will rotate a specific angle for each step. Motors designed specifically to take advantage of this characteristic are referred to as stepping motors or stepper motors. Frequently stepping motors are designed to produce a large number of steps per revolution, for example 50, 100, or 200 steps per revolution (corresponding to a rotation of 7.2 °, 3.6 ° and 1.8 ° per step). An important characteristic of the stepping motor is its compatibility with digital-electronic systems. These systems are common in a wide variety of applications and continue to become more powerful and less expensive. For example, the stepping motor is often used in digital control systems where the motor receives open-loop commands in the form of a train of pulses to turn a shaft or move an object a specific distance. Typical applications include paper-feed and print-head-positioning motors in printers and plotters, drive and head-positioning motors in disk drives and CD players, and worktable and tool positioning in numerically controlled machining equipment.

In many applications, position information can be obtained simply by keeping count of the pulses sent to the motor, in which case position sensors and feedback control are not required.

The angular resolution of a VRM is determined by the number of rotor and stator teeth and can be greatly enhanced by techniques such as castleation, as is discussed in Section 8.2. Stepping motors come in a wide variety of designs and configurations. In addition to variable-reluctance configurations, these include permanent-magnet and hybrid configurations. The use of permanent magnets in combination with a variable-reluctance geometry can significantly enhance the torque and positional accuracy of a stepper motor.

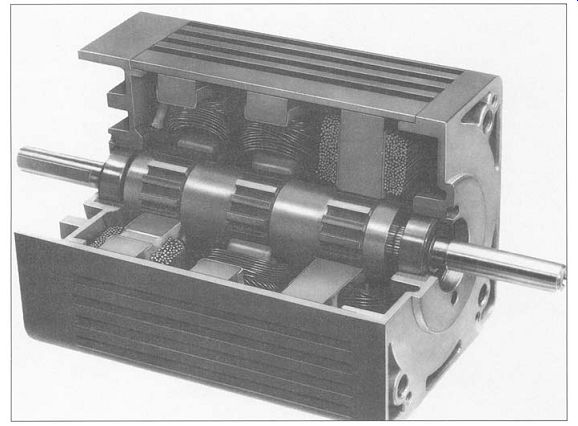

The VRM configurations discussed in Sections 1 through 3 consist of a single rotor and stator with multiple phases. A stepping motor of this configuration is called a single-stack, variable-reluctance stepping motor. An alternate form of variable-reluctance stepping motor is known as a multistack variable-reluctance stepping motor. In this configuration, the motor can be considered to be made up of a set of axially displaced, single-phase VRMs mounted on a single shaft.

FIG. 16 shows a multistack variable-reluctance stepping motor. This type of motor consists of a series of stacks, each axially displaced, of identical geometry and each excited by a single phase winding, as shown in Fig. 17. The motor of Fig. 16 has three stacks and three phases, although motors with additional phases and stacks are common. For an n~-stack motor, the rotor or stator (but not both) on each stack is displaced by 1 / n~ times the pole-pitch angle. In Fig. 16, the rotor poles are aligned, but the stators are offset in angular displacement by one-third of the pole pitch. By successively exciting the individual phases, the rotor can be turned in increments of this displacement angle.

A schematic diagram of a two-phase stepping motor with a permanent-magnet, two-pole rotor is shown in Fig. 18. Note that this machine is in fact a two-phase synchronous machine, similar for example to the three-phase permanent-magnet ac machine of Fig. 5.29. The distinction between such a stepping motor and a synchronous motor arises not from the construction of the motor but rather from how the motor is operated. The synchronous motor is typically intended to drive a load at a specified speed, and the stepping motor is typically intended to control the position of a load.

FIG. 16 Cutaway view of a three-phase, three-stack variable-reluctance

stepping motor. ( Warner Electric.)

The rotor of the stepping motor of Fig. 18 assumes the angles 0m = 0, 45 °, 90°,... as the windings are excited in the sequence:

1. Positive current in phase 1 alone.

2. Equal-magnitude positive currents in phase 1 and phase 2.

3. Positive current in phase 2 alone.

4. Equal-magnitude negative current in phase 1 and positive current in phase 2.

5. Negative current in phase 1 alone.

6. And so on.

Note that if a ferromagnetic rotor were substituted for the permanent-magnet rotor, the rotor would move in a similar fashion.

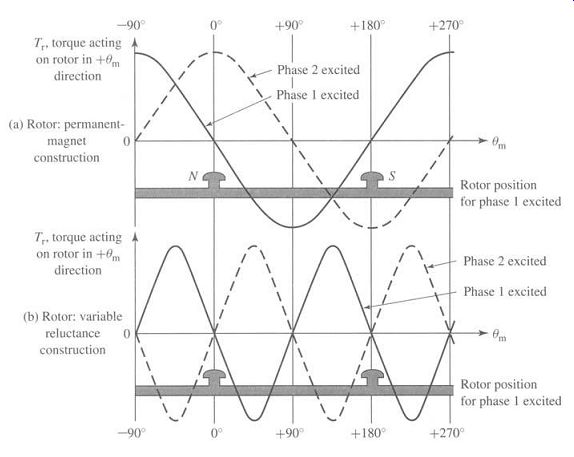

The stepping motor of Fig. 18 can also be used for 90 ° steps by exciting the coils singly. In the latter case, only a permanent-magnet rotor can be used. This can be seen from the torque-angle curves for the two types of rotors shown in Fig. 19.

Whereas the permanent-magnet rotor produces peak torque when the excitation is shifted 90 °, the ferromagnetic rotor produces zero torque and may move in either direction.

FIG. 17 Diagram of one stack and phase of a multiphase, multistack

variable-reluctance stepping motor, such as that in Fig. 16. For an ns-stack

motor, the rotor or stator (but not both) on each stack is displaced

by 1/ns times the pole pitch.

FIG. 18 Schematic diagram of a two-phase permanent-magnet stepping

motor.

FIG. 19 Torque-angle curves for the stepping motor of Fig. 18: (a)

permanent-magnet rotor and (b) variable-reluctance rotor.

The rotor position in the permanent-magnet stepping motor of Fig. 18 is defined by the winding currents with no ambiguity and depends on the direction of the phase currents. Reversing the phase currents will cause the rotor to reverse its orientation.

This is in contrast to VRM configuration with a ferromagnetic rotor, in which two rotor positions are equally stable for any particular set of phase currents, and hence the rotor position cannot be determined uniquely. Permanent-magnet stepping motors are also unlike their VRM counterparts in that torque tending to align the rotor with the stator poles will be generated even when there is no excitation applied to the phase windings. Thus the rotor will have preferred unexcited rest positions, a fact which can be used to advantage in some applications.

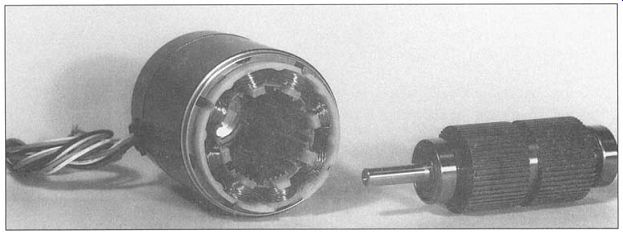

FIG. 20 Disassembled 1.8°/step hybrid stepping motor. (Oriental Motor.)

FIG. 21 Schematic view of a hybrid stepping motor. (a) Two-stack rotor

showing the axially-directed permanent magnet and the pole pieces displaced

by one-half the pole pitch. (b) End view from the rotor north poles and

showing the rotor south poles at the far end (shown crosshatched). Phase

1 of the stator is energized to align the rotor as shown.

The hybrid stepping motor combines characteristics of the variable-reluctance and permanent-magnet stepping motors. A photo of a hybrid stepping motor is shown in Fig. 20, and a schematic view of a hybrid stepping motor is shown in Fig. 21.

The hybrid-stepping-motor rotor configuration appears much like that of a multistack variable-reluctance stepping motor. In the rotor of Fig. 21 a, two identical rotor stacks are displaced axially along the rotor and displaced in angle by one-half the rotor pole pitch, while the stator pole structure is continuous along the length of the rotor. Unlike the multistack variable-reluctance stepping motor, in the hybrid stepping motor, the rotor stacks are separated by an axially-directed permanent magnet. As a result, in Fig. 21 a one end of the rotor can be considered to have a north magnetic pole and the other end a south magnetic pole. FIG. 2 lb shows a schematic end view of a hybrid stepping motor. The stator has four poles with the phase-1 winding wound on the vertical poles and the phase-2 winding wound on the horizontal poles. The rotor is shown with its north-pole end at the near end of the motor and the south-pole end (shown crosshatched) at the far end.

In Fig. 21b, phase 1 is shown excited such that the top stator pole is a south pole while the bottom pole is a north pole. This stator excitation interacts with the permanent-magnet flux of the rotor to align the rotor with a pole on its north-pole end vertically upward and a pole on its south-pole end vertically downward, as shown in the figure. Note that if the stator excitation is removed, there will still be a permanent-magnet torque tending to maintain the rotor in the position shown.

To turn the rotor, excitation is removed from phase 1, and phase 2 is excited. If phase 2 is excited such that the fight-hand stator pole is a south pole and the left-hand one is a north pole, the rotor will rotate 30 ° counterclockwise. Similarly, if the opposite excitation is applied to the phase-2 winding, a 30 ° rotation in the clockwise direction will occur. Thus, by alternately applying phase-1 and phase-2 excitation of the appropriate polarity, the rotor can be made to rotate in either direction by a specified angular increment.

Practical hybrid stepping motors are generally built with more rotor poles than are indicated in the schematic motor of Fig. 21, in order to give much better angular resolution. Correspondingly, the stator poles are often castleated (see Fig. 8) to further increase the angular resolution. In addition, they may be built with more than two stacks per rotor.

The hybrid stepping motor design offers advantages over the permanent-magnet design discussed earlier. It can achieve small step sizes easily and with a simple magnet structure while a purely permanent-magnet motor would require a multipole permanent magnet. In comparison with the variable-reluctance stepping motor, the hybrid design may require less excitation to achieve a given torque because some of the excitation is supplied by the permanent magnet. In addition, the hybrid stepping motor will tend to maintain its position when the stator excitation is removed, as does the permanent-magnet design.

The actual choice of a stepping-motor design for a particular application is determined based on the desired operating characteristics, availability, size, and cost.

In addition to the three classifications of stepping motors discussed in this section, a number of other different and often quite clever designs have been developed. Although these encompass a wide range of configurations and construction techniques, the operating principles remain the same.

Stepping motors may be driven by electronic drive components similar to those discussed in Section 11.4 in the context of VRM drives. Note that the issue of controlling a stepping motor to obtain the desired response under dynamic, transient conditions is quite complex and remains the subject of considerable investigation.

6. SUMMARY

Variable-reluctance machines are perhaps the simplest of electrical machines. They consist of a stator with excitation windings and a magnetic rotor with saliency. Torque is produced by the tendency of the salient-pole rotor to align with excited magnetic poles on the stator.

VRMs are synchronous machines in that they produce net torque only when the rotor motion is in some sense synchronous with the applied stator mmf. This synchronous relationship may be complex, with the rotor speed being some specific fraction of the applied electrical frequency as determined not only by the number of stator and rotor poles but also by the number of stator and rotor teeth on these poles.

In fact, in some cases, the rotor will be found to rotate in the direction opposite to the rotation direction of the applied stator mmf.

Successful operation of a VRM depends on exciting the stator phase windings in a specific fashion correlated to the instantaneous position of the rotor. Thus, rotor position must be measured, and a controller must be employed to determine the appropriate excitation waveforms and to control the output of the inverter. Typically chopping is required to obtain these waveforms. The net result is that although the VRM is itself a simple device, somewhat complex electronics are typically required to make a complete drive system.

The significance of VRMs in engineering applications stems from their low cost, reliability, and controllability. Because their torque depends only on the square of the applied stator currents and not on their direction, these machines can be operated from unidirectional drive systems, reducing the cost of the power electronics. However, it is only recently, with the advent of low-cost, flexible power electronic circuitry and microprocessor-based control systems, that VRMs have begun to see widespread application in systems ranging from traction drives to high-torque, precision position control systems for robotics applications.

Practical experience with VRMs has shown that they have the potential for high reliability. This is due in part to the simplicity of their construction and to the fact that there are no windings on their rotors. In addition, VRM drives can be operated successfully (at a somewhat reduced rating) following the failure of one or more phases, either in the machine or in the inverter. VRMs typically have a large number of stator phases (four or more), and significant output can be achieved even if some of these phases are out of service. Because there is no rotor excitation, there will be no voltage generated in a phase winding which fails open-circuited or current generated in a phase winding which fails short-circuited, and thus the machine can continue to be operated without risk of further damage or additional losses and heating.

Because VRMs can be readily manufactured with a large number of rotor and stator teeth (resulting in large inductance changes for small changes in rotor angle), they can be constructed to produce very large torque per unit volume. There is, however, a trade-off between torque and velocity, and such machines will have a low rotational velocity (consistent with the fact that only so much power can be produced by a given machine frame size). On the opposite extreme, the simple configuration of a VRM rotor and the fact that it contains no windings suggest that it is possible to build extremely rugged VRM rotors. These rotors can withstand high speeds, and motors which operate in excess of 200,000 r/min have been built.

Finally, we have seen that saturation plays a large role in VRM performance.

As recent advances in power electronic and microelectronic circuitry have brought VRM drive systems into the realm of practicality, so have advances in computer-based analytical techniques for magnetic-field analysis. Use of these techniques now makes it practical to perform optimized designs of VRM drive systems which are competitive with alternative technologies in many applications.

Stepping motors are closely related to VRMs in that excitation of each successive phase of the stator results in a specific angular rotation of the rotor. Stepping motors come in a wide variety of designs and configurations. These include variable-reluctance, permanent-magnet, and hybrid configurations. The rotor position of a variable-reluctance stepper motor is not uniquely determined by the phase currents since the phase inductances are not unique functions of the rotor angle. The addition of a permanent magnet changes this situation and the rotor position of a permanent-magnet stepper motor is a unique function of the phase currents.

Stepping motors are the electromechanical companions to digital electronics. By proper application of phase currents to the stator windings, these motors can be made to rotate in well-defined steps ranging down to a fraction of a degree per pulse. They are thus essential components of digitally controlled electromechanical systems where a high degree of precision is required. They are found in a wide range of applications including numerically controlled machine tools, in printers and plotters, and in disk drives.

7. QUIZ

1. Repeat Example 1 for a machine identical to that considered in the example except that the stator pole-face angle is Beta = 45 °.

2. In the paragraph preceding Eq. 1, the text states that "under the assumption of negligible iron reluctance the mutual inductances between the phases of the doubly-salient VRM of Fig. lb will be zero, with the exception of a small, essentially constant component associated with leakage flux." Neglect any leakage flux effects and use magnetic circuit techniques to show that this statement is true.

3. Use magnetic-circuit techniques to show that the phase-to-phase mutual inductance in the 6/4 VRM of Fig. 5 is zero under the assumption of infinite rotor- and stator-iron permeability. Neglect any contributions of leakage flux.

4. A 6/4 VRM of the form of Fig. 5 has the following properties: Stator pole angle/~ = 30 ° Rotor pole angle ot -30 ° Air-gap length g = 0.35 mm Rotor outer radius R = 5.1 cm Active length D = 7 cm This machine is connected as a three-phase motor with opposite poles connected in series to form each phase winding. There are 40 turns per pole (80 turns per phase). The rotor and stator iron can be considered to be of infinite permeability and hence mutual-inductance effects can be neglected.

a. Defining the zero of rotor angle 0m at the position when the phase-1 inductance is maximum, plot and label the inductance of phase 1 as a function of rotor angle.

b. On the plot of part (a), plot the inductances of phases 2 and 3.

c. Find the phase-1 current I0 which results in a magnetic flux density of 1.0 T in the air gap under the phase-1 pole face when the rotor is in a position of maximum phase-1 inductance.

d. Assuming that the phase-1 current is held constant at the value found in part (c) and that there is no current in phases 2 and 3, plot the torque as a function of rotor position.

The motor is to be driven from a three-phase current-source inverter which can be switched on or off to supply either zero current or a constant current of magnitude I0 in phases 2 and 3; plot the torque as a function of rotor position.

e. Under the idealized assumption that the currents can be instantaneously switched, determine the sequence of phase currents (as a function of rotor position) that will result in constant positive motor torque, independent of rotor position.

f. If the frequency of the stator excitation is such that a time To = 35 msec is required to sequence through all three phases under the excitation conditions of part (e), find the rotor angular velocity and its direction of rotation.

5. In Section 2, when discussing Fig. 5, the text states: "In addition to the fact that there are not positions of simultaneous alignment for the 6/4 VRM, it can be seen that there also are no rotor positions at which only a torque of a single sign (either positive or negative) can be produced." Show that this statement is true.

6. Consider a three-phase 6/8 VRM. The stator phases are excited sequentially, requiting a total time of 15 msec. Find the angular velocity of the rotor in r/min.

7. The phase windings of the castleated machine of Fig. 8 are to be excited by turning the phases on and off individually (i.e., only one phase can be on at any given time).

a. Describe the sequence of phase excitations required to move the rotor to the fight (clockwise) by an angle of approximately 21.4 °.

b. The stator phases are to be excited as a regular sequence of pulses.

Calculate the phase order and the time between pulses required to produce a steady-state rotor rotation of 125 r/min in the counterclockwise direction.

8. Replace the 28-tooth rotor of Problem 7 with a rotor with 26 teeth.

a. Phase 1 is excited, and the rotor is allowed to come to rest. If the excitation on phase 1 is removed and excitation is applied to phase 2, calculate the resultant direction and magnitude (in degrees) of rotor rotation.

b. The stator phases are to be excited as a regular sequence of pulses.

Calculate the phase order and the time between pulses required to produce a steady-state rotor rotation of 80 r/min in the counterclockwise direction.

9. Repeat Example 3 for a rotor speed of 4500 r/min.

10. Repeat Example 3 under the condition that the rotor speed is 4500 r/min and that a negative voltage of -250 V is used to turn off the phase current.

11. The three-phase 6/4 VRM of Problem 4 has a winding resistance of 0.15 fl/phase and a leakage inductance of 4.5 mH in each phase. Assume that the rotor is rotating at a constant angular velocity of 1750 ffmin.

a. Plot the phase-1 inductance as a function of the rotor angle 0m.

b. A voltage of 75 V is applied to phase 1 as the rotor reaches the position 0m = -30 ° and is maintained constant until 0m = 0 °. Calculate and plot the phase-1 current as a function of time during this period.

c. When the rotor reaches 0 = 0 °, the applied voltage is reversed so that a voltage of -75 V is applied to the winding. This voltage is maintained until the winding current reaches zero, at which point the winding is open-circuited. Calculate and plot the current decay during the time until the current decays to zero.

d. Calculate and plot the torque during the time periods investigated in parts (b) and (c).

12. Assume that the VRM of Examples 1 and 3 is modified by replacing its rotor with a rotor with 75 ° pole-face angles as shown in Fig. 12a. All other dimensions and parameters of the VRM are unchanged.

a. Calculate and plot L(0m) for this machine.

b. Repeat Example 3 except that the constant voltage 100 V is first applied at 0m = -67.5 ° when dL( Om)/dOm becomes positive and the constant voltage of100 V is then applied at 0m = -7.5 ° (i.e., when d L( Om)/dOm becomes zero) and is maintained until the winding current reaches zero.

c. Plot the corresponding torque.

13. Repeat Example 4 for a symmetrical two-phase 4/2 VRM whose ~.-i characteristic can be represented by the following expression (for phase 1) as a function of 0m over the range 0 < 0m _< 90°:

14. Consider a two-phase stepper motor with a permanent-magnet rotor such as shown in Fig. 18 and whose torque-angle curve is as shown in Fig. 19a.

This machine is to be excited by a four-bit digital sequence corresponding to the following winding excitation:

a. Make a table of 4-bit patterns which will produce rotor angular positions of 0,45°,..., 315 ° .

b. By sequencing through the bit pattern found in part (a) the motor can be made to rotate. What time interval (in milliseconds) between bit-pattern changes will result in a rotor speed of 1200 r/min?

FIG. 22 Castleated hybrid stepping motor for Problem 8.15.

15 FIG. 22 shows a two-phase hybrid stepping motor with castleated poles on the stator. The rotor is shown in the position it occupies when current is flowing into the positive lead of phase 1.

a. If phase one is turned off and phase 2 is excited with current flowing into its positive lead, calculate the corresponding angular rotation of the rotor.

Is it in the clockwise or counterclockwise direction?

b. Describe an excitation sequence for the phase windings which will result in a steady rotation of the rotor in the clockwise direction.

c. Determine the frequency of the phase currents required to achieve a rotor speed of 8 r/min.

16. Consider a multistack, multiphase variable-reluctance stepping motor, such as that shown schematically in Fig. 17, with 14 poles on each of the rotor and stator stacks and three stacks with one phase winding per stack. The motor is built such that the stator poles of each stack are aligned.

a. Calculate the angular displacement between the rotor stacks.

b. Determine the frequency of phase currents required to achieve a rotor speed of 90 deg. r/min.