One part of the power distribution system involved at all points in the system is the conductor. Conductors can be made of aluminum or copper wire. Aluminum is generally used for long-distance distribution because of its lighter weight. Once the power is inside the plant, copper conductors are generally used for distribution. Copper conductors will be solid in bus bar and busway applications, and they will be stranded conductors for all other applications.

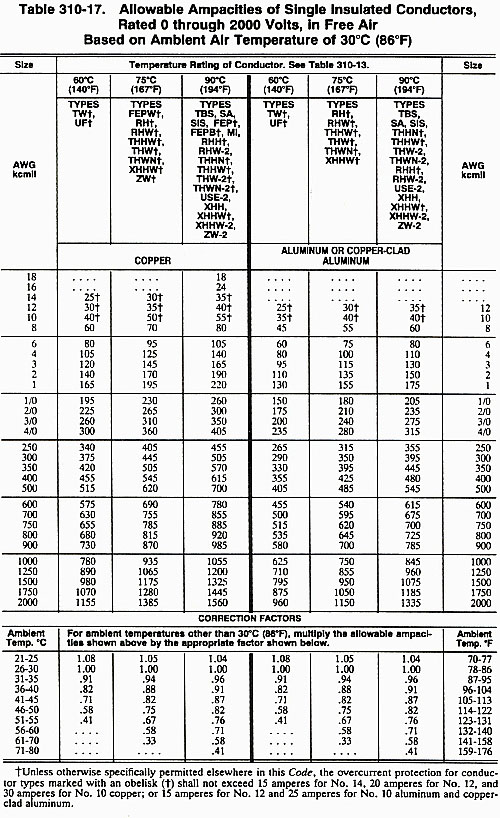

The conductors are sized by the amount of amperage they can carry. A table of typical conductor sizes and their ampacities is provided in Figure 1 (below). The standard used to determine the size of each conductor is called the American Wire Gauge (AWG). These tables have been established by the National Electrical Code (NEC), and they are used to select the proper size conductor to carry the load.

Conductors are also classified by the type of insulation that is used as a cover. The type of cover also determines the voltage rating of the wire. Typical voltage ratings for conductors used in motor control applications include 300, 600, and 1000 V. The voltage and current ratings of the conductor should not be exceeded under any circumstances.

The type of covering is also listed in Figure 1. Abbreviations for each of these coverings are listed in the NEC tables and help to determine the type of wire that should be selected for each application. The outer covering of the wire serves several purposes, including protecting the conductors from coming in contact with metal in the cabinet or other conductors. The cover also provides a location to stamp all specification data regarding the wire, including the voltage rating, AWG size, temperature specification, and type of covering.

Above:

A table of typical conductor sizes and their ampacities.