Enclosures are required to house disconnects, motor starters, and other motor controls. The enclosures are available in a variety of designs that will protect the devices inside from all types of environmental conditions. Figure 1 shows a list of typical enclosure types as classified by the National Electrical Manufacturers Association (NEMA), and Figure 2 shows examples of each type of enclosure.

Type 1 enclosures are designed for general-purpose applications in indoor locations. That is, the enclosure should not be exposed to extreme conditions, such as excessive moisture. Type 2 enclosure is rated for drip-proof conditions that exist indoors. That is, some moisture may come in contact with the enclosure, but it's not approved where equipment must be washed down or steam cleaned daily.

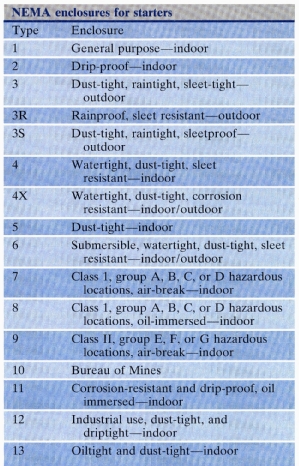

Above: Fig. 1: List of enclosure types provided by the National Electric

Manufacturers Association (NEMA).

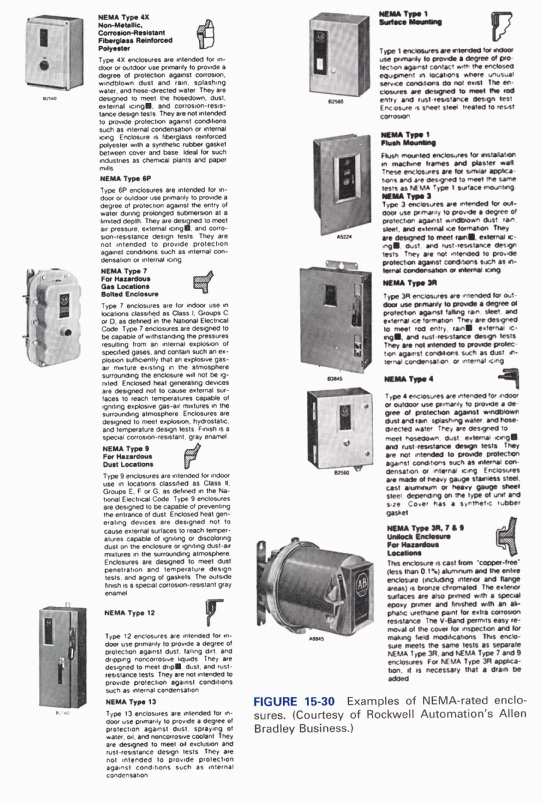

Above: Fig. 2: Examples of NEMA-rated enclosures.

Type 3 enclosures are designed for dust-tight, rain-tight, and sleet-tight conditions that exist outdoors, and type 3R rain-proof, sleet-resistant, and type 3S enclosures are designed for dust-tight, raintight, and sleet-proof conditions. These enclosures are intended for protection against falling rain, sleet, or dust. They are not NEMA enclosures for starters intended to prevent condensation from forming on the inside of the enclosure or on internal components in the enclosure.

If the application is located where windblown water or sleet may be encountered, a type 4 enclosure should be used. The type 4 and 4X enclosures are designed to protect against windblown dust, rain, or water from direct-hose-down conditions. This enclosure is specified by NEMA for water-tight, dust-tight, sleet-resistant indoor and outdoor applications. The 4X enclosure also provides protection in environments where corrosion resistance is required. The covers of these enclosures have protective gaskets that provide a barrier against these conditions. All hardware for conduits must match the same requirements to maintain the integrity of the design throughout the installation.

Type 5 enclosures are designed for dust-tight applications located indoors. This type of enclosure is designed to protect the switch and contacts from a buildup of dust that may prevent proper operation of the switches and starters that are en closed.

Type 6 enclosures are designed to provide submersible, water-tight, dust- tight, sleet-resistant indoor and outdoor applications. The submersible water-tight specification allows the switch to be fully submersed in water to a limited depth and maintain water-tight integrity. This type of enclosure also depends on gaskets to maintain the water-tight condition. As with other enclosures, conduits and connectors must meet the same NEMA standard so that the entire installation maintains the stated protection.

Type 7 enclosures provide class I protection for group A, B, C, or D hazardous locations, with air-break protection for indoor locations. These enclosures are de signed to prevent dangerous gases from penetrating the enclosure and coming into contact with the open parts of switches or other controls. This provides protection in explosive atmospheres. Class I locations are hazardous because flammable gases or vapors may be present in sufficient quantities to cause explosions. Type 8 enclosures provide class 1, group A, B, C, or D hazardous locations, oil immersed for indoor applications. This type of enclosure is very similar to the type 7 enclosure except that it will provide protection against oil immersion instead of air break. This allows the enclosure to be used where oil and machine coolants are used extensively.

Type 9 enclosures provide protection against class II, group E, F, or G hazardous locations and air break for indoor applications. Class II locations are hazardous because of the presence of combustible dust in quantities sufficient to explode or ignite.

Type 10 enclosures are rated for all applications within mines. This type of enclosure must be able to protect switch gear against explosive conditions. Type 11 enclosures provide corrosion resistance and drip-proof, oil-immersion protection for indoor applications. This type of enclosure is used where the vapors and fumes may be corrosive to switch gear or other motor controls that are mounted inside. The exterior of the enclosure is also resistant to corrosion from these fumes. This type of enclosure is also used for applications where machining operations are per formed.

Type 12 enclosures are intended for indoor applications to provide protection against dust, falling dirt, and dripping non-corrosive materials. They are not intended for use against direct spraying of these materials. The last classification of enclosures is type 13.