AMAZON multi-meters discounts AMAZON oscilloscope discounts

Cont. from part 1

MULTISPEED MOTOR CONNECTIONS

Some three-phase motors, referred to as multispeed motors, are designed to provide two separate speed ranges. The speed of an induction motor depends on the number of poles built into the motor and the frequency of the electrical power sup ply. Changing the number of poles provides specific speeds that correspond to the number of poles selected. The more poles per phase, the slower the operating rpm of the motor.

RPM = 120 × Frequency

______________ Number of poles

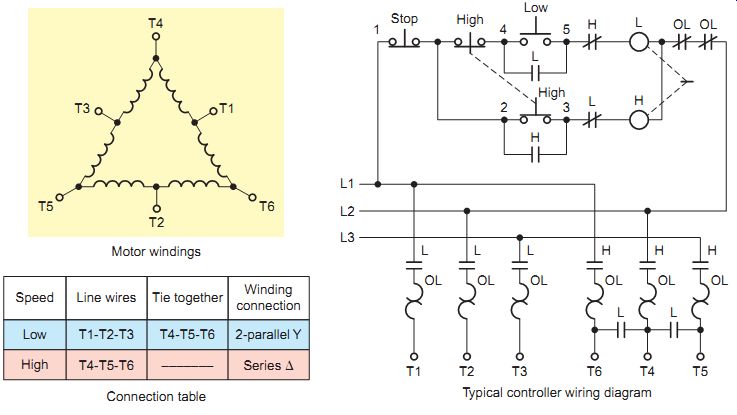

Two-speed motors with single windings can be reconnected, using a controller, to obtain different speeds. The controller circuitry serves to change the connections of the stator windings. These motors are wound for one speed but when the winding is reconnected, the number of magnetic poles within the stator is doubled and the motor speed is reduced to one-half the original speed. This type of reconnection should not be confused with the reconnection of dual-voltage three-phase motors. In the case of multispeed motors, the reconnection results in a motor with a different number of magnetic poles. Three types of single- winding two-speed motors are available: constant horsepower, constant torque, and variable torque. FGR. 31 shows the connections for a constant- horsepower two-speed, three phase motor and controller.

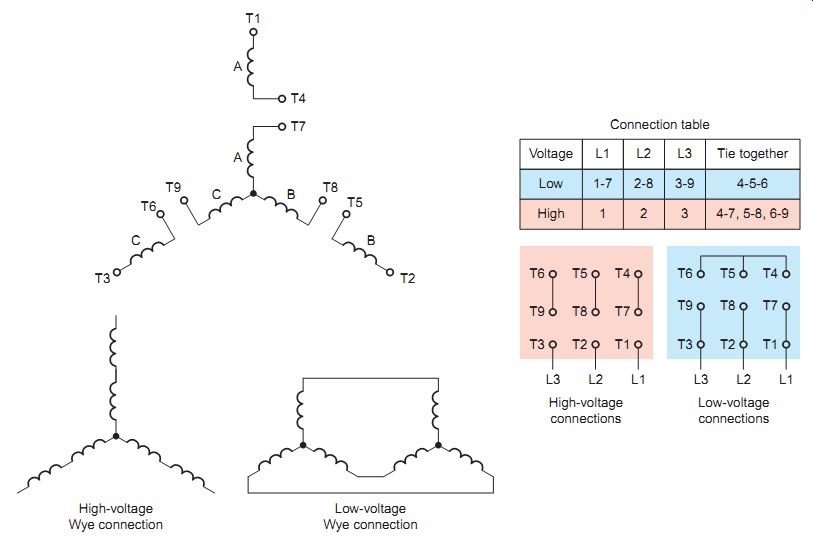

FGR. 30 Dual-voltage wye connections.

FGR. 31 Constant-horsepower two-speed, three-phase motor and controller.

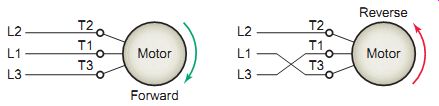

FGR. 32 Reversing the direction of rotation of a three phase motor.

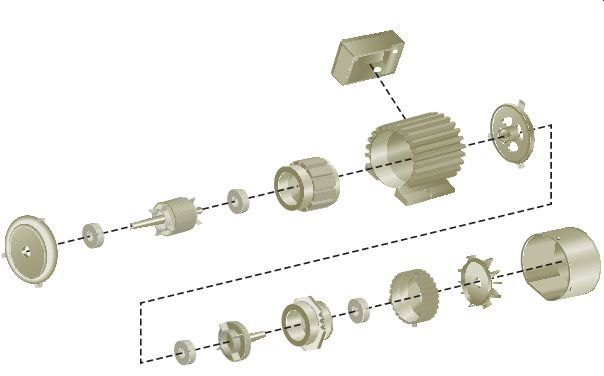

FGR. 33 Inverter duty motor.

To reverse the direction of rotation of any three-phase wye- or delta-connected motor, simply reverse or interchange any two of the three main power leads to the motor. Standard practice is to interchange L1 and L3 as illustrated in FGR. 32. When you are connecting a motor, the direction of rotation is usually not known until the motor is started. In this case, the motor may be temporarily connected to determine the direction of rotation before making permanent connections. In certain applications unintentional reversal of motor rotation can result in serious damage. When this is the case, phase failure and phase reversal relays are used to protect motors, machines, and personnel from the hazards of open phase or reversed-phase conditions.

The speed of an AC induction motor depends on two factors: the number of motor poles and the frequency of the applied power.

In variable-frequency motor drives, variable speed of an induction motor is achieved by varying the frequency of the voltage applied to the motor. The lower the frequency, the slower the operating rpm of the motor. Standard induction motors can be detrimentally affected when operated by variable-frequency drives. "Inverter duty" and "vector duty" describe a class of motors that are capable of operation from a variable-frequency drive. Low temperature rise in this class of motor is accomplished with better insulation systems, additional active material (iron and copper), and/or external fans for better cooling at low speed operation. One type of inverter duty motor is shown in FGR. 33. Part of this particular design includes an independent cooling fan to cool down the motor so that it can operate within a wide speed range without any heating problem.

PART 3 QUIZ

1. In what two general ways are motors classified?

2. List three major organizations involved with motor standards and installation requirements in the United States.

3. What two DC motor operating features make them useful for industrial applications?

4. What part of a DC motor is identified by each of the following lead designations?

a. A1 and A2

b. S1 and S2

c. F1 and F2

5. List the three general types of DC motors.

6. What two factors determine the direction of rotation of a DC motor?

7. In what phase configurations are AC induction motors available?

8. What terms are used to identify the rotating and stationary parts of an AC induction motor?

9. Describe the construction of and external electrical connection to the squirrel-cage rotor used in AC induction motors.

10. Outline the starting sequence of a split-phase motor.

11. Assume the direction of rotation of a split-phase motor needs to be reversed. How is this done?

12. A dual-voltage split-phase motor is to be connected for the lower voltage. What connection of the two run windings would be used?

13. You have the option of operating a dual-voltage motor at either the high or the low voltage level. What are the advantages of operating it at the high voltage level?

14. What is the main advantage of the capacitor motor over the standard split-phase type?

15. How are the three distinct windings of a three-phase motor identified?

16. Large horsepower AC motors are usually three phase. Why?

17. What two basic configurations are used for the connection of all three-phase motors?

18. According to NEMA nomenclature, how are the leads of a nine-lead dual-voltage three-phase motor labeled?

19. State the relationship between the speed of a three phase induction motor and the number of poles per phase.

20. Assume the direction of rotation of a three-phase motor needs to be reversed. How is this done?

21. State the relationship between the speed of a three phase induction motor and the frequency of the power source.

22. Why should inverter-duty AC induction motors be used in conjunction with variable-frequency motor drives?

PART 4 Motor Nameplate and Terminology

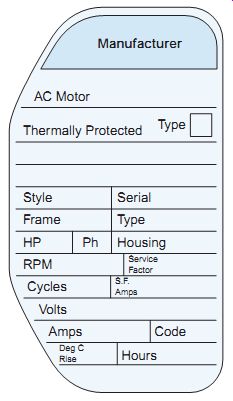

FGR. 34 Typical motor nameplate.

The motor nameplate (FGR. 34) contains important information about the connection and use of the motor. An important part of making motors interchangeable is ensuring that nameplate information is common among manufacturers.

NEC Required Nameplate Information

MOTOR MANUFACTURE

This will include the name and logo of the manufacturer along with catalog numbers, parts numbers, and model numbers used to identify a motor. Each manufacturer uses a unique coding system.

VOLTAGE RATING

Voltage rating is abbreviated V on the nameplate of a motor.

It indicates the voltage at which the motor is designed to operate. The voltage of a motor is usually determined by the supply to which it is being attached. NEMA requires that the motor be able to carry its rated horsepower at nameplate voltage ±10 percent although not necessarily at the rated temperature rise. Thus, a motor with a rated nameplate voltage of 460 V should be expected to operate successfully between 414 V and 506 V.

The voltage may be a single rating such as 115 V or, for dual-voltage motors, a dual rating such as 115 V/230 V. Most 115/230-V motors are shipped from the factory connected for 230 V. A motor connected for 115 V that has 230 V applied will burn up immediately. A motor connected for 230 V that has 115 V applied will be a slow running motor that overheats and trips out.

NEMA standard motor voltages are:

Single-phase motors -115, 230, 115/230, 277, 460, and 230/460 V

Three-phase motors up to 125 hp -208, 230, 460, 230/460, 575, 2,300, and 4,000 V

Three-phase motors above 125 Hp -460, 575, 2,300, and 4,000 V

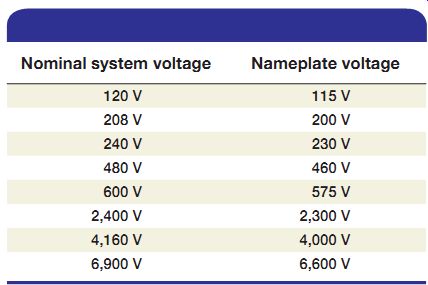

When dealing with motors, it is important to distinguish between nominal system and nameplate volt ages. Examples of the differences between the two are as follows:

CURRENT RATING

The nameplate current rating of a motor is abbreviated A or AMPS. The nameplate current rating is the full-load current at rated load, rated voltage, and rated frequency.

Motors that are not fully loaded draw less than the rated nameplate current. Similarly, motors that are overloaded draw more than the rated nameplate current.

Motors that have dual voltage ratings also have dual cur rent ratings. A dual-voltage motor operated at the higher volt age rating will have the lower current rating. For example, a ½ hp motor rated 115/230 V and 7.4/3.7 A will have a rated current of 3.7 A when operating from a 230 V supply.

LINE FREQUENCY

The line frequency rating of a motor is abbreviated on the nameplate as CY or CYC (cycle), or Hz (hertz). A cycle is one complete wave of alternating voltage or current. Hertz is the unit of frequency and equals the number of cycles per second. In the United States, 60 cycles/second (Hz) is the standard, while in other countries 50 Hz (cycles) is more common.

PHASE RATING

The phase rating of a motor is abbreviated on the name plate as PH. The phase rating is listed as direct current (DC), single-phase alternating current (1? AC) or three phase alternating current (3? AC).

MOTOR SPEED

The rated speed of a motor is indicated on the nameplate in revolutions per minute (rpm). This rated motor speed is not the exact operating speed, but the approximate speed at which a motor rotates when delivering rated horse power to a load.

The number of poles in the motor and the frequency of the supply voltage determine the speed of an AC motor.

The speed of a DC motor is determined by the amount of supply voltage and/or the amount of field current.

AMBIENT TEMPERATURE

The ambient temperature rating of a motor is abbreviated AMD or DEG on the nameplate of a motor. Ambient temperature is the temperature of the air surrounding the motor. In general, maximum ambient temperature for motors is 40° C or 104° F unless the motor is specifically designed for a different temperature and indicates so on its nameplate.

Motors operating at or near rated full load will have reduced life if operated at ambient temperatures above their ratings. If the ambient temperature is over 104° F, a higher-horsepower motor or a special motor designed for operation at higher ambient temperatures must be used.

TEMPERATURE RISE

A motor's permissible temperature rise is abbreviated Deg. C/Rise on the nameplate of the motor. This indicates the amount the motor winding temperature will increase above the ambient temperature because of the heat from the current drawn by the motor at full load. It can also be thought of as the amount by which a motor operating under rated conditions is hotter than its surrounding temperature.

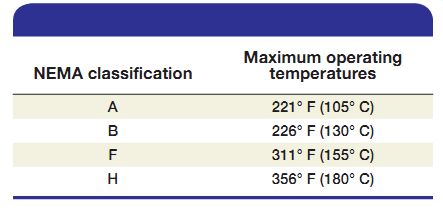

INSULATION CLASS

Motor insulation prevents windings from shorting to each other or to the frame of the motor. The type of insulation used in a motor depends on the operating temperature the motor will experience. As the heat in a motor increases beyond the temperature rating of the insulation, the life of the insulation and of the motor is shortened.

Standard NEMA insulation classes are given by alphabetic classifications according to their maximum temperature rating. A replacement motor must have the same insulation class or a higher temperature rating than the motor it is replacing. The four major NEMA classifications of motor insulation are as follows:

DUTY CYCLE

The duty cycle is listed on the motor nameplate as DUTY, DUTY CYCLE, or TIME RATING. Motors are classified according to the length of time they are expected to operate under full load as either continuous duty or intermittent duty. Continuous duty cycle-rated motors are identified as CONT on the nameplate, while intermittent-duty cycle motors are identified as INTER on the nameplate.

Continuous-duty motors are rated to operate continuously without any damage or reduction in the life of the motor. General-purpose motors will normally be rated for continuous duty. Intermittent-duty motors are rated to operate continuously only for short time periods and then must be allowed to stop and cool before restarting.

HORSEPOWER RATING

The horsepower rating of the motor is abbreviated on the nameplate as HP. Motors below 1 horsepower are referred to as fractional-horsepower motors and motors 1 horsepower and above are called integral-horsepower motors. The HP rating is a measure of the full load out put power the shaft of the motor can produce without reducing the motor's operating life. NEMA has established standard motor horsepower ratings from 1 hp to 450 hp.

Some small fractional-horsepower motors are rated in watts (1 hp = 746 W). Motors rated by the International Electrotechnical Commission (IEC) are rated in kilowatts (kW). When an application calls for a horsepower falling between two sizes, the larger size is chosen to provide the appropriate power to operate the load.

CODE LETTER

An alphabetic letter is used to indicate the National Electric Code Design Code letter for the motor. When AC motors are started with full voltage applied, they draw an "inrush" or "locked-rotor" line current substantially greater than their full-load running current rating. The value of this high current is used to determine circuit breaker and fuse sizes in accordance with NEC requirements. In addition, the starting current can be important on some installations where high starting currents can cause a voltage dip that might affect other equipment.

Motors are furnished with a code letter on the name plate that designates the locked-rotor rating of the motor in kilovolt-amperes (kVA) per nameplate horsepower.

Code letters from A to V are listed in Article 430 of the National Electrical Code. As an example, an M rating allows for 10.0 to 11.19 kVA per horsepower.

DESIGN LETTER

The design letter is an indication of the shape of the motor's torque-speed curve. The most common design letters are A, B, C, D, and E.

Design B is the standard industrial-duty motor, which has reasonable starting torque with moderate starting current and good overall performance for most industrial applications.

Optional Nameplate Information

SERVICE FACTOR

Service factor (abbreviated SF on the nameplate) is a multiplier that is applied to the motor's normal horsepower rating to indicate an increase in power output (or overload capacity) that the motor is capable of providing under certain conditions. For example, a 10-hp motor with a service factor of 1.25 safely develops 125 percent of rated power, or 12.5 hp. Generally, electric motor service factors indicate that a motor can:

• Handle a known overload that is occasional.

• Provide a factor of safety where the environment or service condition is not well defined, especially for general-purpose electric motors.

• Operate at a cooler-than-normal temperature at rated load, thus lengthening insulation life.

Common values of service factor are 1.0, 1.15, and 1.25. When the nameplate does not list a service factor, a service factor of 1.00 is assumed. In some cases the running current at service factor loading is also indicated on the nameplate as service factor amperes (SFA).

MOTOR ENCLOSURE

The selection of a motor enclosure depends on the ambient temperature and surrounding conditions. The two general classifications of motor enclosures are open and totally enclosed. An open motor has ventilating openings, which permit passage of external air over and around the motor windings. A totally enclosed motor is constructed

to prevent the free exchange of air between the inside and outside of the frame, but not sufficiently enclosed to be termed airtight.

FRAME SIZE

Refers to a set of physical dimensions of motors as established by NEMA and IEC. Frame sizes include physical size, construction, dimensions, and certain other physical characteristics of a motor. When you are changing a motor, selecting the same frame size regardless of manufacturer ensures the mounting mechanism and hole positions will match.

Dimensionally, NEMA standards are expressed in

English units and IEC standards are expressed in metric units. NEMA and IEC standards both use letter codes to indicate specific mechanical dimensions, plus number codes for general frame size.

EFFICIENCY

Efficiency is included on the nameplate of many motors.

The efficiency of a motor is a measure of the effectiveness with which the motor converts electrical energy into mechanical energy. Motor efficiency varies from the nameplate value depending on the percentage of the rated load applied to the motor. Most motors operate near their maximum efficiency at rated load.

Energy-efficient motors, also called premium or high efficiency motors, are 2 to 8 percent more efficient than standard motors. Motors qualify as "energy efficient" if they meet or exceed the efficiency levels listed in the NEMA's MG1 publication. Energy-efficient motors owe their higher performance to key design improvements and more accurate manufacturing tolerances.

POWER FACTOR

The letters P.F. when marked on the nameplate of motors stand for power factor. The power factor rating of a motor represents the motor's power factor at rated load and volt age. Motors are inductive loads and have power factors less than 1.0, usually between 0.5 and 0.95, depending on their rated size. A motor with a low power factor will draw more current for the same horsepower than a motor with a high power factor. The power factor of induction motors varies with load and drops significantly when the motor is operated at below 75 percent of full load.

THERMAL PROTECTION

Thermal protection, when marked on the motor nameplate, indicates that the motor was designed and manufactured with its own built-in thermal protection device. There are several types of protective devices that can be built into the motor and used to sense excessive (overload) tempera ture rise and/or current flow. These devices disconnect the motor from its power source if they sense the overload to prevent damage to the insulation of the motor windings.

The primary types of thermal overload protectors include automatic and manual reset devices that sense either current or temperature. With automatic-reset devices, after the motor cools, this electrical circuit-interrupting device automatically restores power to the motor. With manual reset devices, the electrical circuit-interrupting device has an external but ton located on the motor enclosure that must be manually pressed to restore power to the motor. Manual reset protection should be provided where automatic restart of the motor after it cools down could cause personal injury should the motor start unexpectedly. Some low-cost motors have no internal thermal protection and rely on external protection between the motor and the electrical power supply for safety.

CONNECTION DIAGRAMS

Connection diagrams can be found on the nameplate of some motors, or the diagram may be located inside the motor conduit box or on a special connection plate. The diagram will indicate the specific connections for dual-

voltage motors. Some motors can operate in either direction, depending on how the connections to the motor are made, and this information may also be given on the nameplate.

Guide to Motor Terminology

Terminology is of the utmost importance in understanding electrical motor control. Common motor control terms are listed below. Each of these terms will be discussed in detail as they are encountered in the text.

Across-the-line

A method of motor starting. Connects the motor directly to the supply line on starting or running. (Also called full voltage.) Automatic starter A self-acting starter. Completely controlled by the master or pilot switch or some other sensing device.

Auxiliary contact

The contact of a switching device in addition to the main circuit contacts. Operated by the contactor or starter.

Contactor

A type of relay used for power switching.

Jog Momentary operation. Small movement of a driven machine.

Locked-rotor current Measured current with the rotor locked and with rated voltage and frequency applied to the motor.

Low-voltage protection (LVP)

Magnetic control only; not automatic restarting. A three-wire control.

A power failure disconnects service; when power is restored, manual restarting is required.

Low-voltage release (LVR) Magnetic control only; automatic restarting. A two-wire control. A power failure disconnects service; when power is restored, the controller automatically restarts.

Magnetic contactor

A contactor that is operated electromechanically.

Multispeed starter An electric controller with two or more speeds (reversing or nonreversing) and full or reduced voltage starting.

Overload relay

Running overcurrent protection. Operates on excessive current. It does not necessarily provide protection against a short circuit. It causes and maintains interruption of the motor from a power supply.

Plugging Braking by reverse rotation. The motor develops retarding force.

Push button A master switch that is a manually operable plunger or button for actuating a device, assembled into pushbutton stations.

Reduced voltage starter Applies a reduced supply voltage to the motor during starting.

Relay Used in control circuits and operated by a change in one electrical circuit to control a device in the same circuit or another circuit.

Ampere rated.

Remote control

Controls the function initiation or change of electrical device from some remote point.

Selector switch A manually operated switch that has the same construction as push buttons, except that rotating a handle actuates the contacts. The rotating cam may be arranged with incremental indices so that multiple positions can be used to select exclusive operations.

Slip

The difference between the actual speed (motor rpm) and synchronous speed (rotation of the magnetic field).

Starter An electric controller used to start, stop, and protect a connected motor.

Timer

A pilot device, also considered a timing relay, that provides an adjustable time period to per form its function. It can be motor driven, solenoid actuated, or electronically operated.

Torque The twisting or turning force that causes an object to rotate. There are two types of torque that are considered for looking at motors: starting torque and running torque.

PART 4 QUIZ

1. Interpret what each of the following pieces of name plate information specifies:

a. Voltage rating

b. Current rating

c. Phase rating

d. Motor speed

e. Ambient temperature

f. Temperature rise

g. Insulation class

h. Duty cycle

i. Horsepower rating

j. Code letter

k. Design letter

2. List three applications where a motor service factor greater than 1.0 may be desirable.

3. What factors enter into the selection of a proper motor enclosure?

4. Why is it important to consider the frame size when you are replacing a motor?

5. To what do energy-efficient motors owe their higher efficiency levels?

6. In what way does the power factor rating of a given horsepower motor affect its operating current?

7. A motor nameplate indicates that the motor has thermal protection. What exactly does this mean?

8. State the correct motor terminology used to describe each of the following:

a. The current drawn by a motor at standstill with rated voltage and frequency applied.

b. The twisting or turning force of a motor.

c. The difference in speed between the rotation of the magnetic field of a motor and the rotation of the rotor shaft.

d. A device that provides an adjustable time period to perform a function.

e. Used in control circuits and operated by a change in one electrical circuit to control a device in the same circuit or another circuit.

f. Running overcurrent motor protection.

g. Braking a motor by reversing its direction of rotation.

h. Applies a reduced voltage to the motor during starting.

PART 5 Manual and Magnetic Motor Starters

Manual Starter

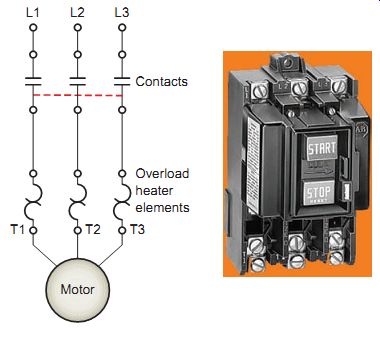

Manual motor starters are a very basic way to supply power to a motor. A manual control circuit is a circuit that requires the operator to control the motor directly at the location of the starter. FGR. 35 shows an example of a three-phase manual-start motor control circuit. The dot ted line across the contacts designates a manual starter (as opposed to a magnetic starter). Incoming power supply wires (L1, L2, and L3) connect to the top of the contacts, and the opposite sides of the contacts are connected to the overload heater elements. The motor terminal connections (T1, T2, and T3) connect to the 3? motor.

Manual starters are operated by the manual start/stop mechanism located on the front of the starter enclosure.

The start/stop mechanism moves all three contacts at once to close (start) or open (stop) the circuit to the motor. The National Electrical Code requires that a starter not only turn a motor on and off but also protect it from overloads.

The three thermal overload protective devices are installed to mechanically trip open the starter contacts when an overload condition is sensed. Manual three-phase starters are used in low horsepower applications such as drill presses and table saws where remote pushbutton control is not required.

Magnetic Starter

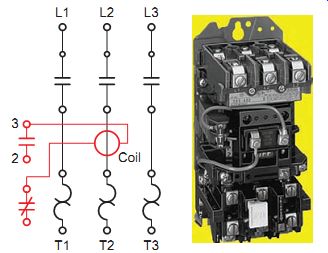

Magnetic motor starters allow a motor to be controlled from any location. FGR. 36 shows a typical three phase across-the-line (full-voltage) magnetic starter. The line terminals, load terminals, motor starter coil, overload relays, and auxiliary holding contact are shown. When the starter coil is energized, the three main contacts as well as the holding contact close. Should an overload condition occur, the normally closed OL relay contact would open. In addition to the power circuit, the manufacturer provides some control circuit wiring. In this case the prewired control circuit wiring consists of two connections to the starter coil. One side of the starter coil is factory wired to the overload relay contact and the other side to the holding contact.

FGR. 35 Manual motor starter.

FGR. 36 Typical three-phase, across-the-line (full voltage) magnetic

starter.

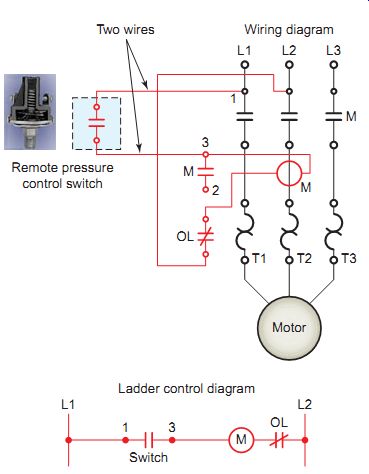

Magnetic motor control circuits are divided into two basic types: the two-wire control circuit, and the three wire control circuit. Two-wire control circuits are designed to start or stop a motor when a remote control device such as a thermostat or pressure switch is activated or deactivated. FGR. 37 shows a typical two-wire control circuit. Notice that the circuit has only two wires leading from the control device to the magnetic starter. The starter operates automatically in response to the state of the control device without the assistance of an operator. When the contacts of the control device close, power is supplied to the starter coil, causing it to energize. As a result, the motor is connected to the line through the power contacts.

The starter coil is deenergized when the contacts of the control device open, switching the motor off.

The two-wire control systems provide low-voltage release but not low-voltage protection. They use a maintained rather than a momentary-contact type of control device. If the motor is stopped by a power interruption, the starter deenergizes (low-voltage release), but also reenergizes if the control device remains closed when the circuit has power restored. Low-voltage protection is not provided, as there is no way for the operator to be automatically protected from the circuit once power has been restored. Two-wire control circuits are used to automatically operate machinery where the automatic restarting characteristic is desirable and there is no danger of persons being injured if the equipment should suddenly restart after a power failure. Sump pumps and refrigerator compressor controls are two common applications for two-wire control systems.

FGR. 37 Two-wire control circuit.

FGR. 38 Three-wire control circuit.

This material and associated copyrights are proprietary to, and used with the permission of Schneider Electric.

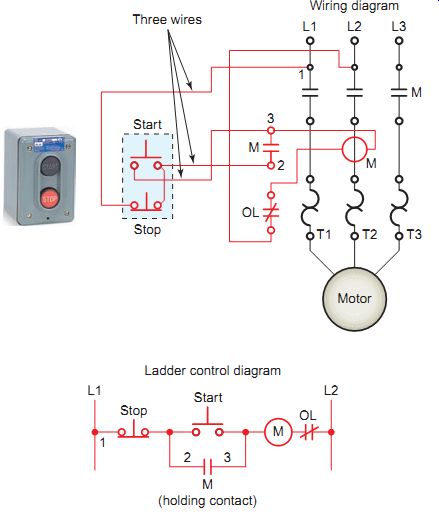

Three-wire control provides low-voltage protection. The starter will drop out when there is a voltage failure, but it will not pick up automatically when voltage returns. Three wire control uses a momentary-contact control device and a holding circuit to provide the power failure protection.

FGR. 38 shows a typical three-wire control circuit. The operation of the circuit can be summarized as follows:

• Three-wires are run from the start/stop pushbutton station to the starter.

• The circuit uses a normally closed (NC) stop push button wired in series with the parallel combination consisting of normally open (NO) start push button and normally open holding contact (M).

• When the momentary-contact start button is closed, line voltage is applied to the starter coil to energize it.

• The three main M contacts close to apply voltage to the motor.

• The auxiliary M contact closes to establish a circuit around the start button.

• When the start button is released, the starter coil remains energized by the closed M auxiliary con tact (also known as the holding, seal-in, or memory contact) and the motor will continue to operate.

• When the momentary-contact stop button is opened, all voltage to the starter coil is lost. The main contacts are opened along with the holding contact and the motor stops.

• The starter drops out at low or no voltage and can not be reenergized unless line voltage returns and the start button is closed.

Basically, three-wire control uses a maintaining circuit consisting of a holding contact wired in parallel with a start button. When the starter drops out, the holding con tact opens and breaks the circuit to the coil until the start button is pressed to restart the motor. In the event of a power failure, the maintaining circuit is designed to protect against automatic restarting when the power returns.

This type of protection must be used where accidents or damage might result from unexpected starts. All devices that start the circuit are connected while those that stop the circuit are connected in series.

PART 5 QUIZ

1. How are the contacts of a manual motor starter closed and opened?

2. One advantage of the magnetic motor starter over manual types is that it allows a motor to be controlled from any location. What makes this possible?

3. Power is lost and then returned to a two-wire motor control circuit. What will happen? Why?

4. Trace the current path of the holding circuit found in a three-wire motor control circuit.

TROUBLESHOOTING

1. Heat is the greatest enemy of a motor. Discuss in what way non-adherence to each of the following motor nameplate parameters could cause a motor to overheat: ( a ) voltage rating; ( b ) current rating; ( c ) ambient temperature; ( d ) duty cycle.

2. Two identical control relay coils are incorrectly connected in series instead of parallel across a 230-V source. Discuss how this might affect the operation of the circuit.

3. A two-wire magnetic motor control circuit control ling a furnace fan uses a thermostat to automatically operate the motor on and off. A single-pole switch is to be installed next to the remote thermostat and wired so that, when closed, it will override the automatic control and allow the fan to operate at all times regardless of the thermostat setting. Draw a ladder control diagram of a circuit that will accomplish this.

4. A three-wire magnetic motor control circuit uses a remote start/stop pushbutton station to operate the motor on and off. Assume the start button is pressed but the starter coil does not energize. List the possible causes of the problem.

5. How is the control voltage obtained in most motor control circuits?

6. Assume you have to purchase a motor to replace the one with the specifications shown below. Visit the website of a motor manufacturer and report on the specifications and price of a replacement motor.

Horsepower 10

Voltage 200

Hertz 60

Phase 3

Full-load amperes 33

RPM 1725

Frame size 215T

Service factor 1.15

Rating 40C AMB-CONT

Locked rotor code J

NEMA design code B

Insulation class B

Full-load efficiency 85.5

Power factor 76

Enclosure OPEN

DISCUSSION TOPICS AND CRITICAL THINKING QUESTIONS

1. Why are contacts from control devices placed only in series with loads?

2. Record all the nameplate data for a given motor and write a short description of what each item specifies.

3. Search the Internet for electric motor connection diagrams. Record all information given for the connection of the following types of motors:

a. DC compound motor

b. AC single-phase dual-voltage induction motor

c. AC three-phase two-speed induction motor

4. The AC squirrel-cage induction motor is the dominant motor technology in use today. Why?