AMAZON multi-meters discounts AMAZON oscilloscope discounts

1. Introduction

The battery is at present the most practical and widely used means of storing electrical energy. The storage capacity of a battery is usually defined in ampere-hours (Ah); energy is strictly defined in kWh or joules, but since the voltage of the battery is nominally fixed and known, the Ah definition is more convenient. The terms battery and cell are often interchanged, although strictly a battery is a group of cells built together in a single unit.

Batteries can be classified into primary and secondary types.

A primary battery stores electrical energy in a chemical form which is introduced at the manufacturing stage. When it is discharged and this chemically stored energy is depleted, the battery is no longer serviceable. Applications for primary batteries are generally in the low-cost domestic environment, in portable equipment such as torches, calculators, radios and hearing aids.

A Secondary (rechargeable) battery will absorb electrical energy, store this in a chemical form and then release electrical energy when required. Once the battery has been discharged and the chemical energy depleted, it can be recharged with a further intake of electrical energy. Many cycles of charging and discharging can be repeated in a secondary battery. Applications cover a wide range. In the domestic environment secondary batteries are used in portable hand tools, laptop computers and portable telephones. Higher-power applications in industry include use in road and rail vehicles and in standby power applications, the latter having already been described in section 11.10.1. The capacity of secondary battery systems ranges from 100 mAh to 2000 Ah. Their useful life ranges from two to 20 years; this will depend, among other things, upon the number of change-discharge cycles and the type and construction of battery used.

The fuel cell is a relatively new method of energy storage which is increasing in acceptance for certain applications. A fuel cell converts the energy of a chemical reaction into electrical energy in a way which is similar, in principle, to the battery, but a fuel cell is 'recharged' by continuous replenishment of the chemical materials.

2. Primary cells

The majority of primary cells now in use fall into one of eight types:

- zinc carbon

- alkaline manganese

- mercury oxide

- silver oxide

- zinc air

- lithium manganese dioxide

- lithium thionyl chloride

- lithium copper oxy-phosphate

Each of these is briefly reviewed in turn in the following sections.

2.1 Zinc carbon

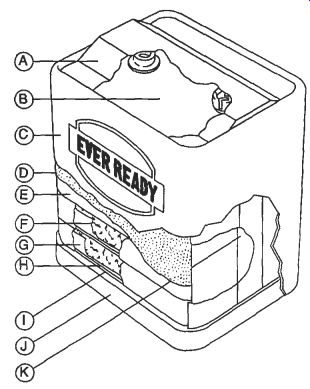

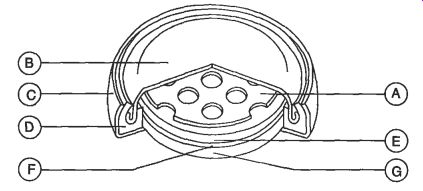

In its latest form, this has been in use since 1950. The basic cell operates with a voltage range of 1.2 V to 1.6 V, and cells are connected in series to form batteries such as MA, AA, C, D, PP3 and PP9. Typical construction of a PP9 battery is shown in Fig. 1.

-------

Fig. 1 Zinc carbon PP9 battery construction

A Protector card. This protects the terminals and is torn away before use.

B Top plate. This plastic plate carries the snap fastener connectors and closes the top of the battery.

C Metal jacket. This is crimped on to the outside of the battery and carries the printed design.

The jacket helps to resist bulging, breakage and leakage and holds all components firmly together.

Wax coating. This seals any capillary passages between cells and the atmosphere, so preventing the loss of moisture.

Plastic cell container. This plastic band holds together all the components of a single cell.

Positive electrode. This is a flat cake containing a mixture of manganese dioxide and carbon black or graphite for conductivity. Ammonium chloride and zinc chloride are other necessary ingredients.

Paper tray. This acts as a separator between mix cake and the zinc electrode.

Carbon coated zinc electrode. Known as a duplex electrode, this is a zinc plate to which is adhered a thin layer of highly conductive carbon which is impervious to electrolyte.

Electrolyte impregnated paper. This contains electrolyte and is an additional separator between the mix cake and the zinc.

Bottom plate. This plastic plate closes the bottom of the battery.

Conducting strip. This makes contact with the negative zinc plate at the base of the stack and is connected to the negative socket at the other end.

---------

Zinc carbon batteries are low in cost, they have an operating temperature range from -10°C to 50 C, and the shelf life at a temperature of 20°C is up to three years.

They are ideally suited to applications with intermittent loads, such as radios, torches, toys, clocks and flashing warning lamps.

2.2 Alkaline manganese

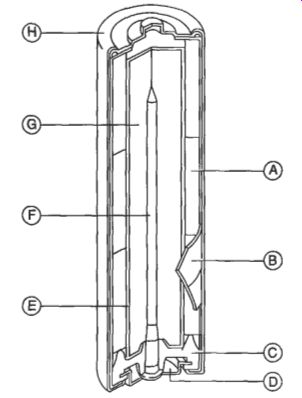

The alkaline manganese battery became commercially available in its present form in the late 1950s. The basic cell operates with a voltage range of 1.35 V to 1.55 V, and cells are connected in series to form the standard battery sizes N, AAA, AA, C, D and PP3. Typical construction of a single-cell battery is shown in Fig. 2.

--------------

A Cathode pellet. This is of synthetic manganese dioxide, with graphite for conductivity, pressed into cylindrical pellets. The pellets make an interference fit with the can, ensuring good electrical contact. The graphite is the cathode current collector.

B Steel can. This acts as the cell container. The preformed stud at the closed end of the can functions as the cell positive terminal.

C Closure. The hard plastic cell closure forms the seal at the open end of the can and carries the bottom cover current collector assembly.

D Bottom cover. This metal plate acts as the negative terminal of the cell. It is welded to the current collector to ensure good electrical contact.

E Separator. This is of non-woven synthetic material.

F Anode current collector. This is a metal 'nail'. G Zinc paste anode. The anode is of amalgamated high purity zinc powder made into a paste with the electrolyte.

H Shrink label. This covers the outside of the cell and carries printed design, and provides insulation of the side of cell.

Fig. 2 Construction of an alkaline manganese battery.

-----------------

Cost is in the medium-low range. The operating temperature range is -15°C to 50°C. and the shelf life at 20°C is up to four years. Alkaline manganese batteries are suited to a current drain of 5 mA to 2 A: this makes them ideally suited to continuous duty applications which can include radios, torches, cassette players, toys and cameras.

2.3 Mercury oxide

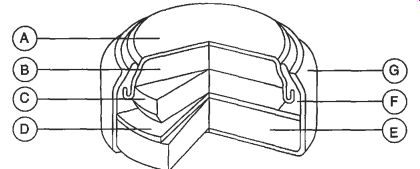

This has been in commercial use since the 1930s. The single cell operates with a narrow voltage range of 1.3 V to 1.4 V. This type is only available as a single button cell, the construction of which is illustrated in Fig. 3.

--------------

Cell cap. The plated steel cap functions as the negative terminal of the cell. The inside of the cap is laminated with copper.

Zinc anode. This is of high purity amalgamated zinc powder.

Absorbent pad. This is of a non-woven material and holds the alkaline electrolyte.

Separator. This is a synthetic ion-permeable material.

Mercuric oxide cathode. The cathode is a pellet of mercuric oxide plus graphite for conductivity and sometimes manganese dioxide. It is compressed into the can.

Sealing grommet. This plastic grommet both seals the cell and insulates the positive and negative terminals.

Cell can. The can is of nickel plated steel and functions as the positive terminal of the cell.

Fig. 3 Mercury oxide button cell

---------------

Cost is in the medium range. The operating temperature range is 0°C to 50 C, and the shelf life at 20°C is up to four years. Mercury oxide button cells are suitable for low current drains of 0.1 mA to 5 mA, with either continuous or intermittent loads.

Their small size and narrow voltage range are ideally suited for use in hearing aids, cameras and electrical instruments.

2.4 Silver oxide

This has been in commercial use since the 1970s. The single cell operates with a very narrow range from 1.50 V to 1.55 V. Construction of a silver oxide button cell is shown in Fig. 4.

Cost is relatively high. They have an operating temperature range from 0°C to 50°C and a shelf life of up to three years. In button cell form, they are suitable for a current drain of 0.1 mA to 5 mA, either continuous or intermittent. Their small size and very narrow voltage range makes them ideal for use in watches, calculators and electrical instruments.

-------------

Cell cap. The plated steel cap functions as the negative terminal of the cell. The inside of the cap is laminated with copper.

Zinc anode. This is a high purity amalgamated zinc powder.

Absorbent pad. This pad is of a non-woven material and holds the alkaline electrolyte.

Separator. This is a synthetic ion-permeable membrane.

Cathode. This is a pellet of silver oxide plus graphite for conductivity. It is compressed into the can.

Sealing grommet. This plastic grommet both seals the cell and insulates the positive and negative terminals.

Cell can. The nickel plated steel can acts as a cell container and as the positive terminal of the cell.

Fig. 4 Silver oxide button cell

------

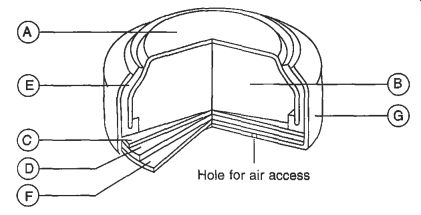

Cell cap. The plated steel cap functions as the negative terminal of the cell.

Zinc anode. This is a high purity amalgamated zinc powder, which also retains the alkaline electrolyte.

Separator. A synthetic ion-permeable membrane.

Cathode. This is a carbon/catalyst mixture with a wet-proofing agent on a mesh support, and with an outer layer of gas- permeable hydrophobic PTFE. Sealing grommet. This plastic grommet seals and insulates the positive and negative terminals, and seals the cathode to the base.

Diffusion membrane. This permeable layer distributes air from the access holes uniformly across the cathode surface.

Can. This plated steel can forms a support for the cathode, acts as a cell container and the positive terminal of the cell. The holes in the can permit air access to the catalyst cathode.

Fig. 5 Zinc air cell

-------

2.5 Zinc air

This battery has been in commercial use since the mid-1970s. A single cell operates with a voltage range of 1.2 V to 1.4 V. The construction of a zinc air button cell is shown in Fig. 5.

Because one of the reactants is air, the battery has a sealing tab which must be removed before it is put into service. Following removal of the tab, the cell voltage will rise to 1.4 V. Cost is in the medium range. Operating temperature is from -10°C to 50°C and the shelf life is almost unlimited while the seal remains unbroken. They are produced as a button cell, and are suitable for a current drain from 1 mA to 10 mA, with either intermittent or continuous loads. The service life is relatively short due to high self- discharge characteristics. but end of life can be accurately estimated because of the flat discharge current. The general performance and the life predictability makes zinc air batteries ideal for use in hearing aids.

2.6 Lithium manganese dioxide

This type of battery has been available since 1975, but it has only become commercially available in the past few years. The single cell operates with a relatively high voltage, in the range 2.8 V to 3.0 V. A typical construction is shown in Fig. 6.

--------------

Current collector. This is a sheet of perforated stainless steel.

Stainless steel top cap. This functions as the negative terminal of the cell.

Stainless steel cell can. This functions as the positive terminal of the cell.

Polypropylene closure. This material is highly impermeable to water vapor and prevents moisture entering the cell after it has been sealed.

Lithium negative electrode. This is punched from sheet lithium.

Separator containing electrolyte. The separator is of non-woven polypropylene cloth and contains electrolyte, a solution of lithium perchlorate in a mixture of propylene carbonate and dimethoxyethane.

Manganese dioxide positive electrode. The cathode is made from a highly active electrolytic oxide.

Fig. 6 Lithium manganese dioxide cell

---------------------

Cost is relatively high. The operating temperature covers a wide range, from -30°C to 50 C, and the shelf life is four to five years. Lithium manganese dioxide batteries are suitable for continuous or intermittent loads; in the form of a button cell they are suitable for 0.1 mA to 10 mA current drain, or as a cylindrical cell they can deliver from 0.1 mA up to 1 A. They have a high discharge efficiency down to -20°C, and are suitable for applications in instruments, watches and cameras.

2.7 Lithium thionyl chloride

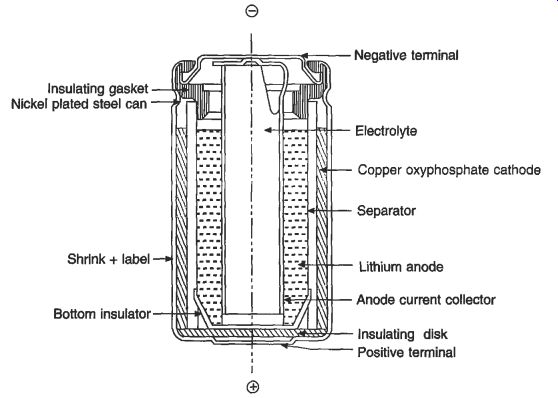

This type of battery has only recently become commercially available. The single cell has a high voltage in the range 3.2 V to 3.5 V, with an open-circuit voltage of 3.67 V. , A cross-section of an example is shown in Fig. 7.

Fig. 7 Lithium thionyl chloride cell

Cost is relatively high. The operating temperature range is one of the highest available, from -55°C to 85 C, and the shelf life is up to 10 years. These batteries m suitable for intermittent or continuous duties, with a current drain from 15 mA up to 1.5 A. Their high energy density, wide temperature range and high discharge efficiency makes these batteries particularly well suited to memory back-up applications in programmable logic controllers, personal computers and alarm systems.

2.8 Lithium copper oxyphosphate

This has only become commercially available recently. The single cell has a voltage range 2.1 V to 2.5 V, with an open-circuit voltage of 2.7 V. A sectional view of a typical unit is shown in Fig. 8.

These batteries are expensive because of their high energy density. They operate over a temperature range -40°C to 60°C and they have a shelf life of up to 10 years.

They are suitable for continuous loads from 37 uA up to 25 mA. The high energy density and wide temperature range make these batteries specially suitable for applications in metering computers.

Fig. 8 Lithium copper oxyphosphate cell.

3. Secondary cells

The main forms of secondary or rechargeable battery are lead acid and nickel cadmium, both of which have been in use for about 100 years.

Nickel cadmium and lead acid batteries are formed by connecting a number of cells in series. Each cell consists of vertical plates which are connected in parallel and are divided into a positive group and a negative group. Adjacent positive and negative plates are insulated from each other by separators or rod insulators which have to provide the following functions:

obstruct the transfer of ions between the plates as little as possible keep in place the active material

enable the escape of charging gases from the electrolyte

All the plates and separators together form a plate-group or element.

The insulators in nickel cadmium batteries are vertical plastic rods, which may be separate or in the form of grids which are inserted between the plates. Corrugated or perforated PVC is also used as a separator. The active material is kept in place by steel pockets.

In lead acid batteries, the separators are normally microporous sheets of plastic, which are usually combined with corrugated and perforated spacers; porous rubber separators are also used. In some designs the separator completely surrounds the positive or negative plate. The selection of separator is very important, and it depends upon the plate design and the use for which the battery is intended. In batteries intended for short discharges, such as diesel engine starting, thin separators and spacers are used, whereas batteries designed for long discharges, as in standby power or emergency lighting, have thick separators and spacers.. Batteries that require extra strength to withstand mechanical stresses often have a glass fiber separator against the positive plates in order to minimize the shedding of active material from these plates.

The outermost plates are of the same polarity on both sides. In lead acid batteries the outside plates are normally negative; in nickel cadmium batteries they are normally positive.

The plategroups are mounted in containers which are filled with electrolyte. The electrolyte is dilute sulphuric acid in lead acid batteries, and potassium hydroxide in nickel cadmium batteries. In a fully charged lead acid battery the electrolyte density is between 1.20 and 1.29. In nickel cadmium batteries it is between 1.18 and 1.30 irrespective of the state of charge.

The containers may house a single cell or they may be of a rnonoblock type, housing several cells. The top (or lid) may be glued or welded to the container, or it may be formed integrally with the container. In the lid is a hole for the vent, which is normally flame arresting, and the cells are topped up with electrolyte through the vent hole.

Below the plates there is an empty space which is known as the sludge space. This is provided so that shredded active material and corrosion products from the supporting structure can be deposited without creating any short-circuits between the plates. The sludge space in nickel cadmium batteries is smaller than in lead acid units because there is no corrosion of the supporting steel structure and no shredding of active material; it is usually created by hanging the plategroup in the lid. In lead acid batteries the sludge space may be created by hanging the plates from the lid or container walls (this is common in stationary batteries), by standing the plates on supports from the bottom (this is common for locomotive starting batteries) or by hanging the positive plates with the negative plates standing on supports (this is also used for stationary batteries). From the plates, the current is carried through plate lugs, a connecting strap or bridge and a pole-bolt. The bolts pass through the lid and are sealed against the lid with gaskets. Above the lid, the cells are connected to form the battery. Monoblocks may have connectors arranged directly through the side of the partition cell wall, in which case the polebolts do not pass through the lid, or the connectors may be located between the cell lid and an outer lid. The monoblocks made in this way are completely insulated and easy to keep clean.

The main forms of secondary cell now commercially available are:

- nickel cadmium - sealed

- nickel cadmium - vented

- nickel metal hydride

- lead acid - tubular

- lead acid - Plante

- lead acid--pasted plate

- lead acid - valve-regulated sealed (VRSLA)

Each of these is described separately in sections 12.3.1 to 12.3.7, and a summary of the main features of the four lead acid types and nickel cadmium is given in Table 12.1.

3.1 Sealed nickel cadmium

Table 1 Comparison of features and performance of the main types of secondary battery

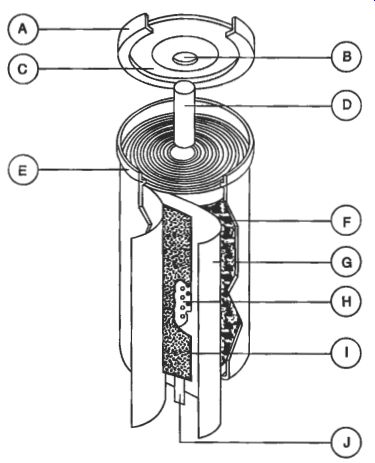

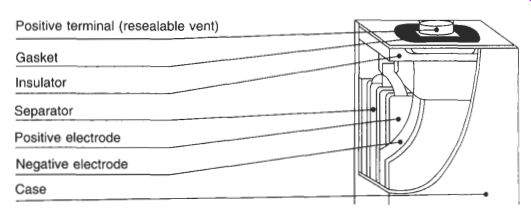

This type of cell has been commercially available since the early 1950s. The single

cell operates across a voltage range 1.0 V to 1.25 V and is ideally suited to a heavy continuous current drain of up to eight times the nominal ampere-hour capacity of the battery. The low internal resistance of the cell makes it ideal for heavy current discharge applications in motor-driven appliances such as portable drills, vacuum cleaners, toys and emergency systems. Batteries of this type are capable of being recharged hundreds of times using a simple constant-current charging method.

The cells tolerate a wide temperature range from -30°C to 50 C, and they have a shelf life of up to eight years at 20°C. Typical construction of a sealed nickel cadmium cell is shown in Fig. 9. The cell is available commercially in a variety of standard sizes including AAA, AA, C, D, PP3 and PP9.

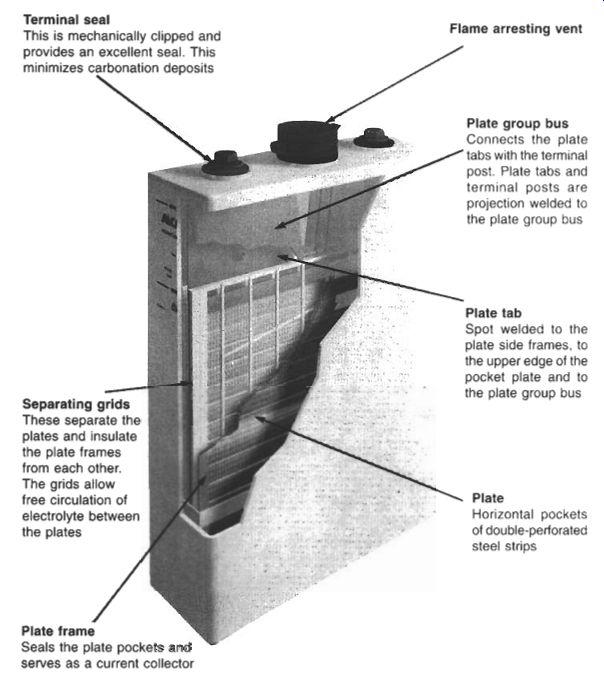

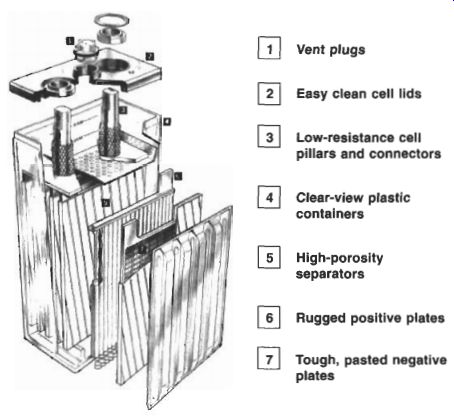

3.2 Vented nickel cadmium

Using the electrochemistry of nickel and cadmium compounds with a potassium hydroxide electrolyte, vented cells use 'pocket' plates which are made from finely perforated nickel-plated steel strip filled with active material, The pocket plates are crimped together to produce a homogeneous plate. Translucent plastic or stainless steel containers are used. An example is shown in Fig. 10.

These batteries are robust and they have the benefits of all-round reliability; they are resistant to shock and extremes of temperature and electrical loading. They can be left discharged without damage and require very little maintenance. Their cycling ability is excellent and can offer a service life of up to 25 years.

Vented nickel cadmium batteries are used typically in long-life applications where reliability through temperature extremes in required and where physical or electrical abuse is likely. These applications include railway rolling stock, off-shore use, power system switch tripping and closing, telecommunications, uninterruptible power supplies, security and emergency systems and engine starting.

---------

A Nylon sealing gasket

B Re-sealing safety vent

C Nickel plated steel top plate (positive)

D Positive connector

E Nickel plated steel can (negative)

F Sintered positive electrode

G Separator

H Support strip

I Negative electrode

J Negative connector

Fig. 9 Sealed nickel cadmium cell

------------

3.3 Nickel metal hydride

The sealed nickel metal hydride battery has become commercially available in the past few years. A single cell operates with a voltage range of 1.1 V to 1.45 V, and a nominal voltage of 1.2 V. The construction of a metal hydride cell is illustrated in Fig. 11.

These batteries are relatively expensive. Their energy density is in the region 44- 46 Wh/kg, which is higher than the sealed nickel cadmium battery. The operating temperature range is -20 C to 60°C and the shelf life is up to five years. Nickel metal hydride batteries are suitable for applications with mA current drains from 0.2 to 3 times the nominal ampere-hour capacity of the battery. The high energy density makes this type of battery ideally suited to applications for memory back-up and portable communications.

Nickel metal hydride batteries will endure recharging up to 500 times, although the method of charging is slightly more complicated than for sealed nickel cadmium systems.

3.4 Lead add--pasted plate

The positive plates of pasted plate cells are made by impressing an oxide paste into a current-collecting lead alloy grid, in which the paste then forms the active material of the plate. The paste is held in position by a long interlocking grid section. In addition to the long-life microporous plastic separator, a glass-fiber mat is used. This becomes embedded in the face of the positive plate holding in place the active material and so prolonging the life of the battery.

Cells can be manufactured with lead antimony selenium alloy plates. These require very little maintenance, offer good cycling performance and are tolerant to elevated temperatures. Alternatively, lead calcium tin alloy plates may be used; these offer even lower maintenance levels.

Pasted-plate lead acid batteries are the lowest in purchase cost; their service life is in the range two to 20 years and the maintenance requirements are low, with extended intervals between watering. They are compact and provide high power density with excellent power output for short durations. Typical applications are in medium-to-long duration uses where initial capital cost is a primary consideration.

These include telecommunications, UPS, power generation transmission, switch tripping and closing, emergency lighting and engine starting.

-------------

Fig. 10 Vented nickel cadmium battery

--------------

Fig. 11 Nickel metal hydride battery

3.5 Lead acid - tubular

In a tubular cell, an example of which is shown in Fig. 12, the positive plate is constructed from a series of vertical lead alloy spines or fingers which resemble a comb. The active material is lead oxide; this is packed around each spine and is retained by tubes of woven glass fiber which are protected by an outer sleeve of woven polyester or perforated PVC. This plate design enables the cell to withstand the frequent charge-discharge cycles which cause rapid deterioration in other types of lead acid cells.

----------

Vent plugs Easy clean cell lids Low-resistance cell pillars and connectors Clear-view plastic containers High-porosity separators Rugged positive plates Tough, pasted negative plates

Fig. 12 Tubular cell lead acid battery

----------

The advantages of the tubular cell are excellent deep cycling characteristics, service life up to 15 years and a compact layout which gives a high power per unit volume. The low antimony types also offer extended watering intervals.

Typical applications are where the power supply is unreliable, and where discharges are likely to be both frequent and deep. These include telecommunications, UPS, emergency lighting and solar energy.

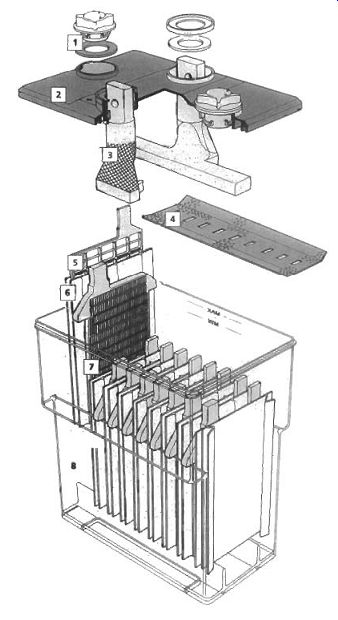

3.6 Lead acid - Plante

The distinguishing feature of the Plant6 cell is the single pure lead casting of the Plante positive plate. The active material is formed from the plate surface, eliminating the need for mechanical bonding of a separately applied active material to a current collector. This makes the Plant6 cell the most reliable of all lead acid types. An example of the construction of Plant6 batteries is shown in Fig. 13.

---------

1. Vent plugs

2. Cell lids

3. Cell pillars and connectors

4. Bar guard

5. Negative plates

6. Separators

7. Plante positive plates

8. Plastic containers

Fig. 13 Lead acid Plant6 cells

---------

Ultra High Performance Plante cells have a thinner plate. This gives the highest standards of reliability for UPS and other high-rate applications.

The advantages of the Plante cell are extremely long life (which can be in excess of 20 years for High Performance cells and 15 years for Ultra High Performance cells) and the highest levels of reliability and integrity. Constant capacity is available throughout the service life, and an assessment of condition and residual life can readily be made by visual inspection. Usage at high temperatures can be tolerated without significantly compromising the life expectancy, and maintenance requirements are very low.

Typical applications are long-life float duties in which the ultimate in reliability is required. These include critical power station systems, telecommunications, UPS, switch tripping and closing. emergency lighting and engine starting.

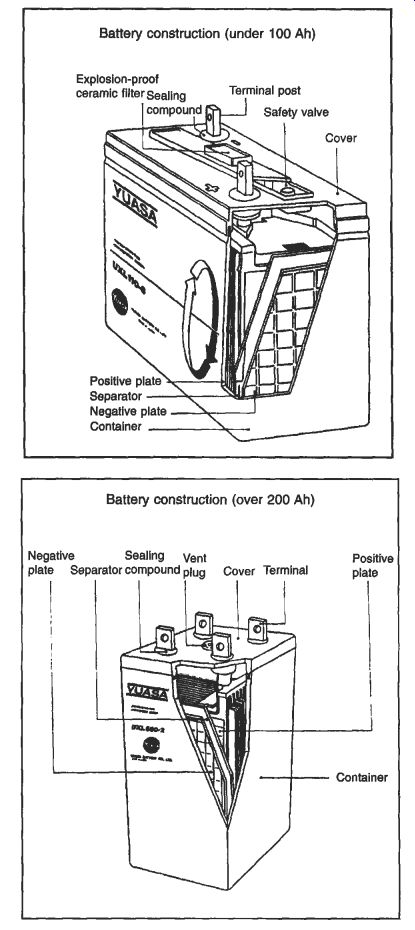

3.7 Lead acid - valve regulated sealed (VRSLA)

In sealed designs, lead calcium or pure lead is used in the grids. The separator is a vital part of the design because of its influence on gas recombination, and the amount of electrolyte that it retains; it often consists of a highly porous sheet of microfiber.

Examples of sealed cells are shown in Fig. 14.

Beside these sealed units, there is a large variety of so-called maintenance-free batteries which rely more upon carefully controlled charging than upon the gas recombination mechanism within the cells. Non-antimonial grids and pasted plates are used, and in most units the electrolyte is immobilized or gelled. The batteries are provided with vents which open at a relatively low overpressure.

The benefits are long life, no topping up, no acid fumes and no requirement for forced ventilation. There is no need for a separate battery room and the units can be located within the enclosure of an electronic system. In addition these batteries are lighter and smaller than traditional vented cells.

Typical applications include main exchanges for telecommunications, PABX systems, cellular radio, microwave links, UPS, switch tripping and closing, emergency lighting and engine starting.

4. Fuel cells

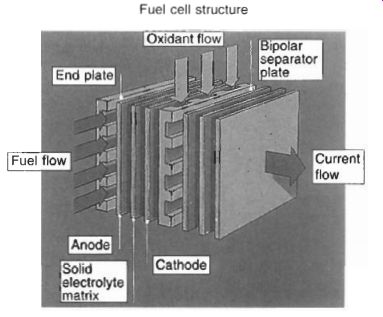

A fuel cell converts the energy of a chemical reaction directly into electrical energy.

The process involves the oxidation of a fuel, which is normally a hydrogen-rich gas, and the reduction of an oxidant, which is usually atmospheric oxygen. Electrons are passed from the fuel electrode to the oxidant electrode through the externally connected load, and the electrical circuit is completed by ionized particles that cross an electrolyte to recombine as water.

The fuel cell has a number of advantages over the conventional heat engine and shaft-driven generator for the production of electrical power. The generation efficiency is higher in a fuel cell, it has a higher power density, lower emission and vibration characteristics, and reduced emission of pollutants.

An individual fuel cell operates at a dc voltage of about 1 V. Cells must therefore be connected in stacks of series and parallel connection in order to deliver the voltage and power required for many applications.

Another complication is that many fuel cells cannot operate effectively using a raw hydrocarbon fuel; most types require a reformer, which converts the hydrocarbon into a hydrogen-rich gas suitable for passing directly into the fuel cell.

The two main types of fuel cell at present being considered are the Solid Polymer Fuel Cell (SPFC) and the Solid Oxide Fuel Cell (SOFC). These two main classes are distinguished by the type of electrolyte they use. This in turn determines their operating temperature.

Fig. 14 Examples of sealed lead acid batteries

Fig. 15 The solid polymer fuel cell

Fig. 16 The solid polymer fuel cell

4.1 The Solid Polymer Fuel Cell (SPFC)

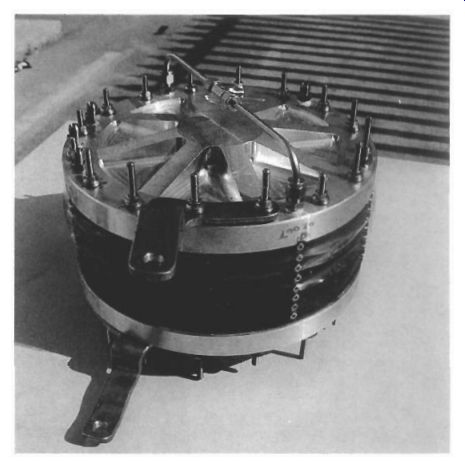

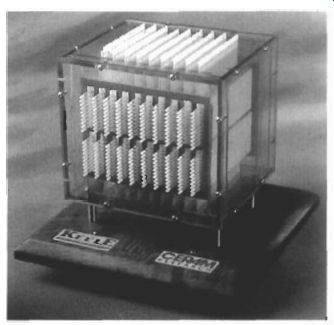

An example of an SPFC is shown in Figs 15 and 16.

The SPFC operates at temperatures below 100°C. It is a potentially clean method of generating electricity which is silent, robust and efficient. Applications for the SPFC cover the domestic, commercial and industrial range, but it will probably be best suited to small-scale Combined Heat and Power (CHP) applications, and to transport duties.

The SPFC is often described by reference to power density, which ranges from 0.25-1.0 kW/liter. Expected life is in the range 8-20 years.

4.2 The Solid Oxide Fuel Cell (SOFC)

The SOFC is illustrated in Fig. 17.

Fig. 17 The solid oxide fuel cell

The SOFC operates at much higher temperatures than the SPFC, in the region 850°C to 1000 C. It offers the possibility of high electrical efficiency together with high-grade exhaust heat; applications for the SOFC are therefore in the combined heat and power field and in other generation applications where a significant heat load is present.

Advantages of the SOFC are a high electrical efficiency, and the facility to produce steam or hot water from the high temperatures that are available. Typical power ratings are in the range 150-250 kW and life expectancy is 5-20 years, with adequate maintenance.

5. Battery charging

5.1 Small commercial batteries (up to 10 Ah)

The rechargeable batteries used in portable equipment are mainly nickel cadmium or nickel metal hydride. Recharging of these batteries can be carried out by the following methods:

transformer-rectifier

switched-mode power supply unit

capacitive chargers

The transformer-rectifier circuit is used to reduce ac mains voltage to a lower dc voltage. The charge delivered to the battery can be regulated using a constant current, a constant voltage, constant temperature or a combination of these. The transformer in this system provides the inherent advantage of isolation between the mains and low-voltage circuits.

In the switched-mode power supply unit, the mains voltage is rectified, switched at a high frequency (between 20 kHz and 1 mHz), converted to low voltage through a high-frequency transformer, rectified back to dc which is then regulated to charge the battery in a controlled manner. Although more complex than the transformer-rectifier circuit, this technique results in a smaller and more efficient charging unit.

In a capacitive charger the mains is rectified and then series coupled with a mains- voltage capacitor with current regulation directly to the battery pack. This makes for a small and cheap charging unit, but it has to be treated with care, since the capacitor is not isolated from the mains.

In addition to these three methods, several manufacturers have responded to the need for shorter recharge periods and better battery condition monitoring by designing specific integrated circuits that provide both the charging control and the monitoring.

5.2 Automotive batteries

The main types of requirement for recharging automotive batteries are:

single battery, out of the vehicle

multiple batteries, out of the vehicle

starter charging, battery in the vehicle

Transformer/reactance is predominantly used in each of these applications, with either a ballast in the form of resistance, or resistance to control the charging current.

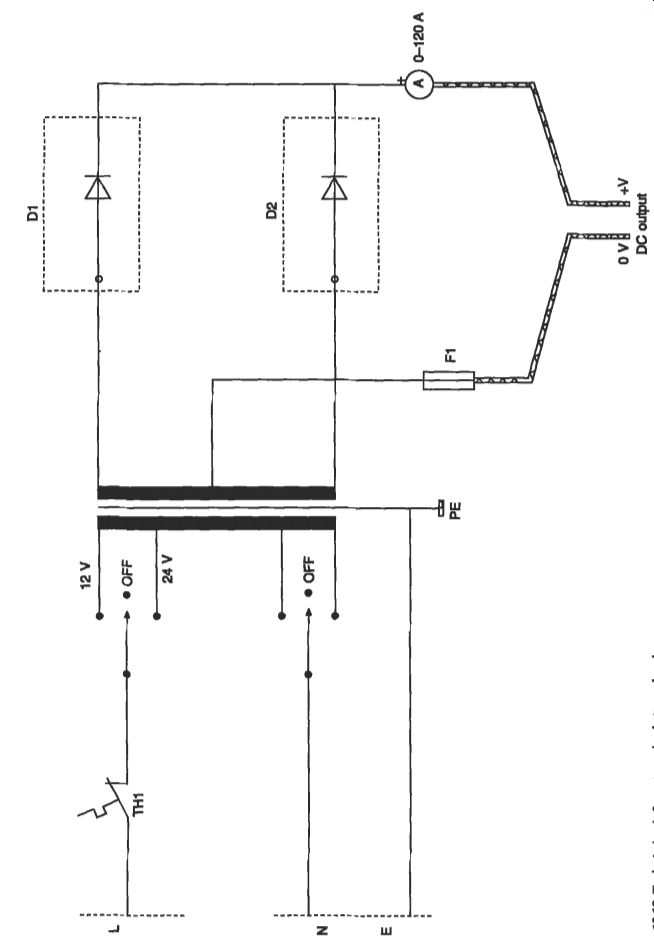

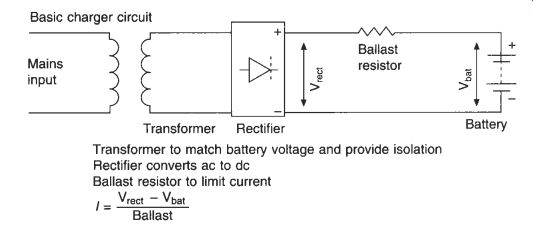

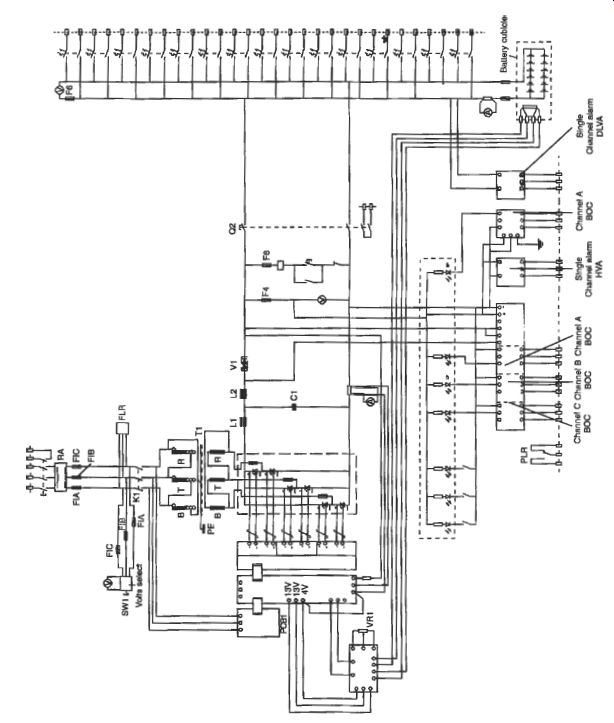

More sophisticated chargers have constant voltage and current-limiting facilities to suit the charging of 'maintenance-free' batteries. A typical circuit is shown in Fig. 18.

Fig. 18.

Vented automotive batteries are usually delivered to an agent in the dry condition.

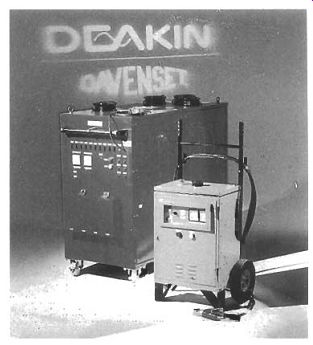

They have to be filled and charged by the agent. A multiple set of batteries connected in series is usually charged for a preset time in this case, and this requires the use of a bench-type charger. Bench chargers are rated from 2 V to 72 V, with a current capability ranging from 10-20 A dc (mean). Examples are illustrated in Fig. 19.

The bench-type charger may also be used for charging a single battery out of a vehicle, or this battery may alternatively be left on charge indefinitely using a constant-voltage, current-limited charger.

Starter charging is used to start a vehicle which has a discharged battery. A large current is delivered for a short period, and starter chargers usually have a short-term rating. They can be rated at 6, 12 or 24 V, delivering a short-circuit rated starting current from 150 A to 500 A dc (rms) and a steady-state output of 10 A to 100 A dc.

Output voltage is from 1.8 V to 3.0 V per cell. Voltage ripple may be typically up to 47 percent with a simple single-phase transformer-rectifier, but the ripple will depend upon output voltage, battery capacity and the state of discharge. Voltage regulation is important in starter charging applications since high-voltage excursions can damage sensitive electrical equipment in the vehicle.

Since these chargers are usually short-time rated, some derating may be required if they have to operate in a high ambient temperature.

Fig. 19 Examples of bench-type battery chargers

Fig. 20 Modified constant potential, or taper charger

Safety features are built into automotive battery chargers in order to avoid the risk of damage to the battery, to vehicle wiring or to the operator. The normal safety features include:

reverse polarity protection

no battery - short-circuit protection

thermal trip - abuse protection

5.3 Motive power

Motive power or traction battery chargers are used in applications where the batteries provide the main propulsion for the vehicle. These applications include fork lift trucks, milk floats, electrical guided vehicles, wheelchairs and golf trolleys. The requirement is to recharge batteries which have been discharged to varying degrees, within a short period (7-14 hours). Both the battery and the charger may be subject to wide temperature variations. A well-designed charger will be simple to operate, will automatically compensate for fluctuations in mains voltage and for differences between batteries arising from such factors as manufacture, age and temperature, and will even tolerate connection to abused batteries which may have some cells short-circuited.

The most common type of charger is the modified constant potential or taper charger shown in Fig. 18. In all but the smallest chargers, the ballast resistor shown in this circuit is replaced by a reactance; this reactance may be in the form of a choke connected in series with the primary or secondary windings of the transformer, or more usually it is built into the transformer as leakage reactance.

While the battery is on charge, the voltage rises steadily from 2.1 V per cell to 2.35 V per cell, at which point the battery is approximately 80 percent charged and gassing begins. Gassing is the result of breakdown and dissipation of the water content in the electrolyte. Charging beyond this point is accompanied by a sharp rise in voltage, and when the battery is fully charged the voltage settles to a constant voltage, the value of which depends upon a number of factors, including battery construction, age and temperature.

During the gassing phase (above 2.35 V per cell) the charging current must be limited in order to prevent excessive overheating and loss of electrolyte. The purpose of the ballast resistor in the charger circuit is to reduce the charging current as the battery voltage rises, hence the name raper charger. By convention, the current output from the charger is quoted at a voltage of 2.0 V per cell, and the proportion of this current which is delivered at 2.6 V per cell is defined as the taper. A typical current limit recommended by battery manufacturers is one-twelfth of the battery capacity (defined as the 5-hour rate in ampere-hours) at the mean gassing voltage of 2.5 V per cell. A disadvantage of the high-reactance taper charging system is that the output may be very sensitive to changes in the input voltage; the charge termination method and the required recharge time must therefore be taken into account in sizing the charger.

Because of the inefficiencies of energy conversion, particularly due to the heating and electrolysis during the gassing phase, the energy delivered by the motive power charger during recharging is 12-15 percent higher than the energy delivered by the battery during discharge.

To recharge a battery fully in less than 14 hours a high rate of charge is necessary and the termination of charging when the battery is fully charged must be controlled.

The two types of device for termination of charge are: voltage-time termination rate-of-charge termination A voltage-time controller detects the point at which the battery voltage reaches 2.35 V per cell, and then allows a fixed 'gassing' time for further charging, which is usually 4 hours. This method is not suitable for simple taper chargers with nominal recharge times of less than 10 hours because of the variation in charge returned during the time period as a result of mains supply fluctuations. If a short recharge time is required with a voltage-time controller then a two-step taper charger is used, in which a higher charging current is used for the first part of the recharge cycle.

When the voltage reaches 2.35 V per cell, the timer is started as above, and the current during the further charging period is reduced by introducing more ballast in the circuit.

The rate-of-charge method of termination has predominated in large chargers during the past decade, offering benefits to both the manufacturer and the user. In the rate-of-charge system the battery voltage is continuously monitored by an electronic circuit. When the battery voltage exceeds 2.35 V per cell, the rate of rise of the battery voltage is calculated and charging is terminated when this rate of rise is zero, that is when the battery voltage is constant. This method can be used with single-rate taper chargers with recharge periods as short as 7 hours because of the higher precision of termination. In order for a rate-of-charge termination system to operate satisfactorily, there must be compensation for the effects of fluctuations in mains supply. A change in mains voltage results in a proportional change in the secondary output voltage from the charger transformer; if uncompensated this will cause a change in charging current and therefore in battery voltage. For a 6 percent change in mains voltage, the charging current may change as much as 20 percent and the battery voltage may change by 3 percent.

Many chargers have the facility for freshening or equalizing.

Freshening charge is supplied to the battery after the termination of normal charge in order to compensate for the normal tendency of a battery to discharge itself. A freshening charge may be a continuous low current, or trickle charging, or it may be a burst of higher current applied at regular intervals.

Equalizing charge is supplied to the battery in addition to the normal charge to ensure that those cells which have been more deeply discharged than others (due, for instance, to tapping off a low-voltage supply) are restored to a fully charged state.

A controlled charger is a programmable power supply based on either thyristor phase angle control or high-frequency switch mode techniques. The main part of the recharge cycle is usually at constant current and the power taken by the charger is therefore constant until the battery voltage reaches 2.35 V per cell. Many options are available for the current-voltage profile during the gassing part of the recharging cycle, but all of these profiles deliver a current which is lower than the first part of the cycle.

Voltage dmp in the cable between the charger and the battery is important because the charge control and termination circuitry relies upon accurate measurement of the battery voltage. It is not normally practical to measure the voltage at the battery terminals because the measuring leads would be either too costly or too susceptible to damage, and it is common practice to sense the voltage at the output of the charger and to make an allowance for the voltage drop in the cables. Alteration to the length or cross-section of these cables will therefore cause errors, especially with low- voltage batteries.

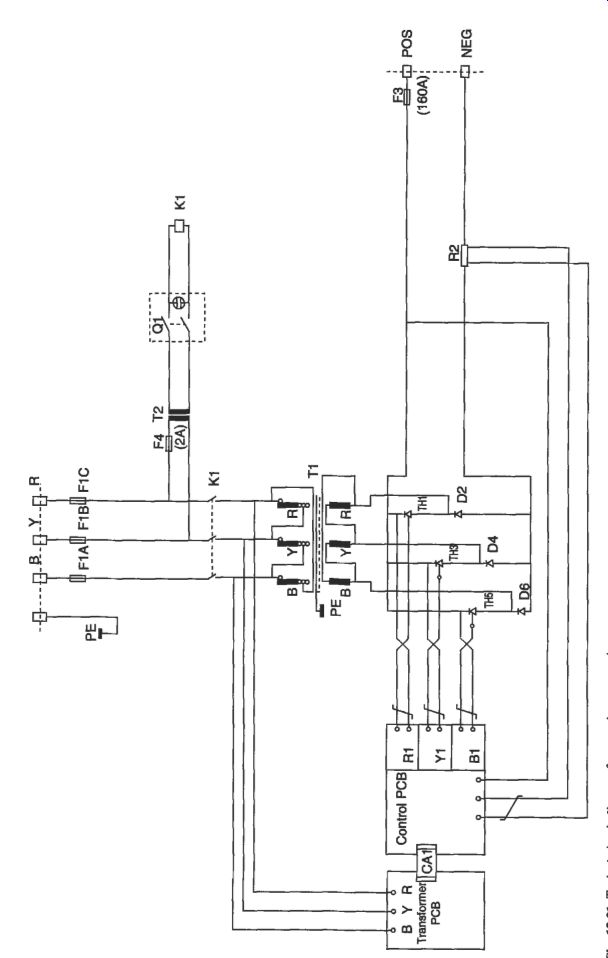

Motive power chargers are typically available from 6 V (three cells) to 160 V (80 cells) with mean dc output currents from 10 A to 200 A. A typical circuit is shown in Fig. 21.

Fig. 21.

Fig. 22 Examples of motive power chargers, with their ratings

-----

Motive power chargers

Charger selection table (based on 80% discharge at 2.0 V per cell)

The dc output current is rated at 2.0 V per cell; the taper characteristic set by the transformer reactance then results in 25 percent output current at typically 2.65 V per cell. Rating is not continuous, and derating to 80 percent is typical to take into account the taper characteristic. Consideration must be given to this if a multiple shift working pattern is to be adopted. Typical charger units, together with their ratings. are shown in Fig. 22.

Voltage ripple is typically 15-25 percent for single-phase chargers and 5-15 percent for three-phase chargers. The precise level of ripple will vary with time. It will depend upon mains voltage, battery capacity and the depth of discharge of the battery.

5.4 Standby power applications

Typical standby power applications include emergency lighting, switch tripping, switch closing and telecommunications. The main functional requirements for the battery charger in these cases are: to ensure that the state of charge of the battery is maintained at an adequate level, without reducing battery life or necessitating undue maintenance to ensure that the output voltage and current of the complete system are compatible with the connected electrical load to ensure after a discharge that the battery is sufficiently recharged within a specified time to perform the required discharge duty to provide adequate condition monitoring, to the appropriate interface standards Assuming initially that the battery is fully charged. the simple option is to do nothing.

A charged battery will discharge if left disconnected from a load and from charging equipment, but if the battery is kept clean and dry this discharge will be quite slow.

For some applications, open-circuit storage is therefore acceptable.

For most applications, however, there is a need for battery charge to be maintained.

The current-voltage characteristic is not linear, and a small increase in charging voltage will result in a large increase in current. Nevertheless, it is always possible to define a voltage which, when applied to a standby power battery, will maintain charge without excessive current, and the charging current flowing into the battery has only to replace the open-circuit losses in the battery, which are usually small.

Once these open-circuit losses have been made up, any additional current flowing is unnecessary for charging purposes and is normally undesirable. In vented cells it causes overheating and gassing and eventually, if not checked, damage and loss of capacity of the cell. In sealed cells there can be overheating, in extreme cases expulsion of gases through the pressure vent, and ultimately a loss of capacity.

On the other hand, if the battery voltage is allowed to fall too much, the open- circuit losses will not be replaced and the battery will slowly discharge.

The charging voltage has therefore to be controlled carefully for best battery maintenance. The usual limits are within +1 percent of the ideal voltage, which is normally termed the float voltage. The float voltage has a negative temperature coefficient which must be accounted for when batteries are to operate in exceptionally hot or cold environments. Float voltages for the major types of standby power cell are shown in Table 2.

For vented cells there are, however, circumstances under which the float voltage should be exceeded. Batteries which are new or have suffered abuse will benefit from a vigorous gassing up to the boost voltage shown in Table 12.2. Batteries which have stood on float charge with no discharge-charge cycle for many months will benefit from a refresh charge with gassing, at the refresh voltages which are also shown in Table 12.2.

Table 2 Typical cell voltages for systems with limited load voltage excursions

Few dc standby power systems can be designed without taking account of limits on the load voltage. For good battery operation it is necessary to charge at the float voltage (or sometimes a higher level), but it is also necessary to discharge the battery to a sufficiently low voltage if the full capacity is to be released from the cells. These considerations impose fundamental limits which define the maximum excursion of the system output voltage. Table 3 shows the minimum and maximum voltages which are reasonable in a 50 V standby power system for each for the three major battery types. Systems with other voltages will require excursions which are in direct proportion.

Table 3 Load voltage ranges in a 50 V standby power system

It can be seen from Table 12.3 that, allowing for the discrete steps in voltage when changing the number of cells, it is not possible to achieve a voltage excursion of less than about k 12 percent under conditions of float alone; the excursion limits are larger in refresh operation, and still larger with boost.

Table 3 shows that the sealed lead acid cell offers minimum overall voltage variation because of the absence of the larger excursions due to refresh and boost charges. If it is not possible to use a sealed lead acid system, another alternative is to disconnect the load for the full boosting operation; this should normally be necessary only at the time of system installation in any case.

A voltage regulator should be included in the system if closer limits of voltage variation are required. Diode regulators are now reliable and widely used; they operate by switching banks of series-connected diodes in and out as the battery voltage slowly vanes. It is important to ensure that switching in the regulator occurs only as a result of changes in battery voltage, and not as a result of load changes; if the regulator responds to changes which occur as a result of a load change, excursions outside the specified voltage limits may occur because of the delays in the process of switching the diode bank. Ensuring that this distinction is made normally requires a computer simulation for all but the simplest regulators. Control of the switching of the diode bank is best achieved by a programmable controller, especially if additional complicated relay-type logic is required in the system. Diode regulators are large and their heat dissipation is substantial. Higher-efficiency regulators using actively switched devices are becoming available, but they are at present limited to relatively low power applications.

Condition monitoring is now included in most dc systems in order to warn of excessive battery voltage excursions. The applications are diverse, but the main features are:

high voltage detection: this is necessary in order to prevent a fault on the supply system from damaging the battery or load circuit

low voltage detection: this warns of load failure due to insufficient voltage, and it is also needed to trigger the disconnection of sealed batteries which may be damaged by excessive discharging

charge failure: this is needed in order to stimulate action to restore the ac supply or to prepare for disconnection of the load

earth leakage: this is needed where an unearthed load system is used, for safety and for the avoidance of 'double faults'

Communication of a fault signal is through a 'volt-free' contact on a relay, which usually signals to the monitoring center using a 110 V or other voltage supply.

For charging of the battery, it has been seen in Table 3 that there are restrictions on the choice of charging voltage. The preference for many applications is to limit the voltage to the float voltage, and while it may be necessary to increase the charging voltage to speed up the recharging, the voltage should be returned to the float voltage as soon as possible. At this float voltage level, all the cell types discussed will be recharged to about 80 percent of their nominal capacity. Assuming the charger current is at the adequate level shown in Table 4, recharge to 80 percent capacity will be achieved in the times indicated in the table.

Table 4 Charging time and current necessary to recharge to 80 percent of capacity using float voltage

To recover the remaining 20 percent of the charge is more difficult, and different techniques are necessary for the three cell types. A vented lead acid battery will be fully recharged at float voltage in about 72 hours, but if the charging voltage is boosted to 2.7 V per cell, a full recharge will take about 14 hours. For a vented nickel cadmium cell full charge will never be achieved without increasing the voltage above the float level. Exact times vary between cell types, but typically a refresh charge at 1.55 V per cell will give full charge in about 200 hours on the highest- performance cells, and boosting to 1.7 V per cell will reduce this time to 9-10 hours.

Sealed lead acid cells will reach full charge after about 72 hours at float voltage; an increase of charge voltage to 2.4 V per cell will reduce the charging time to about 48 hours, but there is no way in which this can be significantly reduced further.

If a fast recharge is essential, an alternative is to oversize the battery; for instance if 100 Ah capacity is required with a full recharge within 8 hours, then a battery with 125 Ah capacity could be installed.

Most cells will protect themselves from excess charging current, provided that the voltage is limited to the float voltage, but above this level excessive charging current can damage the cell. For vented lead acid cells the 7 percent of capacity shown in Table 4 is recommended as an upper limit. For sealed lead acid cells, the recommended upper limit is 50 percent of capacity. Nickel cadmium cells normally require a minimum charge current of 20 percent of capacity, as indicated in Table 4, but a lower limit of 10 percent of capacity is recommended when boosting in order to avoid excessive gassing and electrolyte spray.

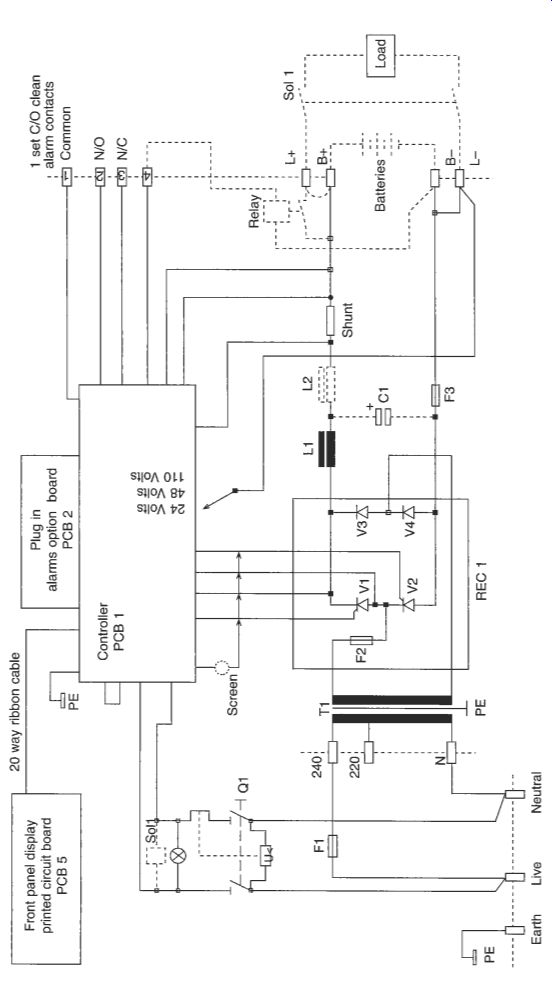

Standby power chargers are available in a wide range of capacities to suit many applications. Typical dc outputs are 6, 12, 24, 30,48, 60, 110,220 and 440 V. with dc mean output current ranging from 1 A to 1000A. DC output current is rated at 100 percent of the output current at the full specified voltage. Regulation of the output is generally within fl percent for an input voltage change of f10 percent and a load current change of 0-100 percent. Typical circuits are shown in Figs 23 and 24.

Although standby power systems are continuously rated, some derating may be necessary for operation in tropical climates if this was not originally specified.

Differing levels of output smoothing can be incorporated into the charging system, depending upon the application. General applications require a maximum of 5 percent ripple, but for telecommunications supplies, specifications are based on CCIlT telecommunication smoothing, which requires 2 mV phospometrically weighted at 800 Hz. The key components of an installation are shown schematically in Fig. 25.

Fig. 23

Fig. 24.

Fig. 25

6 Battery monitoring

The monitoring of battery condition is becoming more important as remote operation and reduced maintenance requirements are increasingly specified in standby power systems. The options which are available are summarized in the following sections.

6.1 Load-discharge testing

The basis of this test is to discharge the battery into a selected load for a preset time, after which the battery voltage is checked. In the majority of cases this will require that the battery is taken off line.

The load-discharge test is very reliable, but it requires a special resistance load bank, and it is labor intensive and time consuming. Figure 26 shows an example of the type of equipment that is required.

6.2 dV/dt-load testing

The technique here is to connect a fixed known load to the battery for a short period and to record the battery voltage over this period.

By comparing the recorded load voltage with data from the battery manufacturer, estimations can be made regarding the condition of the battery and its ability to perform.

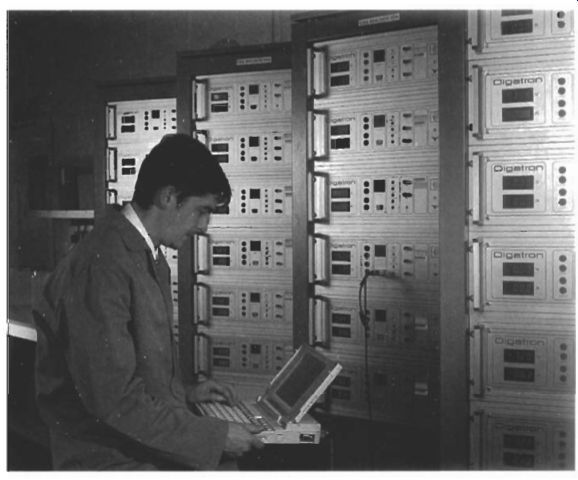

6.3 Computer monitoring of cell voltages

In this case. measurement leads are taken from each cell to a central monitoring computer.

The voltage of each cell is recorded through charge and discharge of the battery.

Although cell voltage is not a direct indication of residual capacity, trends can be observed and weak cells can be identified.

An example of this type of system is illustrated in Fig. 27, which includes a typical screen display.

-----------------

Fig. 25 Key elements of a standby power battery unit

The battery

The battery is a key element in a secure power supply and must be selected with care. The type of battery selected will depend on many factors including: reliability, operating tempera- ture, cost, life, standby time required, maintenance parameters, ventilation and available space. Depending on the type of battery, it can be supplied on a stand or in a ventilated cabinet. The battery should always be located as close as possible to the dc power supply to minimize line voltage drop.

The main types of battery used are:

valve regulated lead acid; minimal gassing so can be used in electronics enclosure, maintenance free, relative installed cost medium, typical life 10 yrs

flat plate lead acid: gas, with adequate ventilation and periodic maintenance required.

Relative installed cost low, typical life 10-15 yrs.

Plante lead acid: gas, with adequate ventilation and periodic maintenance required.

Highest levels of reliability. Relative installed cost high, typical life 20-25 yrs.

nickel cadmium: gas, with adequate ventilation and periodic maintenance required. Ideal for arduous conditions. Relative installed cost very high, typical life 20-25 yrs.

The rectifier/battery charger

The rectifier/charger converts incoming ac mains into dc to provide a stable, constant voltage output with automatic current limiting. The rectifier-charger automatically floats and boost charges the battery simultaneously providing the required dc output to the load.

Control and distribution

Distribution panels typically provide several fused outlets, monitoring of busbar voltage and current, earth fault status together with busbar and inter-busbar controls. Depending upon application, the control and distribution equipment may be contained within the charger cubicle (as shown) or may be housed in a separate matching enclosure.

----------------

Fig. 26 Equipment for load-discharge testing

Fig. 27 Computer monitoring of cell voltages

6.4 Conductance monitoring

This method has increased in popularity in recent years and several manufacturers now offer a standard monitoring product based upon the technique. Figure 28 shows typical equipment.

Monitoring the conductance of individual cells over their working life can give an indication of impending failure, allowing preventive maintenance to be carried out.

A particular advantage is that the readings can be reliably used whatever the state of charge of the battery.

Fig. 28 Conductance monitoring equipment

7. Installation, testing and commissioning

All battery equipment should be installed according to manufacturers' recommendations.

In particular, larger lead acid or nickel cadmium installations should be sited in a correctly constructed room, vehicle, cubicle or rack which allows ready access for maintenance and ensures adequate ventilation of batteries and battery chargers. The battery should not be located close to a source of heat such as a transformer or heater.

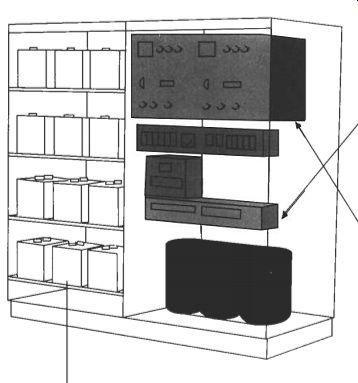

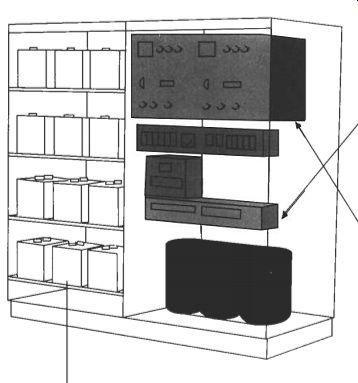

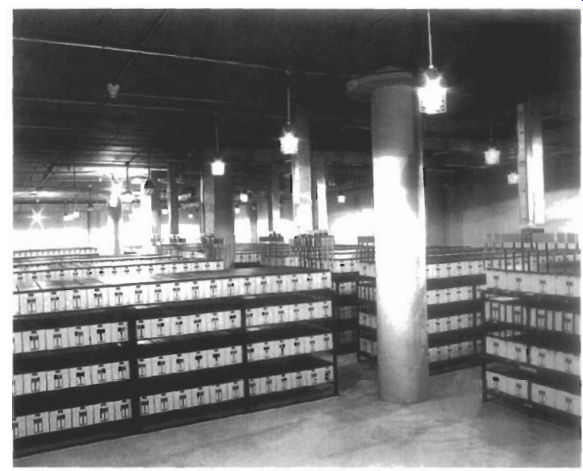

Battery racks should be assembled to manufacturers' instructions, adhering to recommendations regarding spacing between cells, and drip trays and insulators should be fitted where applicable. All cell connections should be cleaned, coated with no-oxide grease and tightened to the suppliers' specification. A typical installation is shown in Fig. 29.

The rating of the ac mains input cable to the battery charger should be based on the worst-case condition, which is the peak current that will be drawn by the charger at the lowest mains voltage. The rating of the dc cables from the battery charger and in the battery should be no lower than the maximum protection fuse rating, and attention should be paid to the overall voltage drop in the system, especially on lower voltage dc systems. The cables should be adequately protected, and segregation may be necessary on systems with a large dc current. All equipment should be earthed with a conductor of the correct cross-sectional area.

Fig. 29 Typical battery installation

Battery systems should be commissioned in accordance with procedures recommended by the manufacturer. It may be necessary to charge batteries for several days before their full capacity is reached, and in some cases a special initial commissioning charge level may be required.

Tests should be set up so that the results enable the operation of the system to be compared with the original specification. For larger systems, the manufacturer should propose a set of witness tests to be performed at the works, followed by final tests to prove capacity and duty on site. A typical test schedule should be designed to establish: the ability of the battery charger to support the standing load, where applicable the ability of the battery charger to recharge a fully discharged battery in the required time, whilst simultaneously time supporting the standing load, again where applicable the ability of the battery charger to maintain regulation within specified limits throughout the required range of load and input conditions correct operation of the monitoring features and instrumentation the ability of the battery and charger system to supply the load for the required period during a power failure

8. Operation and maintenance

8.1 Primary cells

Primary cells cannot be recharged and once their energy is depleted they should be

disposed of in the manner recommended by the manufacturer. The cells should be examined occasionally during their life for signs of leakage or physical deformation.

Chemical hazards can arise if batteries are misused or abused and in extreme cases if there is a risk of fire or explosion.

8.2 Secondary cells

Small secondary cells should be examined periodically under both charging and discharging conditions. Their cycle life is not indefinite, and as the battery ages its ability to accept recharge and hold its capacity will decrease. This ageing is usually shown by the dissipation of heat during charging, as a result of the inability to accept charge, whilst on discharge a reduction of capacity will be observed. Excessive overcharging will cause leakage of electrolyte or deformation of the cell.

Cells should be handled carefully and according to manufacturers' instructions, with the operator wearing the correct protective clothing. When handling vented cells, supplies of saline solution (for eye washing) and clean water should be readily available.

If a cell is to be filled, only purified water should be used when mixing the electrolyte.

The maximum storage time for cells which are filled and nominally charged is 6 months for nickel cadmium, 12 months for valve-regulated lead acid batteries (at 20C) and 8 weeks for vented lead acid batteries. Cells which are stored for longer than this should be periodically charged and the electrolyte level should be checked, where applicable.

Whether filled or empty, the battery may contain explosive gases, and no smoking, sparks or flames should be permitted in the vicinity of the installation.

Although the voltage at any point in a battery system can be reduced by the removal of inter-cell connectors, the cells are electrically live at all times and cannot be de-energized or isolated in the conventional sense. When connecting cells together, insulated tools should be used wherever possible to avoid accidental short-circuits and sparks. Tools should be cleaned before use if they are to be used on both lead acid and nickel cadmium batteries, since acid will destroy a nickel cadmium battery.

On large installations it is good practice to operate a system of 'cell log sheets'. Such sheets or books are normally supplied by the cell manufacturer. Completion of these sheets will require the measurement of voltage, ambient temperature and, if applicable, the specific gravity of each cell at regular intervals. Cell electrolyte level (where applicable) and the tightness of cell connections should also be checked at these intervals.

Other regular operational and maintenance checks on the charger system should include:

ac mains input voltage is correct and within tolerance

dc charger output voltage and current are correct and within tolerance, after compensation for ambient temperature

fuses are intact

protection devices operate correctly

all connections are tight

no components are operating at excessive temperature

Faults to be watched for are:

loose connections in the cells or in the charger system

low or high electrolyte level (where applicable)

debris or electrolyte spillage on the top of cells which may lead to short- circuits

excessive loss of electrolyte (where applicable) due to overcharging or battery ageing

cells overheating because of their inability to accept charge

loss of capacity due to undercharging (specific gravity should be checked where applicable)

loss of charger regulation due to a control circuit fault

ac or dc fuses operated

excessive loading on the battery or on the charger

9. Standards

There are many standards covering various types of battery and battery charging system. The key IEC recommendations together with equivalent BS and EN standards and related North American standards are summarized in Table 5.

Table 5 Comparison of international, regional and national standards for batteries and battery chargers