AMAZON multi-meters discounts AMAZON oscilloscope discounts

(cont. from part 1)

3. Flight data recorder (FDR) specifications

Initial FDR technology required that the unit be able to withstand 100 g of impact; the equipment was often installed alongside other equipment in the avionics bay.

As more experience was gathered in the operational use of FDRs, the impact requirements were increased to 1000 g. It was also learned through experience that the optimum location for the recorder was at the rear of the aircraft. This rational is based on the statistical probability that, following initial impact, the rear structure of the aircraft will remain intact. When the front of the aircraft is crushed, it effectively reduces the shock impact that reaches the rear of the aircraft. Evidence from aircraft accidents shows that the rear fuselage and empennage are most likely to survive intact and there fore provide the optimum location for the recorder. It is imperative that, in the event of an accident, the data recorder be located as swiftly as possible. For this reason they are painted bright orange and are fitted with an underwater location transmitter, see FIG. 3

FIG. 3 Underwater location transmitter

=============

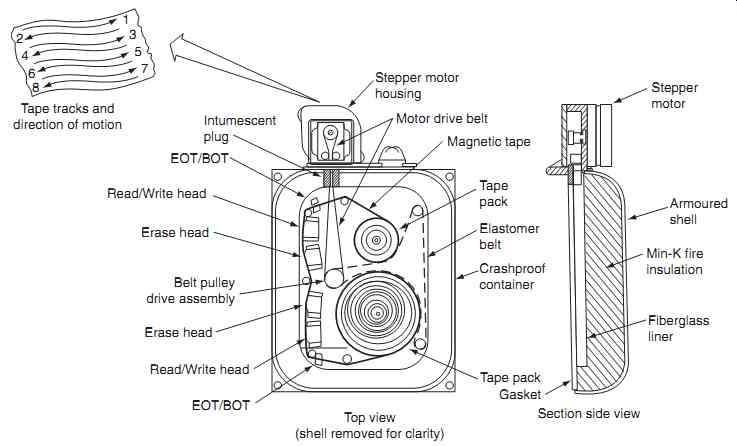

FIG. 5 Crash-proof recorder tape drive

Tape tracks and direction of motion; Intumescent plug; EOT/BOT EOT/BOT Read/Write head Read/Write head; Erase head; Belt pulley drive assembly; Erase head; Top view (shell removed for clarity); Section side view; Stepper motor housing; Motor drive belt; Magnetic tape; Tape pack Elastomer belt; Crashproof container; Tape pack; Gasket; Fiberglass liner; Min-K fire insulation; Armored shell; Stepper motor

===============

Key point

The underwater location transmitter is sometimes called an underwater locator beacon (ULB).

To ensure survivability of a flight data recorder, modern products are typically double-wrapped in strong corrosion-resistant stainless steel or titanium, with high-temperature insulation. The crash-survivable portion of the recorder (see FIG. 4 ) is designed and tested for a variety of severe conditions derived from aircraft crash data; the most significant requirements being:

============

Crash impact: 3400 g deceleration for 6.5 ms.

Crushing: 5000 pounds pressure applied against all six sides of the recorder

Piercing: 500 pounds mass with a hardened steel pin dropped from ten feet

Fire: 1100 ° C for 60 minutes

Water: 20,000 ft (submerged)

============

These are specific requirements for the crash-survivable section of the recorder. This part of the recorder fully encloses the tape and transport mechanism (FIG. 5); the drive motor is contained externally. Generic requirements for the entire product include resistance to a number of environmental conditions including:

-- hydraulic fluids

-- fuel de-icing fluids

-- fire extinguishing agents etc

Key point

The mandatory parameters required for an aircraft DFDR depend on the size of the aircraft and the prevailing regulatory rules applied to the operation of that aircraft.

3.1 Recording tape

Typical DFDR recording tape is 0.25 in. wide made of Kapton or Mylar; these are the trade names for self-lubricating polyamide films which can remain stable in a wide range of temperatures from _ 269°C to _ 400°C. Up to 500 feet of tape is arranged by eight bi-directional tracks with sequential switching.

The tape is transferred from one reel to another by a motor-driven belt, and transported over the write/read heads. The motor is a reversible stepper motor, located outside of the crash-survivable enclosure rotating at a nominal rate of 700 steps per second. Odd-numbered tracks are used when the tape is travelling in the nominal forward direction; even-numbered tracks are used in the reverse direction, see FIG. 5. When an entire track has been used, the direction of travel is switched and the next track utilized. At the end of recording on track eight, the recording will be switched back to track one, and old data is thereby overwritten. The tape travels at speeds up to five inches per second on an incremental basis when data is being written, or five inches per second continuously when data is being read. Beginning of tape (BOT) and end of tape (EOT) sensors are used to reverse the direction of travel and switch to the next track.

Key point

The DFDR on large aircraft has to be able to retain the recorded data for a minimum of the last 25 hours of its operation.

Test your understanding 2

What are the five significant requirements that a crash-survivable recorder has to withstand?

Two four-channel write/read heads are used for recording and playback from the tape. One head is enabled when the tape moves in one direction, and writes the odd numbered tracks. When the tape direction is reversed, the other write/read is enabled and writes to the even numbered tracks. Data is written at a rate of 11.4 kilo bits per second (kbps). Before writing new data, the old data are removed on the engaged track by dedicated erase heads

3.2 Data acquisition

Modern flight data recorders are based on digital technology to enable more parameters to be recorded.

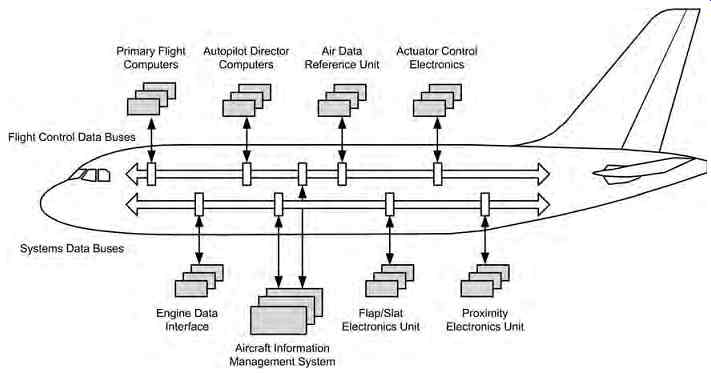

Digital flight data recorders (DFDR) installed on aircraft equipped with a distributed digital data bus ( FIG. 6) are integrated as one of the many avionic systems.

There are many aircraft, however, that have limited or no digital equipment. Depending on the size and category of aircraft, e.g. if it is used for public transport, it still has to have a DFDR. The DFDR will be used for recording both mandatory and domestic parameters. The latter is used for the benefit of the operator; it might only have a 30 minute duration, sufficient for monitoring specific systems, e.g. to evaluate the performance of engines or automatic landings.

This type of data is often recorded on a cassette termed a quick access recorder (QAR); the QAR is removed at the convenience of the operator and information is analyzed via customized software packages.

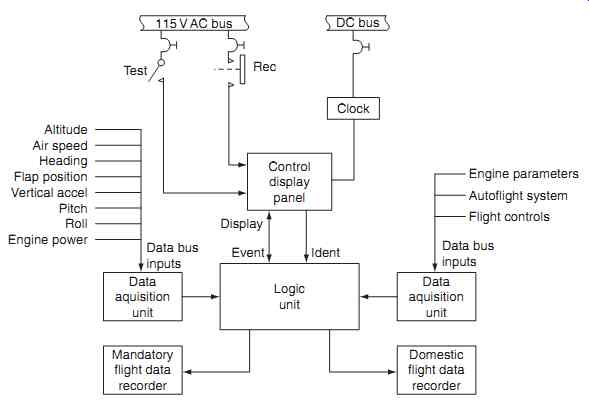

Assuming that the aircraft has limited digital capability, parameters required for both mandatory and domestic recording are gathered in analogue form and converted into digital form via an aircraft integrated data system (AIDS). This system also allows the dig ital information to be retrieved and formatted for analog purposes, e.g. for display on a monitor or printed on a chart; FIG. 7 illustrates a typical system.

The acquisition units sample the data to be recorded and converts them into digital form suitable for recording. The logic unit also inhibits the recording (REC) function until the aircraft is capable of moving under its own power; this switch is controlled by one of many possible options, e.g. when ground power is removed, when an alternator comes on line or when ground speed increases over a specified value. The TEST switch allows the system to be tested on the ground by overriding the REC logic.

Test your understanding 3

What is the purpose of a QAR?

The DFDR control display panel is used to enter the aircraft flight number (or some other identification, weight, date etc. Once the system is in operation, specific parameters being recorded can be displayed on the panel. The control panel often has a push-button momentary switch that is used to mark a particular event. (Pushing the event button puts a discrete signal on the recording to highlight the timing of the event.)

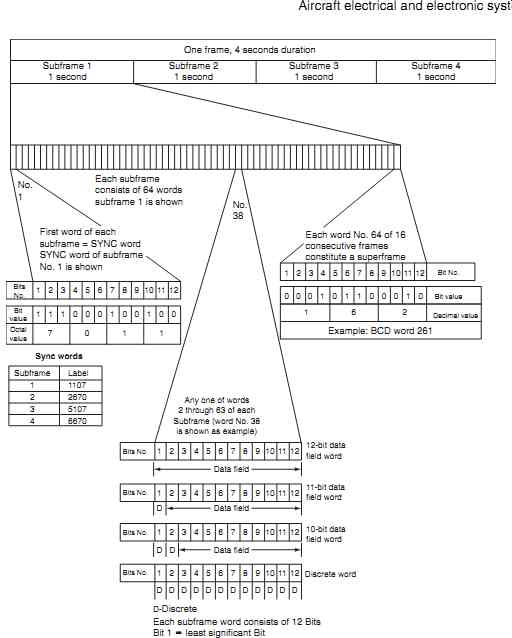

3.3 Digital data recording formats

Typical data output to the DFDR comprises a continuous stream of digital data formed into frames, see FIG. 8. Each frame is divided into four sub-frames, typically of one-second duration each; the sub-frame is formed by 64 12-bit words.

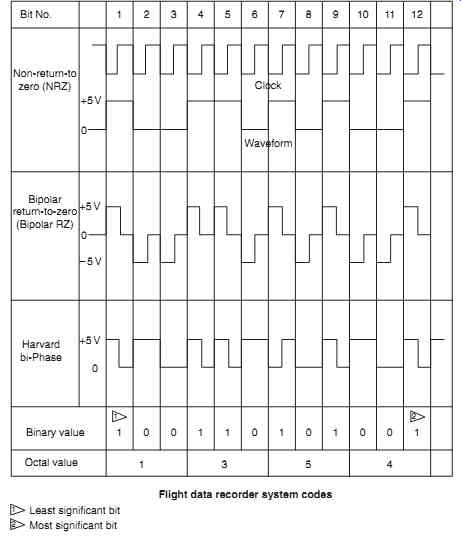

The first word in each sub-frame is a synchronizing word; the other three contain data. Each word contains 12 bits of digital information; the total number of bits in a sub-frame is therefore 768. Various formats are used to form the digital bits of logic one and logic zero, see FIG. 9. These formats include:

-- non-return-to-zero (NRZ)

-- bipolar-return-to-zero return-to-zero (RZ)

-- Harvard bi-phase format.

Non-return-to-zero (NRZ) logic one is formed by a 5 V DC level; logic zero is indicated by 0 V DC. The two logic levels are therefore represented by one of two significant conditions, with no other neutral or rest condition. A clock waveform is required to distinguish between bits. Two wires are used to carry the signal, together with a third wire for a clock reference.

============

115VAC bus DC bus; Test Rec; Clock; Control display panel; Display Event Ident Altitude Air speed Heading Flap position Vertical accel; Pitch; Roll; Engine power; Data bus inputs; Data acquisition unit; Logic unit; Mandatory flight data recorder; Domestic flight data recorder; Data acquisition unit; Data bus inputs; Engine parameters; Autoflight system; Flight controls

===========

FIG. 8 Digital data formed into frames

============

FIG. 9 Digital bits of logic one and logic zero

===========

Bipolar-return-to-zero return-to-zero (RZ) describes a code in which the signal drops (returns)

to zero between each pulse. This takes place even if a number of consecutive logic zeros or ones occur in the signal. Logic one is indicated by a 0.5 V DC level, and logic zero by a _ 0.5 V DC level. The signal returns to 0 V DC in the second half of each bit. The signal is self-clocking; therefore separate clock pulses are not required alongside the signal.

In the Harvard bi-phase format, each bit changes state at its trailing edge; either from high to zero or zero to high independently of its value. A logic one is indicated by a mid-bit change of state; a logic zero is indicated by no mid-bit change of state.

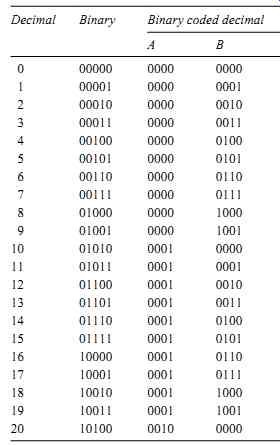

The 64th word of 16 consecutive frames are combined into a super-frame. These words are formed in binary coded decimal (BCD) format; each word comprises four bits, used to represent the denary numbers zero to nine, see Table 6. This illustrates how binary numbers and then BCD represent the denary (or decimal) numbers 0-20.

The advantage of BCD is that it allows conversion to decimal digits for printing or display and faster decimal calculations. This is particularly useful where a numeric value is to be displayed, e.g. recording systems consisting solely of digital logic.

Manipulation of numerical data for the recording readout can be simplified by treating each digit as a separate single sub-circuit. This matches the physical reality of data displayed to the pilot and recorded data. The disadvantage of BCD is the complexity of circuits needed to implement mathematical operations; BCD is a relatively inefficient technique for encoding, i.e. it occupies more memory than a binary representation.

Table 6 Binary coded decimal (BCD)

Test your understanding

How would the following denary numbers be represented in BCD: 27, 3, 1954?

The data transmitted by these super-frames includes frame count, error codes and voltage levels used in the calibration of analogue signals. The DFDR continuously verifies the data integrity from the tape; this is accomplished by backing up the tape after a write operation and then reading the data.

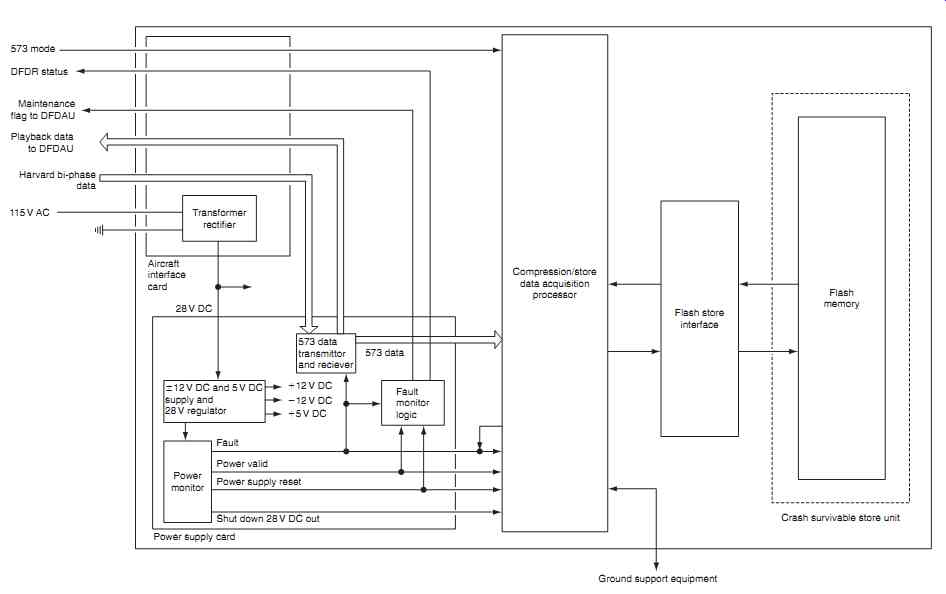

A typical DFDR receives data from an acquisition unit in Harvard bi-phase code. This data is then processed and stored in solid-state non-volatile memory (NVM). The data is received at the interface card and is transferred to the power supply card. Arinc 573 data transmitters and receivers interface with a compression/storage acquisition processor; this processor stores the data in a buffer memory before sending it to a flash memory unit in the crash-survivable portion of the recorder ( FIG. 10).

The compression/storage acquisition processor also monitors the system for faults via built in test routines. If any of these tests should fail, appropriate warning lights or LEDs are illuminated on the front of the unit.

4. Cockpit voice recorders

Commercial aircraft are required to carry a cockpit voice recorder (CVR). This unit captures and stores information derived from a number of the aircraft's audio channels that may later become invaluable in the event of a crash or serious incident. The CVR can provide valuable information that can later be analyzed. The voice recorder preserves a continuing record of typically between 30 to 120 minutes of the most recent flight crew communications and conversations. The storage medium used with the CVR fit ted to modern aircraft is usually based on one or more solid state memory devices whereas, on older aircraft, the CVR is usually based on a continuous loop of magnetic tape. The CVR storage unit must be recoverable in the event of an accident. This means that the storage media must be mounted in an enclosure that can withstand severe mechanical and thermal shock as well as the high pressure that exists when immersed in deep water.

The CVR control panel is usually fitted with a test switch, headphone jack and status light; the recorder itself is fitted with an underwater locator beacon (ULB) to facilitate undersea recovery. The ULB is a self contained device (invariably attached to the front of the CVR) that emits an ultrasonic vibration (typically at 37.5 kHz) when the water-activated switch is immersed in water. A label on the ULB indicates the date by which the internal battery should be replaced.

The specification for a typical ULB is shown in Table 7. An external view of a CVR showing its externally mounted ULB is shown in FIG. 11.

The audio input to the CVR is derived from the captain, first officer and observer position(s) and also from an open area microphone in the flight compartment which is usually mounted in the overhead panel and thus collects audio input from the entire flight deck area.

============

Table 7 Typical ULB specification

Parameter Specification

Operating frequency 37.5 kHz ( _ 1 kHz)

Acoustic output 160 dB relative to 1 µ Pa at 1 m

Pulse repetition rate 0.9 pulses per second

Pulse duration 10 ms

Activation Immersion in either salt water or fresh water

Power source Internal lithium battery

Battery life 6 years standby (shelf life)

Beacon operating life 30 days

Operating depth 20,000 ft (6096 m)

Housing material Aluminum

Length 3.92 in. (9.95 cm)

Diameter 1.3 in. (3.3 cm)

Weight 6.7 oz (190 g )

============

In order to improve visibility and aid recovery, the external housing of the CVR is painted bright orange.

The unit is thermally insulated and hermetically sealed to prevent the ingress of water. Because of the crucial nature of the data preserved by the flight, the unit should only be opened by authorized personnel following recovery from the aircraft.

Magnetic tape CVRs use a multi-track tape trans port mechanism. This comprises a tape drive, four recording heads, a single (full-width) erase head, a monitor head and a bulk erase coil. The bias generator usually operates at around 65 kHz and an internal signal (at around 600 Hz) is provided for test purposes.

Bulk erase can be performed by means of an erase switch; this is interlocked so that erasure can only be performed when the aircraft is on the ground and the parking brake is set. The erase current source is usually derived directly from the aircraft's 115 V AC 400 Hz supply. The magnetic tape (a continuous loop) is typically 308 feet in length and ¼ in. wide.

5. Health and usage monitoring system (HUMS)

HUMS was originally pioneered to monitor helicopters servicing the oil platforms in the North Sea.

It monitors a variety of aircraft parameters, including aircraft vibration, engine and structural health.

Ground support equipment and software are designed to decrease maintenance costs and increase operational readiness. The system includes on-board sensors and data processing to calculate specific maintenance recommendations. HUMS provides engine health and usage monitoring, exceedance monitoring, performance trends, operational usage monitoring and flight data monitoring and recording. Systems developed for helicopters now include rotor track and balance. All the required airborne data acquisition and processing, including crash-survivable cockpit voice recorders (CVR) and flight data recorders (FDR), are often combined into a single line replaceable unit.

6. QUIZ-- Multiple choice questions

1. The flight data recorder must stop automatically:

(a) after the aircraft is incapable of moving under its own power

(b) before the aircraft is incapable of moving under its own power

(c) after landing.

2. Parameters being recorded on the FDR are obtained from sources that are:

(a) not displayed to the flight crew

(b) independent of information displayed to the flight crew

(c) accurately correlated with the information displayed to the flight crew.

3. Inputs form the audio system are recorded on the:

(a) FDR

(b) CVR

(c) ULB.

4. The mandatory parameters required for an aircraft DFDR depend on the:

(a) speed and weight of the aircraft

(b) maximum weight of the aircraft

(c) size of the aircraft and the prevailing regulatory rules applied to that aircraft.

5. The DFDR requires an electronic process such that:

(a) digitally coded data can be converted back (decoded) into its analogue form

(b) digitally coded data can be converted back (encoded) into its analogue form

(c) analogue data can be converted back (decoded) into its digital form.

6. In binary coded decimal (BCD) format, each word comprises:

(a) four bits, used to represent the denary numbers zero to nine

(b) four bits, used to represent the binary numbers zero to nine

(c) four bits, used to represent the denary numbers zero to ten.

7. The DFDR on large aircraft has to be able to retain the recorded data for a minimum of the last:

(a) 30 minutes of its operation

(b) 25 hours of its operation

(c) 25 flights.

8. Lateral acceleration and radio altitude are typical parameters recorded on the:

(a) FDR

(b) CVR

(c) ULB.

9. The FDAU collects, or acquires, a variety of:

(a) analogue signals and converts them into a digital data stream for the recorder

(b) analogue signals and outputs for the recorder

(c) digital signals and converts them into an analogue data stream for the recorder.

10. The flight data recorder must start to record data automatically:

(a) after the aircraft is capable of moving under its own power

(b) after take-off

(c) prior to the aircraft being capable of moving under its own power.

11. Referring to FIG. 12, the underwater locator beacon is activated when immersed in water:

(a) after a time delay

(b) immediately

(c) at a specified depth.

12. Referring to Fig. 8.13, data bits that change at the trailing edge are:

(a) Harvard bi-phase

(b) Non-return-to-zero

(c) Return-to-zero.

FIG. 13 See Question 12

FIG. 14 See Question 13

13. Referring to FIG. 14, what is the purpose of EOT/BOT sensors?

(a) convert digital data into a numerical display

(b) convert analogue data in digital format

(c) reverse the direction of tape travel and switch tracks.