AMAZON multi-meters discounts AMAZON oscilloscope discounts

GOALS:

- • Explain the purpose of phase failure relays.

- • List the hazards of phase failure and phase reversal.

- • Connect solid-state phase monitors.

If two phases of the supply to a three-phase induction motor are interchanged, the motor will reverse its direction of rotation. This action is called phase reversal. In the operation of elevators and in many industrial applications, phase reversal may result in serious damage to the equipment and injury to people using the equipment. In other situations, if a fuse blows or a wire to a motor breaks while the motor is running, the motor will continue to operate on single phase but will experience serious overheating.

To protect motors against these conditions, phase failure and reversal relays are used.

One type of phase failure relay, ill. 1, uses coils connected to two lines of the three phase supply. The currents in these coils set up a rotating magnetic field that tends to turn a copper disc clockwise. This clockwise torque actually is the result of two torques. One polyphase torque tends to turn the disc clock wise, and one single-phase torque tends to turn the disc counterclockwise.

The disc is kept from turning in the clockwise direction by a projection resting against a stop. However, if the disc begins to rotate in the counterclockwise direction, the projecting arm will move a toggle mechanism to open the line contactors and remove the motor from the line.

In other words, if one line is opened, the polyphase torque disappears and the remaining single phase torque rotates the disc counterclockwise.

As a result, the motor is removed from the line. In case of phase reversal, the polyphase torque helps the single-phase torque turn the disc counterclockwise, and again, the motor is disconnected from the line.

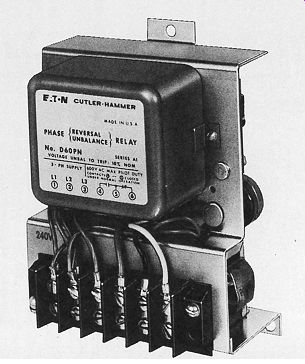

ill. 1 Phase monitoring relay

Other designs of phase failure and phase reversal relays are available to protect motors, machines, and personnel from the hazards of open phase or reverse phase conditions. E.g., one type of relay consists of a static, current-sensitive network connected in series with the line and a switching relay connected in the coil circuit of the starter. The sensing net work continuously monitors the motor line cur rents. If one phase opens, the sensing network immediately detects it and causes the relay to open the starter coil circuit to disconnect the motor from the line. A built-in delay of five cycles prevents nuisance dropouts caused by fluctuating line voltages.

A solid-state phase monitoring relay is shown in ill. 2. This relay provides protection in the event of a voltage unbalance or a phase reversal. The unit automatically resets after the correct voltage conditions return. Indicating lights show when the relay is activated.

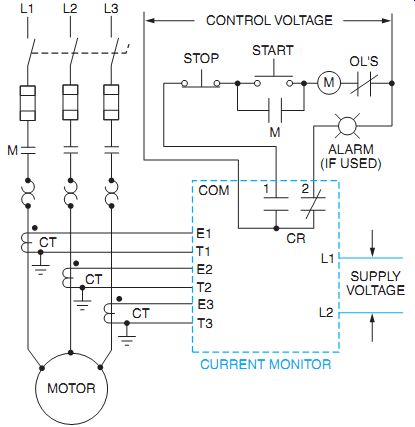

See the electrical connections in ill. 3.

LARGE MOTOR CURRENT MONITOR

ill. 3 shows the elementary wiring diagram for large motor current monitoring.

Current transformers are used for the input to the motor protector module. These modules, or relays, feature ambient temperature-compensated, solid state overload protection, phase loss, phase reversal, locked motor rotor, and instantaneous fault protection. Terminal connections are clearly marked for proper installation.

ill. 2 Solid-state phase monitor relay.

ill. 3 Large motor solid-state current monitor connections.

QUIZ:

1. What is the purpose of phase failure relays?

2. What are the hazards of phase failure and phase reversal?