AMAZON multi-meters discounts AMAZON oscilloscope discounts

GOALS:

- • Describe the purpose and operation of two-way solenoid valves.

- • Describe the purpose and operation of four-way solenoid valves.

- • Connect and troubleshoot solenoid valves.

- • Read and draw wiring symbols for solenoid valves.

Valves are mechanical devices designed to control the flow of fluids such as oil, water, air, and other gases. Many valves are manually operated, but electrically operated valves are most often used in industry because they can be placed close to the devices they operate, thus minimizing the amount of piping required.

Remote control is accomplished by running a single pair of control wires between the valve and a control device such as a manually operated switch or an automatic device.

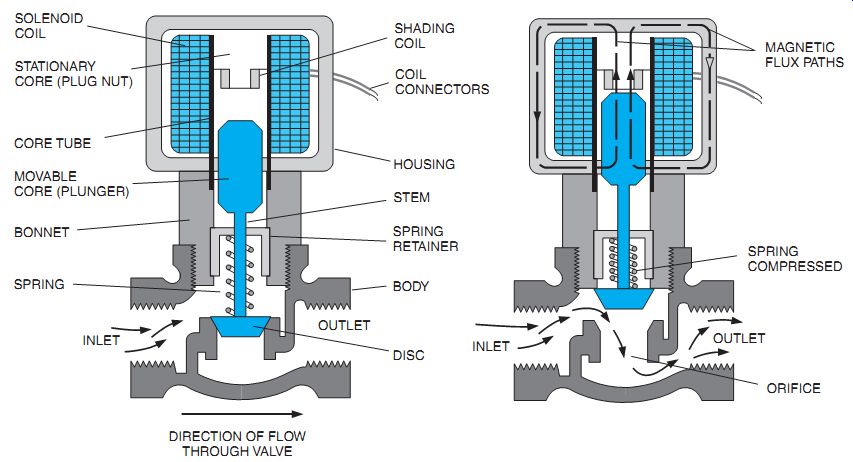

A solenoid valve is a combination of two basic units: an assembly of the solenoid (the electro magnet) and plunger (the core), and a valve containing an opening in which a disc or plug is positioned to regulate the flow. The valve is opened or closed by the movement of the magnetic plunger. When the coil is energized, the plunger (core) is drawn into the solenoid (electromagnet). The valve operates when current is applied to the solenoid. The valve returns automatically to its original position when the current ceases.

Most control pilot devices operate a single pole switch, contact, or solenoid coil. The wiring diagrams of these devices are not difficult to understand, and the actual devices can be connected easily into systems. It is recommended that the electrician know the purpose of and understand the action of the total industrial system for which various electrical control elements are to be used. In this way, the electrician will find it easier to design or assist in designing the electrical control system. It will also be easier for the electrician to install and maintain the control system.

TWO-WAY SOLENOID VALVES

Two-way (in and out) solenoid valves, ill. 1, are magnetically operated valves that are used to control the flow of Freon, methyl chloride, sulfur dioxide, and other liquids in refrigeration and air-conditioning systems. These valves can also be used to control water, oil, and airflow.

Standard applications of solenoid valves generally require that the valve be mounted directly in line in the piping with the inlet and outlet connections directly opposite each other.

Simplified valve mounting is possible with the use of a bottom outlet, which eliminates elbows and bends. In the bottom outlet arrangement the normal side outlet is closed with a standard pipe plug.

The valve body is usually a special brass forging that's carefully checked and tested to ensure that there will be no seepage due to porosities. The armature, or plunger, is made from a high-grade stainless steel. The effects of residual magnetism are eliminated by the use of a kickoff pin and spring, which prevent the armature from sticking. A shading coil ensures that the armature will make a complete seal with the flat surface above it to eliminate noise and vibration.

It is possible to obtain DC coils with a special winding that will prevent the damage that normally results from an instantaneous voltage surge when the circuit's broken. Surge capacitors are not required with this type of coil.

To ensure that the valve will always seat properly, it's recommended that strainers be used to prevent grit or dirt from lodging in the orifice or valve seat. Dirt in these locations will cause leakage. The inlet and outlet connections of the valve must not be reversed. The tightness of the valve depends to a degree on pressure acting downward on the sealing disc. This pres sure is possible only when the inlet is connected to the proper point as indicated on the valve.

ill. 1 Two-way solenoid valves.

FOUR-WAY SOLENOID VALVES

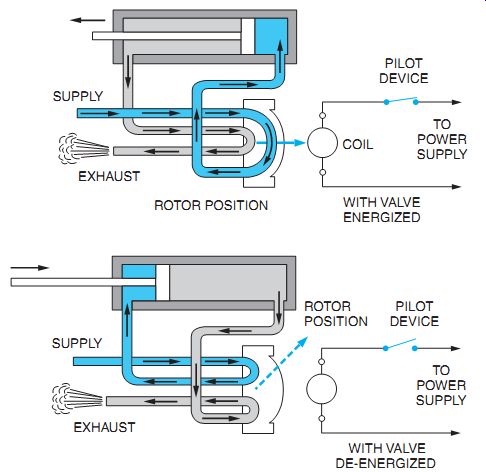

Electrically operated, four-port, four-way air valves are used to control a double-acting cylinder, ill. 2.

When the coil is de-energized, one side of the piston is at atmospheric pressure, and the other side is acted on by the line pressure compressed air. When the valve magnet coil is energized, the valve exhausts the high-pressure side of the piston to atmospheric pressure. As a result, the piston and its associated load reciprocate in response to the valve movement.

Four-way valves are used extensively in industry to control the operation of the pneumatic cylinders used on spot welders, press clutches, machine and assembly jig clamps, tools, and lifts.

ill. 2 Control of double-acting cylinder by a four-way, electrically operated

valve shown with elementary diagrams.

QUIZ:

1. Why is it important to understand the purpose and action of the total operational system when working with controls?

2. If an electrically controlled, two-way solenoid valve is leaking, what is the probable cause?

3. What is the difference between a two-way solenoid valve and a flow switch?