AMAZON multi-meters discounts AMAZON oscilloscope discounts

GOALS:

- • State several advantages of the use of a clutch in a drive.

- • Describe the operating principles of magnetic clutches and drives.

- • Distinguish between single- and multiple-face clutches.

- • Connect magnetic clutch and magnetic drive controls.

- • Recommend troubleshooting solutions for magnetic clutch and drive problems.

ELECTRICALLY CONTROLLED MAGNETIC CLUTCHES

Machinery clutches were originally designed to engage very large motors to their loads after the motors had reached running speeds, ill. 1. Clutches provide smooth starts for operations in which the material being processed might be damaged by abrupt starts, ill. 2. Clutches are also used to start high-inertia loads, because the starting may be difficult for a motor that's sized to handle the running load. When starting conditions are severe, a clutch inserted between the motor and the load means that the motor can run within its load capacity. The motor will take longer to bring the load up to speed, but the motor and load won't be damaged.

As more automatic cycling and faster cycling rates are being required in industrial production, electrically controlled clutches are being used more often.

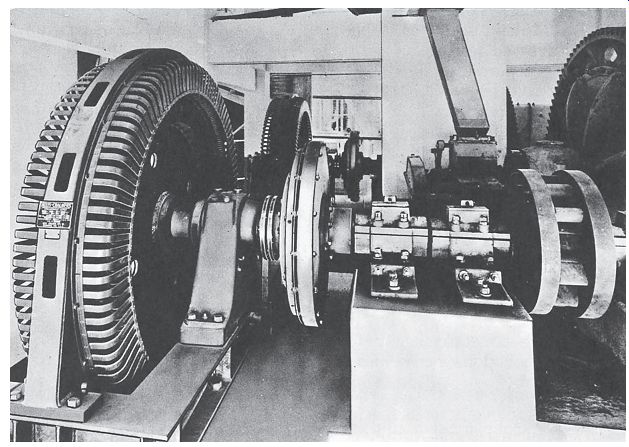

ill. 1 Magnetic clutches in cement mill service. Note the slip rings for clutch

supply.

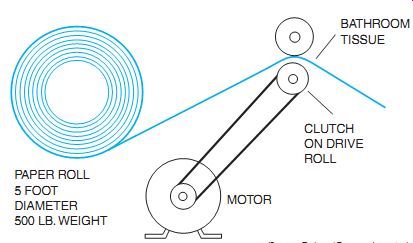

ill. 2 To prevent tearing, a cushioned start is required on a drive roll that

winds bathroom tissue off a large roll. Roll is 5 feet in diameter and weighs

500 pounds when full. Pickup of thin tissue must be very gradual to avoid tearing.

Application also can be used for filmstrip processing machine.

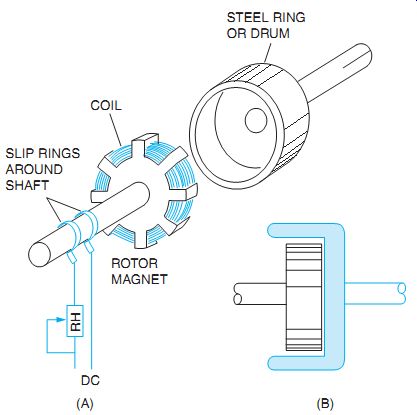

ill. 3 Principle of operation of electrically con trolled clutches. (A) Gradual clutch engagement; (B) more rapid clutch engagement.

Single-Face Clutch

The single-face clutch consists of two discs: one is the field member (electromagnet) and the other is the armature member. The operation of the clutch is similar to that of the electromagnet in a motor starter, ill. 3. The principle of operation is shown in ill. 3. However, this is done more frequently electronically using solid state devices. SCRs are gated to regulate the cur rent flow as in Part (A) and to switch power as in Part (B). When current is applied to the field winding disc through collector (slip) rings, the two discs are drawn together magnetically. The friction face of the field disc is held tightly against the armature disc to provide positive engagement between the rotating drives. When the current is removed, a spring action separates the faces to provide a definite clearance between the discs. In this manner, the motor is mechanically disconnected from the load.

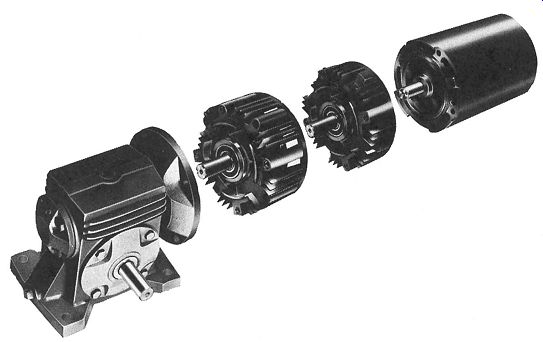

ill. 4 Electric brake and electric clutch modules. Brake is shown on the center

left on driven machine side of the clutch.

Multiple-Face Clutch

Multiple-face clutches are also available. In a double-face clutch, both the armature and field discs are mounted on a single hub with a double-faced friction lining supported between them. When the magnet of the field member is energized, the armature and field members are drawn together. They grip the lining between them to provide the driving torque. When the magnet is de-energized, a spring separates the two members and they rotate independently of each other. Double-face clutches are available in sizes up to 78" diameter.

A water-cooled magnetic clutch is available for applications that require a high degree of slippage between the input and output rotating members. Uses for this type of clutch include tension control (windup and payoff) and cycling (starting and stopping) operations in which large differences between the input and the output speeds are required. Flowing water removes the heat generated by the continued slippage within the clutch. A rotary water union mounted in the end of the rotor shaft means that the water-cooled clutch cannot be end coupled directly to the prime mover. Chains or gears must be used.

A combination clutch and magnetic brake disconnects the load from the drive and simultaneously applies a brake to the load side of the drive. Magnetic clutches and brakes are often used as mechanical power-switching devices in module form. ill. 4 shows a driveline with an electric clutch (center right) and an electric brake. An application of this arrangement is shown in ill. 5. Remember that the quicker the start or stop, the shorter the life of this equipment.

Magnetic clutches are used on automatic machines for starting, running, cycling, and torque limiting. The combinations and variations of these functions are practically limitless.

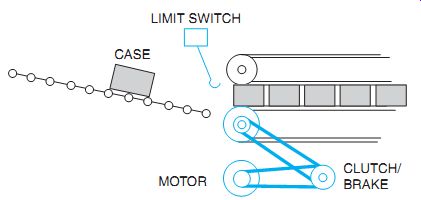

ill. 5 Case sealer is used to hold the top of the carton while the glue is

drying. In the application, cartons come down the gravity conveyor and hit

the switch in front of the sealer. The clutch on the sealer drive is engaged,

moving all cartons in the sealer forward. When the new carton passes the trip

switch, the brake is engaged and the clutch is disengaged. Positioning pro

vides even spacing of cartons, ensuring that they are in the sealer for as

long a time as possible.

ill. 6 Diagram showing (A) an open view of a magnetic drive assembly; (B)

spider rotor magnet rotates within the ring.

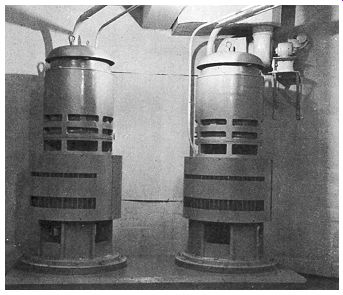

ill. 7 Two magnetic drives driven by 100-hp, 1200 rpm induction motors mounted

on top. Machines are used in typical sewage pumping plants. Pumps are mounted

beneath the floor of drives.

MAGNETIC DRIVES

The magnetic drive couples the motor to the load magnetically. The magnetic drive can be used as a clutch and can be adapted to an adjustable speed drive.

The electromagnetic (or eddy current) coupling is one of the simpler ways to obtain an adjustable output speed from the constant input speed of squirrel cage motors.

There is no mechanical contact between the rotating members of the magnetic drive. Thus, there is no wear. Torque is transmitted between the two rotating units by an electromagnetic reaction created by an energized coil winding.

The slip between the motor and load can be con trolled continuously, with more precision, and over a wider range than is possible with the mechanical friction clutch.

As shown in ill. 6, the magnet rotates within the steel ring or drum. There is an air gap between the ring and the magnet. The magnetic flux crosses the air gap and penetrates the iron ring. The rotation of the ring with relation to the magnet generates eddy currents and magnetic fields in the ring. Magnetic interaction between the two units transmits torque from the motor to the load. This torque is con trolled with a rheostat, which manually or automatically adjusts the direct current supplied to the electromagnet through the slip rings.

When the electromagnet drive responds to an input or command voltage, a further refinement can be obtained in automatic control to regulate and maintain the output speed. The magnetic drive can be used with any type of actuating device or transducer that can provide an electrical signal. E.g., electronic controls and sensors that detect liquid level, air and fluid pressure, temperature, and frequency can provide the input required.

A tachometer generator provides feedback speed control in that it generates a voltage that's proportional to its speed. Any changes in load condition will change the speed. The resulting generator voltage fluctuations are fed to a control circuit, which increases or decreases the magnetic drive field excitation to hold the speed constant.

For applications where a magnetic drive meets the requirements, an adjustable speed is frequently a desirable choice. Magnetic drives are used for applications requiring an adjustable speed such as cranes, hoists, fans, compressors, and pumps, ill. 7.

An electronic microprocessor unit's used to control and regulate the tension applied to strips of metal, paper, film, wire, and cable during the course of processing. It controls the speed and diameter fluctuations of the spool coils. Further, it ensures a constant tension, even at high linear speeds, which is essential to the quality of the finished product.

QUIZ:

1. How is the magnetic clutch engaged and disengaged?

2. What devices may be used to energize the magnetic clutch?

3. Which type of drive is best suited for maintaining large differences in the input and output speeds? Why?

4. What is meant by feedback speed control?

5. How is the magnetic drive used as an adjustable speed drive?