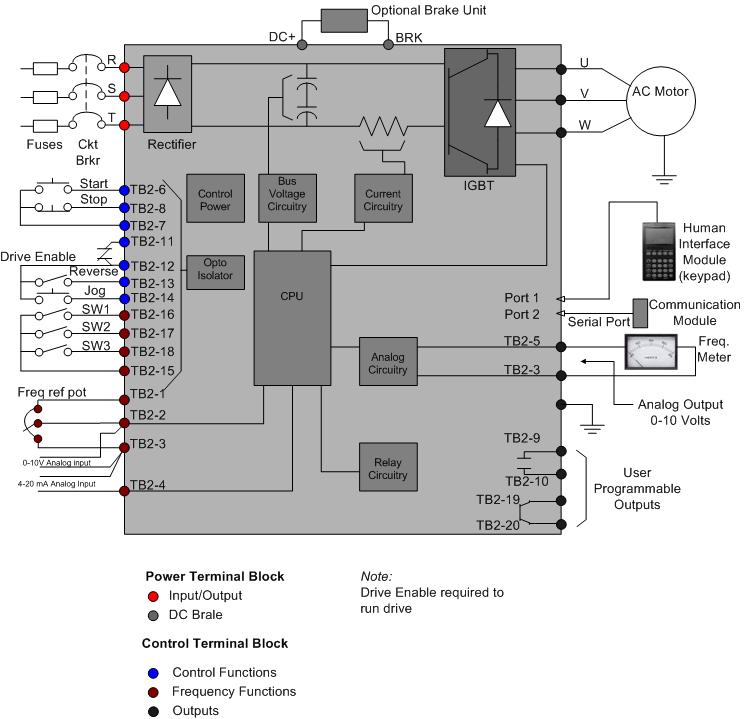

The block diagram below shows a typical variable-frequency drive (aka AC drive) installation. This diagram shows the wires that supply power to the drive, the wires that provide voltage from the drive to the motor, and all the necessary input and output signals that the drive needs for operation. From the diagram one can see that the power source for the AC drive is provided at terminals R, S, and T by 3-phase AC voltage. The value of this voltage can be 208, 240, or 480 volts. The 3-phase voltage is converted to DC voltage in the rectifier section on the drive where six diodes are connected as a 3-phase full-wave bridge rectifier. On larger drives the diodes can be replaced with silicon-controlled rectifiers (SCRs).

The next components in this circuit are the choke and the capacitors that make up the filter section of the drive. The capacitors and choke provide a filter that removes all of the sinusoidal ripple and any trace of the original frequency. The voltage at this point in the drive is pure DC voltage and will be approximately 670 volts.

The output section of this drive contains three pairs of insulated gate bipolar transistors (IGBTs). These transistors are turned on by a pulse-width modulation (PWM) control circuit that times the conduction of each IGBT so that a PWM wave is produced that looks like a sine-wave output. The transistors are turned off approximately 12 times for each half cycle. Each time the transistor is turned on, its amplitude will be adjusted so that the overall shape of the waveform looks like a sine wave. The time each transistor is turned on is adjusted as the frequency for the output signal is adjusted. The overall frequency for the drive output signal to the motor will be determined by the frequency of the PWM sine wave. The frequency can be adjusted from 0 - 400 Hz on some drives and typically it can be adjusted from 0 - 120 Hz. The amplitude of the signal will change to change the voltage of the signal. The voltage and the current for the output signal will be adjusted to provide the correct amount of torque to the motor load. The drive will maintain a volts-per-Hertz ratio (V/Hz) to ensure that the motor has sufficient power to provide torque to respond to changes in the load. The V/Hz ratio can be adjusted slightly to provide more voltage at lower frequencies if the motor is used in these applications where larger loads must be moved accurately at lower speeds. In the block diagram one can also see that a diode is connected in reverse bias across each IGBT to protect it from excess voltage spikes that may occur. The IGBTs are controlled as pairs so that one will provide the positive part of the PWM sine wave and the other will provide the negative part of the wave.

The output terminals of the drive provide a place to connect the three motor leads. These terminals are identified as U, V, and W. The labels R, S, and T for the input voltage and U, V, W for the output terminals are worldwide standards. Some drives made in the U.S. before 1990 may still be identified as L1, L2, and L3 for input terminals and T1, T2, and T3 for output terminals where the motor is connected.

above: A block

diagram of a variable-frequency drive that also shows the components that

are connected to the drive to provide additional control. Adapted from

an Allen-Bradley/Rockell Automation AC drive schematic.