AMAZON multi-meters discounts AMAZON oscilloscope discounts

HYDROELECTRIC SYSTEMS

The use of water power goes back to ancient times. It has been developed to a very high degree, but is now taking a secondary role due to the emphasis on other power sources that are being developed in our country today. Electrical power production systems using water power were developed in the early twentieth century.

The energy of flowing water may be used to generate electrical power.

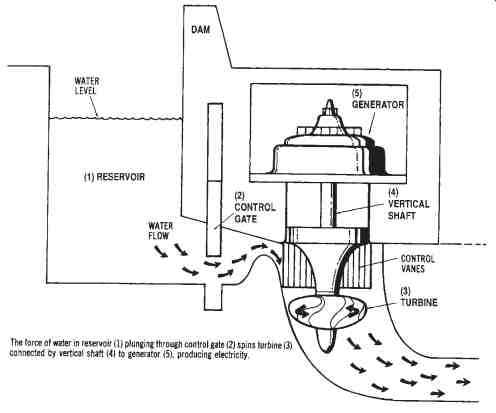

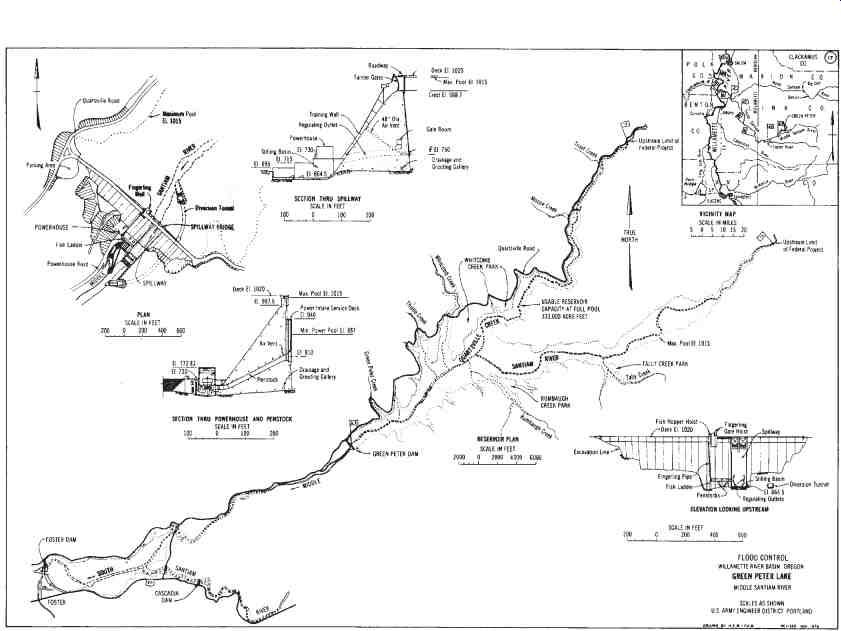

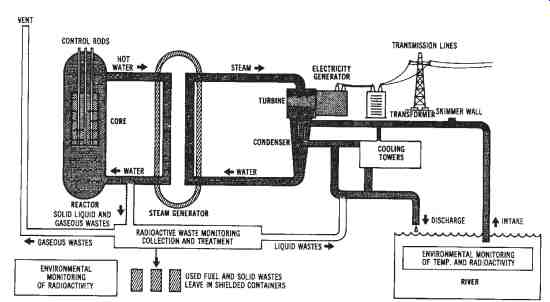

This method of power production is used in hydroelectric power systems, as shown by the simple system illustrated in the diagram in FIG. 12. Water, which is confined in a large reservoir, is channeled through a control gate, which adjusts the flow rate. The flowing water passes through the blades and control vanes of a hydraulic turbine, which produces rotation. This mechanical energy is used to rotate a generator that is connected directly to the turbine shaft. Rotation of the alternator causes electrical power to be produced. However, hydroelectric systems are limited by the availability of large water supplies. Many hydroelectric systems are part of multipurpose facilities. For instance, a hydroelectric power system may be part of a project planned for flood control, recreation, or irrigation. Some hydroelectric power systems are shown in FIGs. 12 through 14.

FIG. 12. Drawing of a basic hydroelectric power system

FIG. 13. Site layout of a hydroelectric project (Portland District,

U.S. Army Corp of Engineers)

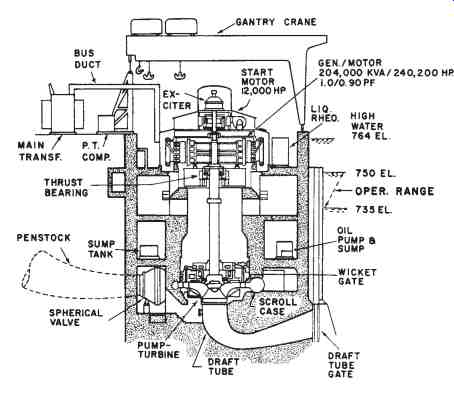

FIG. 14. Cutaway drawing of a hydroelectric power section at

a main unit showing equipment arrangement (Allis-Chalmers Co.)

Hydroelectric System Operation

The turbines used as the mechanical energy sources of hydroelectric systems are very efficient machines. They are ordinarily connected directly to the shaft of a three-phase generator, which produces the electrical power. Water is channeled in from a higher level down into a spiral set of blades on the turbine. The force of water flowing onto these blades causes a rotation of the turbine in the desired direction. The water that flows past the turbine blades is then channeled into a lower-level lake or reservoir area. The angle of the turbine blades can be adjusted to control the speed of rotation of the turbine. Since rotational speed must remain constant to produce a 60-Hz frequency, the blade-angle adjustment and the amount of water channeled onto the blades must be adjusted continuously. Also, varying amounts of force are required to turn the turbine so that different amounts of power are delivered by the turbine to rotate the generator. As the load demand delivered by the generator increases, the power input to the turbine must be increased accordingly. This control is accomplished by adjusting the angle of the blades and the amount of water channeled into the blades. The adjustments are automatically accomplished by servo-control systems.

Hydraulic Turbines

The production of electrical energy by hydroelectric systems is dependent upon the operation of hydraulic turbines. Hydraulic turbines convert the energy produced by the force of moving water into mechanical energy.

This type of turbine is connected to the shaft of a generator at a hydroelectric plant. Since AC generators at power plants must rotate at a constant speed, the hydraulic turbine must turn at a fixed rate of speed. The efficiency of hydraulic turbines is much greater (in excess of 85 percent) than that of most rotating machines.

The type of hydraulic turbine used with a hydroelectric power system determines whether the generators have horizontal or vertical shafts. Vertical shaft designs are the most common. Electrical power is produced by a three-phase AC generator connected directly to the shaft of the hydraulic turbine. Several hydroelectric systems are used as "reserve" systems for peak load times. They may be put into operation much faster than steam-driven power systems. It is also possible for the generators of a hydroelectric system to be operated as three-phase synchronous motors during low-demand periods. The motor can rotate the hydraulic turbine, which is then capable of pumping water. Sufficient water is pumped so that a higher external water level is achieved. The higher water elevation will then assist in the production of power during peak load intervals.

Future of Hydroelectric Systems

About 10 percent of the power produced in the United States is produced by hydroelectric power systems. After the initial cost of constructing a hydroelectric generating facility, the electrical power production cost is relatively inexpensive. Hydroelectric systems are easier to start up and stop than are other power production systems in use today. There are other advantages to hydroelectric systems that are not associated with the production of electrical power. These benefits, derived from the construction of multipurpose dams, include navigational control of waterways, flood control, irrigation, and development of recreational area. Another advantage is that hydroelectric systems do not cause a consumption of the energy source that produces the electrical power, as do other systems in use today.

Hydroelectric generating projects are considered to be low cost, and they produce little pollution. However, in the United States, we have al ready used the most desirable sites for installing hydroelectric systems.

Since the cost of developing other alternative power systems, such as nu-clear and geothermal, has become so great, the development of less desirable hydroelectric sites is now feasible. Future development of hydroelectric power systems may be inevitable.

A motivation for the use of water to produce electrical power is the fact that, if we used this natural resource to its full potential, it would give us other benefits. These were discussed earlier. Although the cost to pro duce electrical power with hydroelectric systems depends on a number of factors, it is generally considered to be a very cheap source of energy. The costs are primarily dependent upon the location of the power plant. The desirability of the site is dependent upon its natural characteristics, which affect the cost of development, and its regional characteristics, which, in turn, affect the market for the power.

In the late 1930s, water power supplied about 40 percent of the electrical power in the United States. Now, however, water power supplies only about 10 percent of the nation's electrical power. This is due to the massive development of other power production methods. It is estimated that, in the future, water power will account for an even smaller percent age of electrical power generation. Despite this projected decrease, hydro electric plants are still being built, and the hydroelectric capacity of the United States is still substantial. Hydroelectric systems are not now being developed rapidly; however, with our ever-increasing energy problems and the shortages of our other natural resources, water systems may still have a useful potential.

Pumped-Storage Hydroelectric Systems

Several megawatts of electrical power are produced in the United States by pumped-storage hydroelectric systems. This type of system operates by pumping water to a higher elevation and storing it in a reservoir until it is released to drop to a lower elevation to drive the hydraulic turbines of a hydroelectric power-generating plant.

The variable nature of the electrical load demand makes pumped-storage systems desirable systems to operate. During low-load periods, the hydraulic turbines may be used as pumps to pump water to a storage reservoir of a higher elevation, from a water source of a lower elevation. The water in the upper reservoir can be stored for long periods of time, if necessary. When the electrical load demand on the power system increases, the water in the upper reservoir can be allowed to flow (by gravity feed) through the hydraulic turbines, which will then rotate the three-phase generators in the power plant. Thus, electrical power can be generated without any appreciable consumption of fuel. The pump-turbine and mo tor-generator units are constructed so that they will operate in two ways: (1) as a pump and motor, and (2) as a turbine and generator. In both cases, the two machines are connected by a common shaft and operate together.

However, the multiple use of these machines, although economically very attractive, limits the amount of time that a pumped-storage system can generate electrical power.

Future of Pumped-storage Systems

The future of pumped-storage systems depends primarily on economic factors. If fuel and capital construction costs continue to rise, pumped storage systems might be developed. The conversion of conventional hydroelectric systems to pumped-storage systems has been considered.

Also, underground pumped-storage systems have been studied. The underground system would have an upper reservoir at ground level and the lower reservoir underground. The operating principle is the same as in a conventional pumped-storage system.

NUCLEAR FISSION SYSTEMS

Nuclear power plants in operation today employ reactors that utilize the nuclear-fission process. Nuclear fission is a complex reaction that results in the division of the nucleus of an atom into two or more nuclei. This splitting of the atom is brought about by the bombardment of the nucleus with neutrons, gamma rays, or other charged particles, and is referred to as induced fission. When an atom is split, it releases a great amount of heat.

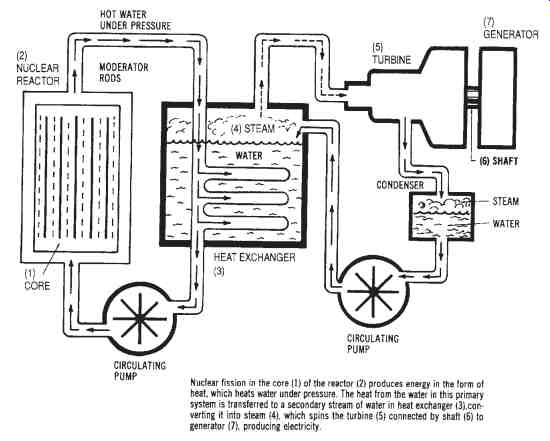

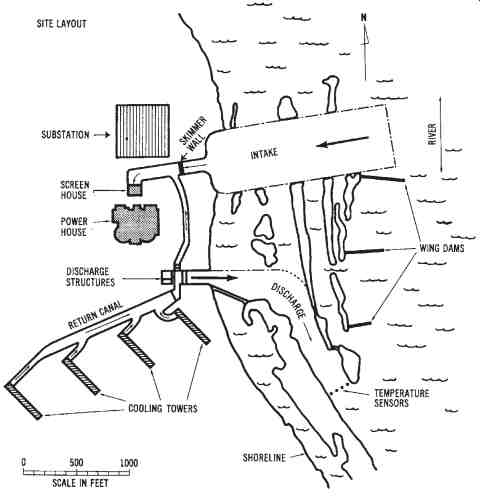

In recent years, several nuclear fission power plants have been put into operation. A nuclear fission power system, shown in FIG. 15, re lies upon heat produced during a nuclear reaction process. Nuclear reactors "burn" nuclear material, whose atoms are split, causing the release of heat. This reaction is referred to as nuclear fission. The heat from the fission process is used to change circulating water into steam. The high-pres sure steam rotates a turbine, which is connected to an electrical generator.

FIG. 15. Drawing illustrating the principles of a nuclear fission

power system.

FIG. 16. Diagram of the nuclear reaction process (Northern States

Power Company)

This is shown in the diagram of FIG. 16.

The nuclear fission system is very similar to fossil fuel systems in that heat is used to produce high-pressure steam that rotates a turbine. The source of heat in the nuclear fission system is a nuclear reaction; in the fossil-fuel system, heat is developed by a burning fuel. At the present time, less than 10 percent of the electrical power produced in the United States comes from nuclear fission sources. However, this percentage is also subject to rapid change as new power facilities are put into operation. A typical nuclear power plant site layout is given in FIG. 17.

FIG. 17. Typical site layout of a nuclear power plant (Northern

States Power Company)

Nuclear Power Fundamentals

In order to better understand the process involved in producing electrical power by nuclear fission plants, we should review some fundamentals. An atom is the smallest particle into which an element can be broken. The central part of an atom is called its nucleus (this is how the term

"nuclear power" was derived). The nucleus of an atom is composed of protons, which are positively charged particles, and neutrons, which have no electrical charge. Electrons, which are negatively charged particles, or bit around the nucleus. An atom of any element is electrically neutral in its natural state, since the number of protons in the nucleus is equal to the number of electrons that orbit around the nucleus.

The number of protons (+) and electrons (-) contained by an atom varies from one atom to another. (For further information concerning atomic number, mass, et cetera, refer to the table of Elements.) The number of neutrons (0) in an atom is not always the same as the number of protons and electrons. Atoms that have additional neutrons are called isotopes. For instance, a hydrogen atom normally has one electron, one proton, and no neutrons. If one neutron is added to this atomic structure, heavy hydrogen, or deuterium, is formed. Deuterium is an isotope of hydrogen.

The element uranium has many different isotopes, each of which contains 92 protons. If the isotope has 143 neutrons in the nucleus, uranium-235 is formed. Uranium-235 has proved to be a valuable nuclear fuel, but less than 1 percent of the uranium metal ore mined is of the uranium-235 type.

The fission or splitting reaction of uranium-235, or other nuclear fuels, is an interesting process. It requires separate controlled neutrons, traveling at high velocities, to penetrate the orbiting electrons around the nucleus of the U-235 isotope. Once a high-velocity neutron has struck the nucleus, the nucleus will split into smaller nuclei. This reaction causes a large quantity of heat to be released. When a nucleus splits, other neutrons from within it are released. These neutrons can cause additional fission re actions in other U-235 isotopes. Thus, the fission reaction occurs as a chain reaction, which causes massive amounts of heat energy to be given off.

Nuclear Fuels

A sustained nuclear fission reaction is dependent upon the use of the proper type of fuel. The most desirable fuels for nuclear fission reactions are uranium-233, uranium-235, and plutonium-239. These three nuclear materials are the only fissionable isotopes capable of producing sustained reactions. Of these nuclear fuels, the only one that occurs naturally is uranium 235. The other two isotopes are produced by artificial means. Ordinarily, nuclear reactors that use uranium-235 as a fuel are called converter reactors.

The possibility of a nuclear fission reaction producing as much or more fuel than is used has been investigated. Such reactors are called breeder reactors and use uranium-233 and plutonium-239 as fuels. During the nuclear reactions that take place in a breeder reactor, materials that are used in the reaction process are converted into fissionable materials. The long-range development of nuclear power production may be dependent upon whether or not breeder reactors can be made available soon. Since the types of nuclear reactors that are presently being used consume uranium-235, it is thought that, in the future, the supply of this fuel will become low, forcing its price to rise substantially. A price increase in this naturally available nuclear fuel would make nuclear power production less economically competitive with other systems.

Uranium fuel for nuclear fission reactors is produced from ore and is then purified and converted to the desired state through a series of processes. Most nuclear fuel elements are made into plates or rods, which are protected by a cladding of stainless steel, zirconium, or aluminum. The cladding must be capable of containing the nuclear fuel, so as not to allow the release of radioactive materials.

Used fuel is released from the fission reactors when it no longer produces heat effectively during the nuclear reaction. It is not depleted at this time; therefore, further processing can bring about the recovery of more fuel from the used fuel. The used fuel, which is released from a nuclear re actor, is usually stored underwater for a period of time to permit cooling and radioactive shielding. This type of storage reduces the radioactivity of the fuel. After the storage period has elapsed, the fuel may be reprocessed more safely and easily. The reprocessing of nuclear fuel is very expensive.

A large factor contributing to this cost is the expense of constructing a re processing facility. These facilities must be extensively shielded for radiation protection, both internally and externally. The production and use of nuclear fuels in the United States is rigidly controlled. An agency of the federal government keeps a continuous account of all nuclear fuels produced, used, or reprocessed.

Nuclear Reactors

There is a variety of types of nuclear reactors. The major type used in the United States has been the water-moderated reactor. The fundamental difference between a nuclear power plant and a conventional power plant is the fuel that is employed. Most conventional power plants burn coal, oil, or gas to create heat, while the present nuclear plants "burn" uranium. Burning uranium has proved to be a very effective source of power production; however, there is much controversy over this source of power.

It is estimated that burning one ounce of uranium produces roughly the same energy output as burning 100 tons of coal. The "burning" that takes place in a nuclear reactor is referred to as nuclear fission. Nuclear fission is the method used in nuclear power generation, and it is quite different from ordinary combustion. The burning of coal results from the carbon combining with oxygen to form carbon dioxide, along with the release of heat. The fissioning or splitting of the uranium atom results in the uranium combining with a neutron and, subsequently, splitting into lighter elements. This process produces a massive quantity of heat.

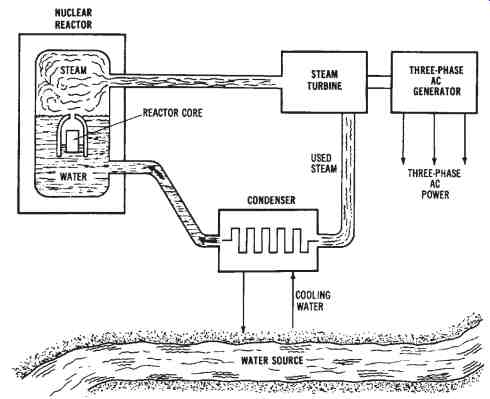

The reactors used at nuclear power plants must be capable of con trolling fission reactions. When nuclear fuels are bombarded by neutrons, they split and release energy, radiation, and other neutrons. This process is a sustained chain reaction, producing a great amount of heat energy, which is used for the production of steam, which is used to rotate a steam turbine-generator system. The nuclear fission power-generating system is about the same as a conventional fossil fuel steam plant, except that a nuclear reactor is used to produce the heat energy, rather than a burning fuel confined in a furnace.

Within the nuclear reactor, there is a mixture of fuel and a moderator material. There are three known nuclear fission fuels: uranium-235, uranium-233, and plutonium-239. Moderators are used to slow the speed of neutrons in fission reactions. Since the neutrons involved in the fission reaction have high energy levels, they are called fast neutrons. They are slowed by collisions with moderator materials such as water, deuterium oxide, beryllium, and other lightweight materials. Neutrons that have been slowed down possess an energy equilibrium and are referred to as thermal neutrons. These thermal neutrons aid in additional fission reactions. Thus, moderators playa significant role in sustaining nuclear fission reactions.

Nuclear reactors differ in several ways. Differences include the type of fuel and moderator, the thermal output capacity, and the type of coolant. Several classifications of nuclear reactors, according to types of coolant, are discussed in the following sections.

FIG. 18. Simplified diagram of a boiling water reactor (BWR)

Moderating Nuclear Reactors

A uranium atom undergoes fission when it absorbs a neutron and, at the same time, produces two lighter elements and emits two or three neutrons. These neutrons, in turn, react with other uranium atoms, which will undergo fission and produce more neutrons. Heat is increased in the reactor as the number of neutrons is increased. If a reactor is left uncontrolled, it may destroy itself. Moderating a reactor, therefore, means controlling the multiplication of neutrons in the reactor core. There are several methods used for moderating nuclear reactors.

Boiling-Water Reactor (BWR)--Water is a popular coolant for reactors. In this type of reactor, shown in FIG. 18, water is pumped into the re actor enclosure. The water is then converted into steam, which is delivered to a steam turbine. The water also serves as the moderator material of the reactor.

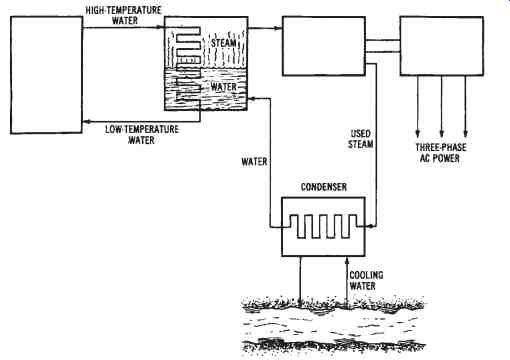

Pressurized-Water Reactor (PWR)--The pressurized-water reactor, shown in FIG. 19 is similar to a boiling-water reactor, except that the coolant water is pumped through the reactor under high pressure. Steam is produced in an adjacent area from a separate stream of water, which is pumped through the steam-production system. Just as in the BWR, the water within the reactor serves as the moderator.

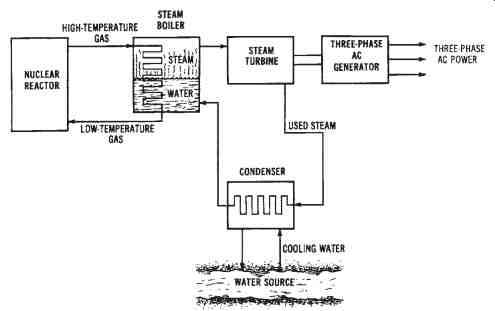

High-temperature Gas-cooled Reactor (HTGR)--The high-temperature gas-cooled reactor, shown in FIG. 20 uses pressurized helium gas to transfer heat from the reactor to a steam-production system. The advantage of helium gas over water is that the helium can operate at much higher temperatures.

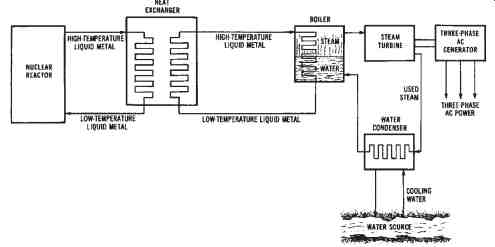

Other types of reactors, such as the liquid-metal fast-breeder reactor (LMFBR) and the molten-salt-cooled reactor, have some potential in electrical power production systems. The LMFBR type is shown in FIG. 21.

FIG. 19. Simplified diagram of a pressurized water reactor (PWR)

OPERATIONAL ASPECTS OF MODERN POWER SYSTEMS

There are several operational aspects of modern electrical power production systems that must be considered. These considerations include the location of power plants, electrical load requirements, and electrical load demand control. Each of these will be discussed in the following sections.

FIG. 20. Simplified diagram of a high-temperature gas-cooled

reactor (HTGR)

FIG. 21. Simplified diagram of a liquid-metal fast-breeder reactor

(LMFBR)

FIG. 21. Simplified diagram of a liquid-metal fast-breeder reactor

(LMFBR)

Location of Electrical Power Plants

A critical issue that now faces those involved in the production of electrical power is the location of power plants. Federal regulations associated with the National Environmental Policy Act (NEPA) have made the location of power plants more difficult. At present, there are a vast number of individual power plants throughout the country. However, the addition of new generating plants involves such current issues as air pollution, water pollution, materials handling (particularly with nuclear plants), fuel availability, and federal, state, and municipal regulations.

These issues have brought about some recent thought about the construction of "energy centers." Such systems would be larger and more standardized than the power plants of today. This concept would reduce the number of plants that are needed to produce a specific quantity of electrical power. Other advantages of this concept include better use of land resources, easier environmental control management, and more economical construction and management of facilities. These advantages may make centralized power production the best alternative, socially, economically, and technically, for meeting future electrical power requirements.

Electrical Load Requirements

The electrical power that must be produced by our power systems varies greatly according to several factors, such as the time of the year, the time of the week, and the time of the day. The level of electrical power sup ply and demand is much more difficult to predict than that of most quantities that are bought and sold. Electrical power must be readily available, in sufficient quantity, whenever it is required. The overall supply and demand situation is something most of us take for granted until our electrical power is interrupted. Electrical power systems in the United States must be interconnected on a regional basis, so that power stations can sup port one another in meeting the variable load demands.

The use of electrical power has been forecasted to increase every ten years at a rate that will cause a doubling of the kilowatt hours required.

Some forecasts, however, show the rate of electrical power demand to have a "leveling-off" period in the near future. This effect may be due to a saturation of the possible uses of electrical power for home appliances, industrial processes, and commercial use. These factors, combined with greater conservation efforts and other social and economic factors, sup port the idea that the electrical power demand will increase at a slower rate in future years. The forecasting of the present demand by the electrical utility companies must be based on an analysis by regions. The demand varies according to the type of consumer supplied by the power stations that constitute the system. Different types of load are encountered when residential, industrial, and commercial systems are supplied by the electrical utility companies.

Industrial use of electrical power accounts for approximately 40 percent of the total kilowatt-hour (kWh) consumption, and the industrial use of electrical power is projected to increase at a rate similar to its present rate, in the near future. The shortage of natural gas should not significantly affect electrical power consumption by industry. Most of the conversions of gas systems will be to systems that use oil in place of gas.

The major increases in residential power demand have been due to an increased use by customers. A smaller increase is accounted for by an in-crease in the number of customers. Such variables as the type of heating used, the use or nonuse of air conditioning, and the use of major appliances (freezers, dryers, ranges) affect the residential electrical power demand.

At present, residential use of electrical power accounts for approximately 30 percent of the total consumption. The rate of increase will probably taper off in the near future.

Commercial use of electrical power accounts for less than 25 percent of the total kWh usage. Commercial power consumption includes usage by office buildings, apartment complexes, school facilities, shopping establishments, and motel and hotel buildings. The prediction of the future electrical power demand by these facilities is somewhat similar to the pre diction of future residential demand. The rate of increase in the commercial use of electrical power is also expected to decline in the future. These percentages are subject to change over time.

Electrical Load-demand Control

As the costs of producing power continue to rise, power companies must search for ways to limit the maximum rate of energy consumption.

To cut down on power usage, industries have begun to initiate programs that will cut down on the load during peak operating periods. The use of certain machines may be limited while other large, power-consuming machines are operating. In larger industrial plants, and at power production plants, it would be impossible to manually control the complex regional switching systems, so computers are being used to control loads.

To prepare the computers for power-consumption control, power companies must determine the peak demand patterns of local industries, and the surrounding region, supplied by a specific power station. The load of an industrial plant may then be balanced, according to area demands, with the power station output. The computer may be programmed to act as a switch, allowing only those processes to operate that are within the load calculated for the plant for a specific time period. If the load drawn by an industry exceeds the limit, the computer may deactivate part of the system. When demand is decreased in one area, the computer can cause the power system to increase power output to another part of the system.

Thus, the industrial load is constantly monitored by the power company to ensure a sufficient supply of power at all times.