AMAZON multi-meters discounts AMAZON oscilloscope discounts

The control of electrical power is a very important part of electrical power system operation. Control is the most complex part of electrical systems. It is, therefore, necessary to limit the discussion in this Section primarily to some of the common types of electromechanical equipment used for electrical power control. Control equipment is used in conjunction with many types of electrical loads. Electrical motors (mechanical loads) use about 50 percent of all electrical motor-control equipment. In most cases, similar equipment is used to control electrical lighting and heating loads.

TERMINOLOGY

This section deals with power control equipment. After studying this section, you should have an understanding of the following terms:

- NEMA

- ANSI

- IEEE

- Across-the-Line Starter Auxiliary Contact

- Dynamic Braking

- Normally Open Contact

- Normally Closed Contact

- Magnetic Contactor

- Drum Controller

- Jogging

- Manual Starter

- Overload Relay

- Plugging

- Normally Closed Pushbutton

- Normally Open Pushbutton

- Reduced-Voltage Starting

- Control Relay

- Safety Switch

- Solenoid

- Timing Relay

- Switches

- SPST

- SPDT

- DPST

- DPDT

- 4-Way

- 3PST

- 3PDT

- Rotary Switch

- Limit Switch

- Temperature Switch

- Float Switch

- Pressure Switch

- Foot Switch

- Pilot Lights

- Full-Voltage

- Transformer-Operated

- Series Resistor

- Illuminated Pushbutton

- Combination Starter

- Controller Enclosures-NEMA

POWER CONTROL STANDARDS, SYMBOLS, AND DEFINITIONS

A great amount of fundamental knowledge is needed in order to fully understand electrical power control. Individuals who are concerned with electrical power control systems should have a good knowledge of the standards, symbols, and definitions that govern electrical power control.

NEMA Standards

The National Electrical Manufacturers' Association (NEMA) has developed standards for electrical control systems. NEMA standards are used extensively to obtain information about the construction and performance of various electrical power control equipment. These standards provide information concerning the voltage, frequency, power, and cur rent ratings for various equipment.

ANSI and IEEE Standards

Two well-known organizations publish standards that are of importance to industry. These organizations are the American National Standards Institute (ANSI) and the Institute of Electrical and Electronic Engineers (IEEE). The standards published by these organizations are for the use of the manufacturing industries, as well as power consumers, and in some cases the general public. These standards are subject to review periodically; therefore, industrial users should keep up to date by obtaining the revisions.

These standards were developed from input from manufacturers, consumers, government agencies, and scientific, technical, and professional organizations. Often these published standards are used by industry as well as governmental agencies. It should be noted that the National Electrical Code, discussed previously, is an American National Standards Institute standard.

Definitions

There are several basic definitions that are used when dealing with electrical power control. These definitions are particularly important when interpreting control diagrams and standards. A listing of several of the important power control definitions follows. You should study these definitions.

- Across-the-line-Control--A method of motor starting in which a motor is connected directly across the power lines when it is started.

- Automatic Starter--A self-acting starter that is completely controlled by control switches, or some other sensing mechanism.

- Auxiliary Contact--A contact that is part of a switching system. It is used in addition to the main contacts, and is operated by the main contacts.

- Braking--A control method that is used to rapidly stop and hold a motor.

- Circuit Breaker--An automatic device that opens under abnormally high current conditions, and can be manually or automatically reset.

- Contact--A current-conducting part of a control device. It is used to open or close a circuit.

- Contactor--A control device that is used to repeatedly open or close an electric power circuit.

- Controller--A device or group of devices that systematically controls the delivery of electric power to the load or loads connected to it.

- Disconnect--A control device or group of devices that will open, so that electrical current in a circuit will be interrupted.

- Drum Controller--A set of electrical contacts mounted on the surface of a rotating cylinder. It is usually used for controlling the on-off for ward-reverse condition of a load.

- Electronic Control--A usually solid-state device that performs part of the control function of a system.

- Full Voltage Control--A control system that connects equipment directly across the power lines when the equipment is started.

- Fuse--A circuit-protection device that disconnects a circuit when an over current condition occurs. It is self-destructing and must be replaced.

- Horsepower--The power output or mechanical work rating of an electrical motor.

- Jogging-Momentary operation that causes a small movement of the load that is being controlled.

- Magnetic Contactor--A contactor which is operated electromagnetically and usually controlled by pushbuttons activated by an operator.

- Manual Controller--An electric control device that functions when operated by mechanical means, usually by an operator.

- Master Switch--A switch that controls the power delivered to other parts of a system.

- Motor--A device (mechanical load) for converting electrical power to mechanical power in the form of rotary motion.

- Multispeed Starter--An electrical power-control device that provides for varying the speed of a motor.

- Overload Relay--Overcurrent protection for a load. While it is in operation, it maintains the interruption of the load from the power supply until it is reset or replaced.

- Overload Relay Reset--A pushbutton that is used to reset a thermal over load relay after the relay has been overloaded.

- Pilot Device--A control device that directs the operation of another device or devices.

- Plugging--A braking method that causes a motor to develop a retarding force in the reverse direction.

- Pushbutton-A button-type control switch that is manually operated for actuating or disconnecting some load device.

- Pushbutton Station--A housing for the pushbuttons that are used to control equipment.

- Reduced-voltage Starter--A control device that applies a reduced voltage to a motor when it is started.

- Relay--A control device that is operated by one electrical circuit to control a load that is part of another electrical circuit.

- Remote Control--A system in which the control of an electrical load takes place from some distant location.

- Safety Switch--An enclosed, manually operated, disconnecting switch used to turn a load off when necessary.

- Solenoid--An electromagnetically actuated control device that is used to produce linear motion for performing various control functions.

- Starter--An electric controller that is used to start, stop, and protect the motor that is connected to it.

- Timer--A control device that provides variable time periods, so that a control function may be performed.

Symbols

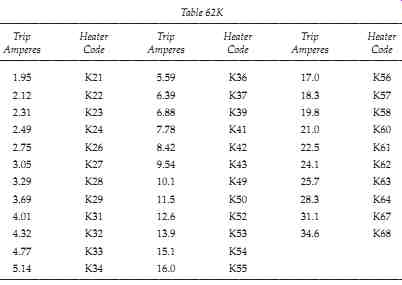

One should have an understanding of the electrical symbols that are commonly used with power control systems. A few of these are somewhat different from basic electrical symbols. Some typical symbols are shown in FIG. 1. You should especially observe the symbols that are used for the various types of switches and pushbuttons.

FIG. 1. Common power control symbols

POWER CONTROL USING SWITCHES

An important, but often overlooked, part of electrical power control is the various types of switches used. This section will examine the many types of switches that are used to control electrical power. The primary function of a switch is to turn a circuit on or off; however, many more complex switching functions can be performed using switches. The emphasis in this section will be on switches that are used for motor control. Keep in mind that other load devices can also be controlled in a similar manner by switches.

Toggle Switches

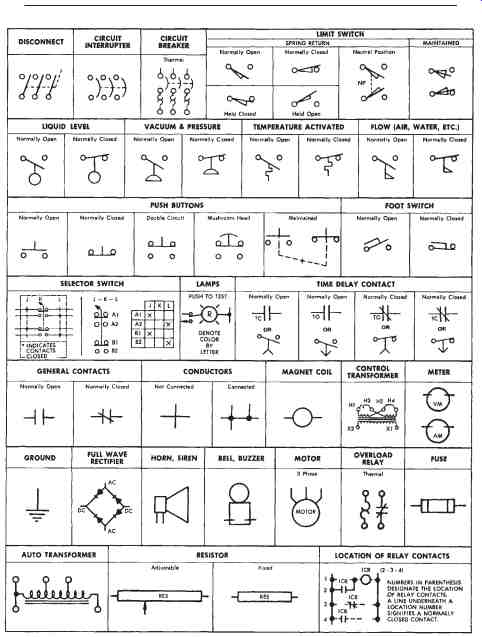

Among the simplest types of switches are toggle switches. The symbols for several kinds of toggle switches are shown in FIG. 2. You should become familiar with the symbols that are used for various types of toggle switches and with the control functions that they can accomplish.

FIG. 2. Types of toggle switches: (A) Single pole, single throw (SPST),

(B) Three way or single pole, double throw (SPDT), (C) Double pole, single

throw (DPST), (D) Double pole, double throw (DPDT), (E) Three pole, single

throw (3PST), (F) Three pole, double throw (3PDT)

Rocker Switches

Another type of switch is called a rocker switch. Rocker switches are used for on-off control. They may be either momentary-contact, for accomplishing temporary control, or sustained contact, for causing a load to remain in an on or off condition until the switch position is manually changed.

Pushbutton Switches

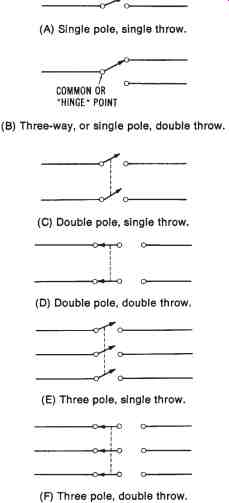

Pushbutton switches are commonly used. Many motor control applications use push buttons as a means of starting, stopping, or reversing a motor; the pushbuttons are manually operated to close or open the control circuit of the motor. There are several types of pushbuttons used in the control of motors. Figure 15 3 diagrams some pushbutton styles. Pushbuttons are usually mounted in enclosures.

Ordinarily, pushbuttons are either the normally closed (NC) or normally open (NO) type. An NC pushbutton is closed until it is depressed manually.

It will open a circuit when it is depressed. The NO pushbutton is open until it is manually depressed, and then, once it is depressed, it will close a circuit. The "start" pushbutton of a motor control station is an NO type, while the "stop" switch is an NC type.

FIG. 3. Pushbutton styles

Rotary Switches

Another common type of switch is the rotary switch. Many different switching combinations can be wired using a rotary switch. The shaft of a rotary switch is attached to sets of moving contacts. When the rotary shaft is turned to different positions, these moving contacts touch different sets of stationary contacts, which are mounted on ceramic segments. The shaft can lock into place in any of several positions. A common type of rotary switch is shown in FIG. 4. Rotary switches are usually controlled by manually turning the rotary shaft clockwise or counterclockwise. A knob is normally fastened to the end of the rotary shaft to permit easier turning of the shaft.

Limit Switches

Limit switches are made in a variety of sizes. Limit switches are merely on/off switches that use a mechanical movement to cause a change in the operation of the electrical control circuit of a motor or other load de-vice. The electrical current developed as a result of the mechanical movement is used to limit movement of the machine, or to make some change in its operational sequence. Limit switches are often used in sequencing, routing, sorting, or counting operations in industry. Ordinarily, they are used in conjunction with hydraulic or pneumatic controls, electrical re lays, or other motor-operated machinery, such as drill presses, lathes, or conveyor systems.

In its most basic form, a limit switch converts mechanical motion into an electrical control current. Part of the limit switch is the cam, an external part which is usually mounted on a machine. The cam applies force to the actuator of the limit switch. The actuator is the part of the limit switch that causes the internal NO or NC contacts to change state. The actuator operates by either linear or rotary motion of the cam, which applies force to the limit switch. Two other terms associated with limit switches are pre-travel and overtravel. Pre-travel is the distance that the actuator must move to change the normally open or normally closed state of the limit switch contacts. Overtravel is the distance the actuator moves beyond the point at which the contacts change state. Both pre-travel and overtravel settings are important in machine setups where limit switches are used.

Temperature Switches

Temperature switches are among the most common types of control devices used in industry. The control element of a temperature switch contains a specific amount of liquid. The liquid increases in volume when the temperature increases. Thus, changes in temperature can be used to change the position of a set of contacts within the temperature-switch en closure. Temperature switches may be adjusted throughout a range of temperature settings.

Float Switches

Float switches are used when it is necessary to control the level of a liquid. The float switch has its operating lever connected to a rod and float assembly. The float assembly is placed into a tank of liquid, where the motion of the liquid controls the movement of the operating lever of the float switch. The float switch usually has a set of NO and NC contacts, which are controlled by the position of the operating lever. The contacts are connected to a pump-motor circuit. In operation, the NO contacts are connected in series with a pump-motor control circuit. When the liquid level is reduced, the float switch will be lowered to a point where the operating lever will be moved far enough that the contacts will be caused to change to a closed state. The closing of the contacts will cause the pump motor to turn on. More liquid will then be pumped into the tank until the liquid level has risen high enough to cause the float switch to turn the pump mo tor off.

Pressure Switches

Another type of electrical control device is called a pressure switch.

A pressure switch has a set of electrical contacts that change states as the result of a variation in the pressure of air, hydraulic fluid, water, or some other medium. Some pressure switches are diaphragm operated. They rely upon the intake or expelling of a medium, such as air, which takes place in a diaphragm assembly within the pressure-switch enclosure. Another type of pressure switch uses a piston mechanism to initiate the action of opening or closing the switch contacts. In this type of switch, the movement of a piston is controlled by the pressure of the medium (air, water, et cetera).

Foot Switches

A foot switch is a switch that is controlled by a foot pedal. This type of switch is used for applications in which a machine operator has to use both hands during the operation of the machine. The foot switch provides an additional control position for the operation of a machine, for times when the hands cannot be used.

Drum-controller Switches

Drum controllers are special-purpose switches, which are ordinarily used to control large motors. They may be used with either single-phase or three-phase motors. The usual functions of a drum-controller switch are start/stop control or the forward/reverse/stop control of electrical motors. Contacts are moved as the handle of the controller is turned to provide machine control.

Pilot Lights for Switches

Pilot lights usually operate in conjunction with switches. Motor-control devices often require that some visual indication of the operating condition of the motor be provided. Pilot lights of various types are used to provide such a visual indication. They usually indicate either an on or off condition. For instance, a pilot light could be wired in parallel with a mo tor to indicate when it is on. Some types of pilot lights are:

1. Full-voltage Across-the-line Lights--These are relatively inexpensive lights, but they do not last as long as other types.

2. Transformer-operated Lights--These use a relatively low voltage to activate the lamp, but they require the expense of an additional transformer, which ordinarily reduces the operating voltage to 6 volts.

3. Resistor-type Lights--These lights use a series resistor to reduce the voltage across the lamp.

4. Illuminated Pushbutton--In these, the functions of the pushbutton and the pilot-light device are combined into one item of equipment, which reduces the mounting-space requirement.

CONTROL EQUIPMENT FOR ELECTRIC MOTORS

There are several types of electromechanical equipment used for the control of electric-motor power. The selection of power-control equipment will affect the efficiency of the power-system operation and the performance of the machinery. It is very important to use the proper type of equipment for each power-control application. This section will concentrate on the types of equipment used for motor control.

Motor-starting Control

A motor-starting device is a type of power control used to accelerate a motor from a "stopped" condition to its normal operating speed. There are many variations in motor starter design, the simplest being a manually operated on/off switch connected in series with one or more power lines. This type of starter is used only for smaller motors that do not draw an excessive amount of current.

Another type of motor starter is the magnetic starter, which relies upon an electromagnetic effect to open or close the power-source circuit of the motor. Often, motor starters are grouped together for the control of adjacent equipment in an industrial plant. Such groupings of motor starters and associated control equipment are called control centers. Control centers provide a relatively easy access to the power distribution system, since they are relatively compact, and the control equipment is not scattered throughout a large area. Motor-starting systems will be discussed in greater detail in Section 16.

Function of Motor Starters

Various types of motor starters are used for control of motor power.

The functions of a starter vary in complexity; however, motor starters usually perform one or more of the following functions:

1. On and off control.

2. Acceleration.

3. Overload protection.

4. Reversing the direction of rotation.

Some starters control a motor by being connected directly across the power input lines. Other starters reduce the level of input voltage that is applied to the motor when it is started, so as to reduce the value of the starting current. Ordinarily, motor overload protection is contained in the same enclosure as the magnetic contactor.

Sizes of Motor Contactors

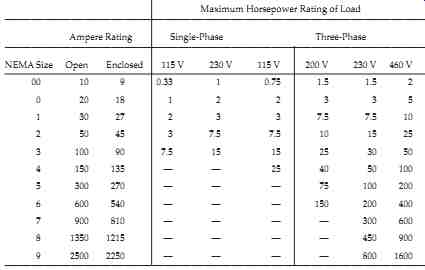

The contactors used with motor starters are rated according to their current capacity. The National Electrical Manufacturers Association (NEMA) has developed standard sizes for magnetic contactors according to their current capacity. TABLE 1 lists the NEMA standard sizes for magnetic contactors. By looking at this chart, you can see that a NEMA size 1 contactor has a 30-ampere current capacity if it is open (not mounted in a metal enclosure), and a 27-ampere capacity if it is enclosed. The corresponding maximum horsepower ratings of loads for each of the NEMA contactor sizes are also shown in TABLE 1.

TABLE 1. Sizes of Magnetic Contactors

Manual Starters

Some motors use manual starters to control their operation. This type of starter provides starting, stopping, and overload protection similar to that of a magnetic contactor. However, manual starters must be mounted near the motor that is being controlled. Remote-control operation is not possible, as it would be with a magnetic contactor. This is due to the small control current that is required by the magnetic contactor. Magnetic contactors also provide a low-voltage protection by the dropout of the contacts when a low-voltage level occurs. Manual starters remain closed until they are manually turned off. They are usually limited to small sizes.

Motor Overload Protection

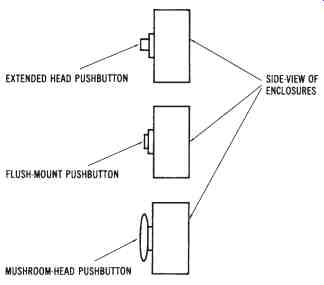

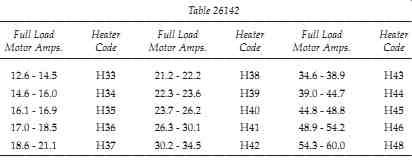

Both manual and magnetic starters can have overload protection contained in their enclosures. It is common practice to place either bimetallic or melting-alloy overload relays in series with the motor branch circuit power lines. These devices are commonly called heaters. An overload protective relay is selected according to the current rating of the motor circuit to which it is connected. An identification number is used on overload protective devices. This number is used to determine the current that will cause the overload device to "trip" or open the branch circuit. Some typical overload protection or heater tables are given in Tables 2 and 3.

TABLE 2 is used for melting-alloy-type devices. The Table Number (26142) is selected according to the type and size of controller, the size of motor, and the type of power distribution (single-phase or three-phase). For example, a heater with an H37 code number is used with a motor that has a full-load current of 18.6 to 21.1 amperes.

TABLE 3 is used with bimetallic overload relays. They are selected in the same manner as melting-alloy relays. However, this table shows the trip amperes of the heater. A heater with a K53 code number has a 13.9 trip-ampere rating. Thus, a current in excess of 13.9 amperes would cause the heater element to trip. This would open the motor branch circuit by removing the power from the motor.

TABLE 2. Melting Allow Devices

Classes of Motor Starters

The types of motor starters that are commercially available are divided into five classes. These classes, which were established by NEMA, are:

1. Class A-Alternating current (AC), manual or magnetic, air-break or oil-immersed starters that operate on 600 volts or less.

2. Class B-Direct current (DC), manual or magnetic, air-break starters that operate on 600 volts or less.

3. Class C-AC, intermediate voltage starters.

4. Class D-DC, intermediate voltage starters.

5. Class E-AC, magnetic starters that operate on 2200 volts to 4600 volts. Class E1 uses contacts, and Class E2 uses fuses.

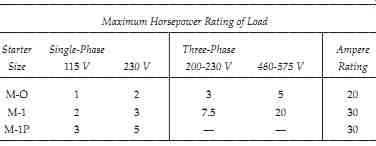

Sizes of Manual Starters

A uniform method has also been established for sizing manual mo tor starters. Some examples of the sizes of full-voltage manual starters are:

1. Size M-O-For single-phase 115-volt motors up to 1 horsepower.

2. Size M-1-For single-phase 115-volt motors up to 2 horsepower.

3. Size M-1P-For single-phase 115-volt motors up to 3 horsepower.

These sizes are summarized in TABLE 4.

TABLE 4. Sizes of Manual Starters: Maximum Horsepower Rating of Load

Combination Starters

A popular type of motor starter used in control applications is the combination starter. These starters incorporate protective devices such as fused-disconnect switches, air-type circuit breakers, or a system of fuses and circuit breakers mounted in a common enclosure. They are used on systems of 600 volts or less.

Criteria for Selecting Motor Controllers

There are several important criteria that should be considered when selecting electric motor controllers. Among these are:

1. The type of motor-AC or DC, induction or wound rotor.

2. The motor ratings-voltage, current, duty cycle, and service factor.

3. Motor operating conditions-ambient temperature and type of atmosphere.

4. Utility company regulations-power factor, demand factor, load requirements, and the local codes.

5. Type of mechanical load connected to motor-torque requirement.

In order to become more familiar with the criteria listed above, you must be able to interpret the data on a motor nameplate. The information contained on a typical nameplate is summarized as follows:

Manufacturing Co.--The company that built the motor.

Motor Type--A specific type of motor, that is: split-phase AC, universal, three-phase induction, et cetera.

Identification Number--Number assigned by the manufacturer.

Model Number--Number assigned by the manufacturer.

Frame Type--Frame size defined by NEMA.

Number of Phases (AC)--Single-phase or three-phase.

Horsepower--The amount produced at rated speed.

Cycles (AC)--Frequency the motor should be used with (usually 60 Hz). Speed (r/min)-The amount at rated hp, voltage, and frequency.

Voltage Rating--Operating voltage of motor.

Current Rating (amperes)--Current drawn at rated load, voltage, and frequency.

Thermal Protection--The type of overload protection used.

Temperature Rating (°C)--Amount of temperature that the motor will rise over ambient temperature, when operated.

Time Rating--Time the motor can be operated without overheating (usually continuous).

Amps--Current drawn at rated load, voltage, and frequency.

Motor-controller Enclosures

The purpose of a motor-controller enclosure is obvious. The operator is protected against accidental contact with high voltages that could cause death or shock. In some cases, however, the enclosures are used to protect the control equipment from its operating environment, which may contain water, heavy dust, or combustible materials. The categories of motor controller enclosures have been standardized by NEMA. The following list, courtesy of Furnas Electric Company, summarizes various classifications.

NEMA 1 General-Purpose enclosures protect personnel from accidental electrical contact with the enclosed apparatus. These enclosures satisfy indoor applications in normal atmospheres that are free of excessive moisture, dust, and explosive materials.

NEMA 3 (3R) Weatherproof enclosures protect the control from weather hazards.

These enclosures are suitable for applications on ship docks, canal locks, and construction work, and for application in subways and tunnels. The door seals with a rubber gasket. They are furnished with conduit hub and pole mounting bracket.

NEMA 4 Weathertight enclosures are suitable for application outdoors on ship docks and in dairies, breweries, et cetera. This type meets standard hose test requirements. They are sealed with a rubber gasket in the door. NEMA 4X Corrosion Resistant fiberglass enclosures are virtually maintenance free.

These U.L.-listed units are adaptable to any conduit system by means of readily available metal, fiberglass, or PVC conduit hubs, and are suitable for NEMA 3, 3R, 3S, 4, and 12 applications because they are dust-tight, rain tight, water-tight, and oil-tight.

NEMA 12 Industrial-Use enclosures also satisfy dust-tight applications. These en closures exclude dust, lint, fibers, and oil or coolant seepage. The hinged cover seals with a rubber gasket.

NEMA 13 Oil-tight pushbutton enclosures protect against dust, seepage, external condensation, oil, water, and coolant spray.

NEMA 7. For atmospheres containing hazardous gas, NEMA 7 enclosures satisfy Class 1, Group C or D applications, as outlined in Section 500 of the National Electrical Code Standard of the National Board of Fire Underwriters for Electrical Wiring and Apparatus. These cast aluminum enclosures are designed for use in atmospheres containing ethylether vapors, ethylene, cyclopropane, gasoline, hexane, naptha, benzine, butane, propane, alcohol, acetone, benzol, lacquer solvent vapors, or natural gas. Machined surfaces between the cover and the base provide the seal.

NEMA 9, For atmospheres containing explosive dust, NEMA 9 enclosures satisfy Class II, Group E, F, and G applications, as outlined by the National Electrical Code for metal dust, carbon black, coal, coke, flour, starch, or grain dusts.

The enclosure is cast aluminum with machined surfaces between cover and base to provide seal.

NEMA TYPES 1B1, 1B2, IB3 Flush Types provide behind-the-panel mounting into machine bases, columns, or plaster walls to conserve space and to provide a more pleasant appearance. NEMA 1B1 mounts into an enclosed machine cavity, NEMA 1B2 includes its own enclosure behind the panel to exclude shavings and chips that might fall from above. NEMA IB3 for plaster walls includes an adjustment to compensate for wall irregularities.

OTHER ELECTROMECHANICAL POWER CONTROL EQUIPMENT

There are so many types of electromechanical power control equipment used today that it is almost impossible to discuss each type. How ever, some of the very important types will be discussed in the following paragraphs.

Relays

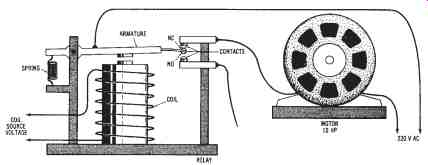

Relays represent one of the most widely used control devices avail able today. The electromagnet of a relay contains a stationary core. Mounted close to one end of the core is a movable piece of magnetic material called the armature. When the coil is activated electrically, it produces a magnetic field in the metal core. The armature is then attracted to the core, which in turn produces a mechanical motion. When the coil is de-energized, the armature is returned to its original position by spring action.

The armature of a relay is generally designed so that electrical con tact points respond to its movement. Activation of the relay coil will cause the contact points to "make" or "break," according to the design of the relay. A relay could be described as an electromagnetic switching mechanism. There are an almost endless number of special-purpose relays and switch combinations used for electrical power control. FIG. 5 shows a simplified diagram of the construction of a relay that is used to control a motor.

Relays use a small amount of current to create an electromagnetic field that is strong enough to attract the armature. When the armature is attracted, it either opens or closes the contacts. The contacts then either turn on or turn off circuits that are using large amounts of current. The minimal current that must flow through the relay coil, in order to create a magnetic field strong enough to "attract" the armature, is known as the "pickup" or "make" current. The current through the relay coil that allows the magnetic field to become weak enough to release the armature is known as the "break" or "dropout" current.

There are two types of contacts used in conjunction with most re lays-normally open (NO) and normally closed (NC). The NO contacts remain open when the relay coil is de-energized, and are closed only when the relay is energized. The NC contacts remain closed when the relay is de-energized, and are open only when the coil is energized.

FIG. 5. Simplified diagram of the construction of a relay that is used

to control a motor

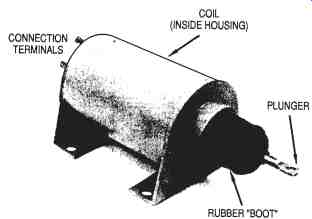

Solenoids

A solenoid, shown in FIG. 6 is an electromagnetic coil with a movable core that is constructed of a magnetic material. The core, or plunger, is sometimes attached to an external spring. This spring causes the plunger to remain in a fixed position until moved by the electromagnetic field that is created by current through the coil. This external spring also causes the core or plunger to return to its original position when the coil is de-energized.

Solenoids are used for a variety of control applications. Many gas and fuel oil furnaces use solenoid valves to automatically turn the fuel supply on or off upon demand. Most dishwashers use one or more solenoids to control the flow of water.

FIG. 6. A solenoid

Specialized Relays

There are many types of relays used for electrical power control.

General-purpose relays are used for low-power applications. They are relatively inexpensive and small in size. Many small, general-purpose re lays are mounted in octal base (8-pin) plug-in sockets. Latching relays are another type of relay. They are almost identical to the relays discussed previously, but they have a latching mechanism that holds the contacts in position after the power has been removed from the coil. A latching re lay usually has a special type of unlatching coil connected in series with a pushbutton stop switch. Solid-state relays are used when improved re liability, or a rapid rate of operation, is necessary. Electromagnetic relays will wear out after prolonged use, and have to be replaced periodically.

Solid-state relays, like other solid state devices, have a long life expectancy. They are not sensitive to shock, vibration, dust, moisture, or corrosion.

Timing relays are used to turn a load device on or off after a specific period of time.

The operation of a pneumatic timing relay is dependent upon the movement of air within a chamber. Air movement is controlled by an adjustable orifice that controls the rate of air movement through the chamber. The air-flow rate determines the rate of movement of a diaphragm or piston assembly. This assembly is connected to the contacts of the relay.

Therefore, the orifice adjustment controls the air-flow rate, which determines the time from the activation of the relay until a load connected to it is turned on or off. There are other types of timing relays, such as solid state, thermal, oil-filled, dashpot, and motor-driven timers. Timing relays are useful for sequencing operations that require a time delay between operations. A typical application would be as follows: (1) a "start" push button is pressed, (2) a timing relay is activated, (3) after a 5-second time delay, a motor is turned on.

ELECTRONIC POWER CONTROL

Solid-state power controllers are capable of replacing electromagnetic circuit breakers and relays used for electrical power control. The introduction of computerized control for industrial equipment has brought about a new technology of machine control. Many industrial machines, such as automated manufacturing and robotic equipment, are now con trolled by computerized circuits. An understanding of the basic principles of electrical control is, however, still very important for technicians.