AMAZON multi-meters discounts AMAZON oscilloscope discounts

<<<Cont. from Part 4

11 Testing of Motors and Generators

Today's machines are subjected to extremely high electrical and mechanical stresses and therefore have shorter life spans as compared to yesterday's bulky machines. Furthermore, unfavorable operating conditions may lead to unexpected troubles, which can have harmful effects on machine life. The insulation system is extremely important and therefore should be checked on a regular basis. IEEE standard 1415-2006, IEEE Guide for Induction Machinery Maintenance Testing and Failure Analysis provides maintenance testing and failure analysis guidance for form-wound, squirrel cage, induction motors rated up to 15 kV. It addresses the stator (winding and core) rotor (winding and core) vibration and noise bearings and shafts structure, frame ventilation, and accessories. This guide is intended to be used by personnel responsible for the operation and maintenance of large induction machines.

TBL. 1 of the IEEE standard 1415-2006, IEEE Guide for Induction Machinery Testing and Failure Analysis, gives a list of the various tests that are in wide spread use in the industry for testing induction machines. This table lists the test description, effectiveness, typical frequency, and the pertinent IEEE standard reference for each test. The IEEE TBL. 1 is represented in TBL. 10 for reader's reference. The reader is urged to consult this table and the IEEE standard 1415-2006 when performing test on induction machinery.

The tests listed in TBL. 10 are all encompassing, and many of the nonelectrical tests are not in the scope of this book. The reader should refer to the last column of the TBL. 10 for additional information on the tests not covered in this Section . The state of the machine insulation can be checked by means of the tests discussed below:

========

TBL. 10 Comparison of Maintenance Tests for Induction Machinery

-- Test Description Effectiveness | Online, Off-Line | Typical Test Frequency (Years) | Test Precautions | Industry Standard

-- AC high potential Overvoltage test applied from conductor-to-ground to test ground-wall insulation of the stator winding Pass/fail test; not effective for trending Off-line Factory test or as necessary Potentially destructive IEEE 112 NEMA MG1 IEEE 4 IEEE 95 Acceleration time Measure acceleration time starting Difficult for trending Online 1-2 Bearing insulation; Insulation resistance shaft to ground Pass/fail test Off-line 0.5-1 IEEE 43 IEEE 112 Bearing temperature Measurement of bearing metal, bearing housing, or bearing oil temperature.

Applies to all bearings, oil lubricated and grease lubricated Effective for trending. Must account for ambient temperature Online 0.5-1 Continuously Capacitance AC test to measure insulation capacitance line-to-ground Effective on single coils during manufacturing of medium-voltage machines. Possibly effective for trending Off-line Factory 1-2 IEEE 286 Core loss (loop) Test for shorted stator core laminations Pass/fail test; not typically effective for trending, although under controlled conditions may be used for trending Off-line Typically during a rewind process Be prepared to stop test abruptly if core damage is suspected IEEE 62.2

--

Coupling insulation; Insulation resistance coupling to shaft Pass/fail test Off-line 1-1.5 after outage Current running Measure stator current stator heating Roughly determines overload-10% error possible on load estimate Online 1-2 Continuously IEEE 112 NEMA MG1 Current starting Measure stator current during acceleration time Acceleration time or reduced torque/rotor problems Online 1-2 IEEE 112 Current signature analysis; Analysis of stator current to detect broken rotor bars or broken shorted circuit rings Requires experienced operator.

Effective for detection and can be used for trending. Load must be constant and over 30% Online 3-5 Continuously Dielectric absorption Timed overpotential test ratio of the 3 min IR reading to the 30 s IR reading Effective for trending Off-line 1-2 IEEE 43 & 95 for IR Test in general DC high potential Overvoltage test applied line-to-ground test, measures leakage current Step voltage or ramp method effective for trending Off-line 1-2 Maximal voltage according to industry standards IEEE 95 NEMA MG1 Dissipation factor and tip-up AC test to measure dissipation-capacitance line-to-ground Effective on single coils during manufacturing of medium voltage machines. Possible effective for trending Off-line 1-2 IEEE 286 Grease analysis Appearance, smell, grit, content of grease sample grease-lubricated machine bearings Effective for trending Off-line 0.5-1

---

integrity (laminations)

rotor core of disassembled machine trending Phase angle Electrical evaluation of windings using low-voltage AC measurements Possibly effective for trending if corrected for winding temperature and rotor position Off-line 1-2 IEEE 388 ANSI/ EASA AR 100 Variable frequency test Compares phases' complex impedances at different frequencies. Possibly effective for insulation diagnostics Possibly effective for trending, if corrected for winding temperature and rotor position Off-line 1-2 IEEE 389 Phase balance AC test to measure stator winding balance and rotor circuit condition Possibly effective for trending if kept at same rotor position than previous tests Off-line 1-2 IEEE 388 IEEE 389 ANSI/ EASA AR 100 Insulation resistance Measures resistance of insulation between conductor and ground; to detect wet or dirty insulation and dielectric integrity Effective for trending if corrected for temperature. Adequate scale range required Off-line 1-2 after outage IEEE 43 IEEE 56 IEEE 62.2 IEEE 1432

---

Oil analysis; Analysis of oil for lubricant characteristics and wear particle concentration oil-lubricated machine bearings Effective for trending Off-line analysis sample can be taken online 0.5-1 PD AC test to measure PD (corona) line-to-ground Requires experienced operator.

With some technologies possibly effective for trending Online 0.5-5 Continuously IEEE 1434 PI Ratio of 10 min IR to 1 min IR to detect wet or dirty insulation and possibly aged insulation Effective for trending machines; should have adequate scale range Off-line 1-2 IEEE 43 Impedance starting Monitors equivalent complex instantaneous impedance.

Finds locked or stalled failure on start Effective for trending Online 1-2 NEMA MG1 Insulation PF, PF and tip-up AC test to measure insulation PF line-to-ground Effective on single coils during manufacturing of medium voltage machines. Possible effective for trending Off-line Factory IEEE 286 Shaft grounding currents Measure shaft current and waveform on oscilloscope shaft to ground Indicator of change trendable Online 3-5 IEEE 112 Shaft voltage Measure shaft voltage and waveform on oscilloscope shaft to ground Indicator of change trendable Online 3-5 IEEE 112 Speed Measure of shaft rpm shaft speed Determine overload effective for trending Online 3-5 20% error possible for load estimate IEEE 112 NEMA MG1

---

Surge test Impulse voltage tests turn-to-turn insulation and inductive stator balance Good manufacturing and field test.

Higher stress on line end coils matches stress distribution during voltage transients Off-line Factory or 1-2 field Use maximal voltage according to industry standards IEEE 522 NEMA MG1 Thermography Observe with thermal camera machine in-service Observe for hot spots. Effective for trending and finding ventilation blockage, poor electrical connection, core damage or coupling misalignment Online 3-5 Thermography Rotor bar testing Observe rotor bars and end rings for uneven heating Off-line Repair Current should be limited Torque ripple Monitors air gap torque of motor. Detects rotor bar condition, mechanical unbalance and motor-load looseness, shock loading and possibly other mechanical failures Effective for trending Online 0.5-2 Ultrasound; Ultrasound noise from antifriction bearings. Also can be used to evaluate bonding of babbitt to bearing shell on oil film type bearings Effective for trending Online 1-1.5

--

Vibration Shaft or bearing housing vibration Direct on bearing Housing or proximity to shaft Effective for trending Online 0.5-1 Voltage drop Measure bus voltage during starting Effective for trending Online 3-5 Voltage supply Measure bus voltage stator heating rotor heating Effective for trending Online Continuously IEEE 112 NEMA MG1 Winding resistance (including cable) Measures winding resistance stator windings and machine terminations detects poor connections Effective for trending. Correct for temperature or percent unbalance Off-line 1-1.5 IEEE 112 IEEE 118 Winding temperature Indirect measurement of winding temperature.

Applies to machine with built-in RTDs or thermocouples Effective for trending. Must account for ambient temperature and load Online 0.5-1 Continuously Source: From IEEE-std 1415-2006, IEEE Guide to Induction Machinery Maintenance Testing and Failure Analysis.

========

11.1 Insulation Resistance and Dielectric Absorption Tests

The simplest and most basic tests for checking insulation integrity of machines are the insulation resistance and dielectric absorption (DA) tests.

Refer to Section 2 for details on how to perform these tests.

11.2 High-Potential Test

AC or DC voltage high potential test may be performed on machines stator windings. The size of the machine windings (i.e., insulation volume) will deter mine whether an AC high potential test can be performed in the field because if the machine is very large the field portable AC high potential test set may not have the capability to charge the winding insulation. The DC voltage high potential test is discussed in Section 2.7 in Section 2, therefore this discussion only addresses the AC voltage high potential test for machines.

The high-potential test of the armature (stator) winding of a large motor or generator is preceded by a visual inspection and insulation resistance measurements. It provides the moment of truth concerning the condition of insulation.

High-potential tests may be performed with the rotor in place or with it removed. It is advantageous to consult and follow the manufacturer's recommendations and schedules, taking into account the operating history of a machine. For example, it is recommended that on large machines the rotor be removed every 5 years and high-potential tests performed every 2-3 years.

To prepare the tests, the machine terminals are disconnected from the bus bars, the neutral connection is broken so that each phase winding may be subjected to a test voltage with respect to the other phase windings, and the rotor (if in place) is grounded. Protective ground cables should be connected to all disconnected bus bars and the neutral conductor. Each phase winding is short circuited so that uniform test voltage will be applied to each end. A test lead is attached to each phase winding and secured and terminated so that a convenient connection to the high-voltage test lead and to ground can be made. Temporary insulation, plastic bags over sharp points, and tie offs must be arranged to give correct clearance for the test voltage. A minimum of clearance of 7 in. per 10 kV, 60 Hz, is recommended for base conductor clearance.

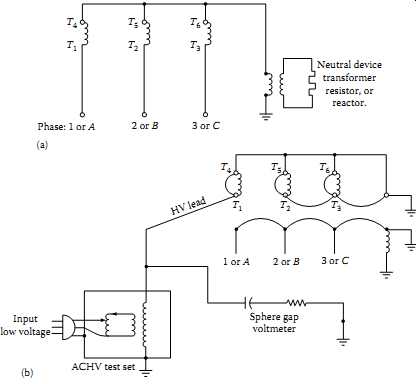

The 60 Hz AC high-potential test applies stresses to machine winding as near as possible to those that normally exist under operating conditions. Even though the 60 Hz test is preferred over DC or 0.1 Hz tests, there are few AC sets of adequate size (kVA) available to perform this test on large machines. The size of the test set may be calculated from the following formula: kVA = 0.377 CE2, where C is the machine winding capacitance in microfarads and E is the maximum test voltage in kilovolts. For example, in-service operation on a 13.8 kV machine, each phase winding is stressed at 13.8/v - 3 or approximately 8 kV to ground with midpoint only at 4 kV to ground. The ends of windings T4, T5, and T6 ( FIG 42a) are nearly at zero stress. The insulation toward the ends T4, T5, and T6, could be worn and still not fail in service unless damage to the winding becomes severe. During the high-voltage test, the windings are short circuited. The high-voltage lead is connected to both T1 and T4 and later to T2 and T3 and T5 and T6. Both ends of the winding are subjected to the same potential, full-test voltage. Weak points of any part of the winding that might not fail in service should fail under test. This is desirable since worn-out coils should be repaired or replaced to avoid unexpected and sudden failure.

Protection against accidental application of an overvoltage can be provided by connecting an air gap voltmeter with an appropriate series resistor between the high-voltage test lead and ground. A setting of 2-5 kV above the high-voltage test value will provide necessary protection. The test connection is shown in FIG 42b.

FIG 42 AC high-potential test connections. (a) Typical in-service generator

stator connections and (b) AC high-potential test connection for generator

connection.

High-potential tests are used in connection with manufacture, repair or reconditioning, and routine testing of machines. The following test procedures and safety precautions are important while conducting these tests:

Keep everyone from coming in contact with any part of the circuit or apparatus while the test is being conducted.

After the test has been made, never touch the winding tested until it has been correctly connected to ground to remove any static charge it may have retained.

All leads to the circuit being tested should be connected to one terminal of the source of the test voltage. All leads to all other circuits and all metal parts should be connected to ground.

No leads are to be left unconnected for high-potential tests as this may cause an extremely severe strain at some point of the winding.

When making an AC voltage high-potential test, the voltage should be increased to full voltage as rapidly as consistent with its value.

This voltage should be maintained for 1 min. After completion of the test, the voltage should be reduced at a rate that will bring it to one quarter value or less in not more than 15 s.

When making DC voltage high-potential test, the voltage should be applied in controlled voltage steps. Refer to Section 2 for details on performing DC voltage high-potential tests.

Effective AC voltages to apply to motors and generators are listed in TBL. 11.

========

TBL. 11 Alternating High-Voltage Test Values for Motors and Generators

Type of Motor and Generator Motors and Generators Reconditioned but Not Rewound or Restored to Original Condition Motors and Generators Rewound and Restored to Original Condition (Acceptance) Armature Field Armature Field Above 250 V and above 0.5 hp 0.67 (2EL-L + 1000) V Seven times the excitation voltage but not less than 1000 V or more than 2300 V (2EL-L + 1000)V Ten times the excitation voltage but not less than 1500 V or more than 3500 V Below 250 V and below 0.5 hp 600 V 600 V 900 V 900 V a The IEEE standard 1415-2006 provides the following guidance. In the case of failed windings, where insulation is replaced or a partial rewind is performed, a reduced voltage final test may be used. Typically, the AC test voltages for these reduced tests are in the range of 125%-135% of rated line-to-line terminal voltage.

========

11.3 PF Test

This method allows successful ground insulation tests on machine individual stator phase windings. This test is usually connected up to and including 100% line-to-ground voltage. The PF is the ratio of the stator insulation loss (watts) and volt-amperes at a specified test voltage. This can be represented by the following equation:

s aa PF { }/{ } WVI =

where Ws is the watts loss Ia is the charging current in milliamperes Va is the test voltage in kilovolts The evaluation of the test data is best interpreted by comparing with previous test results or by comparing test results among phases or with those test results obtained on units of similar manufacture and rating. It is generally found that machines up to 24 kV will have a PF of 3% or less, depending upon the insulation system. The PF tip-up test may also be performed to further evaluate the insulation system. The tip-up test is defined as the increase in PF as voltage is increased from 2 kV to operating voltage. Refer to Section 3.6.7 in Section 3 for more details on PF testing.

11.4 Dissipation Factor Tan d Test

The machine winding may be considered as consisting of capacitance and resistance.

The active (resistive) power and reactive (capacitive) power can be represented by the following equations:

… where PR is the active power PC is the reactive power C is the capacitance in microfarads R is the resistance in ohms XC is the capacitive reactance in ohms IR is the resistive current IC is the capacitive current w is the radian frequency.

The active power of the resistance in this equivalent circuit represents all capacitor losses. These losses occur on the surface and in the interior of the dielectric. The power P determines the loss of the capacitor. The dissipation factor tan d measuring bridge (Schering bridge) is designed to simulate the capacitor (the machine winding) by a series connection of resistance Rs and capacitance Cs. The corresponding values for the series connection for a given frequency can be converted by the following formula:

The losses measured by the Schering bridge and the tan d can be represented as the following:

Substituting the value of CS in the preceding equation, we have

For small values of tan d (i.e., less than 1), we can neglect tan2 d; we have

tan PCE = wd

The value of CS is measured as Cx by the Schering bridge. The resistance and the inductance of the leads have to be considered for high capacitances and resistances; otherwise they are negligible. The PF and tan d tests are discussed in more detail in Section 3.

11.5 Partial Discharge Test

One of the causes of machine insulation degradation and failure is due to partial discharge (PD) in the gas-filled voids in the stator insulation system.

The online or off-line PD test can be used to directly measure the pulse cur rents generated by PD within a machine winding. The machine-winding insulation has voids that are filled with air or gas and they are of varying sizes. The PD pulses are of very short duration (few nanoseconds) because the void cavities are small however some pulses may be larger than other PD pulses. The PD test is applicable to form-wound stator windings of machines rated at 2300 V and above. Each PD pulse current originating in specific part of the winding will travels along the coil conductors. The PD current pulses in turn generate voltage pulses because of the surge impedance of the coils in the slots. Any device sensitive to high frequency can detect the PD pulses and thereby these small charge fluctuations (in coulomb) are measured by testing the corresponding current variations. By this method the weak points of the insulation (location of the PD) are measured. However, this method does not provide information on the condition of insulation at those points where PD has not occurred. PD is an electrical discharge that only partially bridges the insulation between conductors. Especially for machines rated greater than 4 kV, PD can be a sign of deterioration involving external surfaces (slot or end turn) or of delamination internal to the ground wall. PD current pulses can be measured in two ways: (1) off-line PD measurements and (2) online PD measurements.

The off-line PD test requires a power supply to energize the winding to at least rated phase-to-neutral voltage. It is best to perform this test one phase at a time with the other two phases grounded. The most common means of detecting the PD current pulses is to use a high-voltage capacitor connected to the stator terminals. The capacitor blocks the normal 60 HZ AC voltage applied to energize the windings while passing the high frequency PD pulse currents. The output of the high-voltage capacitor is coupled to a resistive or inductive-capacitive load. The PD high-frequency current passing through the capacitor create a voltage pulse across the resistive or inductive-capacitive network which then can be displayed on an oscilloscope, or other display device. Every PD will create its own pulse and the magnitude of a particular PD pulse will be proportional to the size of void cavity.

During the off-line PD test, the applied voltage is gradually raised while monitoring the PD pulses on the oscilloscope at the machine terminals. The voltage at which the PD is first detected is known as PD inception voltage.

The voltage is then raised to rated line-to-neutral operating voltage and held for 10 to 15 min while PD pulses are recorded. The voltage is then gradually reduced and the voltage at which the PD is no longer visible is recorded. This voltage is known as the PD extinction voltage. For motors rated 2300-4000 V, the phase-to-neutral voltage may not be sufficient to produce discharges, therefore some owners will perform the PD test at line-to-line voltage.

It should be kept in mind that using line-to-line voltage for PD test exceeds the normal insulation voltage rating of the winding and could lead to winding insulation failure. During off-line PD measurements, it may be possible to measure at the line end and neutral end of the individual circuits or phases with all other circuits grounded or alternatively with all circuits tested in parallel. This will provide an indication as to whether the PD is more pronounced at the line or neutral ends and whether the phase-to-phase insulation is a source of PD activity.

The off-line PD test as discussed above does not pinpoint the location of the PD discharges in the stator windings. To determine the location of the PD discharges in the stator, PD probe test is performed. Two special probes are available to help locate the site of PD in the stator. One probe is designed to detect the electromagnetic (radio frequency) energy and the other to detect acoustic energy. The electromagnetic probe is usually tuned to 5 MHz essentially making it a modified AM radio with an antenna mounted on a one end of the probe handle. The probe with the antenna end then can be moved around the stator windings to locate where the PD is occurring. The ultra sonic probe is a directional microphone that picks up the acoustic pulses that are being generated by the movement of high-velocity electrons and ions due to PD in the stator windings. The ultrasonic sensor, used with appropriate safety precautions, can be useful for locating sites of higher PD activity at specific slots in the core of the machine. To perform PD probe test may require partially dismantling the machine, such as removing the rotor.

The online PD test is performed during normal operation when the machine is running at constant operating voltage. The PD monitor directly detects stator winding PD activity thereby including the effects of load, temperature, and voltage, which can provide important information as to the probable cause of the PD activity. The PD activity generates current pulses that are typically of very short duration and propagate throughout the stator windings. Each PD pulse comprises of frequencies ranging from DC to several hundred megahertz. The online PD test is similar to the off-line PD test in many respects and they require use of sensors, which can take the form of the following:

- Coupling capacitors at line terminals

- Radio frequency current transformer on ground wire

- Radio frequency current transformer on ground of insulation shield of supply cable

- Radio frequency current transformer on conductor between neutral of stator and grounding impedance;

- Impedance across joint between machine frame and terminal box

The instrumentation used with these sensors can consist of the following:

Radio noise meter for narrow band measurements between 100 kHz and several hundreds of megahertz. Each type of PD, such as slot discharge or end arm discharge may have its own unique frequency spectrum.

Broadband measurement using an oscilloscope or pulse height analyzer to provide an indication as to the number, polarity, and phase position of the PD pulses. Polarity may indicate whether the PD is on a surface or if it is internal. Phase position may indicate whether the PD involves the groundwall, or phase-to-phase insulation.

During online measurements, the operator of the radio noise meter needs to identify RF signals from radio stations and sites of PD activity or sparking external to the machine so as to exclude these data from the analysis. Online PD measurements using broadband detection systems may make use of bandwidth, attenuation, and pulse travel time for noise reduction. Trending of individual machines based on periodic or continuous online PD measurements under identical operating conditions, or comparison between similar machines can indicate a need for off-line PD measurements to confirm and locate the probable source of the discharge activity.

Because of the complexity in which PD pulses propagate within machine windings and the profound effect of bandwidth upon the response of the PD detection instrumentation, it has not been possible to establish meaningful limits for the PD magnitudes, which are measured at the terminal of the machine. Comparisons may be possible between machines of the same design using the same sensors and detection instrumentation of identical bandwidth. For additional information, refer to IEEE standard 1434-2000, IEEE Trial-Use Guide to the Measurement of Partial Discharges in Rotating Machinery.

11.6 Slot Discharge Test

This test is performed to evaluate the coil surface grounding in the slot portion. The stator coil outer surfaces are painted with conducting varnish in order to make good electrical contact with the machine frame to prevent voids. However, at higher voltages, ionization can take place in the voids, resulting in insulation damage. The slot discharge test consists of applying approximately 7 kV AC and observing the wave form on an oscilloscope.

This wave form is compared to a wave form of one coil side arcing to the slot at a single point. The slot discharge phenomena usually consist of high frequencies, such as 2500 Hz/s. The line disturbances are usually filtered out in order to obtain an accurate slot discharge phenomena.

11.7 Conductor Insulation Tests

The insulation failure between conductors of motors and generators depends upon the machine insulation design. Failure between conductors can be as likely as the failure of ground insulation. Coils are tested during manufacture well above the minimum sparking voltage to ensure that the coils do not fail owing to thermal effects, vibrations, and the like. Where a high level of reliability is needed, maintenance testing of conductor insulation should be performed to the level of new coil test values. Normally, this test should be performed at the factory or repair shop facilities. The following test methods are in common use:

Surge comparison test

Induced surge voltage test

Rotating spark-gap-type high-frequency oscillator

11.8 Motor and Generator Component Tests

These tests include insulation resistance tests on components of motors and generators such as RTDs, exciter windings, stator insulated through bolts, rotor windings, and so on. These tests consist of the following:

1. Resistance measurement and insulation resistance of the RTDs

2. Insulation resistance of insulated stator-through-bolts

3. Test the inter-laminar insulation of stator core

4. Rotor winding tests

a. Insulation resistance

b. Winding resistance

c. Winding impedance

d. Winding flux distribution (pole voltage drop test)

The reader should consult the equipment manufacturer for recommendations or the pertinent IEEE standard such as IEEE-56-1991, IEEE-95-2007, and IEEE-112-2004 on conducting these tests.

11.9 Voltage Surge Comparison Test

It is a well-known fact that many motor failures begin as turn-to-turn shorts within a single winding. These turn-to-turn shorts then create hot spots which in turn degrade the insulation in adjacent turns until the entire winding fails.

The mechanism of this type of failure may take a long time to develop depending upon the operating characteristics of the motor. This type of failure or degradation cannot be detected by the insulation resistance test (megohm meter) or high-potential testing because of its incipient nature; however, this type of incipient type of fault can be detected by surge comparison testing.

Many types of faults may be detected by the use of surge testing, such as turn-to turn, coil-to-coil, phase-to-phase as well as opens and grounds.

The surge comparison tester is used to simultaneously test turn-to-turn, coil-to-coil, and coil-to-ground insulation. The surge tester is an electronic device that applies surge voltage stress between turns of a coil, between phases, from winding to ground, and it can detect short-circuited turns in windings under test. The surge voltage is of very short duration and there fore will not damage the windings. However, the surge voltage can be increased high enough so that insulation breakdown and arcing can be observed. The surge comparison test can be used as a go or no-go test.

This test is a very useful diagnostic test for quality-control shop testing when reconditioning or rewinding wound components and in the field to detect early impending winding insulation failures. Rewound and reconditioned motors and generators should be given a surge comparison test before varnishing so that winding faults, such as shorted turns or coils, reversed coil groups or phases, and incorrect number of turns in a coil, can be corrected before the windings are treated with varnish.

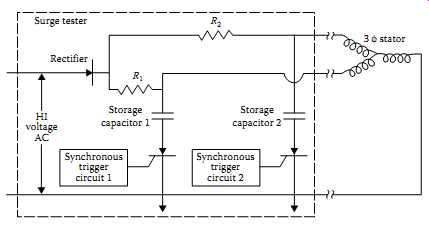

Surge testing is accomplished by impressing pulses of very rapid rise from a surge comparison tester (capacitor) into the machine windings. These pulses each produce a damped oscillation of current, or resonant frequency, between the capacitor of the tester and the winding. The pulse and the resulting oscillation is monitored by means of an oscilloscope. Then by observing the pattern on the oscilloscope, the existence and nature of the fault in the machine winding can be determined.

===

FIG 43 Simplified voltage surge comparison tester.

Surge tester HI voltage AC Rectifier

Storage capacitor 1

Storage capacitor 2 3 f stator

Synchronous trigger circuit 2

Synchronous trigger circuit 1 R1 R2

===

Surge Comparison testing is an extension of the principle of simple surge testing. If for example, we knew what inductance a winding should have, we could look at the single wave pattern and be assured that it is the correct frequency. That frequency of oscillation would be:

1/ 2 f LC = p

…where …f is the frequency, L is the inductance, C is the capacitance

Since we seldom know the inductance value of a machine winding accurately, we need a more flexible yet accurate method to analyze a signal trace on the oscilloscope. To do this, we use a dual trace scope and two identical capacitance discharge circuits to charge two different machine windings that should match at the same time. For example, in the testing of three-phase machine stator we know that each of the three phases should have the same inductance. Consequently, by comparing one phase against another we have two complete, and hopefully, identical L-C circuits for our test to work. A simplified schematic of the surge comparison tester is shown in FIG 43.

Detection of one-turn shorts or grounded coil is possible in all windings of few parallel circuits. Often only a small trace separation may be detectable with a one-turn short in a very large motor that has several parallel paths per phase. However, the winding connections can be broken to reduce the parallel paths in order to obtain a larger trace.

It may be difficult to indicate the type of fault from the wave shape observed on the oscilloscope; however, a double trace indicates that a definite fault exists, which should be investigated. Double lines at the top of the trace and at the horizontal centerline for formed and mush-wound stators are typical and do not indicate faults.

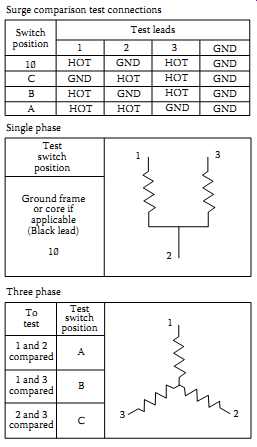

The surge comparison tester is a universal type instrument capable of testing single- and three-phase machine windings. Single-phase windings should be tested in pairs whereas the three-phase windings should be tested two phase windings at a time. Single-phase and three-phase machine windings of various sizes can be tested as shown in the connection diagram of FIG 44.

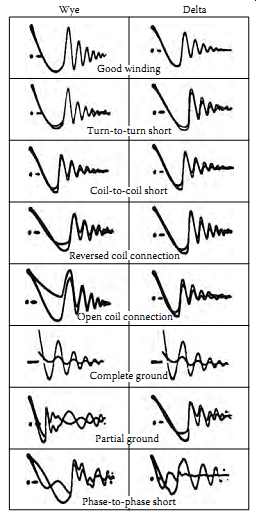

The waveshapes for typical winding faults for the wye- and delta-connected machines are shown in FIG 45.

===

FIG 44 Typical voltage surge comparison test connections for single-

and three-phase machines.

Test switch position, Single phase, Switch position, Test leads, Surge comparison test connections, Test switch position

Ground frame or core if applicable (Black lead) Three phase; To test 1 and 2 compared 1 and 3 compared 2 and 3 compared

===

12 Other Insulation Test Methods

DC voltage testing has been used extensively for high-capacitance current load such as machine windings and high-voltage cables. However, the stress distribution imposed by DC voltage does not stress the insulation system the same as does the AC voltage test. Field testing with AC voltage requires substantially large test equipment (because of the capacitive charging requirements), which is impractical. Therefore, the need for new test methods has led to the development of the one-tenth hertz test and resonant test methods for testing large machines with AC voltage. These two methods are described briefly next.

FIG 45 Waveshapes for typical winding faults for the Wye- and Delta-connected

machines.

12.1 Very Low Frequency Testing

This test is a variation of the 60 Hz AC high-potential test and is referred to as "one-tenth hertz" or very low frequency (VLF) Testing. It utilizes a very low frequency, such as 0.1 Hz voltage for searching flaws in the insulation system similar to that of 60 Hz test voltage equipment. The equipment, how ever, is considerably lighter and easier to handle. By using 0.1 Hz instead of 60 Hz voltage, the size (kVA) of test equipment is reduced by a ratio of 1:600. This is because the capacitive charging current is 1/600 of the current needed at power (60 Hz) frequency. Current VLF test equipment is cost-effective and reasonably portable. Experience with VLF testing indicates that the voltage stress distribution across the groundwall insulation is similar to the power frequency. Therefore, the VLF testing has the same advantages as that of the power frequency AC high-potential testing. The recommended test value for maintenance and acceptance testing is 1.15 times the 60 Hz test value to achieve an equal searching effect, that is, 1.15 (1.3E + 1000) and 1.15 (1.5E + 1000) V, respectively, where E is the rated line-to-line rms voltage of the equipment under test. The 1.3 and 1.5 factors correspondence to 65% and 75% multipliers that are used for maintenance and acceptance testing. Refer to Section 6 for more detail on VLF testing for cables.

12.2 Series Resonant Testing

Series resonant testing is used to test very large machines where power frequency (60 Hz) testing cannot be used because of its size and portability. It is been used for field testing of large generators, sulfur hexafluoride (SF6) bus systems, and switchgear. It can also be used for PF, dielectric loss, cable fault location, and corona with some modifications to the test equipment. At series resonance, the energy (I 2 R) supplied to the test specimen is dissipated in the insulation system. Energy stored in the tuned circuit (i.e., at resonance) transfers back-and-forth between capacitance and inductance each half-cycle. The ratio of energy stored to energy dissipated per half-cycle is known as the quality factor. A higher value of Q gives a low-loss circuit, whereas a low value of Q gives a lossy circuit. Q can be represented by the following equations:

{Maximum energy stored in or during a cycle}

{Energy loss per half cycle in } , and in a series resonance circuit of RLC, the voltage across the capacitor is given the following equation:

or I Vc I= QV, where V is the applied voltage.

The Q of typical winding systems is 40-80 for high-quality capacitance loads. At resonance the current in the circuit is in phase with the voltage, V. Therefore, input power is P = VI, and the reactive power available to the capacitive load is:

kVA QVI QP

Therefore,

kVA/Q Reactive output power/Q P

==

The power required from the mains is reduced to 1/Q of the reactive load requirements. This results in a very substantial reduction in input requirements.

The series resonant method consists of low kVA source input driving a LC series circuit. If breakdown in the capacitive load should occur, the fault cur rent is limited to a low value by the high inductance value in series with the fault. Furthermore, the output wave form is purely sinusoidal because the harmonics of tuned frequency are attenuated. The attenuation of power frequency harmonics makes series resonance testing very attractive for dielectric loss and PD testing. Consult the manufacturer's instructions on the operation and use of the series resonance test set.

13 Vibration Analysis

Vibration monitoring is perhaps the most beneficial test for rotating machines for identifying mechanical and electrical problems. Vibration analysis can monitor many abnormalities among them being wear, imbalance, misalignment, mechanical looseness, bearing damage, structural resonance, fatigue, etc.

Although diagnostics are sometimes based on a single vibration spectrum, as in most preventive and predictive maintenance programs, vibration spectra are acquired periodically and stored in a database. The data is then trended by searching for changes in levels at the problem or forcing frequencies. It is important that the trended data be acquired at the same location, in the same orientation, under the same operating conditions and with the same analyzer settings (frequency range, window type, number of spectral aver ages, number of spectral lines, etc.) every time. For this reason, transducer mounting pads permanently mounted on the machine are a good idea.

The most common transducer is typically an accelerometer. Of the three types of vibration transducers (noncontacting shaft vibration probes with proximeters, velocity pickups, and accelerometers), the accelerometer has the widest bandwidth. It is desirable to securely mount the accelerometer or velocity transducer as close as possible to the bearings. For large high-speed machines with hydrodynamic (sleeve) bearings, the use of noncontacting shaft vibration probes is recommended for vibration analysis.

Some of the mechanical problems detected by vibration spectra are imbalance, misalignment, looseness, bent shaft, and bearing problems. Identification of an electrical or mechanical problem depends upon the frequency spectra and the frequency relationship between running speed, electrical vibration, and other machine internal or driven-equipment components. The phase between accelerations at three locations (drive end bearing, opposite drive end bearing, and axial reading) may also be used in the diagnosis of problems. Readings should be taken on all bearings in the horizontal, vertical, and axial directions.

Electrical problems reflected in vibration spectra include machine out of magnetic center (uneven air gap, rotor not round or bent rotor, rotor and stator misaligned, elliptical stator bore), loose connectors, open or shorted stator windings, and rotor bar irregularities or broken rotor bars. Generally, these problems are also reflected in the 1X and, possibly, 2X, or higher harmonic vibrations coupled with twice line frequencies (2FL) (most common with electrical vibration).

===

TBL. 12 Vibration Spectra Frequency for Typical Electrical and Electromagnetic Problems Problem Frequencies Rotor Problems 1X ± m × FP 2X ± m × FP RBPF ± m × 2 × FL 2 × RBPF ± m ×2 ×FL FP = FS × NP may appear, itself, in the vibration spectrum. Because FP is small, a high resolution FFT spectrum (large number of lines) or zoom capabilities may be required to see these sidebands around the 1X, 2FL frequencies and its harmonics.

The RBPF is a substantially higher frequency than the 1X and its harmonics, so that a large bandwidth high resolution FFT may be required to see these components. Broken rotor bars show as FP sidebands around 2FL with associated RBPF harmonics. A lesser 1X RBPF harmonic indicates loose rotor bars, while a high 1X RBPF indicates broken rotor bars.

Stator problems 2 × FL Vibrations or siren-like noise may also be generated at the stator slot pass frequency.

Out of magnetic center 2 × FL

These vibrations are generated by eccentric center magnetic forces. A 2 × FL component may result from soft foot or misalignment (mechanical problems). A high number of spectral lines or zoom analysis may be required in order to resolve the sidebands and resolve the 2 × FL component from the ×1 or its harmonics. A higher ×2 or ×3 running speed harmonic indicates looseness or misalignment. Looseness is most often coupled with a raised noise floor.

2 × FL ± m × FP Loose connectors 2 × FL Source: From IEEE Std 1415-2006, IEEE Guide to Induction Machinery Maintenance Testing and Failure Analysis.

Notes: FL, the line frequency (50 or 60 Hz); s, the slip; FS, the slip frequency (s × FL); NP , the number of machine poles; FP , the pole pass frequency (FS × NP); rpm, revolutions per minute; NRB, the number of rotor bars; RBPF, the rotor band pass frequency (rpm × NRB); 1X, one times shaft rpm; m, any integer.

===

Monitoring the vibration levels as the electrical power is disconnected from the machine is one method used to determine if a vibration is due to mechanical versus electromagnetic or electrical problems. If the cause is primarily electrical/electromagnetic, vibration levels will drop immediately (whereas levels decrease only as the machine slows down if the problem is mechanical in origin). This type of test is referred to as a "coast-down" test.

Vibrations associated with electrical/electromagnetic problems also tend to be load dependent. This is a reflection of the role that the machine slip frequency plays in the generation of these vibrations. The frequencies at which electrical and electromagnetic problems are reflected in vibration spectra are summarized in TBL. 12.