AMAZON multi-meters discounts AMAZON oscilloscope discounts

.The desire to devise electrical machines without sliding contacts has resulted in experimental and commercial “brushless dc motors.” Most of these motors have limited torque capability—they are usually specified for use with fans or various instrumental applications. However, work has also been done along this line with regard to large motors and generators. The objective, in any case, is to eliminate the maintenance factor inherent with commutators and brushes. The controllability of dc machines inspires their selection, whereas the reliability of the commutator brush assembly is an adverse factor. Thus, it has been natural to desire the merger of the flexible operating characteristics of the dc motor with the simplicity of the squirrel-cage ac motor. For example, the fact that solid-state inverters can now be built with large power capacities demands another look at the induction motor. Despite its designation as a near-constant speed machine, the combination of inverter and induction motor now yields a variable-speed machine with no sliding contacts.

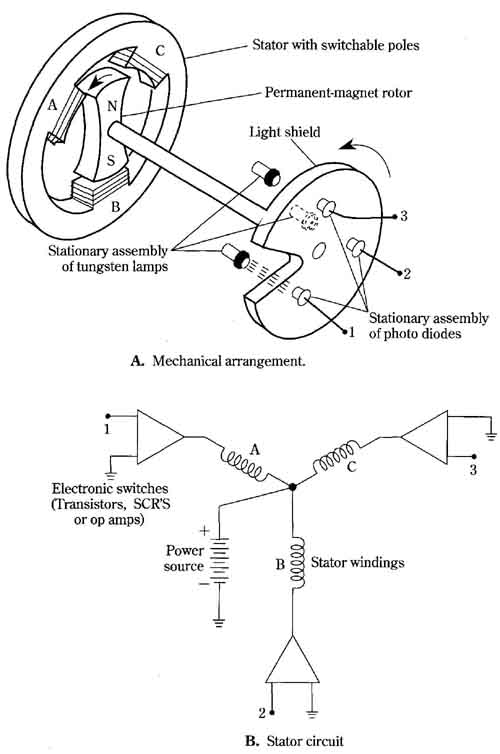

Perhaps more in line with present thinking is a device such as that illustrated in FIG. 4. Here the permanent-magnet rotor is made to “chase” sequentially switched stator poles. As soon as magnetic alignment occurs, the attracting pole is dc-energized and the next stator pole in the direction of rotation is energized. A variation of this basic scheme employs Hall-effect elements to directly sense the position of either the rotor itself, or a suitably magnetized disk on the shaft. The advantage of such magnetic sensing is that power need not be dissipated in light sources. The toy- like aspect of such no-contact commutation might be deceptive. Circuits using optic sensors and SCRs can be devised for the control of giant machines. An attractive feature of noncommutator motors is the possibility of extending control to include positioning, synchronization of two or more machines, reversing and braking.

FIG. 4 An experimental brushless dc motor. (Stator with switchable

poles; Stationary assembly of tungsten lamps, etc.) A. Mechanical arrangement.

Electronic switches (Transistors, SCR’S or op amps) Power source. B.

Stator circuit.

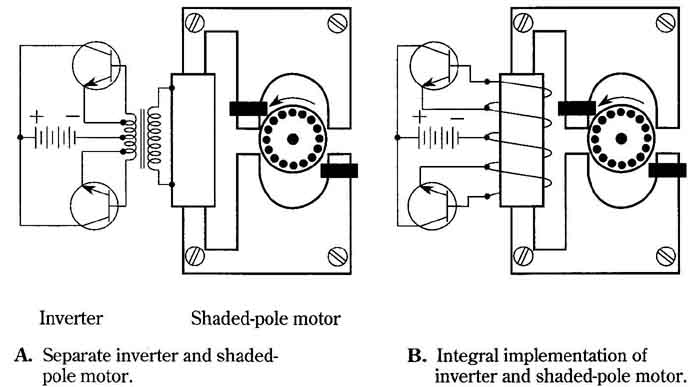

FIG. 5 Other types of brushless dc motors. A. Separate inverter and

shaded- pole motor. B. Integral implementation of inverter and shaded-pole

motor. (Inverter; Shaded-pole motor)

Readily obtainable on the market are small dc fan and blower motors comprising a small ac motor in conjunction with a solid-state inverter. Usually the motor is the shaded-pole type. More sophisticated designs use a permanent split-capacitor motor or a two-phase motor. The general idea involved is shown in FIG. 5. Sometimes, leads are brought out of the package to provide for optional ac or dc operation. The result is a “universal motor” without the commutator and brushes. A compelling feature of these inverter motors is their relatively low RFI. It’s true that the inverter generates switching spikes. However these spikes are more amenable to manipulation and filtering than are the sporadic transients associated with commutator sparking and arcing.