AMAZON multi-meters discounts AMAZON oscilloscope discounts

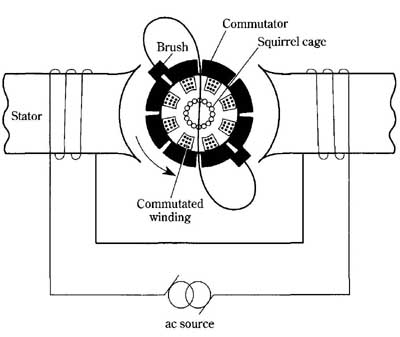

.The repulsion-induction motor can be called a sophisticated version of the repulsion-start motor just described. Approximately the same overall objective is achieved, without the centrifugal mechanism. And, other than the commutator and short-circuited brushes there is no switching process involved as the motor accelerates. Also, the brushes are never lifted from contact with the commutator. The basic design of this simplified machine is shown in FIG. 17. The brushes, commutator, and the commutated armature winding are arranged much as in a repulsion motor. Deeply embedded in the armature iron, however, is a squirrel-cage type winding with short-circuiting rings welded at each end. Recalling that the stators of single- phase repulsion and induction motors are basically the same, it’s natural to ponder which motor mode predominates in this hybrid machine.

During the starting interval, the slip frequency is initially equal to that of the power line. Inasmuch as the squirrel-cage winding has deliberately been made highly inductive, its reactance impedes the flow of short-circuit current. Under these conditions, the squirrel cage contributes very little torque as long as the motor speed remains a small fraction of synchronous speed. So, initially, the rotation of the armature is produced by the torque developed in the commutated armature winding. This is desirable, because the repulsion motor is a star performer in the torque department and is capable of exerting brute turning effort in the vicinity of zero speed.

FIG. 17 The repulsion-induction motor.

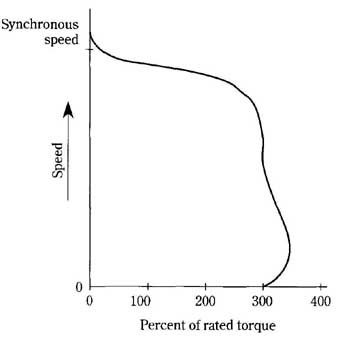

As the armature accelerates, the frequency of the current induced in the squirrel cage decreases. This results in less inductive reactance and, therefore, greater torque- producing current. At the same time, the repulsion-motor torque is decreasing, this being the “nature of the beast.” Refer to the repulsion-motor speed-torque curve of FIG. 4. Somewhere in the vicinity of 80 percent of synchronous speed, induction-motor action begins to predominate. Therefore, the speed-regulation curve departs from what it would be for a repulsion motor and assumes the flatter characteristic generally associated with induction motors. An exception is the speed range above the synchronous speed. But, how can an induction motor perform in this speed range?

It’s still true that induction motors can only approach synchronous speed. Certainly, they cannot exceed it. The existence of a super-synchronous speed range in the repulsion-induction motor is due to the fact that the repulsion-motor characteristics continue to exert influence even at zero torque demand. Thus, if the shaft of this motor is spinning freely, without any external load, the torque developed by the commutated-armature winding boosts the speed above its synchronous value. How ever, the extent of this action is limited because of countertorque developed by the squirrel-cage winding—it functions as an induction generator above synchronous speed. The unique behavior of this machine stems from the fact that the inductive reactance responsible for the interchange of motor characteristics does not display the abrupt and positive action of an electrical switch.

By the same rationale, inductive motor action is present down to zero speed. In deed, there is always an interchange of energy between the two windings. This coupling between the windings makes the starting torque slightly less than that obtained in the switch-type repulsion-start motor previously discussed. However, the power factor and the commutation tend to be improved by the presence of the two windings.

Unlike other induction machines, the repulsion-induction motor has the desirable features of a speed-torque characteristic that is not subject to “breakdown” by temporary overloads. The speed-torque curve is shown in FIG. 18.

FIG. 18 Speed/torque curve for the repulsion-induction motor. Synchronous

speed vs. Percent of rated torque

---- --