AMAZON multi-meters discounts AMAZON oscilloscope discounts

OBJECTIVES

...

describe the basic sequence of actions of the following types of controllers when used to control three-phase ac induction motors: jogging-type controller, quick-stop ac controller (plugging), dynamic braking controller, resistance starter controller, automatic autotransformer compensator, automatic controller for wound-rotor induction motors, wye-delta controller, and automatic controller for synchronous motors.

• identify and use the various National Electrical Code sections pertaining to controllers and remote control circuits for motors.

• state why ac adjustable speed drives are used.

• list the types of adjustable speed drives.

• describe the operating principles of different ac adjustable speed drives.

• list the advantages and disadvantages of some units.

The industrial electrician is required to install, maintain, and repair automatic ac controllers which start up and provide speed control for squirrel-cage induction motors, wound-rotor induction motors, and synchronous motors.

MOTOR CONTROLLERS WITH JOGGING CAPABILITY

Many industrial processes require that the driven machines involved in the process be inched or moved small distances. Motor controllers designed to provide control for this type of operation are called jogging controllers. Jogging is defined as the quickly repeated closure of a controller circuit to start a motor from rest for the purpose of accomplishing small movements of the driven machine.

An across-the-line magnetic motor switch may be used to provide jogging control if the proper type of pushbutton station is used in the control circuit. Such a pushbutton station is called a start-jog-stop station.

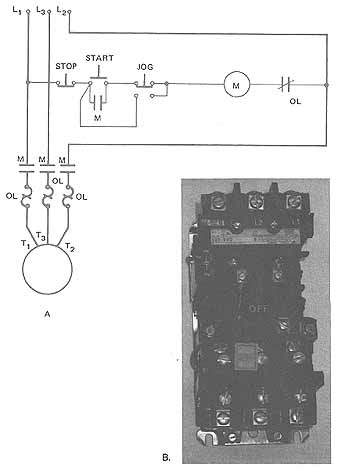

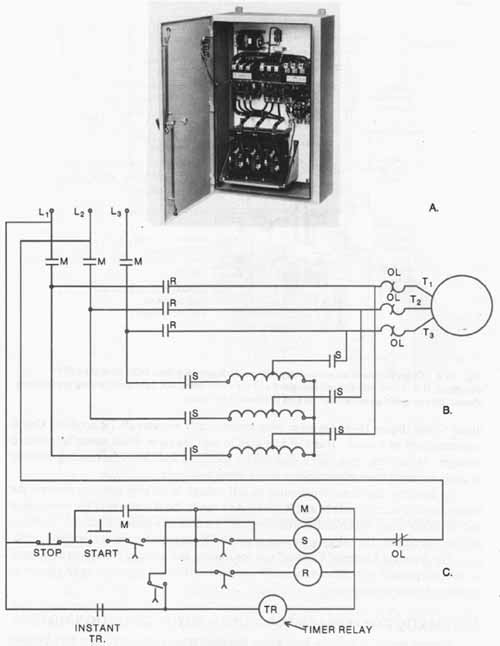

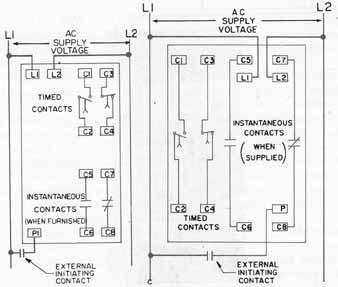

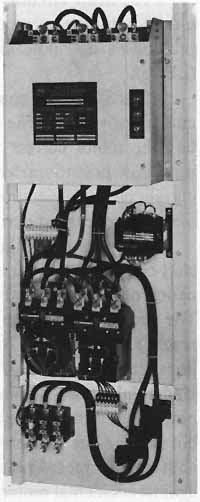

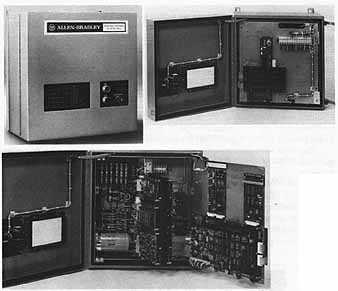

ill 1 A is a diagram of the connections for a three-phase, squirrel-cage induction motor connected to a jogging-type, across-the-line motor starting switch.

ill 1 B shows the starter with the cover removed. Note in figure 1 that the connections and operation of the start and stop pushbuttons are the same as those of a standard pushbutton station with start and stop positions. The connections for the jog pushbutton, however, are more complex and should be studied in detail. When the jog pushbutton is pressed, coil M is energized, main contacts M close, and the motor starts turning. The small auxiliary contacts M also close, but don't function as a sealing circuit around the jog pushbutton because pushing the jog pushbutton also opens the sealing circuit. As a result, as soon as the jog pushbutton is released, coil M is deenergized and all M contacts open. Before the jog pushbutton returns to its normal position, the sealing contacts M open and thus the control circuit remains open. This control also can be used for standard start-stop operations. In summary then, repeated closures of the jog pushbutton start the motor momentarily so that the driven machine can be inched or jogged to the desired position.

QUICK-STOP AC CONTROLLER (PLUGGING)

Some industrial applications require that three-phase motors be stopped quickly. If any two of the line leads feeding a three-phase motor are reversed, a counter torque is set up which brings the motor to a quick standstill before it begins to rotate in the reverse direction. If the circuit's interrupted at the instant the motor begins to turn in the opposite direction, the rotor will just stop. This method of bringing a motor to a quick stop is called plugging. The motor controller required to provide this type of operation is an across-the-line magnetic motor starter with reversing control and a special plugging relay. The plugging relay is belt-driven from an auxiliary pulley on the motor shaft, or onto a through shaft motor.

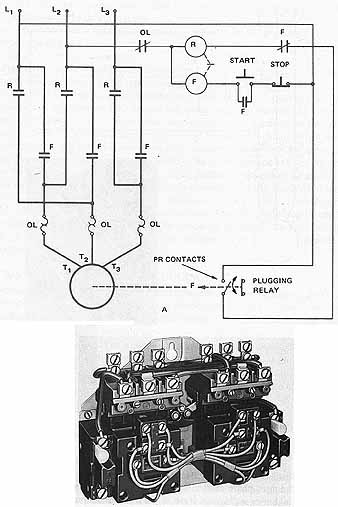

The connections for a quick-stop ac controller are illustrated in 2A. The controller itself is illustrated in 1 6—2B. When the start pushbutton is pressed, relay coil F is energized. As a result, the small, normally closed F contacts open. These contacts are connected in series with the reverse coil, which locks out reverse operation. In addition, the other small, normally open F contacts close and maintain the start pushbutton circuit. When the start button is released, the circuit of coil F is maintained through the sealing circuit, main contacts F close, and the rated three-phase voltage is applied to the motor terminals. Then, the motor comes up to speed and contacts PR of the plugging relay close.

When the stop pushbutton is pressed, the F relay coil is deenergized. As a result of this action, the main F contacts for the motor circuit open and disconnect the motor from the three-phase source. In addition, the small F sealing contacts open, de-energizing the holding or sealing circuit around the start pushbutton. Finally, the small F contacts in series with the reverse relay close to their normal position and the reverse relay coil is energized.

ill. 1: A) Elementary diagram connections for a three-phase

motor with jogging B) Magnetic starter removed from enclosure.

ill. 2 A) Elementary circuit with a plugging relay B) Ac full

voltage reversing starter, size 1.

The main R contacts now close to reconnect the three-phase line voltage to the motor terminals. The connections of two line leads are interchanged. The resulting reversing counter-torque developed in the motor brings it to a quick stop. At the moment the motor begins to turn in the reverse direction, contacts PR open due to the mechanical action of the PR relay unit. Coil R is deenergized and the R contacts open and interrupt the power supply to the motor. Since the motor is just beginning to turn in the opposite direction, it comes to a standstill. The motor supplies the mechanical power to drive a disk which causes contacts PR to close when the motor is in operation.

DYNAMIC BRAKING WITH INDUCTION MOTORS

It should be recalled from the study of dc controllers that dynamic braking is a method used to help bring a motor to a quicker stop without the extensive use of friction brakes. In this application, dynamic braking means that the motor involved is used as a generator. An energy dissipating resistance is connected across the terminals of the motor after it's disconnected from the line.

Dynamic braking also can be applied to induction motors. When the stop pushbutton is pressed, the motor is disconnected from the three-phase source and the stator windings are excited by a dc source. A stationary magnetic field is developed by the direct current in the stator windings. As the squirrel-cage rotor revolves through this stationary field, a high rotor current is created. This rotor current reacts with the stationary field of the stator to produce a countertorque that slows and stops the motor.

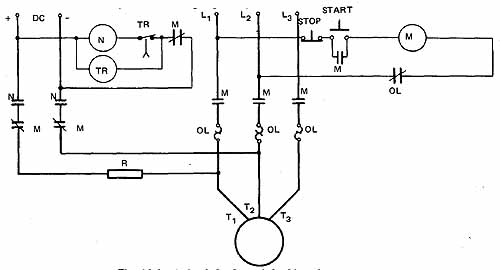

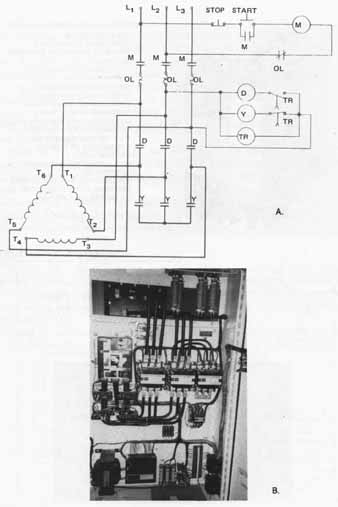

ill 3 is a diagram of an ac motor installation with an across-the-line magnetic motor starter and dynamic braking capability.

ill. 3: diagram of an ac motor installation.

When the start pushbutton is pressed, coil M is energized. At this instant, the main M contacts close and connect the motor terminals to the three-phase source, and the auxiliary, normally open M contacts close and provide a maintaining circuit around the start pushbutton. When relay coil M is energized, the normally closed contacts M in the dc control circuit open, with the result that both the main dc relay coil N and the time-delay relay coil TR are deenergized and interlocks in the dc circuit open. The three-phase volt age applied to the motor terminals causes the motor to accelerate to the rated speed.

When the stop pushbutton is pressed, coil M is deenergized. At this moment, a number of actions occur: 1) the main contacts M open and disconnect the motor from the three-phase source; 2) the auxiliary M contacts open (these contacts act as a maintaining circuit); 3) protective interlocks M in the dc circuit close; and 4) the auxiliary, normally closed contacts M in the dc control circuit close and energize the time-delay relay and the main relay coil N. Energizing relay coil N causes the closing of contacts N so that dc volt age is connected on the ac windings through a current-limiting resistance. As a result, the motor comes to a quick stop. Following a definite period after the motor has stopped, measured in seconds, relay coil TR operates and opens contacts TR to cause coil N to become deenergized. Thus, contacts N open and disconnect the motor windings from the dc source. The controller now is ready for the next starting cycle.

Timing contacts are shown in their deenergized condition. Timers are either on-delay or off-delay and are used in motor control work. The actual timer mechanism varies depending on the vintage of the controller and the manufacturer. See unit 13 for complete description of the timer symbols and operations.

RESISTANCE STARTER CONTROLLER

When a squirrel-cage induction motor is connected directly across the rated line voltage, the starting current may be 300 percent to 600 percent of the rated current of the motor. In large motors, this high current may cause serious voltage regulation problems and overloading of industrial power feeders.

The starting current of a squirrel-cage induction motor can be reduced by using a resistance starter controller. This type of controller inserts equal resistance values in each line wire at the instant the motor is started. After the motor accelerates to a value near its rated speed, the resistance is cut out of the circuit and full line voltage is applied to the motor terminals.

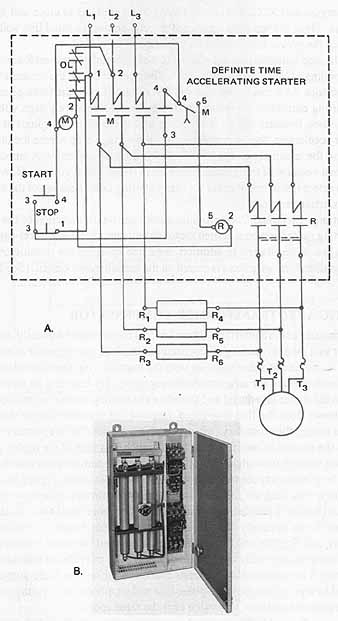

ill. 4 A) Definite lime acceleration with resistance starting

B) Two-point primary resistance starter rated at 25 hp, 600 V.

ill 4A is a diagram of the circuit connections for a resistance starter. A photo of this starter is figure 1 6—4B. When the start button is pressed, main relay coil M is energized. The main contacts close and connect the motor to the three-phase source through the three resistors (R). The circuit for coil M is maintained through the small auxiliary contacts (3 and 4) which act as a sealing circuit around the normally open start push-button. When the main contacts of relay coil M are closed, a mechanical device, called a definite time relay, is started. After a predetermined time elapses, the definite time contacts close and energize coil R. Coil R causes three sets of contacts to close and shunt out the three resistors. Thus, the motor is connected directly across the rated line voltage with no interruption of the power line (closed transition).

When the stop button is pressed, the circuits of both coil M and coil R are opened. This causes the opening of the main contacts, the sealing contacts, and the contacts which shunt the series resistors. As a result, the motor is disconnected from the three-phase source.

The starting current in the resistance starter causes a relatively high voltage drop in the three resistors. Because of this, the voltage across the motor terminals at start is low. As the motor accelerates, the current decreases, the voltage drop across the three resistors decreases, and the terminal voltage of the motor increases gradually. A smooth acceleration is obtained because of this gradual increase in the terminal voltage. However, it may be unwise to select resistance starting for many starting tasks because of the energy dissipated in the starting resistors.

The National Electrical Code provides guidelines on the selection of the correct fuse sizes for starting protection on a branch motor circuit containing a squirrel-cage induction motor with a resistance starter. In addition, the Code specifies the running overload protection required, and the wire sizes required on the branch motor circuit.

AUTOMATIC AUTOTRANSFORMER COMPENSATOR

The automatic autotransformer ( 5A) compensator basically operates in the same manner as a manual starting compensator. A manual compensator is used to manually connect an autotransformer in series with the motor during the starting cycle. A compensator is another name for an autotransformer starter. By inserting an autotransformer, the voltage to the motor is reduced and therefore the starting current is reduced. The starting current drawn from the line is reduced. Because the autotransformer steps down the voltage to the motor, the secondary (motor) current is higher than the primary current. The result is that the current drawn from the line is much less than if the motor were started with a reduced voltage through a resistor. The automatic compensator has the advantage in that it can be pushbutton-controlled from a convenient location. ill 5B is a typical schematic wiring diagram for an automatic autotransformer compensator.

ill. 5: A) Reduced voltage starter, autotransformer type, with

a pneumatic timer. Elementary diagram of an autotransformer compensator

for starting an induction motor

If the start button is pressed, a circuit's established from line 1 through the following devices to line 2: the normally closed stop button, the start button, contacts TR (timing relay) to relay coil S (start coil), and the normally closed overload contacts. Coil M is energized, closing the normally open small contacts M to provide the maintaining circuit.

When coil S is energized, all contacts marked S close. The three autotransformers are connected in wye across the three-phase line and supply reduced voltage to the motor. The motor begins to accelerate to a value near the rated speed.

As illustrated in 5B, a second circuit's established through the timer relay by contacts TR. The timer relay begins operating as soon as it's energized. After a definited timed period ( 6) the timer relay mechanically actuates all TR contacts. Coil S is deenergized as a result. This coil was used to start the three-phase motor on reduced voltages. At the same time, coil R (run coil) is energized and closes the running contacts to apply the rated three-phase voltage to the motor terminals.

At this time, the motor is operating on full voltage. If the stop button is pressed, the holding coil circuit for coils M and R opens. As a result, the R contacts to the motor open and the motor stops. When coil R is deenergized, the normally closed R contacts close the pilot motor circuit. The pilot motor runs to set all TR contacts for the next starting cycle.

The National Electrical Code rulings for starting and running protection also apply to motors operated with either a manually operated starting compensator or an automatic autotransforrner compensator.

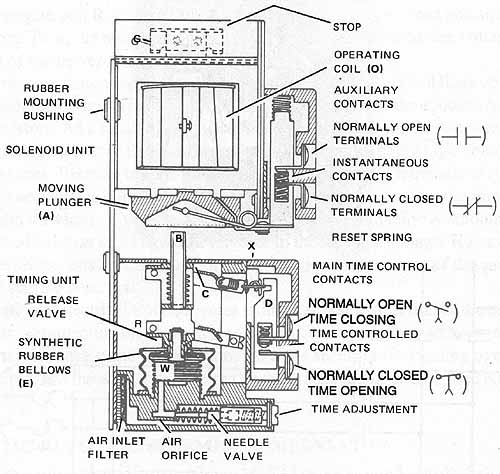

ill. 6 Cross section of an ac on-delay timer, which provides

time delay after the coil is energized. It is shown with the coil energized and the timer timed out. Schematic wiring symbols are shown (de-energized

positions) for various portions of the timer.

AUTOMATIC CONTROLLER FOR WOUND-ROTOR INDUCTION MOTORS

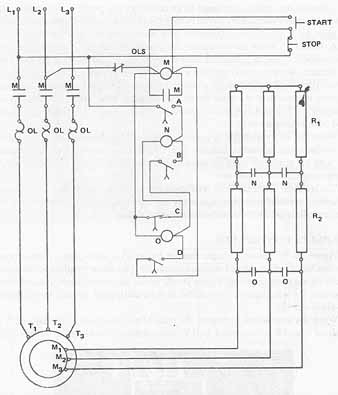

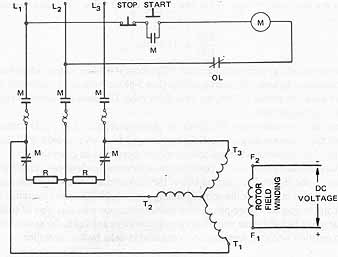

Manual speed controllers, such as the faceplate type or the drum type, may be used to provide speed control for wound-rotor induction motors in industrial applications. If the resistance in the rotor circuit of a wound-rotor induction motor is to be used only on starting, then an automatic controller may be used, figure 7. In this case, resistors in the rotor circuit are automatically removed by contactors arranged to operate in sequence at definite time intervals.

ill. 7: Elementary diagram of an automobile controller for

a wound-rotor induction motor

As illustrated in 7, when the start button is pressed, the main relay coil M is energized. The main contacts are closed to connect the stator circuit of the motor directly across the three-phase line voltage. All of the resistance of the controller is inserted in the secondary circuit of the motor as it begins to accelerate.

After the start button is released to its normally open position, the small auxiliary contacts M act as a maintaining circuit to keep the circuit of coil M closed. Contacts A are held open for a timed period (seconds) by a mechanical or electronic device ( 8A, B, and C). When the A contacts close, coil N is energized through the normally closed contacts C, and all N contacts close to shunt out the R resistors in the rotor circuit.

Contacts B also are held open for a definite number of seconds by a mechanical or electronic device. When B contacts close, coil 0 is energized, all 0 contacts close, and all resistance is cut out of the rotor circuit. At the same time, the C contacts open and deenergize coil N which then opens contacts N. The D contacts then close and maintain a closed circuit through coil 0.

When the stop pushbutton is pressed, relay coil M is deenergized, and contacts M open to disconnect the motor from the line. Coil 0 also is deenergized and contacts 0 open, with the result that all of the resistance is inserted in the rotor circuit for the next starting cycle.

The National Electrical Code regulations for wire size, starting overload protection, and running overload protection also apply to both manual speed controllers and automatic controllers used with wound-rotor induction motors.

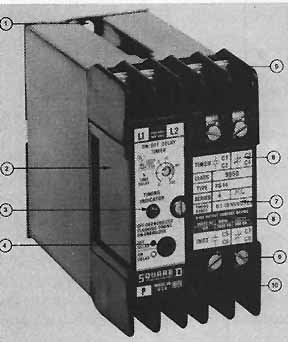

ill. 8 A) Solid-state timing relays with different plug-in

program keys.

ill. 8 B-C) Solid-state timing relays with different plug-in

program keys:

1. STANDARD INDUSTRIAL CONTROL RELAY MOUNTING

2. REMOVABLE TIMER COVER PROTECTS TIME DELAY AND MODE SETTING

3. LED (LIGHT EMITTING DIODE) TIMING INDICATOR

4. CONVERTIBLE TIME DELAY MODE SHOWS THROUGH COVER

5. ONE N.O. AND ONE N.C. TIMED NEMA B150 HARD OUTPUT CONTACTS (10 AMPERE CONTINUOUS)

6. TERMINALS CLEARLY MARKED

7. FIVE TIMING RANGES FROM 0.05 SECONDS TO 10 HOURS

8. MARKING AREA

9. SELF-LIFTING PRESSURE WIRE CONNECTORS

10. OPTIONAL INSTANTANEOUS NEMA B150 HARD OUTPUT CONTACTS (10 AMPERE CONTINUOUS)

WYE-DELTA CONTROLLER

ill 9A shows a simple method by which a three-phase, delta-connected motor can be started on reduced voltage by connecting the stator windings of the motor in wye during the starting period. ill 9B shows the actual starter. After the motor accelerates, the windings are reconnected in delta and placed directly across the rated three-phase voltage.

ill. 9 A) Elementary diagram of wye-delta motor starting B)

Photo of wye delta, 200 hp, closed transition.

When the start button is pressed, the main M contacts close, and relay coil Y and time-delay relay TR are energized. Coil Y causes contacts Y to close and the windings of the motor are connected in wye. If the line voltage is 230 volts, the voltage across each winding is:

230/1.73 = 133 volts

The voltage across each winding is only 58 percent of the line voltage when the windings are connected in wye at the start position. (See 3-phase Voltage)

After a definite period of time, the time-delay relay TR opens the circuit of relay coil Y and the Y. contacts open.

Then, the time-delay relay TR closes the circuit of relay coil D. All D contacts are closed and the motor winding connections are changed from wye to delta. Full line volt age is applied to the motor windings and the motor operates at its rated speed.

Motors started by a wye-delta controller must have the leads of each phase winding brought out to the terminal connection box of the motor. In addition, the phase windings must be connected in delta for the normal running position. NOTE: The electrician should never attempt to operate a three-phase, wye-connected motor with this type of controller. This is due to the fact that there will be an excessive voltage applied to the motor windings in the run position when the windings are connected in delta by the controller.

AUTOMATIC CONTROLLER FOR SYNCHRONOUS MOTORS

Synchronous motors may be started by means of an across-the-line magnetic motor starting switch, a manual starting compensator, or an automatic starting compensator. Dynamic braking may be provided by the controller.

ill 10 is a diagram of the connections for a synchronous motor controller with dynamic braking. When the start button is pressed, main relay coil M is energized. The four normally open M contacts close and the two normally closed M contacts open. Three-phase voltage is applied to the motor terminals. When the motor accelerates to a speed near the synchronous speed, the dc field circuit's energized by secondary controls.

When the stop button is pressed, main relay coil M is deenergized. The M contacts open and disconnect the motor terminals from the three-phase line. The two normally closed M contacts reconnect the motor windings through the resistors and the dc field remains energized. As a result, the synchronous motor acts as an ac generator and delivers electrical energy to the two R resistors. The use of this type of controller results in a more rapid slowing of a synchronous motor.

The National Electrical Code provides guidelines for branch-circuit fuse protection and running overload protection for branch circuits feeding three-phase synchronous motors, and for allowable conductor sizes for branch circuits feeding synchronous motors. Local building and electrical code authorities should be consulted before installations are made with motors and controllers which don't comply with National Electrical Code rulings.

ill. 16-10 Synchronous motor controller with dynamic braking

SOLID-STATE REDUCED VOLTAGE STARTERS

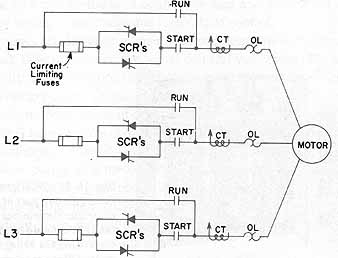

Solid-state devices and equipment are used for reduced voltage motor starting, electrical energy saving control circuits, variable speed drives, motor protection and other applications. A motor starter consists of a control circuit, a motor power circuit, and protective devices for the wiring and the motor. The functions of a starter are performed by contactors and overload relays in electromechanical motor starters. In solid-state starters, the control functions are performed by semiconductors. They are controlled by integrated circuits and microprocessors to provide the protective functions, operating instructions, and control.

Construction and Operation

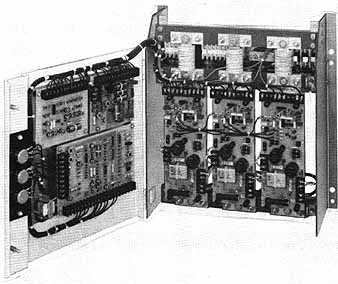

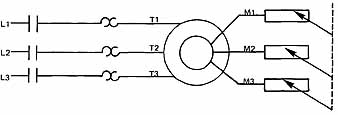

The solid-state reduced-voltage starter provides a smooth, stepless acceleration of a three-phase induction motor. This is accomplished by gradually turning on six power SCRS (silicon controlled rectifiers). Two SCRs per phase are connected in a back-to-back or reverse parallel arrangement, figure 11. The SCRs are mounted on a heat (dissipating) sink to make up a power pole (phase). Each power pole contains the gate firing circuits as discussed in unit 13. An integrated thermal sensor is also provided to deenergize the starter if an over-temperature condition exists.

The firing circuitry on each power pole is controlled by a logic module. These modules monitor the starter for correct start up and operating conditions. Some motor starters provide a visual indicator of the starting condition through the use of light-emitting diodes (LEDs).

The SCRs are connected back to back so that they may pass ac and control the amount of voltage. The current-limiting starter is a common type; it's designed to maintain the motor current at a constant level throughout the acceleration period. A cur rent-limit potentiometer adjustment is provided to preset this current. A starter with current ramp acceleration is designed to begin acceleration at a low current level and then increase the current during the acceleration period.

As indicated in figure 11, this starter includes both start and run contactors. The start contacts are in series with the SCRs; the run contacts are in parallel with the combi nation of SCRs and start contacts. When the starter is energized, the start contacts close. The motor acceleration is then controlled by phasing-on the SCRs, When the motor reaches full speed, the run contacts close and the motor is connected directly across the lines (closed transition). At this point, the SCRs are turned off and the start contacts open. Under full speed running conditions, the SCRs are out of the circuit, eliminating SCR power losses during the run cycle. This feature saves energy; it also guards against possible damage due to overvoltage transients. With the starter in the deenergized position, all contacts are open, isolating the motor from the line. This open circuit condition protects against accidental motor rotation as a result of SCR misfiring and /or SCR damage caused by overvoltage transients. A solid-state reduced-voltage starter is illustrated in 12. Field connections are very similar to those for electromechanical starters.

ill. 11 Solid-state reduced voltage starter power circuit.

Reduced Voltage Operation To reduce the voltage applied to the motor in a solid-state starter, the SCRs can be turned on by the “gate” electrode for any desired part of each half cycle. Usually the SCRs turn off as the current wave reaches zero. They stay off until gated on again in the next half cycle. Some devices can vary the switching and timing. By switching the controlled current gating, the effective ac voltage can be varied to the motor. This voltage can be varied from zero to full voltage as required. The voltage is applied at some preset minimum value that can start the motor rotating. As the motor speed builds up, the SCR “on” time is gradually increased. The voltage is increased until the motor is placed across the line at full voltage. Mechanical shock is reduced and the current inrush can be regulated and controlled as desired ( 13). The solid-state reduced-voltage starter can replace any of the electromechanical starters already described for reduced voltage starting.

ill. 12 Solid-state reduced voltage starter power circuit.

ill. 13 SCR controller section, the regulating part of the

starter. The controller determines to what degree the SCR’s should be phased

on, thereby controlling the voltage applied to the motor.

CODE REFERENCES FOR MOTOR CONTROLLERS

The following sections of the National Electrical Code are concerned with motor controllers and remote control circuits.

1. Sections 430-8 and 430-9 refer to the identification of motors and controllers with respect to controller nameplate ratings and terminal markings.

2. Section 430-C is concerned with overload protection.

3. Section 430-37 gives the number of running overcurrent relays required for different electrical systems.

4. Section 430-D is concerned with branch-circuit protection.

5. Sections 430-71 to 430-74 are concerned with the control circuits of controllers.

6. Sections 430-81 to 430-90 are concerned with controller installations.

7. Sections 430-101 to 430-113 cover motor disconnecting means.

AC ADJUSTABLE SPEED DRIVES

Adjustable speed drives have a flexibility that's particularly useful in specialized applications. For this reason, these drives are widely used throughout industry for convey ors used to move materials, hoists, grinders, mixers, pumps, variable speed fans, saws, and crushers. The advantages of ac drives include the maximum utilization of the driven equipment, better coordination of production processes, and reduced wear on mechanical equipment.

The ac induction motor is the major converter of electrical energy into another usable form. About two-thirds of the electrical energy produced in the United States is delivered to motors.

Much of the power that's consumed by ac motors goes into the operation of fans, blowers, and pumps. It has been estimated that approximately 50% of the motors in use are for these types of loads. Such loads are particularly appropriate to look at for energy savings. Several alternate methods of control for fans and pumps have been developed and show energy savings over traditional methods of control.

Fans and pumps are designed to meet the maximum demand of the system in which they are installed. Often, however, the actual demand varies and may be much less than the design capacity. Such conditions are accommodated by adding outlet dampers to fans or throttling valves to pumps. These controls are effective and simple, but affect the efficiency of the system. Other forms of control have been developed to adapt machinery to varying demands. These controls don't decrease the efficiency of the system as much as the traditional methods of control. One of the newer methods is the direct variable speed control of the fan or pump. This method produces a more efficient means of flow control compared to the other existing methods.

In addition to a tangible reduction in the power required to operate equipment and machinery resulting from the use of adjustable speed drives, other benefits include extended bearing life and pump seal life.

WOUND ROTOR AC MOTORS

Wound rotor motor drives use a specially constructed ac motor to accomplish speed control. The windings of the motor rotor are brought out of the motor through slip rings on the rotor shaft. ill 14 shows an elementary diagram of a wound rotor motor with an adjustable speed drive. These windings are connected to a controller which places variable resistors in series with the windings. The torque performance of the motor can be controlled using these variable resistors.

Wound rotor motors are more common in the larger sizes, in the range of 300 horse power and above.

ill. 14 Elementary diagram of an adjustable speed drive wound

rotor motor

Features of Wound Rotor Motors

Wound rotor motors have the following advantages which make them suitable for a variety of applications:

• Cost — the initial cost is moderate for the high horsepower units.

• Control — not all the power need be controlled, resulting in a moderate size and simple controller.

• Construction — the simple construction of the motor and control lends itself to maintenance without the need for a high level of training.

• High inertia loads — the drive works well on high inertia loads.

Disadvantages of Wound Rotor Motors

• Custom motor-. the motor has a rotor wound with wire, slip rings, and isn't readily available.

• Efficiency — the drive does not maintain a high efficiency at low speeds.

• Speed range — the drive usually is limited to a speed range of two to one.

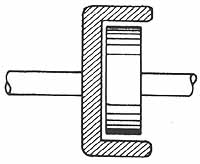

ill. 15 Spider rotor coil magnet rotated within a steel drum

TYPES OF ADJUSTABLE SPEED DRIVES

Several types of variable speed drives can be used with wound rotor induction motors. These drives are eddy current (magnetic) drives, variable pitch drives, and adjust able frequency drives.

Eddy Current (Magnet) Drives

The eddy current drive couples the motor to the load magnetically ( 15). The electromagnetic coupling is a simple way to obtain an adjustable output speed from the constant input speed of squirrel cage motors. There is no mechanical contact between the rotating members of the eddy current drive; thus, there is no wear. Torque is transmitted between the two rotating units by in electromagnetic reaction created by an energized rotating coil winding. The rotation of the ring with relation to the electromagnet generates eddy currents and magnetic fields in the ring. Magnetic interaction between the two units transmits torque from the motor to the load. The slip between the motor and the load can be controlled continuously with great precision.

Torque can be controlled using a thyristor in an ac or dc circuit, or by using a rheostat to control the field through slip rings. When the eddy current drive responds to an input or command voltage, the speed of the driven machine changes. A further refinement can be obtained in automatic control to regulate and maintain the output speed. The magnetic drive can be used with nearly any type of actuating device or transducer that can pro vide an electrical signal. E.g., the input can be provided by static controls and sensors which detect liquid level, air and fluid pressures, temperature, and frequency.

Magnetic eddy current drives are used for applications requiring an adjustable speed such as cranes, hoists, fans, compressors, and pumps ( 16).

Variable Pitch Drives

The speed of an ac squirrel cage induction motor depends upon the frequency (hertz) of the supply current and the number of poles of the motor. The equation expressing this relationship is:

RPM = 60xHertz/Pairs of Poles

ill. 16 Two magnetic drives driven by 100-hp Induction motors

mounted on top.

ill. 17 Variable pitch pulley method of obtaining continuously

adjustable speed from constant speed shaft.

A frequency changer may be used to vary the speed of this type of motor. A possible method is to drive an alternator through an adjustable mechanical speed drive.

The voltage is regulated automatically during frequency changes. An ac motor drives a variable cone pulley or sheave, which is belted to another variable pulley on the output shaft ( 17). When the relative diameters of the two pulleys are changed, the speed between the input and the output can be controlled. As the alternator speed is varied, the output frequency varies, thereby varying the speed of the motor, or motors, connected electrically to the alternator supply.

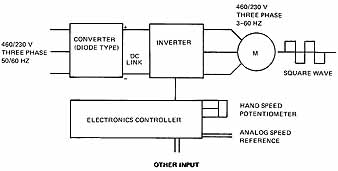

Adjustable Frequency AC Drives

Adjustable frequency (static solid-state) drives are also commonly called inverters. The power conversion losses are greatly reduced when using these transistor controllers for adjustable speed drives. They are available in a range of horsepowers from fractional to 1,000 hp. Adjustable frequency drives are designed to operate standard ac induction motors. This allows them to be added easily to an existing system. (ill 16-18).

Where energy saving is a major concern the drives are ideal for pumping and fan applications. They are also used for many process control or machine applications where performance is a major concern. Many adjustable speed precision applications were limited to the use of dc motors. By using adjustable frequency controllers with optional dynamic braking, standard squirrel cage motors can now be used in these applications. Municipal, industrial, commercial and mining applications include: sewage, waste water, slurry and booster pumps, ventilation and variable air volume fans; conveyors; production machines and compressors.

ill. 18 Controller operation

AC VARIABLE SPEED/VARIABLE FREQUENCY CONTROLS

AC motors are designed to run at a specific full load speed. This design speed takes into account various losses in the motor including copper losses of the stator and the rotor and other losses such as iron losses, friction, and windage. The end result is some speed less than synchronous speed, which is calculated by the following formula:

Synchronous RPM = 120 Freq/ # poles

Use this formula to determine the synchronous speed of a motor if the number of poles and the applied frequency are known. The number of poles is usually fixed and the frequency of a normal power feed in the U.S.A. is 60 Hz. Therefore, to operate an ac motor at other than its design speed, either the number of poles or the frequency must be altered. Some adjustable speed motors are able to reconnect the poles or connect a separate winding of poles to establish other set speeds. To vary the speed of an ac motor over a wide range of speeds, the applied frequency is altered.

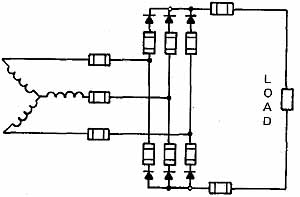

There are two basic techniques for altering the frequency of the applied power through electronic means. Both techniques use the principle of rectifying the three-phase ac 60 Hz input power to a dc supply (see figure 19). Then filter the dc to provide smooth dc to the inverter section of the electronic controller. The amplitude of the output voltage must change with the frequency, because at low frequency the impedance of the motor is low and the voltage must also be reduced to prevent overheating of the motor. Conversely, as the frequency is raised above 60 Hz, the motor’s impedance is increased and voltage must also increase to maintain motor torque.

One method of speed control is the variable voltage inverter. The dc voltage applied to the inverter is adjusted, then the pulse is modified to create various frequencies (see figure 18).

The other and more common method is known as pulse width modulation, or PWM. The voltage output of the dc-to-ac inverter is really a series of pulses of DC that's stepped to produce a “staircase” approximation of the sine wave at the frequency desired, to control the motor speed. The controller uses a sensor and a set point to determine output frequency and the desired set speed.

The control modules adjust the output of a dc voltage control module as it adjusts the output of the frequency control module. The frequency control module typically drives the output power controller, there are two of these for each of the three phases; one controls the positive half cycles of one phase and one controls the negative half cycles of the same phase. Six output modules are required for three phases.

When connected to a motor the stepped output wave form appears close to a sine wave because of the motor’s inductance. Frequency then determines the speed of the motor in conjunction with the set number of poles.

ill. 19 Three-phase, full-wave rectifier with connected load.

INTRODUCTION TO PROGRAMMABLE CONTROLLERS

Modern motor control requires more exact timing and faster, more consistent operations than those provided by the older electromechanical relays and timers. Because modern manufacturing requirements also rely on flexibility of systems, a fast change sys tem was needed that didn’t require extensive redesign, building, hand wiring, and testing to create a new motor control scheme.

ill. 20 Adjustable frequency motor drive controller.

Along with this change in needs, the microprocessor was improved to make it more reliable in industrial environments and more trouble-free in operation. The combination of these events produced the Programmable Controller, or PC.

Various versions of the PC are made by different manufacturers and have various capabilities. However, all programmable controllers have at least three basic components:

The first is a processor, which is a microprocessor that contains the instructions and makes the decisions; the second component is an input/output section, which receives input information from the process it's controlling, and connects it to the controller in the proper format. It also takes the output from the controller and interfaces to the real world of control devices; the third main component is the programmer. This is the operator’s access to the controller. The programs are written in ladder logic style, which is familiar to most electricians. This familiarity was the factor that allowed the programmable controller to be so widely accepted as a control system. Controls were easily converted and adapted by current electricians without having to learn extensive new microprocessor programming language.

PCs are used where the control system is likely to be changed frequently and usually where there are multiple functions for the controller to monitor, compare, count, time, or operate. These conditions make the use of a PC economical and practical.

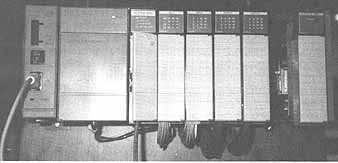

Large control systems may have various input/output cards that must be coordinated according to the “field wiring.” E.g.: ac and dc voltage at various levels, Transistor-Transistor Logic (TTL), Input/Output (10), Analog I/O, Thermocouple or Binary Coded Decimal (BCD). ill 21 is a programmable controller.

The intent of this guide isn't to teach programming of the PC, but to familiarize the electrician with the possibility of motor control using the PC. A Technician ‘s Guide to Programmable Controllers, by Richard A. Cox, Delmar Publishers Inc., is an excellent reference to gain further “generic” information.

ill. 21 Programmable controller, with one input/output card

removed

SUMMARY

There are many methods used to start, stop, jog, and reverse three-phase motors. The basic operations generally use a magnetic controller to supply power to the motor. The reversing controller is used in the plugging operation to momentarily reverse the power and therefore bring the motor to a quick stop. Dynamic braking can also be used to stop an ac motor by applying dc to the motor field. Various methods of reducing the starting current to the motor employ the application of reduced voltage at the motor terminals during the starting period. Resistance or reactance can be inserted in series with the motor to reduce the voltage. An autotransformer may be used to reduce the applied voltage. Wound-rotor motors use secondary resistors to keep the starting current to a minimum. Wye-delta starters can be used to reduce the starting current to the motor by changing the configuration of the connections. Solid state starters are now being installed to reduce the inrush current and to control the speed and the stopping characteristics.

Variable-frequency drives use electronics to control the frequency to the motor and therefore control the speed of the motor. Many motor-control schemes can be developed with the use of a programmable controller. This electronic equivalent of a relay system is used to provide exact timing and complex, but changeable, control through the use of a microprocessor-based system.

REVIEW / QUIZ:

1. What is meant by the term jogging?

2. What is meant by the term plugging?

3. How is dynamic braking applied to an ac induction motor? ___

4. How is dynamic braking applied to a synchronous motor? ___

5. Draw a schematic diagram of the connections for the control circuit of an across-the line magnetic motor switch with jogging capability. Include the main relay coil, the pushbutton station with start, jog, and stop pushbuttons, and the sealing contactor.

6. What identifying information should appear on a motor controller so that the controller complies with the requirements of the National Electrical Code?

7. Draw a schematic diagram of an automatic controller used for a three-phase, wound-rotor induction motor.

8. A three-phase, squirrel-cage induction motor has the following ratings: 15 horse power, 230 volts, 42 amperes per terminal, 40 degrees Celsius, and code classification F. In the spaces in the following table, insert the correct values for fuse protection and running overcurrent protection for this motor when used with each of the types of controllers listed.

Type of Controller |

Fuse Protection: Nontime-delay |

Fuse Protection: Time-delay |

Running Overcurrent Protection |

a. Resistance starter |

|

|

|

b. Automatic autotransformer compensator |

|

|

|

c. Across-the-line magnetic motor starting switch with jogging capability |

|

|

|

d. Across-the-line magnetic motor starting switch with plugging capability |

|

|

|

9. What is the purpose of an automatic autotransformer starting compensator?

10. What is the purpose of an automatic controller used with wound-rotor induction motors?

11. A wye-delta controller starts the motor at …

a. 173 percent of the line voltage.

b. 58 percent of the line voltage.

c. full line voltage.

d. 25 percent of the line voltage.

12. A three-phase, wye-connected motor

a. should never be started by a wye-delta controller.

b. should always be started by a wye-delta controller.

c. can be started by a wye-delta controller if proper timers are used.

d. can be started by a wye-delta controller if proper pushbuttons are used.

13. How are SCRs connected to pass and control ac?___

14. If a solid-state controller has contactors in the power circuit, in what position are the contacts of start and run in the off position? Why?

15. Why are adjustable speed drives used? _______

16. List the types of ac adjustable speed drives. ______

17. How is the speed of the wound rotor motor adjusted?

18. How is the eddy current drive coupled to the load? ____

19. How is the ac frequency varied in the mechanical method drive? ____

20. What is the formula for calculating ac motor speed?

21. What basic devices are provided in the adjustable frequency drive? ____

22. With an apparent high degree of skill required to maintain an adjustable frequency drive control, how does the plant electrician repair one? ___