AMAZON multi-meters discounts AMAZON oscilloscope discounts

Goals:

1. Identify the electrical factors that deter mine the severity of an electric shock.

2. Be aware of general principles of electrical safety including wearing approved protective clothing and using protective equipment.

3. Explain the safety aspect of grounding an electrical motor installation.

4. Outline the basic steps in a lockout procedure.

5. Be aware of the functions of the different organizations responsible for electrical codes and standards.

Protecting against Electrical Shock

Safety is the number one priority in any job. Every year, electrical accidents cause serious injury or death. Many of these casualties are young people just entering the workplace. They are involved in accidents that result from carelessness, from the pressures and distractions of a new job, or from a lack of understanding about electricity. This section is designed to develop an awareness of the dangers associated with electrical power and the potential dangers that can exist on the job or at a training facility.

Electrical Shock

The human body conducts electricity. Even low currents may cause severe health effects.

Spasms, burns, muscle paralysis, or death can result, depending on the amount of the current flowing through the body, the route it takes, and the duration of exposure.

The main factor for determining the severity of an electric shock is the amount of electric current that passes through the body. This current is dependent upon the voltage and the resistance of the path it follows through the body.

Electrical resistance ( R ) is the opposition to the flow of current in a circuit and is measured in ohms (Greek letter Omega). The lower the body resistance, the greater the current flow and potential electric shock hazard. Body resistance can be divided into external (skin resistance) and internal (body tissues and blood stream resistance). Dry skin is a good insulator; moisture lowers the resistance of skin, which explains why shock intensity is greater when the hands are wet. Internal resistance is low owing to the salt and moisture content of the blood. There is a wide degree of variation in body resistance. A shock that may be fatal to one person may cause only brief discomfort to another.

Typical body resistance values are:

- • Dry skin-100,000 to 600,000 ohm

- • Wet skin-1,000 ohm

- • Internal body (hand to foot)-400 to 600 ohm

- • Ear to ear-100 ohm

Thin or wet skin is much less resistant than thick or dry skin. When skin resistance is low, the current may cause little or no skin damage but severely burn internal organs and tissues. Conversely, high skin resistance can produce severe skin burns but prevent the current from entering the body.

Voltage ( E ) is the pressure that causes the flow of electric current in a circuit and is measured in units called volts (V). The amount of voltage that's dangerous to life varies with each individual because of differences in body resistance and heart conditions. Generally, any voltage above 30 V is considered dangerous.

Electric current ( I ) is the rate of flow of electrons in a circuit and is measured in amperes (A) or milli amperes (mA). One milliampere is one-thousandth of an ampere. The amount of current flowing through a per son's body depends on the voltage and resistance. Body current can be calculated using the following Ohm's law formula:

Current = Voltage/Resistance

If you came into direct contact with 120 volts and your body resistance was 100,000, then the current that would flow would be:

This is just about at the threshold of perception, so it would produce only a tingle.

If you were sweaty and barefoot, then your resistance to ground might be as low as 1,000 ohms. Then the current would be:

This is a lethal shock, capable of producing ventricular fibrillation (rapid irregular contractions of the heart) and death!

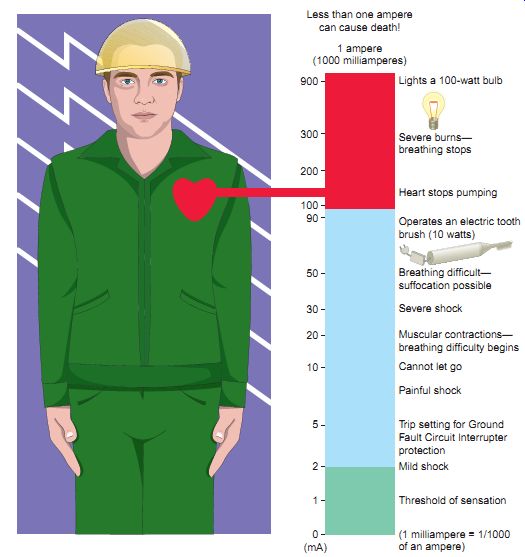

Voltage isn't as reliable an indication of shock intensity because the body's resistance varies so widely that it's impossible to predict how much current will result from a given voltage. The amount of current that passes through the body and the length of time of exposure are perhaps the two most reliable criteria of shock intensity. Once current enters the body it follows through the circulatory system in preference to the external skin. Ill. 1 illustrates the relative magnitude and effect of electric current. It doesn't take much current to cause a painful or even fatal shock. A current of 1 mA (1/1000 of an ampere) can be felt. A cur rent of 10 mA will produce a shock of sufficient intensity to prevent voluntary control of muscles, which explains why, in some cases, the victim of electric shock is unable to release grip on the conductor while the current is flowing.

A current of 100 mA passing through the body for a second or longer can be fatal. Generally, any current flow above 0.005 A, or 5 mA, is considered dangerous.

A 1.5-V flashlight cell can deliver more than enough current to kill a human being, yet it's safe to handle. This is because the resistance of human skin is high enough to limit greatly the flow of electric current. In lower voltage circuits, resistance restricts current flow to very low values. Therefore, there is little danger of an electric shock.

Higher voltages, on the other hand, can force enough cur rent though the skin to produce a shock. The danger of harmful shock increases as the voltage increases.

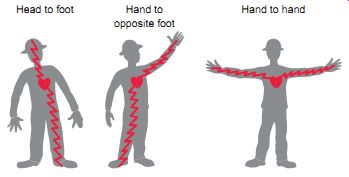

The pathway through the body is another factor influencing the effect of an electric shock. E.g., a current from hand to foot, which passes through the heart and part of the central nervous system, is far more dangerous than a shock between two points on the same arm.

AC (alternating current) of the common 60-Hz frequency is three to five times more dangerous than DC (direct current) of the same voltage and current value. DC tends to cause a convulsive contraction of the muscles, often forcing the victim away from further current expo sure. The effects of AC on the body depend to a great extent on the frequency: low-frequency currents (50-60 Hz) are usually more dangerous than high-frequency currents. AC causes muscle spasm, often "freezing" the hand (the most common part of the body to make contact) to the circuit.

The fist clenches around the current source, resulting in prolonged exposure with severe burns.

-- Relative magnitude and effect of electric current on the body.

Less than one ampere can cause death! 1 ampere (1000 milliamperes); 900 300 200 100 90 50 30 20 10 5 2 1 0 (mA) Lights a 100-watt bulb Severe burns; breathing stops Heart stops pumping, Operates an electric tooth brush (10 watts), Breathing difficult- suffocation possible, Severe shock, Muscular contractions- breathing difficulty begins, Cannot let go, Painful shock, Trip setting for Ground Fault Circuit Interrupter protection, Mild shock, Threshold of sensation (1 milliampere = 1/1000 of an ampere)

-- Typical electric current pathways that stop normal pumping of the heart.

-- Typical safety signs.

-- The most common electric-related injury is a burn. The major types of burns:

• Electrical burns, which are a result of electric current flowing through the tissues or bones. The burn itself may be only on the skin surface or deeper layers of the skin may be affected.

• Arc burns, which are a result of an extremely high temperature caused by an electric arc (as high as 35,000 °F) in close proximity to the body. Electric arcs can occur as a result of poor electrical contact or failed insulation.

• Thermal contact burns, which are a result of the skin coming in contact with the hot surfaces of overheated components. They can be caused by contact with objects dispersed as a result of the blast associated with an electric arc.

If a person does suffer a severe shock, it's important to free the victim from the current as quickly as can be done safely. Don't touch the person until the electric power is turned off. You cannot help by becoming a second victim. The victim should be attended to immediately by a person trained in CPR (cardiopulmonary resuscitation).

Ill. 1 Relative magnitude and effect of electric current on the body.

Ill. 2 Typical electric current pathways that stop normal pumping

of the heart.

Ill. 3 Typical safety signs.

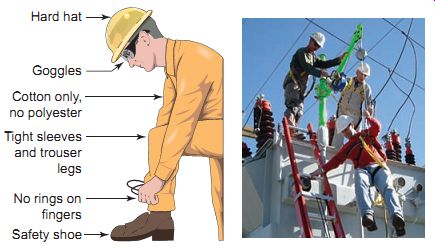

Ill. 4 Appropriate attire should be worn for each particular job site and work activity.

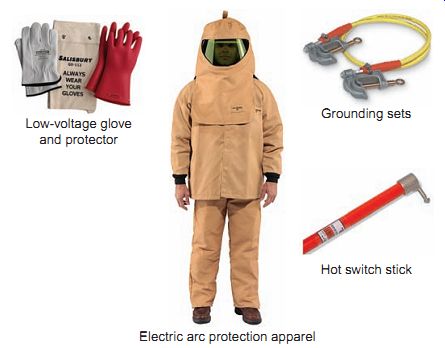

Ill. 5 Electrical safety equipment. Low-voltage glove and protector;

Electric arc protection apparel; Hot switch stick; Grounding sets

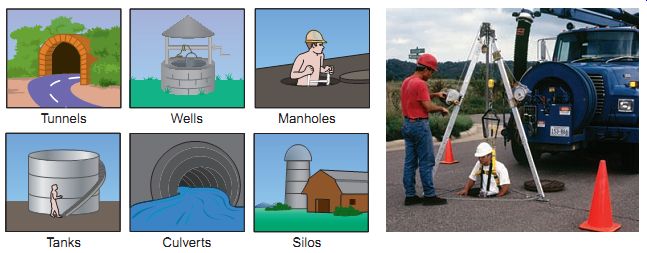

Ill. 6 Confined spaces. Tunnels Wells Manholes Tanks Culverts Silos

Personal Protective Equipment

Construction and manufacturing worksites, by nature, are potentially hazardous places. For this reason, safety has become an increasingly large factor in the working environment. The electrical industry, in particular, regards safety to be unquestionably the most single important priority because of the hazardous nature of the business. A safe operation depends largely upon all personnel being informed and aware of potential hazards. Safety signs and tags indicate areas or tasks that can pose a hazard to personnel and /or equipment. Signs and tags may pro vide warnings specific to the hazard, or they may provide safety instructions (Ill. 3).

To perform a job safely, the proper protective clothing must be used. Appropriate attire should be worn for each particular job site and work activity (Ill. 4). The following points should be observed:

1. Hard hats, safety shoes, and goggles must be worn in areas where they are specified. In addition, hard hats shall be approved for the purpose of the electrical work being performed. Metal hats are not acceptable!

2. Safety earmuffs or earplugs must be worn in noisy areas.

3. Clothing should fit snugly to avoid the danger of becoming entangled in moving machinery. Avoid wearing synthetic-fiber clothing such as polyester material as these types of materials may melt or ignite when exposed to high temperatures and may increase the severity of a burn. Instead always wear cotton clothing.

4. Remove all metal jewelry when working on energized circuits; gold and silver are excellent conductors of electricity.

5. Confine long hair or keep hair trimmed when working around machinery.

A wide variety of electrical safety equipment is avail able to prevent injury from exposure to live electric circuits (Ill. 5). Electrical workers should be familiar with safety standards such as NFP-70E that pertain to the type of protective equipment required, as well as how such equipment shall be cared for. To make sure electrical protective equipment actually performs as designed, it must be inspected for damage before each day's use and immediately following any incident that can reasonably be suspected of having caused damage. All electrical protection equipment must be listed and may include the following:

Rubber Protective Equipment--Rubber gloves are used to prevent the skin from coming into contact with energized circuits. A separate outer leather cover is used to protect the rubber glove from punctures and other damage. Rubber blankets are used to prevent contact with energized conductors or circuit parts when working near exposed energized circuits. All rubber protective equipment must be marked with the appropriate voltage rating and the last inspection date.

It is important that the insulating value of both rubber gloves and blankets have a voltage rating that matches that of the circuit or equipment they are to be used with. Insulating gloves must be given an air test, along with inspection. Twirl the glove around quickly or roll it down to trap air inside. Squeeze the palm, fingers, and thumb to detect any escaping air. If the glove does not pass this inspection it must be disposed of.

Protection Apparel--Special protective equipment available for high-voltage applications include high voltage sleeves, high-voltage boots, nonconductive protective helmets, nonconductive eyewear and face protection, switchboard blankets, and flash suits.

Hot Sticks--Hot sticks are insulated tools designed for the manual operation of high-voltage disconnecting switches, high-voltage fuse removal and insertion, as well as the connection and removal of temporary grounds on high-voltage circuits. A hot stick is made up of two parts, the head, or hood, and the insulating rod. The head can be made of metal or hardened plastic, while the insulating section may be wood, plastic, or other effective insulating materials.

Shorting Probes--Shorting probes are used on de-energized circuits to discharge any charged capacitors or built-up static charges that may be present when power to the circuit's disconnected. Also, when working on or near any high-voltage circuits, shorting probes should be connected and left attached as an extra safety pre caution in the event of any accidental application of voltage to the circuit. When installing a shorting probe, first connect the test clip to a good ground contact.

Next, hold the shorting probe by the handle and hook the probe end over the part or terminal to be grounded.

Never touch any metal part of the shorting probe while grounding circuits or components.

Face Shields--Listed face shields should be worn during all switching operations where there is a possibility of injury to the eyes or face from electrical arcs or flashes, or from flying or falling objects that may result from an electrical explosion.

With proper precautions, there is no reason for you to ever receive a serious electrical shock. Receiving an electrical shock is a clear warning that proper safety measures have not been followed. To maintain a high level of electrical safety while you work, there are a number of pre cautions you should follow. Your individual job will have its own unique safety requirements. However, the following are given as essential basics.

• Never take a shock on purpose.

• Keep material or equipment at least 10 feet away from high-voltage overhead power lines.

• Don't close any switch unless you are familiar with the circuit that it controls and know the reason for its being open.

• When working on any circuit, take steps to ensure that the controlling switch isn't operated in your absence.

Switches should be padlocked open, and warning notices should be displayed (lockout/tagout).

• Avoid working on "live" circuits as much as possible.

• When installing new machinery, ensure that the framework is efficiently and permanently grounded.

• Always treat circuits as "live" until you have proven them to be "dead." Presumption at this point can kill you. It is a good practice to take a meter reading before starting work on a dead circuit.

• Avoid touching any grounded objects while working on electrical equipment.

• Remember that even with a 120-V control system, you may well have a higher voltage in the panel.

Always work so that you are clear of any of the higher voltages. (Even though you are testing a 120-V system, you are most certainly in close proximity to 240-V or 480-V power.)

• Don't reach into energized equipment while it's being operated. This is particularly important in high-voltage circuits.

• Use good electrical practices even in temporary wiring for testing. At times you may need to make alternate connections, but make them secure enough so that they are not in themselves an electrical hazard.

• When working on live equipment containing voltages over approximately 30-V, work with only one hand.

Keeping one hand out of the way greatly reduces the possibility of passing a current through the chest.

• Safely discharge capacitors before handling them.

Capacitors connected in live motor control circuits can store a lethal charge for a considerable time after the voltage to the circuits has been switched off. Although Article 460 of the National Electric Code (NEC) requires an automatic discharge within 1 minute, never assume that the discharge is working! Always verify that there is no voltage present.

Confined spaces can be found in almost any workplace.

Ill. 6 illustrates examples of typical confined spaces.

In general, a "confined space" is an enclosed or partially enclosed space that:

• Is not primarily designed or intended for human occupancy.

• Has a restricted entrance or exit by way of location, size, or means.

• Can represent a risk for the health and safety of any one who enters, because of its design, construction, location, or atmosphere; the materials or substances in it; work activities being carried out in it; or the mechanical, process, and safety hazards present.

All hazards found in a regular workspace can also be found in a confined space. However, they can be even more hazardous in a confined space than in a regular worksite. Hazards in confined spaces can include poor air quality, fire hazard, noise, moving parts of equipment, temperature extremes, poor visibility, and barrier failure resulting in a flood or release of free-flowing solid.

A "permit-required confined space" is a confined space that has specific health and safety hazards associated with it. Permit-required confined spaces require assessment of procedures in compliance with Occupational Safety and Health Administration (OSHA) standards prior to entry.

QUIZ:

1. Does the severity of an electric shock increase or decrease with each of the following changes?

a. A decrease in the source voltage

b. An increase in body current flow

c. An increase in body resistance

d. A decrease in the length of time of exposure

2. a. Calculate the theoretical body current flow (in amperes and milliamperes) of an electric shock victim who comes in contact with a 120-V energy source. Assume a total resistance of 15,000 Ohm (skin, body, and ground contacts).

b. What effect, if any, would this amount of current likely have on the body?

3. Normally a 6-volt lantern battery capable of delivering 2 A of current is considered safe to handle. Why?

4. Why is AC of a 60-Hz frequency considered to be potentially more dangerous than DC of the same voltage and current value?

5. State the piece of electrical safety equipment that should be used to perform each of the following tasks:

a. A switching operation where there is a risk of injury to the eyes or face from an electric arc.

b. Using a multimeter to verify the line voltage on a 3-phase 480 volt system.

c. Opening a manually operated high-voltage disconnect switch.

6. Outline the safety procedure to follow when you are connecting shorting probes across deenergized circuits.

7. List three pieces of personal protection equipment required to be worn on most job sites.

cont to part 2