AMAZON multi-meters discounts AMAZON oscilloscope discounts

1. Need for Reactive Power Compensation

Except in a very few special situations, electrical energy is generated, transmitted, distributed, and utilized as alternating current (AC). However, AC has several distinct disadvantages. One of these is the necessity of reactive power that needs to be supplied along with active power. Reactive power can be leading or lagging. While it is the active power that contributes to the energy consumed, or transmitted, reactive power does not contribute to the energy. Reactive power is an inherent part of the "total power." Reactive power is either generated or consumed in almost every component of the system, generation, transmission, and distribution and eventually by the loads. The impedance of a branch of a circuit in an AC system consists of two components, resistance and reactance. Reactance can be either inductive or capacitive, which contributes to reactive power in the circuit. Most of the loads are inductive, and must be supplied with lagging reactive power. It is economical to supply this reactive power closer to the load in the distribution system.

In this section, reactive power compensation, mainly in transmission systems installed at substations, is discussed. Reactive power compensation in power systems can be either shunt or series. Both will be discussed.

1.1 Shunt Reactive Power Compensation

Since most loads are inductive and consume lagging reactive power, the compensation required is usually supplied by leading reactive power. Shunt compensation of reactive power can be employed either at load level, substation level, or at transmission level. It can be capacitive (leading) or inductive (lagging) reactive power, although in most cases as explained before, compensation is capacitive. The most common form of leading reactive power compensation is by connecting shunt capacitors to the line.

1.2 Shunt Capacitors

Shunt capacitors are employed at substation level for the following reasons:

1. Voltage regulation: The main reason that shunt capacitors are installed at substations is to control the voltage within required levels. Load varies over the day, with very low load from midnight to early morning and peak values occurring in the evening between 4 and 7 pm. Shape of the load curve also varies from weekday to weekend, with weekend load typically low. As the load varies, voltage at the substation bus and at the load bus varies. Since the load power factor is always lagging, a shunt-connected capacitor bank at the substation can raise voltage when the load is high.

The shunt capacitor banks can be permanently connected to the bus (fixed capacitor bank) or can be switched as needed. Switching can be based on time, if load variation is predictable, or can be based on voltage, power factor, or line current.

2. Reducing power losses: Compensating the load lagging power factor with the bus-connected shunt capacitor bank improves the power factor and reduces current flow through the transmission lines, transformers, generators, etc. This will reduce power losses (I2 R losses) in this equipment.

3. Increased utilization of equipment: Shunt compensation with capacitor banks reduces kVA loading of lines, transformers, and generators, which means with compensation they can be used for delivering more power without overloading the equipment.

Reactive power compensation in a power system is of two types-shunt and series. Shunt compensation can be installed near the load, in a distribution substation, along the distribution feeder, or in a transmission substation. Each application has different purposes. Shunt reactive compensation can be inductive or capacitive. At load level, at the distribution substation, and along the distribution feeder, compensation is usually capacitive. In a transmission substation, both inductive and capacitive reactive compensations are installed.

2. Application of Shunt Capacitor Banks in Distribution Systems: A Utility Perspective

The Salt River Project (SRP) is a public power utility serving more than 720,000 (April 2000) customers in central Arizona. Thousands of capacitor banks are installed in the entire distribution system.

The primary usage for capacitor banks in the distribution system is to maintain a certain power factor at peak loading conditions. The target power factor is 0.98 leading at system peak. This figure was set as an attempt to have a unity power factor on the 69 kV side of the substation transformer. The leading power factor compensates for the industrial substations that have no capacitors. The unity power factor maintains a balance with ties to other utilities.

The main purpose of the capacitors is not for voltage support, as the case may be at utilities with long distribution feeders. Most of the feeders in the SRP service area do not have long runs (substations are about 2 miles apart) and load tap changers on the substation transformers are used for voltage regulation.

The SRP system is a summer peaking system. After each summer peak, a capacitor study is performed to determine the capacitor requirements for the next summer. The input to the computer program for evaluating capacitor additions consists of three major components:

• Megawatts and megavars for each substation transformer at peak;

• A listing of the capacitor banks with size and operating status at time of peak;

• The next summer's projected loads

By looking at the present peak MW and Mvars and comparing the results to the projected MW loads, Mvar deficiencies can be determined. The output of the program is reviewed and a listing of potential needs is developed. The system operations personnel also review the study results and their input is included in making final decisions about capacitor bank additions.

Once the list of additional reactive power requirements is finalized, determinations are made about the placement of each bank. The capacitor requirement is developed on a per-transformer basis. The ratio of the kvar connected to kVA per feeder, the position on the feeder of existing capacitor banks, and any concentration of present or future load are all considered in determining the position of the new capacitor banks. All new capacitor banks are 1200 kvar. The feeder type at the location of the capacitor bank determines if the capacitor will be pole-mounted (overhead) or pad-mounted (underground).

Capacitor banks are also requested when new feeders are being proposed for master plan communities, large housing developments, or heavy commercial developments.

Table 1 shows the number and size of capacitor banks in the SRP system in 1998. Table 2 shows the number of line capacitors by type of control.

Substation capacitor banks (three or four per transformer) are usually staged to come on and go off at specific load levels.

TABLE 1 Number and Size of Capacitor Banks in the SRP System

TABLE 2 SRP Line Capacitors by Type of Control

Type of Control | Number of Bank

Current 4 Fixed 450 Time 1760 Temperature 38 (used as fixed) Voltage 5

3. Static VAR Control

Static VAR compensators, commonly known as SVCs, are shunt-connected devices, vary the reactive power output by controlling or switching the reactive impedance components by means of power electronics. This category includes the following equipment:

Thyristor-controlled reactors (TCR) with fixed capacitors (FC)

Thyristor switched capacitors (TSC)

Thyristor-controlled reactors in combination with mechanically or thyristor switched capacitors

SVCs are installed to solve a variety of power system problems:

1. Voltage regulation

2. Reduce voltage flicker caused by varying loads like arc furnace, etc.

3. Increase power transfer capacity of transmission systems

4. Increase transient stability limits of a power system

5. Increase damping of power oscillations

6. Reduce temporary overvoltages

7. Damp subsynchronous oscillations

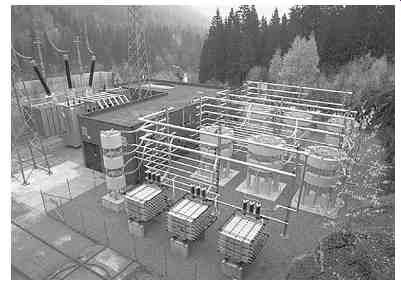

A view of an SVC installation is shown in FIG. 1.

3.1 Description of SVC

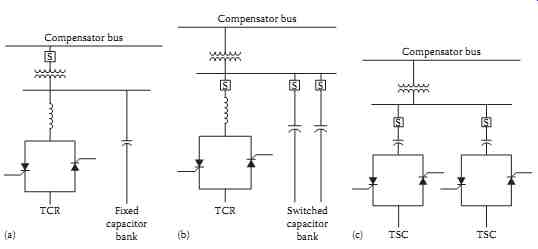

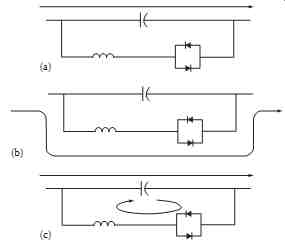

FIG. 2 shows three basic versions of SVC. FIG. 2a shows configuration of TCR with fixed capacitor banks. The main components of an SVC are thyristor valves, reactors, the control system, and the step-down transformer.

FIG. 1 View of SVC installation. (Photo courtesy of ABB Inc., Auburn

Hills, MI.)

FIG. 2 Three versions of SVC. (a) TCR with fixed capacitor bank; (b)

TCR with switched capacitor banks; and (c) TSC compensator.

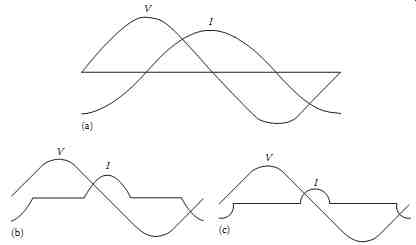

FIG. 3 TCR voltage (V) and current (I) waveforms for three conduction

levels. Thyristor gating angle = a; conduction angle = s. (a) a = 90° and

s = 180°; (b) a = 120° and s = 120°; and (c) a = 150° and s = 60°.

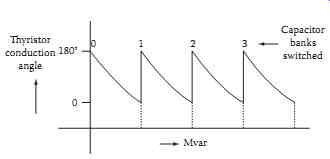

FIG. 4 Reactive power variation of TCR with switched capacitor banks.

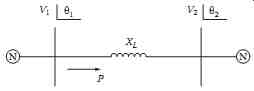

FIG. 5 Power flow through transmission line.

3.2 How Does SVC Work?

As the load varies in a distribution system, a variable voltage drop will occur in the system impedance, which is mainly reactive. Assuming the generator voltage remains constant, the voltage at the load bus will vary. The voltage drop is a function of the reactive component of the load current, and system and transformer reactance. When the loads change very rapidly, or fluctuate frequently, it may cause "volt age flicker" at the customers' loads. Voltage flicker can be annoying and irritating to customers because of the "lamp flicker" it causes. Some loads can also be sensitive to these rapid voltage fluctuations.

An SVC can compensate voltage drop for load variations and maintain constant voltage by control ling the duration of current flow in each cycle through the reactor. Current flow in the reactor can be controlled by controlling the gating of thyristors that control the conduction period of the thyristor in each cycle, from zero conduction (gate signal off) to full-cycle conduction. In FIG. 2a, for example, assume the MVA of the fixed capacitor bank is equal to the MVA of the reactor when the reactor branch is conducting for full cycle. Hence, when the reactor branch is conducting full cycle, the net reactive power drawn by the SVC (combination of capacitor bank and TCR) will be zero. When the load reactive power (which is usually inductive) varies, the SVC reactive power will be varied to match the load reactive power by controlling the duration of the conduction of current in the thyristor-controlled reactive power branch. FIG. 3 shows current waveforms for three conduction levels, 60°, 120°, and 180°. FIG. 3a shows waveforms for thyristor gating angle (a) of 90°, which gives a conduction angle (s) of 180° for each thyristor. This is the case for full-cycle conduction, since the two back-to-back thyristors conduct in each half-cycle. This case is equivalent to shorting the thyristors. FIG. 3b is the case when the gating signal is delayed for 30° after the voltage peak, and results in a conduction angle of 120°.

FIG. 3c is the case for a = 150° and s = 60°.

With a fixed capacitor bank as shown in FIG. 2a, it is possible to vary the net reactive power of the SVC from 0 to the full capacitive VAR only. This is sufficient for most applications of voltage regulation, as in most cases only capacitive VARs are required to compensate the inductive VARs of the load.

If the capacitor can be switched on and off, the Mvar can be varied from full inductive to full capacitive, up to the rating of the inductive and capacitive branches. The capacitor bank can be switched by mechanical breakers (see FIG. 2b) if time delay (usually 5-10 cycles) is not a consideration, or they can be switched fast (less than 1 cycle) by thyristor switches (see FIG. 2c).

Reactive power variation with switched capacitor banks for an SVC is shown in FIG. 4.

4. Series Compensation

Series compensation is commonly used in high-voltage AC transmission systems. They were first installed in the late 1940s. Series compensation increases power transmission capability, both steady state and transient, of a transmission line. Since there is an increasing opposition from the public to construction of EHV transmission lines, series capacitors are attractive for increasing the capabilities of transmission lines. Series capacitors also introduce some additional problems for the power system.

These will be discussed later.

Power transmitted through the transmission system (shown in FIG. 5) is given by…

…Where…

P2 is the power transmitted through the transmission system

V1 is the voltage at sending end of the line

V2 is the voltage at receiving end of transmission line

XL is the reactance of the transmission line

d is the phase angle between V1 and V2

Equation 19.1 shows that if the total reactance of a transmission system is reduced by installing capacitance in series with the line, the power transmitted through the line can be increased.

With a series capacitor installed in the line, Equation 1 can be written as...

...where K = XC/XL is the degree of compensation, usually expressed in percent. A 70% series compensation means the value of the series capacitor in ohms is 70% of the line reactance.

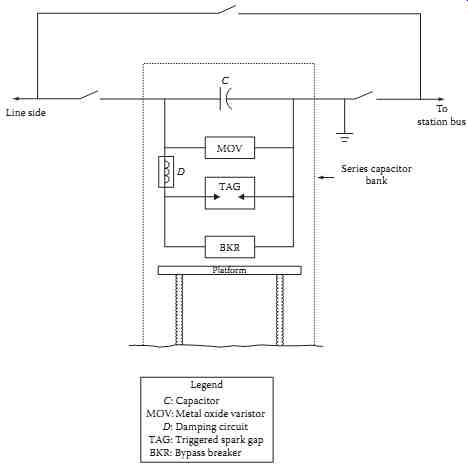

FIG. 6 Schematic one-line diagram of series capacitor bank.

5. Series Capacitor Bank

A series capacitor bank consists of a capacitor bank, overvoltage protection system, and a bypass breaker, all elevated on a platform, which is insulated for the line voltage. See FIG. 6. The overvoltage protection is comprised of a zinc oxide varistor and a triggered spark gap, which are connected in parallel to the capacitor bank, and a damping reactor. Prior to the development of the high-energy zinc oxide varistor in the 1970s, a silicon carbide nonlinear resistor was used for overvoltage protection.

Silicon carbide resistors require a spark gap in series because the nonlinearity of the resistors is not high enough. The zinc oxide varistor has better nonlinear resistive characteristics, provides better protection, and has become the standard protection system for series capacitor banks.

The capacitor bank is usually rated to withstand the line current for normal power flow conditions and power swing conditions. It is not economical to design the capacitors to withstand the currents and voltages associated with faults. Under these conditions, capacitors are protected by a metal oxide varistor (MOV) bank. The MOV has a highly nonlinear resistive characteristic and conducts negligible current until the voltage across it reaches the protective level. For internal faults, which are defined as faults within the line section in which the series capacitor bank is located, fault currents can be very high. Under these conditions, both the capacitor bank and MOV will be bypassed by the "triggered spark gap." The damping reactor (D) will limit the capacitor discharge current and damps the oscillations caused by spark gap operation or when the bypass breaker is closed. The amplitude, frequency of oscillation, and rate of damping of the capacitor discharge current will be determined by the circuit parameters, C (series capacitor), L (damping inductor), and resistance in the circuit, which in most cases are losses in the damping reactor.

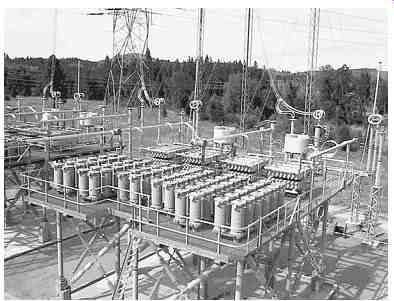

A view of series capacitor bank installation is shown in FIG. 7.

FIG. 7 Aerial view of 500 kV series capacitor installation. (ABB Inc.)

5.1 Description of Main Components

5.1.1 Capacitors

The capacitor bank for each phase consists of several capacitor units in series-parallel arrangement, to make up the required voltage, current, and Mvar rating of the bank. Each individual capacitor unit has one porcelain bushing. The other terminal is connected to the stainless steel casing. The capacitor unit usually has a built-in discharge resistor inside the case. Capacitors are usually all film design with insulating fluid that is non-PCB. Two types of fuses are used for individual capacitor units-internally fused or externally fused. Externally fused units are more commonly used in the United States. Internally fused capacitors are prevalent in European installations.

5.1.2 Metal Oxide Varistor

A metal oxide varistor (MOV) is built from zinc oxide disks in series and parallel arrangement to achieve the required protective level and energy requirement. One to four columns of zinc oxide disks are installed in each sealed porcelain container, similar to a high-voltage surge arrester. A typical MOV protection system contains several porcelain containers, all connected in parallel. The number of parallel zinc oxide disk columns required depends on the amount of energy to be discharged through the MOV during the worst-case design scenario. Typical MOV protection system specifications are as follows.

The MOV protection system for the series capacitor bank is usually rated to withstand energy discharged for all faults in the system external to the line section in which the series capacitor bank is located. Faults include single-phase, phase-to-phase, and three-phase faults. The user should also specify the fault duration. Most of the faults in EHV systems will be cleared by the primary protection system in three to four cycles. Backup fault clearing can be from 12 to 16 cycles duration. The user should specify whether the MOV should be designed to withstand energy for backup fault clearing times. Sometimes it is specified that the MOV be rated for all faults with primary protection clearing time, but for only single-phase faults for backup fault clearing time. Statistically, most of the faults are single-phase faults.

The energy discharged through the MOV is continuously monitored and if it exceeds the rated value, the MOV will be protected by the firing of a triggered air gap, which will bypass the MOV.

5.1.3 Triggered Air Gap

The triggered air gap provides a fast means of bypassing the series capacitor bank and the MOV system when the trigger signal is issued under certain fault conditions (e.g., internal faults) or when the energy discharged through the MOV exceeds the rated value. It typically consists of a gap assembly of two large electrodes with an air gap between them. Sometimes two or more air gaps in series can also be employed. The gap between the electrodes is set such that the gap assembly sparkover voltage without trigger signal will be substantially higher than the protective level of the MOV, even under the most unfavorable atmospheric conditions.

5.1.4 Damping Reactor

A damping reactor is usually an air-core design with parameters of resistance and inductance to meet the design goal of achieving the specified amplitude, frequency, and rate of damping. The capacitor discharge current when bypassed by a triggered air gap or a bypass breaker will be damped oscillation with amplitude, rate of damping, and frequency determined by circuit parameters.

5.1.5 Bypass Breaker

The bypass breaker is usually a standard line circuit breaker with a rated voltage based on voltage across the capacitor bank. In most of the installations, the bypass breaker is located separate from the capacitor bank platform and outside the safety fence. This makes maintenance easy. Both terminals of the breaker standing on insulator columns are insulated for the line voltage. It is usually an SF6 puffer-type breaker, with controls at ground level.

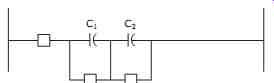

FIG. 8 Breaker controlled variable series compensation.

5.1.6 Relay and Protection System

The relay and protection system for the capacitor bank is located at ground level, in the station control room, with information from and to the platform transmitted via fiber-optic cables. The present practice involves all measured quantities on the platform being transmitted to ground level, with all signal processing done at ground level.

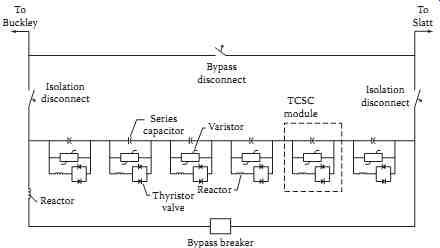

FIG. 9 One-line diagram of TCSC installed at Slatt substation.

FIG. 10 Current flow during various operating modes of TCSC. (a) No thyristor

value current (gating blocked). (b) Bypassed with thyristor. (c) Inserted

with vernier control, circulating some current through thyristor value.

5.2 Subsynchronous Resonance

Series capacitors, when radially connected to the transmission lines from the generation near by, can create a subsynchronous resonance (SSR) condition in the system under some circumstances. SSR can cause damage to the generator shaft and insulation failure of the windings of the generator. This phenomenon is well described in several textbooks, given in the reference list at the end of this section.

5.3 Adjustable Series Compensation

The ability to vary the series compensation will give more control of power flow through the line, and can improve the dynamic stability limit of the power system. If the series capacitor bank is installed in steps, bypassing one or more steps with bypass breakers can change the amount of series compensation of the line. For example, as shown in FIG. 8, if the bank consists of 33% and 67% of the total compensation, four steps, 0%, 33%, 67%, and 100%, can be obtained by bypassing both banks, smaller bank (33%), larger bank (67%), and not bypassing both banks, respectively.

Varying the series compensation by switching with mechanical breakers is slow, which is acceptable for the control of steady-state power flow. However, for improving the dynamic stability of the system, series compensation has to be varied quickly. This can be accomplished by thyristor-controlled series compensation (TCSC).

5.4 Thyristor-Controlled Series Compensation

Thyristor-controlled series compensation (TCSC) provides fast control and variation of the impedance of the series capacitor bank. To date (1999), three prototype installations, one each by ABB, Siemens, and the General Electric Company (GE), have been installed in the United States. TCSC is part of the flexible AC transmission system (FACTS), which is an application of power electronics for control of the AC system to improve the power flow, operation, and control of the AC system. TCSC improves the sys tem performance for SSR damping, power swing damping, transient stability, and power flow control.

The latest of the three prototype installations is the one at the Slatt 500 kV substation in the Slatt- Buckley 500 kV line near the Oregon-Washington border in the United States. This is jointly funded by the Electric Power Research Institute (EPRI), the Bonneville Power Administration (BPA), and the General Electric Company (GE). A one-line diagram of the Slatt TCSC is shown in FIG. 9. The capacitor bank (8 Ohm) is divided into six identical TCSC modules. Each module consists of a capacitor (1.33 Ohm), back-to-back thyristor valves controlling power flow in both directions, a reactor (0.2 Ohm), and a varistor. The reactors in each module, in series with thyristor valves, limit the rate of change of cur rent through the thyristors. The control of current flow through the reactor also varies the impedance of the combined capacitor-reactor combination, giving the variable impedance. When thyristor gating is blocked, complete line current flows through the capacitance only, and the impedance is 1.33 ohm capacitive (see FIG. 10a). When the thyristors are gated for full conduction ( FIG. 10b), most of the line current flows through the reactor-thyristor branch (a small current flows through the capacitor) and the resulting impedance is 0.12 Ohm inductive. If thyristors are gated for partial conduction only ( FIG. 10c), circulating current will flow between capacitor and inductor, and the impedance can be varied from 1.33 to 4.0 Ohm, depending on the angle of conduction of the thyristor valves. The latter is called the vernier operating mode.

The complete capacitor bank with all six modules can be bypassed by the bypass breaker. This bypass breaker is located outside the main capacitor bank platform, similar to the case for the conventional series capacitor bank. There is also a reactor connected in series with the bypass breaker to limit the magnitude of capacitor discharge current through the breaker. All reactors are of air-core dry-type design and rated for the full line current rating. MOVs connected in parallel with the capacitors in each module provide overvoltage protection. The MOV for a TCSC requires significantly less energy absorption capability than is the case for a conventional series capacitor of comparable size, because gating of thyristor valves provides quick protection for faulted conditions.