AMAZON multi-meters discounts AMAZON oscilloscope discounts

.

OVERVIEW:

1. Traditional Line Design Practice: Structure Types in Use • Factors Affecting Structure Type Selection

2. Current Deterministic Design Practice: Reliability Level • Security Level

3. Improved Design Approaches

4. General Design Criteria-Methodology

An overhead transmission line (OHTL) is a very complex, continuous, electrical/mechanical system. Its function is to transport power safely from the circuit breaker on one end to the circuit breaker on the other. It’s physically composed of many individual components made up of different materials having a wide variety of mechanical properties, such as:

• Flexible vs. rigid

• Ductile vs. brittle

• Variant dispersions of strength

• Wear and deterioration occurring at different rates when applied in different applications within one micro-environment or in the same application within different micro-environments

This discussion will address the nature of the structures which are required to provide the clearances between the current-carrying conductors, as well as their safe support above the earth. During this discussion, reference will be made to the following definitions:

Capability: Capacity ( ×) availability

Reliability level: Ability of a line (or component) to perform its expected capability

Security level: Ability of a line to restrict progressive damage after the failure of the first component

Safety level: Ability of a line to perform its function safely

===

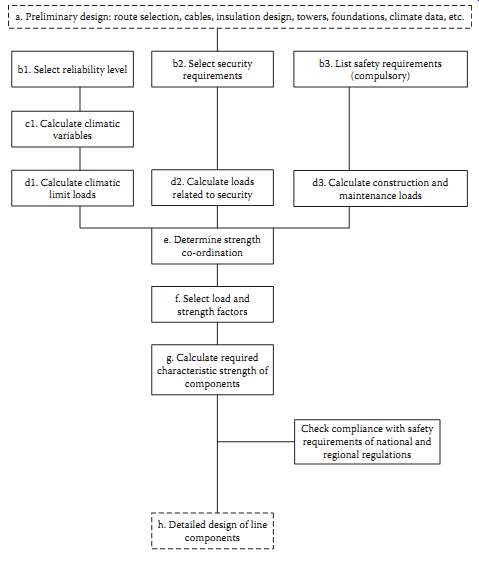

Event A × OCFa Event B × OCFb Event C × OCFc NESC × OCF (from Code) Load 0 Loading event Design load

Above: FIG. 1 Development of a loading agenda.

===

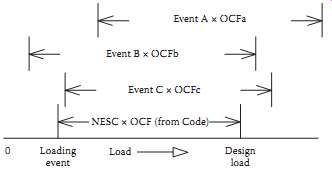

Material cost (+) Erection cost =Total installed costs Final line configuration Conventional Performance criteria Line route conditions Static loads Clearances Topography Constraints Accessibility Ruling span Size/select components Local practice

Above: FIG. 2 Search for cost effectiveness.

===

Traditional Line Design Practice

Present line design practice views the support structure as an isolated element supporting half span of conductors and overhead ground wires (OHGWs) on either side of the structure. Based on the voltage level of the line, the conductors and OHGWs are con figured to provide, at least, the minimum clearances mandated by the National Electrical Safety Code (NESC) (IEEE, 1990), as well as other applicable codes.

This configuration is designed to control the separation of:

• Energized parts from other energized parts

• Energized parts from the support structure of other objects located along the r-o-w

• Energized parts above ground

The NESC divides the United States into three large global loading zones: heavy, medium, and light and specifies radial ice thickness/wind pressure/temperature relationships to define the minimum load levels that must be used within each loading zone. In addition, the Code introduces the concept of an Overload Capacity Factor (OCF) to cover uncertainties stemming from the:

• Likelihood of occurrence of the specified load

• Dispersion of structure strength

• Grade of construction

• Deterioration of strength during service life

• Structure function (suspension, dead-end, angle)

• Other line support components (guys, foundations, etc.)

Present line design practice normally consists of the following steps:

1. The owning utility prepares an agenda of loading events consisting of

a. Mandatory regulations from the NESC and other codes

b. Climatic events believed to be representative of the line's specific location

c. Contingency loading events of interest; i.e., broken conductor

d. Special requirements and expectations

Each of these loading events is multiplied by its own OCF to cover uncertainties associated with it to produce an agenda of final ultimate design loads (see FIG. 1).

2. A ruling span is identified based on the sag/tension requirements for the preselected conductor.

3. A structure type is selected based on past experience or on recommendations of potential structure suppliers.

4. Ultimate design loads resulting from the ruling span are applied statically as components in the longitudinal, transverse, and vertical directions, and the structure deterministically designed.

5. Using the loads and structure configuration, ground line reactions are calculated and used to accomplish the foundation design.

6. The ruling span line configuration is adjusted to fit the actual r-o-w profile.

7. Structure/foundation designs are modified to account for variation in actual span lengths, changes in elevation, and running angles.

8. Since most utilities expect the tangent structure to be the weakest link in the line system, hard ware, insulators, and other accessory components are selected to be stronger than the structure.

In as much as structure types are available in a wide variety of concepts, materials, and costs, several iterations would normally be attempted in search of the most cost effective line design based on total installed costs (see FIG. 2).

While deterministic design using static loads applied in quadrature is a convenient mathematical approach, it’s obviously not representative of the real-world exposure of the structural support system.

OHTLs are tens of yards wide and miles long and usually extend over many widely variant micro-topographical and microclimatic zones, each capable of delivering unique events consisting of magnitude of load at a probability-of-occurrence. That component along the r-o-w that has the highest probability of occurrence of failure from a loading event becomes the weak link in the structure design and establishes the reliability level for the total line section. Since different components are made from different materials that have different response characteristics and that wear, age, and deteriorate at different rates, it’s to be expected that the weak link:

• Will likely be different in different line designs

• Will likely be different in different site locations within the same line

• Can change from one component to another over time

--1.1 Structure Types in Use

Structures come in a wide variety of styles:

• Lattice towers

• Cantilevered or guyed poles and masts

• Framed structures

• Combinations of the above

They are available in a wide variety of materials:

• Metal:

Galvanized steel and aluminum rods, bars and rolled shapes

Fabricated plate Tubes

• Concrete:

Spun with pretensioned or post-tensioned reinforcing cable Statically cast nontensioned reinforcing steel Single or multiple piece

• Wood

As grown

Glued laminar

• Plastics

• Composites

• Crossarms and braces

• Variations of all of the above

Depending on their style and material contents, structures vary considerably in how they respond to load. Some are rigid. Some are flexible. Those structures that can safely deflect under load and absorb energy while doing so, provide an ameliorating influence on progressive damage after the failure of the first element.

--1.2 Factors Affecting Structure Type Selection

There are usually many factors that impact on the selection of the structure type for use in an OHTL. Some of the more significant are briefly identified below.

Erection technique: It’s obvious that different structure types require different erection techniques. As an example, steel lattice towers consist of hundreds of individual members that must be bolted together, assembled, and erected onto the four previously installed foundations. A tapered steel pole, on the other hand, is likely to be produced in a single piece and erected directly on its previously installed foundation in one hoist. The lattice tower requires a large amount of labor to accomplish the considerable number of bolted joints, whereas the pole requires the installation of a few nuts applied to the foundation anchor bolts plus a few to install the crossarms. The steel pole requires a large-capacity crane with a high reach which would probably not be needed for the tower. Therefore, labor needs to be balanced against the need for large, special equipment and the site's accessibility for such equipment.

Public concerns: Probably the most difficult factors to deal with arise as a result of the concerns of the general public living, working, or coming in proximity to the line. It’s common practice to hold public hearings as part of the approval process for a new line. Such public hearings offer a platform for neighbors to express individual concerns that generally must be satisfactorily addressed before the required permit will be issued. A few comments demonstrate this problem.

The general public usually perceives transmission structures as "eyesores" and distractions in the local landscape. To combat this, an industry study was made in the late 1960s sponsored by the Edison Electric Institute and accomplished by Henry Dreyfuss, the internationally recognized industrial designer. While the guidelines did not overcome all the objections, they did provide a means of satisfying certain very highly controversial installations.

Parents of small children and safety engineers often raise the issue of lattice masts, towers, and guys, constituting an "attractive challenge" to determined climbers, particularly youngsters.

Inspection, assessment, and maintenance: Depending on the owning utility, it’s likely their in-house practices will influence the selection of the structure type for use in a specific line location. Inspections and assessment are usually made by human inspectors who use diagnostic technologies to augment their personal senses of sight and touch. The nature and location of the symptoms of critical interest are such that they can be most effectively examined from specific perspectives. Inspectors must work from the most advantageous location when making inspections. Methods can include observations from ground or fly-by patrol, climbing, bucket trucks, or helicopters. Likewise, there are certain maintenance activities that are known or believed to be required for particular structure types. The equipment necessary to maintain the structure should be taken into consideration during the structure type selection process to assure there will be no unexpected conflict between maintenance needs and r-o-w restrictions.

Future upgrading or uprating: Because of the difficulty of procuring r-o-w's and obtaining the necessary permits to build new lines, many utilities improve their future options by selecting structure types for current line projects that will permit future upgrading and/or uprating initiatives.

Current Deterministic Design Practice

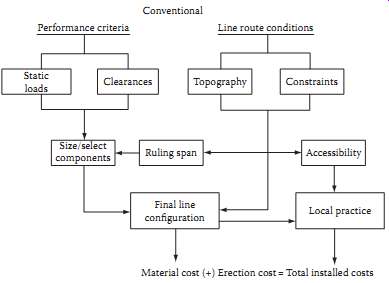

FIG. 3 shows a loading agenda for a double-circuit, 345-kV line built in the upper Midwest region of the United States on steel lattice towers. Over and above the requirements of the NESC, the utility had specified these loading events:

• A heavy wind condition

• A wind on bare tower

• Two maximum vertical loads on the OHGW and conductor supports

• Two broken wire contingencies

TANGENT AND LIGHT ANGLE SUSPENSION TOWER - 345 DOUBLE CIRCUIT OHGW: Two 7/16? diameter galvanized steel strand

Conductors: Six twin conductor bundles of 1431 KCM 45/7 ACSR

Weight span: 1650 ft Wind span: 1100 ft Line angle: 0° to 2°

====

Above: FIG. 3 Example of loading agenda.

Load Case| Load Event | Radial Ice (?) | Wind Pressure Wire (psf ) | Wind Pressure Structure (psf ) | Load Direction | OCF

[1 2 3 4 5 6 7]

[NESC Heavy One broken OHGW combined with wind and ice One broken conductor bundle combined with wind and ice Heavy wind Wind on bare tower (no conductors or OHGW) Vertical load at any OHGW support of 3,780 lbs. (not simultaneously) Vertical load at any conductor support of 17,790 lbs. (not simultaneously)]

====

Load case | Load event

NESC heavy One broken OHGW combined with wind and ice One broken conductor bundle combined with wind and ice Heavy wind Wind on bare tower (no conductors or OHGW) Vertical load at any conductor support of 17,790 lbs.

(not simultaneously) Vertical load at any OHGW support of 3780 lbs.

(not simultaneously)

Above: FIG. 4 Results of deterministic design.

===

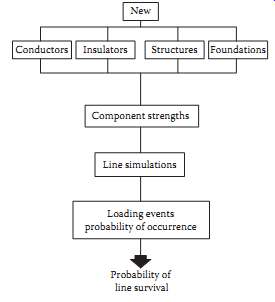

New Conductors Insulators Structures Foundations Component strengths Line simulations Loading events probability of occurrence Probability of line survival

Above: FIG. 5 Line simulation study.

===

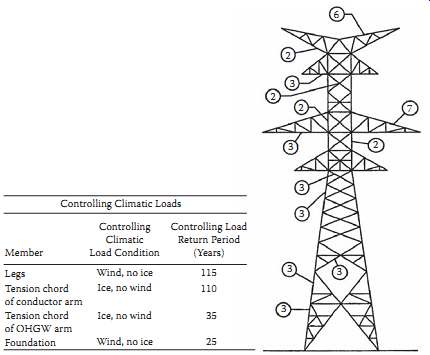

Controlling Climatic Loads

Member:

Legs Tension chord of conductor arm Tension chord of OHGW arm Foundation

Controlling Climatic

Load Condition:

Wind, no ice Wind, no ice Ice, no wind Ice, no wind

Controlling Load Return Period

(Years)

115 110 35 25

Above: FIG. 6 Simulation study output.

===

It was expected that this combination of loading events would result in a structural support design with the capability of sustaining 50-year recurrence loads likely to occur in the general area where the line was built. FIG. 4 shows that different members of the structure, as designed, were under the control of different loading cases from this loading agenda. While interesting, this does not

• Provide a way to identify weak links in the support structure

• Provide a means for predicting performance of the line system

• Provide a framework for decision-making

--2.1 Reliability Level

The shortcomings of deterministic design can be demonstrated by using 3D modeling/simulation technology which is in current use in forensic investigation of line failures. The approach is outlined in FIG. 5. After the structure (as designed) is properly modeled, loading events of increasing magnitude are analytically applied from different directions until the actual critical capacity for each key member of interest is reached. The probability of occurrence for those specific loading events can then be predicted for the specific location of that structure within that line section by professionals skilled in the art of micrometeorology.

FIG. 6 shows a few of the key members in the example for FIG. 4:

• The legs had a probability of failure in that location of once in 115 years.

• Tension chords in the conductor arm and OHGW arm had probabilities of failure of 110 and 35 years, respectively.

• A certain wind condition at an angle was found to be critical for the foundation design with a probability of occurrence at that location of once in 25 years.

Some interesting observations can be drawn:

• The legs were conservatively designed.

• The loss of an OHGW is a more likely event than the loss of a conductor.

• The foundation was found to be the weak link.

In addition to the interesting observations on relative reliability levels of different components within the structural support system, the output of the simulation study also provides the basis for a decision making process which can be used to determine the cost effectiveness of management initiatives. Under the simple laws of statistics, when there are two independent outcomes to an event, the probability of the first outcome is equal to one minus the probability of the second. When these outcomes are survival and failure:

Annual probability of survival 1 Annual probability of failure ...

If it’s desired to know what the probability of survival is over an extended length of time, i.e., n years of service life:

Applying this principle to the components in the deterministic structure design and considering a 50-year service life as expected by the designers:

• The legs had a Ps of 65%

• The tension chord in the conductor arm had a Ps of 63%

• The tension chord of the OHGW arm had a Ps of 23%

• The foundation had a Ps of 13%

--2.2 Security Level

It should be remembered, however, that the failure of every component does not necessarily progress into extensive damage. A comparison of the total risk that would result from the initial failure of components of interest can be accomplished by making a security-level check of the line design.

Since the OHTL is a contiguous mechanical system, the forces from the conductors and OHGWs on one side of each tangent structure are balanced and restrained by those on the other side. When a critical component in the conductor/OHGW system fails, energy stored within the conductor system is released suddenly and sets up unbalanced transients that can cause failure of critical components at the next structure. This can set off a cascading effect that will continue to travel downline until it encounters a point in the line strong enough to withstand the unbalance. Unfortunately, a security check of the total line cannot be accomplished from the information describing the one structure in FIG. 4; but perhaps some generalized observations can be drawn for demonstration purposes.

Since the structure was designed for broken conductor bundle and broken OHGW contingencies, it appears the line would not be subjected to a cascade from a broken bare conductor, but what if the conductor was coated with ice at the time? Since ice increases the energy trapped within the conductor prior to release, it might be of interest to determine how much ice would be "enough." Three-dimensional modeling would be employed to simulate ice coating of increasing thicknesses until the critical amount is defined. A proper micrometeorological study could then identify the probability of occurrence of a storm system capable of delivering that amount of ice at that specific location.

In the example, a wind condition with no ice was identified that would be capable of causing foundation failure once every 25 years. A security-level check would predict the amount of resulting losses and damages that would be expected from this initiating event compared to the broken-conductor-under ice-load contingencies.

Improved Design Approaches

The above discussion indicates that technologies are available today for assessing the true capability of an OHTL that was created using the conventional practice of specifying ultimate static loads and designing a structure that would properly support them. Because there are many different structure types made from different materials, this was not always straightforward. Accordingly, many technical societies prepared guidelines on how to design the specific structure needed. These are listed in the accompanying references. The interested reader should realize that these documents are subject to periodic review and revision and should, therefore, seek the most current version.

While the technical fraternity recognizes that the mentioned technologies are useful for analyzing existing lines and determining management initiatives, something more direct for designing new lines is needed. There are many efforts under way. The most promising of these is Improved Design Criteria of OHTLs Based on Reliability Concepts, currently under development by CIGRE Study Committee 22: Recommendations for Overhead Lines. Section 10.A outlines the methodology involved in words and in a diagram. The technique is based on the premise that loads and strengths are stochastic variables and the combined reliability is computable if the statistical functions of loads and strength are known. The referenced report has been circulated internationally for trial use and comment. It’s expected that the returned comments will be carefully considered, integrated into the report, and the final version submitted to the International Electrotechnical Commission (IEC) for consideration as an International Standard.

General Design Criteria-Methodology

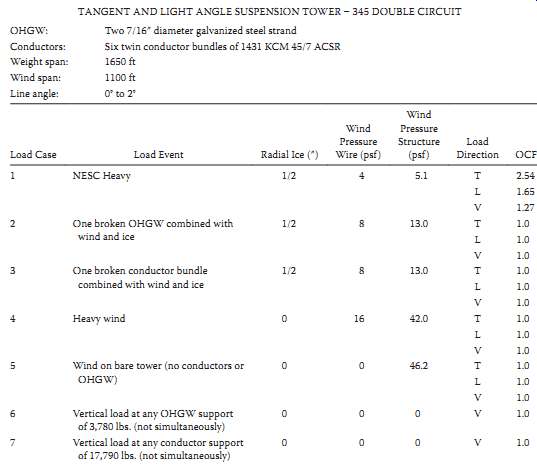

The recommended methodology for designing transmission line components is summarized in FIG. 7 and can be described as follows:

a. Gather preliminary line design data and available climatic data.*

b1. Select the reliability level in terms of return period of design loads. (Note: Some national regulations and/or codes of practice sometimes impose design requirements, directly or indirectly, that may restrict the choice offered to designers.)

b2. Select the security requirements (failure containment).

b3. List safety requirements imposed by mandatory regulations and construction and maintenance loads.

c. Calculate climatic variables corresponding to selected return period of design loads.

d1. Calculate climatic limit loadings on components.

d2. Calculate loads corresponding to security requirements.

d3. Calculate loads related to safety requirements during construction and maintenance.

e. Determine the suitable strength coordination between line components.

f. Select appropriate load and strength factors applicable to load and strength equations.

g. Calculate the characteristic strengths required for components.

h. Design line components for the above strength requirements.

This document deals with items (b) through (g). Items (a) and (h) are not part of the scope of this document. They are identified by a dotted frame in FIG. 7.

Source: Improved design criteria of overhead transmission lines based on reliability concepts, CIGRE SC22 Report, October, 1995.

===

a. Preliminary design: route selection, cables, insulation design, towers, foundations, climate data, etc.

b1. Select reliability level

b2. Select security requirements

b3. List safety requirements (compulsory)

d1. Calculate climatic limit loads

c1. Calculate climatic variables

d2. Calculate loads related to security

d3. Calculate construction and maintenance loads

e. Determine strength co-ordination

f. Select load and strength factors

g. Calculate required characteristic strength of components

Check compliance with safety requirements of national and regional regulations

h. Detailed design of line components