AMAZON multi-meters discounts AMAZON oscilloscope discounts

[Note: "Tables" and various equations (denoted by "e.") are not yet avail., but coming soon.]

1. Surge Voltage Sources and Waveshapes

Surge voltages are a significant hazard in power transmission and distribution systems. Surges are the causes of much equipment failure, such as downed conductors, fires, and step and touch potentials, which may injure people nearby. The design manufacture and installation of electrical power equipment and systems must be fundamentally based on safety both for users of the equipment and for those who operate and maintain it. As with other electrical hazards, there are extensive sets of industry standards, governmental regulations, and electrical and building codes which must be followed. The first hazard of high voltages, as we have seen, is the threat of shock, which with high voltage transients may jump across the air to a person standing near an energized conductor. Even if a person is touching a conductor, the high voltage causes a higher current to flow through them than would otherwise happen. However, the short duration and high frequency of transients may mitigate these effects to some extent. High transient voltages can cause the failure of insulation, the failure of fuses and circuit breakers to interrupt faults, the destruction of load equipment, and resulting explosions, fires, and other hazards.

Surges may be caused by a variety of sources:

Lightning strokes may hit a variety of locations within the power system. Shielding failures may cause a direct stroke to hit a phase conductor. When a lightning stroke hits an overhead ground wire, it may cause the voltage on the tower to exceed the voltage on the conductors, causing a back flashover across the insulator string. When there is a lightning strike to the earth near the tower, an induced flashover can result.

Power equipment itself may cause transient overvoltages, even during normal operation.

Forced interruption of current during switching (current chop) can cause significant overvoltages in some cases. Switching of thyristors, vacuum switches, and fast circuit breakers can cause energization transients. When the current changes rapidly, causes voltage surges due to sudden change of current. An example of this is the blowing of current-limiting fuses (CLFs). Restriking is arcing across the contacts during fault interruption by circuit-switching devices.

This causes voltage increases similar to that due to arcing ground faults on an ungrounded LV system. Another cause of overvoltage transients is sudden contact between MV and LV system conductors.

While voltage transients have very fast rise times when generated, they may be considerably slowed by passing through power system conductors and equipment. Rise times may be limited by the surge passing through isolation transformers, passing through a system with many stub taps, surge capacitor protection, and snubber circuits.

The surge voltage waveshapes are defined in standard test procedures (IEEE, 2012b). The equation for the surge voltage is called the impulse function:

eqn.1

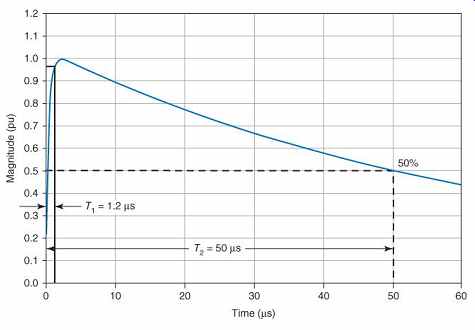

The full-wave impulse test, shown in FIG. 1 has a rise time of and decays to 50% of the peak value in . This is called the 1.2/50 impulse wave. Using (eqn.1), , while. The peak or crest voltage used in the test is the basic lightning impulse level (BIL) of the system. This approximates the shape of the surge from lightning.

FIG. 1: 1.2 µs × 50 µs lightning surge for full-wave BIL test.

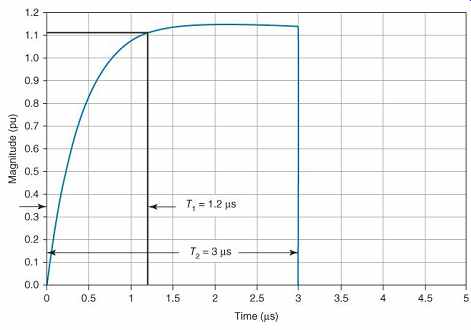

The chopped-wave impulse test (FIG. 2) has a rise time, and the voltage is chopped after suitable time. The crest voltage is set to 110-115% of the system BIL.

FIG. 2: 1.2 µs waveform for chopped-wave test.

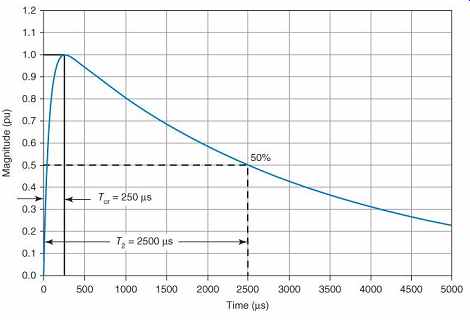

FIG. 3: 250 µs × 2500 µs switching surge for BSL test.

The switching surge test uses a slow front waveform with one of the following characteristics:

1. Time to crest 30-60 µs

2. Time to crest 150-300 µs

3. Time to crest 1000-2000 µs.

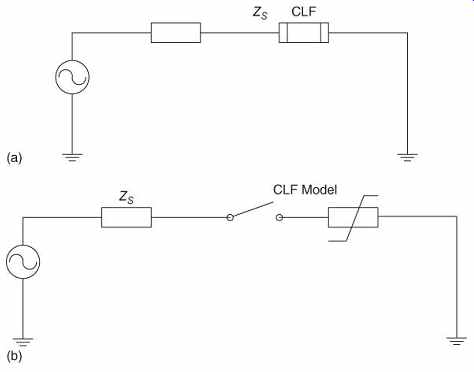

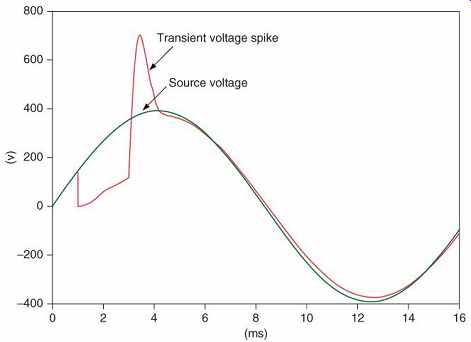

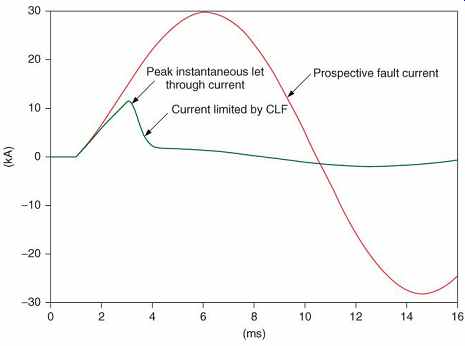

For a 250/2500 impulse, an example of which is shown in FIG. 3, and in (eqn.1). The switching surge caused by sudden interruption of fault current by a CLF) develops when the available (prospective) fault current is reduced to less than its normal value by the melting of the fusible element. In a CLF, the links are usually silver, buried in fine quartz sand inside the fuse's cylindrical casing. The melting fuse link also melts the sand, forming a glass-like insulating barrier to form, rapidly interrupting the arcing fault current. The reduced current is called the let-through current. The di/dt caused a rapid increase in voltage producing the transient voltage spike. The CLF can be modeled as one or more nonlinear resistances. A simplified version of this model, using a time-varying resistance, is shown in FIG. 4. Figure 5 and 6 are plots of the simulation results, showing the voltage spike produced by the current-limiting action of the fuse.

FIG. 4 Modeling of current limiting fuse.

(a) One-line diagram of current-limiting fuse (CLF); (b) simplified simulation model of CLF using switch and nonlinear resistance.

FIG. 5 Overvoltage caused by CLF opening.

FIG. 6 Current limitation caused by CLF interruption of a fault.

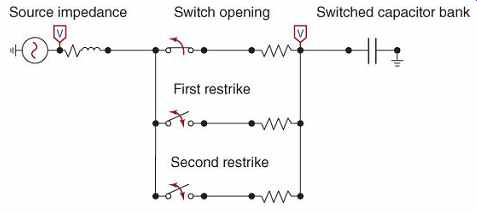

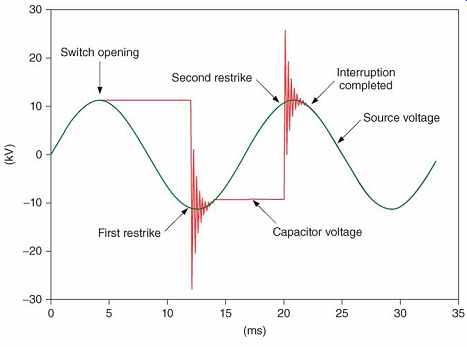

Opening of circuit breakers on capacitors may produce overvoltages resulting in restrike. The restrike is caused by the voltage across the opening contacts to exceed the breakdown voltage of the gap. The restrike phenomenon can be modeled using the concept that an arc may be considered as a resistance. Each restrike is considered as a switch rapidly closing and then opening on a resistance. This model is shown in FIG. 7, and the simulation results in FIG. 8. Once the contacts open, the capacitor holds the voltage on the capacitor side constant, while the voltage on the line side continues on its sinusoidal path. If the circuit breaker contacts have not opened sufficiently as the peak voltage approaches, a restrike may occur. This is the "first restrike" in the figure.

This results in a high frequency, high voltage transient oscillation and momentary interruption of the current. The voltage on the capacitor side is now held at the opposite peak voltage, and the scenario repeats on the next half-cycle. The resulting transient can reach three times the peak voltage.

FIG. 7 Equivalent circuit for capacitor switching restrike phenomena.

FIG. 8 Transient response for capacitor switching restrike phenomena.

2. Surge Propagation, Refraction, and Reflection

Surges are high frequency waves which travel on a system designed for low frequency waves.

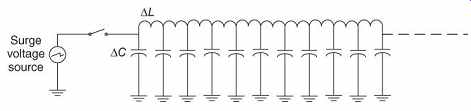

The surge waveform may have only one peak. A transmission line carries the wave by the constant interchange of energy between the distributed capacitance and inductance. This can be modeled as a lumped line of discrete inductors ?L and capacitors ?C ( FIG. 9).

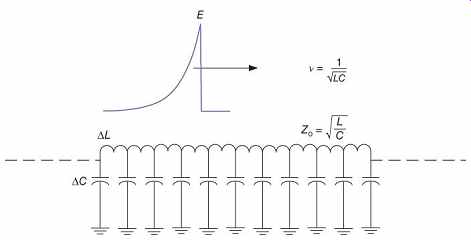

The velocity of the wave ( FIG. 10) is

eqn.2

…where…

= velocity in m/s

= inductance in H/m

= capacitance in F/m.

FIG. 9 Cable conductor distributed constant equivalent circuit.

FIG. 10 Surge-voltage wave in transit along a line of surge impedance Z0.

The ratio of voltage to current is called the surge impedance, , which is entirely resistive, and is also determined by and :

eqn.3

Typical surge impedance values are for an open-wire overhead line and for a solid dielectric metal-sheathed cable. Typical surge velocities are for an open-wire overhead line and for a solid dielectric metal-sheathed cable.

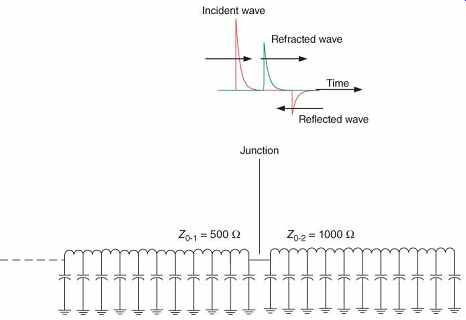

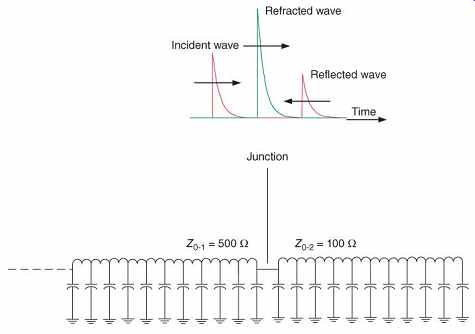

When a surge meets a junction between two circuits having different surge impedances ( and ), a reflection and refraction of the incident wave occurs. This is similar to the reflection and refraction of light passing from one medium to another. The magnitude of the reflected wave may be shown to be:

eqn.4

The magnitude of the refracted wave may be shown to be:

eqn.5

Thus, given a positive incident wave, the reflected wave may have positive or negative polarities while the refracted wave is always positive. If the reflected wave is positive, because the wave is in transition from low to high impedance, it will add to the incident wave, thereby increasing the total transient voltage seen on the incident side of the junction ( FIG. 11). If the reflected wave is negative, because the wave is in transition from high to low impedance, it will subtract from the incident wave, thereby decreasing the total transient voltage seen on the incident side of the junction ( FIG. 12).

FIG. 11 Traveling current wave reflection and refraction at low to high impedance

junction.

FIG. 12 Traveling current wave reflection and refraction at high to low impedance

junction.

On encountering a junction terminated with a higher surge impedance, a surge voltage wave traveling along a transmission line will increase in voltage to as much as double if the junction is terminated in an open circuit. The terminal voltage will not exceed two times the traveling-wave value under all possible conditions. Even with a surge arrester placed ahead of the junction at a finite distance, the resultant junction voltage rise will depend on:

1. the steepness of the surge voltage wave;

2. the propagation velocity along the line;

3. the distance of the line extension ΔD;

4. the magnitude of surge impedance connected to the junction.

The rise in terminal voltage will be aggravated by

1. the steeper front wave;

2. greater ΔD;

3. slower line propagation velocity;

4. greater magnitude of the terminating surge impedance.

3. Insulation Withstand Characteristics and Protection

The high potential, low frequency test lasts for 1 min, and is an elevated voltage, 60 Hz insulation test. For transformer testing it is a 1 min, elevated voltage, constant V-Hz test. The full-wave impulse test crest voltage establishes equipment BIL using the wave. This test is most stressful on line-to-ground insulation.

The chopped-wave impulse test crest voltage is 10-15% higher than the BIL and follows a positive wave, steep negative gradient. The chopped-wave test is most stressful on turn-to-turn insulation. The front of wave impulse test crest voltage is higher than for the chopped-wave test. The impulse is chopped on the rising front of the wave before it reaches the crest voltage. The switching surge impulse test crest voltage is lower than the BIL. The test rise time is slower than for the impulse test; however, switching surges can be fast front waves. The BILs for common electric power equipment, according to ANSI standards, are shown in Tables 1- 5. It can be seen that dry-type transformers typically have lower BIL than liquid-filled ones, which has been the cause of numerous failures of dry-type transformers with inadequate surge protection.

Note that rotating machines do not have BILs, but have an impulse-level time characteristic shown in FIG. 10. When surge capacitors are used for motor protection, the steep wavefront of a surge is slowed as shown in curve . The high potential test and impulse voltage requirements are shown in Tables 6 and 7.

Table 1 Basic Impulse Insulation Levels (BILs) of Power Circuit Breakers, Switchgear Assemblies, and Metal-Enclosed Buses

Voltage Rating (kV)

Basic Impulse Insulation Level (BIL) (kV)

Table 2 Impulse Test Levels for Liquid-Immersed Power Transformers

Table 3 Impulse Test Levels for Liquid-Immersed Distribution Transformers

Table 4 Impulse Test Levels for Dry-Type Transformers, Delta or Ungrounded Wye

Table 5 Impulse Test Levels for Dry-Type Transformers, Grounded Wye

Table 6 Rotating Machine 60 Hz, 1 min High Potential Test Voltages, Phase to Ground

Table 7 Rotating-Machine 60 Hz Winding Impulse Voltages, Phase to Ground

A thorough knowledge of the insulation system withstand capabilities and endurance qualities is required. The likely sources of overvoltage exposure and character, magnitude, duration, and repetition rate that is likely to be impressed on the apparatus and circuits need to be identified. Appropriate application of surge protection devices is the most effective tool for achieving the desired insulation security. The problem of protection is complicated by the fact that insulation failure results from excessive magnitude of impressed voltage and from the aggregate sum total duration of such overvoltages.

4. Surge Arrester Characteristics

All arresters are based on using a nonlinear voltage/current characteristic to reduce overvoltages, as shown in FIG. 11. Surge arrester design has evolved over the years from gapped, pellet, and expulsion type arresters.

The silicon carbide (SiC) valve-type arrester was the most widely used type of arrester for many decades in the twentieth century. The valve element consists of nonlinear resistance.

The parallel gap element provides isolation from normal line-to-ground voltage and reseals after-surge discharge to prevent flow of follow current. Application difficulty for valve-type arresters stemmed from variable arc characteristics with gapped designs.

All modern arresters are gapless metal oxide (ZnO) type. The ZnO valve element is sufficiently nonlinear to eliminate the need for gap elements. The nonlinear element provides a more constant voltage throughout the range of application. ZnO arresters initiate and complete their surge protective cycle more ideally than do gapped valve-type arresters.

On the basis of their durability, surge arresters come in three classes for a range of applications. These are:

1. Distribution class

2. Intermediate class

3. Station class.

Distribution-class arresters are the least expensive, least durable, and have the lowest repetitive duty capability. They are capable of discharging a rectangular current wave.

Intermediate-class arresters are of medium expense and durability, having a medium repetitive duty capability. They are capable of discharging up to 161 km (100 miles) of transmission line.

Station-class arresters have the greatest expense and durability, with the maximum repetitive duty capability of all classes. They are capable of discharging 240-320 km (150-200 miles) of transmission line. Some arresters have discharge capabilities in excess of minimum requirements. Manufacturer data should be consulted when selecting arresters for particular applications.

5. Surge Arrester Application

Selection of arrester rating is by a number of published characteristics (IEEE, 2012b). The maximum continuous overvoltage (MCOV) should be greater than or equal to the maximum line-to-neutral voltage. The temporary overvoltage (TOV) rating should be greater than or equal to the maximum line-to-ground voltage during a single-line to ground fault (SLGF). The line-to-ground voltage can be calculated as the line-to-line voltage multiplied by the coefficient of grounding.

The TOV is reduced by previous energy.

While selecting the arrester class,

• switching impulse energy capability =

switching surge duty imposed by the system;

• discharge currents in effectively shielded (in-plant) systems are relatively low and usually have no bearing on arrester selection.

Generally,

• use station class to protect components of 7.5 MVA or more and essential rotating machines;

• use intermediate class. to protect 1-20 MVA substations and other rotating machines;

• use distribution class to protect distribution class apparatus, small rotating machines and dry-type transformers.

For selection of arrester location,

• place arrester as close as possible to the equipment being protected;

• reflected wave from protected equipment should participate in the clamping process.

The process of sizing arresters to protect an insulation system is called insulation coordination. The following factors need to be considered:

PM = (insulation withstand level/voltage @ equip-1) 100% CWW = chopped wave withstand level BIL = basic impulse insulation level SSL = switching surge level FOW = front of wave protective (sparkover) level LPL = lightning protective (sparkover) level SPL = switching surge protective (sparkover) level The recommended protective margins are PM(1) = (CCW/FOW· 1) 100% ~ 20% PM(2) = (BIL/LPL· 1) 100% ~ 20% PM(1) = (SSL/SPL. 1) 100% ~ 15% Distribution system coordination is usually based on only PM(1) and PM(2) as switching surges are normally less severe than lightning in such systems.