In section 6 we discussed the wearing of parts made primarily from rubber. In this section, we will focus on the wearing of parts made from metals. Also included is wearing of brake discs and shoes.

SHOCK ABSORBERS

The combination coil spring and shock absorber that is found on the wheel of the car is actually part of the suspension system. The spring, not the shock absorber, is the component that actually absorbs road shocks. The job of the shock absorber is to dampen or “still” the many vibrations the spring makes as it absorbs shocks caused by road conditions and to hold the wheel to the road.

You can test for weak shock absorbers by bouncing the car while parked. The car body should bounce only once or twice. If the car doesn’t “settle down” after one or two hard bounces, the shocks might be weak. Some cars have the spring and shock absorber combined into a single, replaceable unit called a McPherson strut. Also, many Chrysler products do not use coil springs on the front suspension, but use torsion bars instead. Torsion bars absorb road shocks by twisting.

The larger the shock absorber, the more fluid it has inside it. The more fluid it has, the more spring energy it can absorb. Larger shocks normally work at lower pressures for longer life. Heavy-duty shocks have more fluid than standard-duty shocks, so they will last longer for only a slightly higher cost. Use only the heavy-duty type shock sized for your car. Table 7-1 lists the four types of shock absorbers and their characteristics.

Table 7-1. Types of Shock Absorbers.

Type |

Driving Conditions |

Ride |

Replacement |

Standard duty |

Normal speeds on well-paved roads. No heavy loads. |

Soft |

Often |

Heavy duty |

Rough roads at high speeds. Some towing or heavy loads |

Firm but not hard |

Less often than standard duty. |

Spring type or load-leveling |

Heavy loads or frequent towing |

May be hard |

About as often as heavy duty |

High performance |

High speed driving as in police cars |

Firm to uncomfortable |

Long life |

Wear

Shock absorbers are factory-filled with an exact amount of fluid (liquid or gas), then sealed shut. They cannot be refilled, and there is no service that can be performed on the shock absorber itself to increase its life. Once worn, shocks need to be replaced.

A shock absorber can wear out in one of two ways. First, it can develop a leak. This becomes evident when oil moisture is noticed on the outside of the shock absorber. We advise replacing immediately. Second, the piston rod of the shock absorber can become scratched during installation or from a buildup of abrasive road dirt. This can cause premature wear of the piston rod seals, and subsequent internal seal failure. Eventually, you will notice a mushy ride and possible external leakage around the shock body. Other than factory defects or damage due to accidents, these are the only two ways shocks fail.

In Section 6 we pointed out that the rubber shock bushings located at the mounting locations on the shock can wear out. Again, check for loose or cracked bushings. Replace as required.

Replace worn shock absorbers in complete sets of four. Replacing only front or rear shocks can result in a rocking or pitching ride because the old shocks will not equalize reaction to bumps with the new. Even from the best set of shocks, expect a lifetime of only 25,000 to 30,000 miles. Normally the wearing process of these many miles is so gradual it’s hard to notice. Our suggestion is to replace all the shocks at 25,000 miles, regardless—or sooner if they leak or exhibit weakness before then. This is most important in improving tire life, because a weak shock will allow the wheel to spin when rebound is not controlled. More importantly, weak or worn shocks are dangerous because they make it difficult to control a bouncing car.

Tips for Longer Shock Life

Periodic checking of bushings to verify tightness of installation is one way to keep shock absorbers lasting longer; improving driving habits is another. Here is a list of some things you might try.

1. Cut down on high-speed cornering.

2. If possible, avoid rough, bumpy roads.

3. Come to a gradual stop; never stop so quickly (unless in an emergency) that the car pitches front violently.

4. Distribute passengers and loads evenly throughout the car as much as possible.

5. Install shocks designed for frequent towing or heavy loads if you perform such functions often.

6. Never grip the piston rod with pliers or dirty hands. It is highly polished, and any scratches or dirt will accelerate internal seal wear.

7. Never extend a shock while it is upside down or lying on its side. Air can enter the shock in this way and cause a weak, mushy ride.

8. Slow down when crossing obstacles such as potholes or railroad tracks. This will lessen the spring energy the shock must absorb.

THE EXHAUST SYSTEM

In an internal combustion engine, fuel burns inside the cavity created by the cylinder walls and the moving piston. The fuel burns very rapidly in order to keep the piston and crankshaft assembly moving at a speed suitable to match driving conditions. In fact, the fuel burns so fast that you can think of it as exploding up to 16,000 times per minute. These explosions can be compared to a firecracker going off; they make noise. Each explosion in the cylinder generates a sound wave at least 50 feet long, with pulsations 20 to 250 times a second at high exhaust gas velocity. It falls upon the muffler and resonator (if so equipped) to quiet this noise.

Mufflers and resonators work by decreasing the exhaust gas velocity and by absorbing the sound waves (in special materials within the muffler), or canceling them by interference with other sound waves from the engine. To help decrease the exhaust gas velocity, mufflers should have volumes six to eight times the piston displacement. Most mufflers and resonators contain baffles, with or without holes to absorb sound and cancel sound waves. Also, some mufflers split the exhaust gas flow into two paths, having it meet again out of phase before leaving the tailpipe, thus canceling it out.

Mufflers and resonators are part of the exhaust system which, in addition, is composed of the exhaust manifold and connecting pipes and pipe hangers. Single exhaust passenger cars include an exhaust pipe, muffler, resonator (if so equipped), and a tailpipe that discharges exhaust gases at the rear of the car. An exhaust crossover pipe may be used on V-8 model cars to connect the two exhaust manifolds.

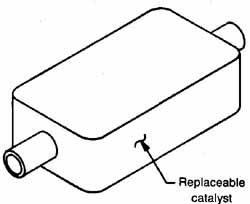

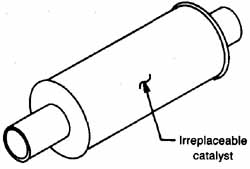

On dual-exhaust systems (available on V-8 models only), two assemblies consisting of exhaust manifolds, mufflers, resonators, and tailpipes are used. Each assembly is connected to its own exhaust manifold. On modern cars, a catalytic converter is also part of the exhaust system. This is an emission-control device used to reduce hydrocarbon, carbon monoxide, and oxides of nitrogen pollutants from the exhaust gas. The catalyst used in converters eventually wears out or clogs from oil emissions in the exhaust gas. Some types of catalyst are replaceable, those in bead-type converters, for example. The bead-type converters are normally flat or pan-shaped. Monolith converters, using irreplaceable catalysts, are usually more tubular, and when the catalyst wears out, the entire converter assembly must be replaced (Figs. 7-1 and 7-2).

Fig. 1. Bead-type catalytic converter.

Fig. 2. Monolith catalytic converter.

There are two types of catalysts. The conventional oxidation catalyst is made from platinum and palladium, and acts on hydrocarbon and carbon monoxide pollutants. It is sometimes called a two-way catalyst. The second type of catalyst, called a three-way catalyst, controls oxide of nitrogen, as well as hydrocarbon and carbon monoxide pollutants. The catalyst that controls oxides of nitrogen is made from rhodium and platinum.

Normal Wear

The life of exhaust system parts is dependent largely on the type of driving done. Short trips of 3 to 6 miles duration—especially in colder weather—or a lot of stop-and-go driving can rust the muffler and perhaps the tailpipe, too, in as little as 20,000 miles. On cars that have dual-exhaust systems, muffler and tailpipe life can be far less than 20,000 miles for this type of driving.

The reason for such short life is that on short trips, condensed moisture from the exhaust gas collects in the mufflers and pipes. In fact, for each gallon of gasoline, almost 1 gallon of acidic water is generated .by the engine. The exhaust system might not have enough time to heat up and evaporate this moisture. Because the moisture is highly acidic, it will rapidly corrode metal. Mufflers are particularly susceptible to this corrosion because of their complex and thin insides.

If you are forced to drive on short trips or in city stop-and-go traffic, then the above wear is considered normal for your car. Expect to replace exhaust system parts frequently. As much as possible, try to combine several short trips into one longer trip in order to give the exhaust system more time to rid itself of moisture. An excellent idea is to purchase a lifetime-guaranteed muffler at replacement time. No matter how many mufflers wear out, they will be replaced free of charge.

As pointed out above, if the car is driven on longer trips (over 6 miles in summer or 10 in winter), the exhaust system parts should get hot enough to evaporate the exhaust moisture. Exhaust system parts will last much longer as corrosive action is reduced. In addition, exhaust system parts will last longer on single-exhaust systems as opposed to dual-exhaust systems, because all exhaust gases must pass through a single muffler and pipes. As a result, the exhaust system will reach high temperature more quickly and the acidic moisture will evaporate sooner.

Normal wear, even on longer trips, is still a result of the corrosive action of the acidic exhaust moisture on metal parts, but exhaust system parts last very much longer. Mufflers and tailpipes (the last system parts to warm up), can last to 60,000 miles under these conditions. If you are getting this kind of life from exhaust parts, there is really nothing you can do to increase it. Just be sure to invest in a lifetime guarantee muffler at replacement time.

Other normal wear consists of loose, broken, or misaligned clamps, hangers, shields, and brackets. If any of these exist, check the exhaust system parts and make sure everything is properly aligned. Adjust or replace parts as necessary.

Anytime the car is on a lift for service, or the car rattles or hisses from underneath, inspect the entire exhaust system. Inspect the pipes, catalytic converters, mufflers, and resonators for cracked joints, broken welds, or corrosion damage that causes leaks. Make sure the clamps and hangers are in good shape. The bolt threads should not be corroded or stripped, and insulators should not be cracked. A good bet is to replace clamps and hangers when they are loosened, or if they have been on the car for more than 3 years. Use special care when inspecting the exhaust system or working on it; wait until it cools down.

Try jabbing at rusted areas with a screwdriver. If you go through the metal, replace the part. Also, try tapping the parts of the exhaust system. The metal is in good shape if you hear a ringing sound. A dull sound might mean the part is corroded. Jiggle the exhaust parts and inspect for movement. The entire system should move as one integrated part. Individual joints should not flex; adjust them if they do.

Abnormal Wear

Abnormal wear of the exhaust system is caused by either road damage, excessive oil burning, or an engine badly out of time.

Road damage can be caused by any number of things. Driving at high speeds over rough roads can cause the exhaust system parts to jar out of adjustment. Also, small stones can penetrate already corrosion-weakened metal parts. Drive slowly and cautiously if you encounter hazardous road conditions.

Excessive oil burning is a primary reason for premature catalytic converter failure. Converters can become clogged with oil and/or burned oil to the point that the car will not operate because the exhaust gases can’t get through the system. Most of the time, unfortunately, this problem goes uncorrected because fixing the oil consumption problem can be costly, especially if new piston rings are needed. However, by following the recommended oil change interval in Section 3, excessive oil burning will probably never occur. In older cars that already burn oil, decide whether the repairs are warranted from a cost viewpoint. In any case, don’t let this condition continue. Oil burning will not only clog the converter, but it is a foul condition that pollutes the air.

An engine that is badly out of tune will pass a number of things along to the exhaust system that the system is not designed to handle. Worn spark plugs and carburetion problems may result in incomplete combustion and subsequently introduce unburned gasoline into the exhaust system. Timing out of specification can send unburned gasoline through the exhaust system, as well as subject it to shocks it is not designed to handle. Clogged air filters may result in breathing restrictions for the engine, with loss of adequate flow through the exhaust system. This could accentuate condensation problems. Keep the engine in tune by following our recommendations in Sections 8, 9, and 10.

BRAKES

Aside from the steering, the brake system is the most vital safety system on the car. We couldn’t slow down or stop without it. Brakes work by friction—in fact, the brake on each wheel is simply a friction-generated, heat machine. When the car is brought to a stop, the slipping of the brake shoe friction material against the wheel generates heat. The amount of heat varies according to the weight of the car and the square of the speed. The faster the car is traveling and the heavier the load in the car, the more heat is generated to bring the car to a stop. If the speed of the car is doubled, four times the heat is generated to stop the car.

Types of Brakes and Brake Systems

All modern cars use essentially two types of brakes: the internal expanding shoe type or the disc brakes. Some cars combine these types, typically using disc brakes on the front wheel and shoe brakes on the rear wheels.

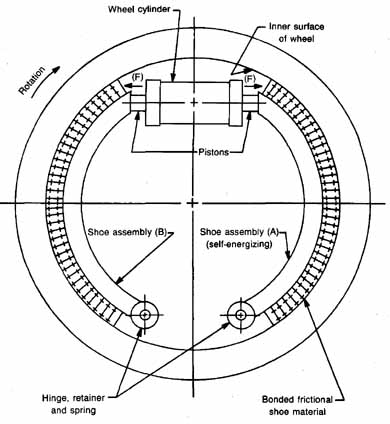

The internal expanding shoe brake (Fig. 3) consists of the wheel, two shoe assemblies, various springs and retaining devices, and a wheel cylinder. As shown on the illustration, the wheel cylinder supplies the needed actuating forces (F). The shoe assemblies are lined with a friction material commonly made of molded asbestos that is glued or riveted to the metal shoe.

Fig. 3. Internal expanding shoe brake.

As you apply the brake pedal, hydraulic pressure causes the wheel cylinder to expand its two pistons against the brake shoe at (F). This force throws the shoe (actually the friction surface of the shoe) against the inner surface of the wheel. The angular velocity of the wheel is gradually changed to heat energy as the car slows down.

An important feature of this type of brake is the self-energizing capacity of brake shoe (A). For the wheel rotation noted, when the wheel cylinder applies the force (F) to brake shoe (A), the shoe is drawn into the moving wheel much as a magnet draws a piece of steel to it. Therefore, the braking capacity of shoe (A) is over twice that of shoe (B) for the same shoe size. Some manufacturers take advantage of this by making shoe (B) slightly smaller. This arrangement improves the design because the additional wheel surface exposure that isn’t covered by an overly large shoe improves the heat dissipation capacity of the wheel.

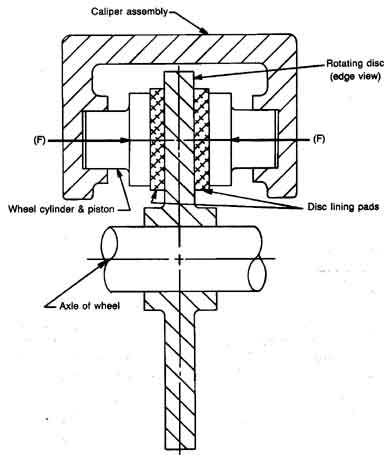

The other major type of brake assembly is the disc brake (Fig. 4). Here the shoes pinch the rotating disc that is attached to the wheel, in much the same way you would use your fingers to pinch a coin. Disc brakes have no self-energizing features and are, therefore, frequently used with a power assist to boost the actuating force (F) to a degree that proper braking can occur. Disc brakes are, however, self-adjusting. The brake lining pads retract enough to allow a slight drag. No adjustment is necessary, it is actually not even possible, on disc brakes.

Fig. 4. Disc brake.

As pointed out above, the rotating disc is a metal plate that is attached to and turns with the wheel. The caliper assembly straddles the rotating disc. This assembly is composed of brake cylinder (or cylinders), pistons, and disc shoe pads. As you apply the brake pedal, hydraulic pressure causes the wheel cylinder to expand the pistons, causing the disc shoe pads to press against both sides of the rotating disc.

Disc brakes are more exposed to cooling air than shoe brakes, so they dissipate heat faster and run cooler. This makes them less subject to swerving and fade than shoe brakes. The only problem with disc brakes is installation of a parking brake when discs are used on all four wheels. Because this is expensive, most cars use discs on the front and shoes on the rear. In addition, front brakes handle up to 75% of braking work, so installation of front discs and rear shoes is just plain good design.

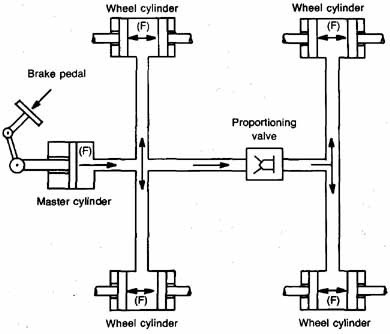

Regardless of the type brakes used, the hydraulic system is practically the same (Fig. 5). It consists of the brake pedal, master cylinder, tubing, proportioning valve, and wheel cylinder. The braking force (F) is transmitted equally from the master cylinder to all four wheel cylinders by application of the brake pedal. If the brakes are power assisted, master cylinder pressure is boosted by the engine vacuum. Starting in 1968, all modern cars use a dual hydraulic system. In such systems, the master cylinder contains two fluid reservoirs, two pistons, and two brake lines: one line for the front wheel cylinders and one line for the rear wheel cylinders. Should one system fail, the car could still be brought to a stop using the other system.

Fig. 5. Brake hydraulic system.

The hydraulic fluid used in brake systems is a mineral oil with additives. Use super heavy-duty fluid for shoe brakes. It is amber in color. For disc brakes, use brake fluid with a high boiling point (500 degrees Fahrenheit). It is a blue-green color. You can use the disc brake fluid in a shoe-type system if the master cylinder has a rubber diaphragm underneath its cover, but never use a shoe fluid in a disc system. Check the level of the fluid at least twice per year.

Wear

Each time the brakes are applied to slow down or stop the car, minute particles of friction material are worn away. Normally, this wear can proceed over 40,000 miles, until the lining material is so thin that replacement is necessary. This is considered normal. City or stop-and-go driving will wear linings much more quickly than long distance or highway driving.

Brakes work at their optimum when the frictional characteristics of the lining do not vary. To maintain the linings in this state is, of course, impossible. Actually, friction can vary with a number of conditions, including temperature, wear, and environment. Keep the linings dry and free of grease or brake fluid. If grease and brake fluid do build up, they cannot be cleaned from linings; replacement of the linings is necessary. Brakes that grab indicate a fluid-soaked lining.

Inspect the brake adjustment and lining thickness on shoe brakes twice a year. Brakes that drag too heavily on the wheel are a hazard and accelerated wear can be expected. If the brake drags too much it can become glazed or shiny. Glazed brakes tend to slip and are a safety hazard. Replacement might be required.

Perform a complete brake system inspection once a year. At this time, consider a thorough bleeding of all brake lines, cleaning of wheel assemblies, and honing of wheel cylinders. Keep the whole brake system in top shape for your personal safety and peace of mind. Refer to Table 7-2 for some representative brake system problems.

Table 7-2. Telltale Brake System Problems.

Symptom |

Cause |

Cure |

Light brake pull when stopping Strong brake pull when stopping Grinding or scraping noises when stopping Clicking Smell of brake fluid Squeal Rattling or clanking on rough roads Pulsations in brake pedal |

Front or rear brakes out of adjustment or worn Front brake problem or faulty wheel alignment Worn brake linings Burred shoes Hydraulic system leak Caliper mounting bolts or adapter bracket loose Loose shoe and lining assembly Wheel or disc untrue |

Adjust or replace Adjust or replace brake, align front end Replace linings Replace shoes Inspect and repair Adjust and tighten Adjust or replace Turn on lathe to true |

(See any good auto service manual for many other symptoms, causes, and cures.)

SUMMARY OF RECOMMENDATIONS

Shock Absorbers

• Always use heavy-duty shocks.

• Buy shocks that are lifetime guaranteed.

• Replace shocks about every 25,000 miles.

• Improve driving habits to increase shock life.

Exhaust System

• Combine a few short driving trips into one long one for better exhaust system part life.

• Buy mufflers and resonators that are lifetime guaranteed.

• Service the manifold heat control valve yearly.

• Inspect the exhaust system every time the car is on the lift or when rattles or hissing is heard underneath the car.

Brakes

• Use specified brake fluid only. Never mix fluids for use on shoe brakes with that for disc brakes.

• Check brake fluid level twice a year or when the pedal feels soft.

• Inspect the brake hydraulic system for leaks every time the car is on the lift.

• Consider metallic brake linings only for heavy trailering use or when doing frequent mountain travel.

• Keep brake linings dry and free of grease and brake fluid.

• Adjust shoe-type brakes twice a year. Inspect for lining wear and thickness at the same interval.

• Perform a complete brake system check and cleaning once a year.

MECHANICS TIPS

Shock Absorbers

• Replace shock absorbers in pairs and all four at one time for best handling results.

• Don’t buy bargain replacement shock absorbers; they won’t last.

• Replacing shock absorbers can be a dirty and sometimes frustrating job. Leave it to your mechanic.

Exhaust System

• For emergency repairs, invest in a muffler repair kit and keep it handy, along with your other auto supplies.

• If you lose a muffler on the highway, don’t panic. There is usually no safety concern, just a lot of noise. Get it replaced at your earliest convenience.

• Replacing mufflers and other exhaust system parts is a demanding, dirty job. Without a hydraulic lift the job can be a headache. Take the car to your mechanic or muffler specialty shop for best results.

Brakes

• In wet weather, lightly apply the brakes periodically to keep them dry. This is especially important when driving through a lot of puddles.

• Some brake materials have asbestos as part of the friction lining. When servicing the brakes, be careful not to breath in brake shoe lining dust or particles.

• Your brakes are the major safety feature in your car. Keep them in perfect order.

Prev: Wear of Tires, Hoses, Belts, and Other Rubber Parts

Next: Mechanical

Tune-Ups

Home top

of page