There are many parts in the car that eventually fail by scraping or rubbing against other parts or surfaces. In fact, most of the parts that wear out in the car do so in this manner. This section presents the theory of wear and reviews the way that softer parts such as belts, hoses, and tires wear out.

THEORY OF WEAR

Failure of the surface of a part by wear usually occurs only after a very long time. For example, tires don’t “wear out” in 1 day. Normally, tire wear occurs over years (or many miles) of use and is characterized by shallow tread depth. For example, a flat tire caused by a puncture from a nail or sharp glass cannot be classified as a wear failure. Wear failure takes a relatively long time to occur. There are three principal types of wear at work in the car: adhesive, abrasive, and pitting wear.

Adhesive Wear

There is no surface made by man that is perfectly smooth. All surfaces, even the smoothest, have some surface markings, which are especially evident under a microscope. Many rough peaks and Valleys come into focus. The roughness peaks act as points of adhesion. As two surfaces slide over each other, wear will occur because of the grinding and plucking away of material at these points of adhesion. Piston rings, camshaft surfaces, and improperly lubricated bearings, for example, can wear in this manner.

Abrasive Wear

When a hard, rough surface slides against a softer one, abrasive wear can occur. An excellent example of abrasive wear is the effect of sandpaper on wood. The abrasive particles on the sandpaper are very hard and rough, while the surface of the wood is much softer. The sandpaper particles actually plough a series of grooves, removing wood material with each stroke. Another example of abrasive wear is when hard, rough particles are introduced between sliding surfaces (as in dirt in journal bearings). Tire wear is also abrasive wear. A hard, rough road surface is responsible for tire wear, acting on the tire just like sandpaper acts on wood. The reason tires last as long as they do is that the relative motion between the tire and road is not only a sliding motion but a rolling motion as well, and the rolling motion does not contribute as significantly to tire wear as sliding motion does.

Pitting Wear

Pitting is caused by the surface failure of a material as a result of repeated surface stresses that exceed the strength of the material. Pitting stops when these stresses become less than the strength of the material. Pitting is a common mode of failure for gear teeth. Usually poor design is responsible for this type of wear.

TIRES

The air used to inflate tires must support the total weight of a car, plus passengers and cargo. In addition, tires and the air used to inflate them control stopping, turning, and smoothness of ride. As we will see, insuring proper tire inflation is one of the most important steps that can be taken to prolong tire life and help guarantee satisfactory and safe performance.

Construction

Tires are constructed of rubber, fabric, and steel. On the inside, tires are made of a tough fabric that is reinforced with steel threading to add strength. All the components are molded on a heated form. The heat vulcanizes the rubber to make it more resistant to wear. Vulcanization is a toughening process used for many different rubber products. Tires consist of four basic parts: the body, bead, cord, and tread (Fig. 1).

The body (or sidewall) acts to help support the weight of the car. It must be properly inflated so that it is stiff enough to bounce back from various road shocks and yet flexible enough to provide a comfortable ride. As with other parts of the tire, it must also be abrasion-resistant.

The function of the tire bead is to hold the tire securely against the wheel rim to prevent air leakage. The bead is constructed of rings of steel wire that prevent the inside diameter of the tire from stretching because of air pressure and centrifugal rotational force. All tires have bead gauges molded to the body to show proper tire seating to the wheel rim. The distance between the edge of the wheel rim and the bead gauge should be even all around the rim (Fig 6-2).

Cords provide the material of the body wall and a mounting surface for the tread. They are made from various materials including nylon, rayon, polyester, glass-fiber, and steel. Each has its own advantages of ride comfort, abrasion resistance, and resistance to road damage.

The tire tread is the part of the tire that grips the road. It permits the tire to roll smoothly along the road and must take on a variety of surfaces. The tread is made al most entirely of synthetic rubbers, with the addition of sulfur and carbon black to harden the rubber. Tread designs vary greatly, with no one design proven superior. Choose a tread design to match driving conditions or for general use. Some of the newer tread designs can be used for a combination of driving conditions.

Types

There are three major types of tires, classified by the way the cords are molded into the tire and the use of belts in the tread area. These are bias-ply, belted bias-ply, and radial ply. We will only discuss radial-ply tires here.

In a radial-ply tire, the body cords are molded from bead to bead at 90 degrees to the tire diameter. Bias-ply tires have the cords molded at angles between 30 and 38 degrees. Running the cords at 90 degrees in the radial-ply tire results in a very rigid tread, but a flexible sidewall or body—giving superior road handling quality and longer wear. If you can afford them, radial-ply tires are the best choice.

Caution: Use radial-ply tires in sets of four. Never mix radials with non-radials. If you change to snow tires in the winter, buy radial-ply snow tires if you are using radial ply tires on the other axle. Using different types of tires results in different types of traction, which can lead to dangerous handling problems.

Care

Tires probably require more care than any other part on a car. Tires not only support the weight of the car, they do many other jobs depending on whether they are located on the front or rear axle. Tires on front-wheel drive cars must perform all of the work of the front axles, plus many of the jobs of the rear wheels as well.

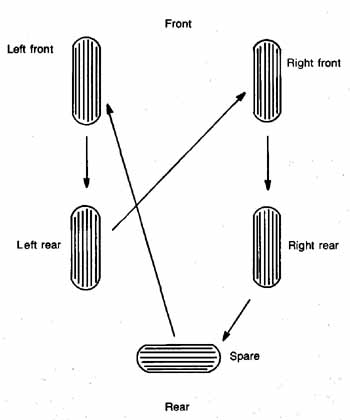

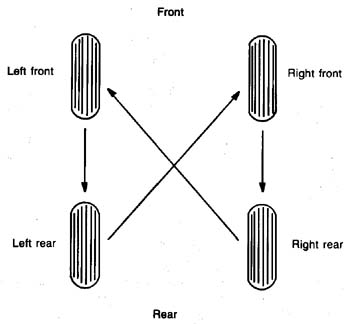

Rotation. Front wheels steer the car, absorb misalignment irregularities, and are more subject to braking wear than the rear wheels. Rear wheels drive or push the car, hold the car on curves, and absorb sudden stops and starts. The different kinds of work these tires perform result in different kinds of wear. In order to maximize tire life and equalize wear on all tires, they should be rotated at regular intervals as specified by the manufacturer. In the absence of a manufacturer’s recommendation, rotate the tires every 12,000 miles according to the pattern in Figs. 6-3 and 6-4.

Fig. 3. Tire rotation—with spare tire.

Fig. 4. Tire rotation—without spare tire.

Make sure the wheel and tire are properly balanced at this interval. Note that radial, belted bias-ply, and studded winter tires should not be rotated. Radial and belted bias ply tires are to be switched from front to rear or vice-versa. They must always rotate in the original wheel positions as when first installed. These tires, because of their construction, acquire a sort of “permanent set” that will adversely affect performance if you reinstall them in different positions.

Storage. Store tires in a clean, dry area away from tools. Don’t pile other storage items on tires. Lay the tires flat, if possible, on an oil-free floor. Tires can also be stored in a rack and stood on the tread.

Inflation. The most important thing you can do to prolong the life of car tires is to keep them properly inflated. Check tire pressure once per month when tires are cold and more often in winter because cold weather causes tire pressure to decrease. Remember that every 10-degree Fahrenheit temperature drop will decrease tire pressure by 1 psi.

Every mechanic has a recommendation for proper tire inflation. Some of them even recommend different inflation pressures to match differing circumstances, such as winter driving or driving on a long trip. This is simply not true. Always keep them inflated according to manufacturer’s specifications.

Low tire pressure will cause the tread to slip and scuff on the shoulders. It also reduces the stiffness of the sidewall, leading to excessive flexure and overheating. Overheating will cause accelerated wear and, on older tires, sudden failure.

High tire pressure is equally undesirable. It causes center wear in the tread and overstrains the sidewall, making it more susceptible to fabric breaks. Keep the pressure at the recommended level.

Cleaning. Clean the tire treads anytime you notice embedded nails, stones, or pieces of metal or glass. These items can lead to tire leaks and punctures, and will accelerate tread wear. In extreme cases they could lead to diminished tire traction.

If new whitewall tires are purchased, they normally come with a protective coating on the whitewalls. Remove this coating at the dealer or soon after. Remove road dirt on whitewalls with soap and water only. Never use gasoline or kerosene because they deteriorate the rubber and will discolor the whitewall.

Keep the tire valves clean. They must have valve caps to help keep dirt, water — and in winter, ice — out of the valve core.

Normal Wear

All tires, even on the best-maintained cars, will eventually wear out. The key to normal tire wear is to diminish the sliding effects (or sliding friction) and accentuate the rolling effects (or rolling friction) of the tire against the road. As we pointed out previously, sliding of one surface over another results in more wear than rolling motion between two surfaces. In fact, sliding wear on passenger car tires is estimated to be 90 to 100 times greater than rolling wear.

Normal tire wear results from a combination of rolling and sliding friction. Every time you round a curve, sliding friction increases. Every time you start or stop your car, sliding friction increases. Every time sliding friction increases, tire wear rates increase. If we could all drive on straight roads and start and stop gradually, we could keep rolling friction dominant over sliding friction. Therefore, driving habits are a prominent force in the fight for longer tire life. Slow down on curves and avoid quick stops and “jack-rabbit” starts. Keep the sliding to a minimum! Rolling friction will still cause wear; but it is far less severe.

Abnormal Wear

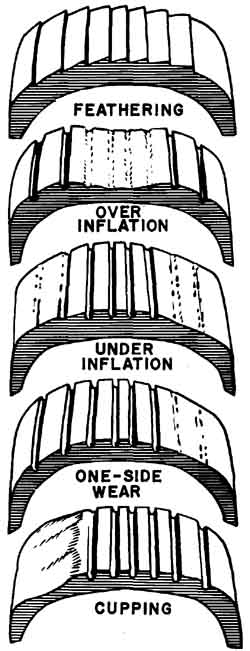

Abnormal tire wear can be due to a number of conditions or combinations of conditions. The more damaging conditions include under-inflation, over-inflation, poor driving habits, misaligned front wheels, out-of-balance wheels, bent suspension parts, out-of-round brake drums, brakes out of adjustment, and driving on rough roads for extended periods. Refer to Fig. 5 below for recognizable abnormal wear patterns.

Overinflation causes the center of the tread to wear at a greater rate than the edges. Conversely, underinflation will cause the edges of the tread to wear at a greater rate than the center. Again, keep tire pressure at the recommended level.

Driving too fast around curves and corners is evidenced by tread worn more at the edges than the center, along with a rounded tread profile. Another poor driving habit is jerky braking. A tire will exhibit a saw-toothed profile at the edges of individual treads from jerky braking habits.

Misalignment of the front wheels is a major cause of rapid, abnormal tire wear. In some extreme, uncorrected cases, tire life can be reduced to 10% of normal. Tires that hiss or squeal while in operation may indicate incorrect toe-in. You might also notice small feather-edges at one side of an individual tread that point to toe-in problems. Spotty tread wear or tread with only one side worn can indicate incorrect caster or camber.

Uneven tread wear can also be indicative of out-of-balance wheels, out-of-round brake drums, or brakes that need adjusting. Correct these problems immediately, then rotate the tires according to the patterns in Figs. 6-3 and 6-4 to help even out the tire wear.

Wheel Balancing

As pointed out above, an out-of-balance wheel can cause abnormal tire wear. Unbalanced wheels can set up violent vibrations that not only contribute to abnormal tire wear, but result in handling and braking problems. Balancing the wheel equally distributes the weight of the wheel, brake drum, hub, and tire around the center of the axle or axis of rotation.

There are two ways a wheel can be unbalanced: statically and dynamically. You can tell static unbalance by a pounding action of the wheel sometimes called “wheel tramp.” A wobble or shimmy of the wheel is an indication of dynamic unbalance. Check wheel balance after every wheel or tire repair, at the time snow tires are installed, or twice per year. Missing balance weights also signal the time to rebalance. And remember that, although the front wheels are more sensitive to unbalance, all four wheels should be balanced both statically and dynamically.

Fig 6-5

HOSES

Rubber hose is used throughout the car to do a number of jobs. It always acts as a conduit to convey liquids or gases to various locations. Heater hoses convey hot engine coolant to the car heater/defroster for our comfort in cold weather. Radiator hose delivers cooled liquid to keep the engine running without overheating. Brake hose supplies high-pressure hydraulic or brake fluid to the wheel cylinders to stop the car, and acts to absorb surges and vibrations between car body and wheels. Vacuum hose contains low-pressure air that can be used to operate the vacuum advance on the carburetor, a vacuum-controlled fuel pump, or vacuum-concealed headlights.

Parts

There are three parts to a hose: (Fig. 6) the cover, the carcass, and the tube. The cover protects the internal parts of the hose from harmful effects of the environment. It is made from natural rubber or a synthetic rubber. The carcass provides the hose with the strength to resist bursting under pressure. In vacuum hose, the carcass resists collapse due to the higher atmospheric pressure on the outside of the hose. The carcass can be made from fabric plies, fiber or wire braids, knitted fiber yarns, woven fiber yarns, or wire. The tube conveys the liquid or gas to where it is needed. It must be resistant to the liquid inside it and must not contaminate the liquid. It is constructed of the same types of materials as the cover.

Fig. 6. Parts of a hose.

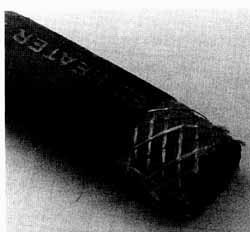

Failure

In general, there are only a few major causes of wear and eventual failure in auto hose. They include aging, puncture, improper installation and routing; excessive exposure to oil, grease, or gasoline; excessive exposure to ozone; and workmanship errors (Table 6-1).

Table 6-1. Hose Failures and Their Causes.

Symptom |

Cause |

Cure |

1. Hose tube hard and cracked. |

Heat that leaches plasticizers* Out of the tube. Also, too much air in tube. |

Eliminate overheating. Eliminate air leaks. |

2. Cover deteriorated. |

Battery acid, steam cleaners, salt water, chemical cleaners, oils, greases, gasoline. |

Reroute hose or protect during engine cleaning. |

3. Burst hose on outside bond. |

Use of less than recommended bend radius. |

Re-route hose. |

4. Burst hose; appears kinked and flattened. |

Twisting of hose during installation. |

Install hose without twisting. |

5. Burst hose. Hose deteriorated with surface crazed |

Old age caused by weathering and ozone. |

Replace hose at regular intervals. Do not park car around electrical equipment (motors) that produce ozone. |

All hose will eventually age and fail as a result of weathering, heat, and chemical action. Keep all fluids that flow in hose clean and free of foreign particles. Change engine coolant yearly. Make sure that when new hose is installed, it is routed according to manufacturer’s recommendation—keep it away from hot engine parts. Wipe down hose periodically with a soft rag moistened with water. If hose becomes caked with grease or oil, use a cleaner that will not attack the hose.

Inspect hose according to the following list.

1. Replace cracked, swollen, restricted, or punctured hose.

2. Hose should be firm but not hard. Hardness indicates imminent failure.

3. Make sure hose clamps are not installed overly tight. A too-tight hose clamp can cut the hose cover and lead to premature failure.

4. Radiator hose normally has a steel wire wound within the hose material or placed inside the hose. Its function is to keep the radiator hose inside diameter fully open, ensuring proper coolant flow. The radiator hose should not feel soft or mushy. Replace accordingly.

5. Don’t forget to check the radiator overflow tube. If it becomes clogged, cooling system venting will be impaired and cause radiator damage. Replace or clean accordingly.

6. Check brake hose whenever brake service is performed or whenever the car is on a lift. Check for cracks, worn spots, and interference with chassis or wheel parts. If replacement is warranted, use only approved replacement hose.

BELTS

Almost all cars make use of belts to transmit power from the crankshaft to auxiliary engine equipment such as fans, water pumps, power steering pumps, alternator/generator equipment, and air-conditioning compressors. These belts are normally V-shaped in cross- section and, hence, are called V-belts. V-belts ride in pulleys with V-shaped grooves. The V-belt should ride with its top surface approximately flush with the top of the pulley groove. Clearance must exist between the bottom of the V-belt and the bottom of the pulley groove to allow the V-belt to ride on the walls of the pulley groove.

V-belts are made of fabric fashioned into a cord impregnated with rubber. The cord material can be made of cotton, synthetic materials, or steel.

Another belt used in modern cars is the cogged V-belt, which replaces the chain belt used for timing purposes. In our opinion, this design use of rubberized belting is a poor one. These timing belts frequently break, rendering the car immobile. They are expensive and difficult to replace. If your car uses a rubber belt for timing purposes, inspect it frequently for wear and/or damage.

There are only a few things you can do to ensure long belt life. Check the condition of the belt periodically, say monthly. Cracked, brittle, glazed, or worn belts must be replaced as soon as possible. Check the belt tension periodically with a belt tension gauge. A loose belt can cause the water pump to run slowly and can lead to overheating problems. It can also lead to premature battery failure by allowing the alternator to slip, thereby slowly draining the battery. Don’t try to adjust the belt tension by feel: in modern cars this method is not accurate enough. Use a belt tension gauge to set correct tension, as specified by the shop manual.

For a V-belt to properly do its job and last a long time, it must also run tightly in the pulley groove. If the belt slips it will squeak and wear prematurely. Usually a few drops of belt lubricant on the inside edges of the belt will stop the squeaking and prevent the belt from slipping. Be sure the belt is properly adjusted before using the V-belt lube.

OTHER RUBBER PARTS

Rubber or rubber-like parts are used throughout the car. Doors, trunks, and hoods all have rubber gaskets to keep out the weather. Inspect these at least yearly. They can be lubed with spray-on silicon.

Trunk and engine hoods may also have rubber bumpers to absorb road vibrations and the force from slamming them shut. Replace them if they are missing, cracked, or broken.

Cars that have separate frames and bodies use rubber bumpers at certain places between the frame and body to absorb vibrations. Find their location in your car by referring to the shop manual, and inspect them yearly. Replace as required. Unibody cars might not have these rubber bumpers.

Shock absorbers use rubber bushings in the mounting arrangement. Check these yearly for cracking. You can buy replacement bushings without buying new shock absorbers. The cost is less than a dollar and the improvement in ride, handling, and safety is well worth it.

Check the condition of the rubber filler hose between the gasoline fill port and gasoline tank yearly or every time the car is on the lift. A hard, cracked, or worn hose needs to be replaced. This hose is made of rubber to absorb the differential movement between the car body and gas tank.

SUMMARY OF RECOMMENDATIONS

• Check for proper tire inflation weekly.

• Buy radial bias-ply tires at replacement time. Don’t mix radials with other type tires.

• Rotate tires periodically—every 12,000 miles or yearly.

• Clean tire treads periodically, about every 2 weeks.

• Balance tires when repairs are made, when changing to snow tires, when wheel weights are missing, or twice per year.

• Improve driving habits to lengthen tire life: slow down on curves and corners, and eliminate jack-rabbit” starts and stops.

• Change engine coolant yearly to improve the life of radiator and heater hoses.

• Inspect brake hose when brake service is performed or when the car is on the lift for any other service. Replace accordingly.

• Inspect rubber belting monthly. Replace or adjust as necessary.

• Inspect miscellaneous rubber parts at least yearly.

MECHANIC’S TIPS

Tires

• Always use a quality tire—radials if possible. Be sure the tire is suited for type of vehicle and the conditions under which it is used—for example, snow, all-terrain, or all-season tires. Tires are designed for various applications.

• Follow manufacturer’s suggestions on inflation and rotation of tires for longer tire life and safer driving.

• Check alignment and balance if tires begin to wear in an abnormal pattern.

• Never mix tire sizes or tire types on the same axle; this could be dangerous under certain conditions.

Hoses and Belts

• When replacing hoses of any type, always use the proper hose for each application and be sure it is a quality brand name. Never substitute an incorrect hose to make a permanent repair, or to cut cost of repairs.

• Check hoses for cracks and splits—signs of age and possible failure. Never check radiator hoses when system is hot or under pressure.

• Hoses and belts should be replaced every 3 years, even if they seem to be in good shape. The insides of hoses or undersides of belts are often not inspected the way they should be.

• Be certain to replace belts with proper sizes and width—as manufacturer suggests.

• Do not over-tighten belts—not only will the belt wear out before it should, but many times the bearings in the component being driven by the over-tightened belt will fail from overloading in one direction.

• Check all rubber parts more often than you think you need to. Many times a faulty hose or belt is overlooked; and this same hose or belt could be the culprit when you find yourself broken down in the middle of nowhere.

Prev: Automatic Transmissions Next: Shocks,

Mufflers, and Brakes

Home top

of page