Automatic transmissions are used in all sorts of vehicles: cars, trucks, buses, off-road heavy-duty vehicles, and sport vehicles. All automatic transmissions used on recent cars have the same general operating principles. All transmissions, manual and automatic, provide the means of selecting a forward or reverse direction for the car. Transmissions also provide combinations of speed and torque to start the car moving and keep it moving. These speed and torque ratio combinations provide the means to achieve the power, speed, and operating economy desired. Automatic transmissions perform most of the duties of the clutch and manual transmission automatically.

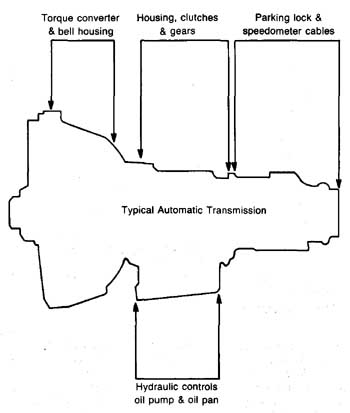

While all automatic transmissions in modern cars have the same general operating principles, parts of one type or manufacturer cannot usually be used in a transmission of another type or manufacturer. Automatic transmissions have hundreds of parts. Explaining the function of each is not our aim here. These parts can be arranged, how ever, into four major components or systems: the torque converter, the gear train, the hydraulic control system (HCS), and the transmission housing (Fig. 1).

Fig. 1. Automatic transmission.

TORQUE CONVERTER

The torque converter is mounted between the engine and the transmission gear train. The motion of the engine is transmitted via the rear end of the rotating crankshaft to the front of the torque converter assembly. Inside the torque converter this motion is transferred to the transmission gear train via a fluid connection or fluid coupling, rather than a mechanical connection or coupling (friction disc). The transmission fluid provides the means by which this fluid coupling can act. Stators and impellers inside the torque converter assembly utilize the energy of the flowing transmission fluid to transmit rotational motion to the gear train. They act much like a windmill to change fluid flow energy to mechanical shaft energy.

The purpose of the torque converter, then, is to transmit engine torque from the engine to the transmission. The torque converter also increases engine torque and reduces speed as required, depending on operating demands. It absorbs drive train and engine torsional vibrations, acts as an automatic clutch, and smooths engine operation by acting as a flywheel.

The torque converter performs these many functions, normally without requiring routine service. Typically, a torque converter can last 100,000 miles or longer under ideal conditions. Poor driving habits and lack of proper service to other car systems that affect performance of the torque converter are responsible for most torque converter problems and result in short life.

Avoid putting the transmission into drive or reverse with the engine racing too fast. Try pumping the accelerator pedal to reduce idle speed when initially starting out. Also, avoid repeated shifts from reverse to drive and drive to reverse, as when stuck in snow or on a slippery surface. These shifts are frequently made too suddenly and at too high of an engine speed.

Tune the engine at regular intervals, being especially careful to adjust the engine idle speed to specification. Faulty engine performance and too high of an idle speed will have detrimental effects on the torque converter. Also, faulty engine cooling, damaged transmission oil cooler lines, or an overloaded engine or transmission (when towing) affect the life of the torque converter.

GEAR TRAIN

The gear train connects the torque converter to the drive shaft. It consists of a planetary gear set or sets and gear shafts. The gear train in an automatic transmission provides much the same services as the gear train in a manual transmission. Forward gears ( two to four) are provided to match the forward speeds desired. A reverse speed gear (one only) is used to move the car in reverse. A neutral gear arrangement allows the engine to continue running while the car is stationary. Unlike manual transmissions, however, a park gear position is provided with automatic transmissions to prevent the car from moving when parked.

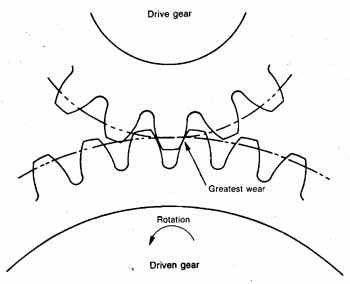

Gear trains in automatic transmissions are normally very reliable and provide long service. However, some wear is to be expected because of the relative movement of gear teeth. This wear is especially noticeable on the drive sides of the gear teeth since that is where the highest forces occur (Fig. 2). In addition, the gear train contains a number of bearings, bushings, and shafts that are also subject to wear.

Fig. 2. Wear of gear teeth.

Premature wear can be caused by low or high transmission fluid levels. Incorrect fluid levels can overheat the clutches and bands that act as holding devices to control gear operation (more about these components later). Overheating can cause failure of friction surfaces on clutches and bands, and can thin the fluid to a point where proper gear lubrication is lost. It seems obvious that dirt trapped within the transmission will cause premature wear of any close-fitting moving parts. This is a good reason to change the transmission fluid and filter often—perhaps every 25,000 miles, or sooner if towing heavy loads.

Transmission clutches and bands act as holding devices to control gear operation. Normally the bands are adjustable, so the discussion will focus on them. Bands are either rigid or flexible strips of material that are lined with a friction surface. This friction surface can be made from a relatively hard metallic coating or a soft organic material. The choice of surface coating depends on the gear operation it will affect. Metallic coatings are used on low and reverse gear bands, while the softer organic coatings are used on the faster-turning forward gear drums.

Bands are applied around gear drums by hydraulically controlled servo-pistons. The friction coating on the surface of the band keeps the gear drum from turning when the servo activates to tighten the band around the drum. The clearance between drum and band is crucial and is adjusted with an adjusting screw. This clearance should be checked and adjusted, if necessary, every time the transmission fluid is changed.

Use of the proper manufacturer’s transmission fluid is absolutely necessary for proper band operation. Incorrect fluid will change the frictional characteristics between band and drum, causing subsequent changes in shifting characteristics. This is evidenced by harsher or delayed shifts. Damage can eventually result.

HYDRAULIC CONTROL SYSTEM

The hydraulic control system (HCS) delivers the transmission fluid at the correct location, pressure, and temperature to be used by the various transmission parts. The HCS provides fluid for the torque converter, provides the correct pressure to operate clutches and bands that control gear operation, and assures lubrication and cooling to all the torque converter and transmission parts.

The HCS consists of many parts and components, as listed below:

1. A reservoir or sump to contain the transmission fluid.

2. Pressure-regulating valves to maintain correct fluid pressure to various components.

3. Flow-control valves to regulate the correct amount of fluid to various components.

4. Hydraulic servos to operate clutches and bands.

5. Cushioning devices to prevent sudden and harsh clutch and band application.

6. A lube system to provide adequate transmission fluid to the various components needing lubrication.

7. A cooling system to guard against overheating.

8. Numerous seals and gaskets to contain the transmission fluid.

9. The transmission fluid itself.

The transmission fluid is the only part of the HCS that will be discussed in detail.

TRANSMISSION HOUSING

The transmission housing is the envelope that contains all the internal parts and components of the transmission. It consists of the bell housing for the torque converter, a case for the gear train and the HCS, the reservoir, and the extension housing for the transmission output shaft. It also provides the means to bolt the transmission to the car engine and frame.

In rear-drive cars the transmission and torque converter are attached to the rear of the engine. The drive shaft transmits the engine torque and motion to the rear axle.

The differential, located in the rear axle, splits the drive to the two rear wheels. In front- drive cars the transmission, torque converter, and differential are mounted in one assembly in the front of the car, usually under or beside the engine. Open drive axles or half-shafts transmit the drive from the differential to the two front wheels. This arrangement is called a transaxle.

AUTOMATIC TRANSMISSION FLUIDS

Automatic transmission fluid (ATF) is nothing more than mineral oil of the correct viscosity with specially formulated additives. Viscosity index improver slows the rate of viscosity change in the fluid as temperature changes, just as with engine oil. Viscosity index improver additive improves transmission operation. Other additives include oxidation inhibitors and foam inhibitors. Foam inhibitors reduce entrapment of air in the ATF for effective operation of clutches and bands. Air entrapment can be caused by operating the transmission with incorrect fluid level. ATF and any additives must be compatible with all transmission materials, including steel, bronze, cast iron, aluminum, friction materials, and seal and gasket materials. A red dye is added to the ATF to distinguish transmission leaks from engine oil leaks.

Early ATF’s were the same as engine oil. However, with the advent of bigger engines, air conditioning, and towing, heavier demands were placed on the transmission and fluid. Here’s a brief history:

• Type A fluid—1949 GM, used in all automatic transmissions.

• Type A Suffix A—1957 GM, used to reduce varnish buildup.

• Type F—early 1960’s, used for Ford transmissions only.

• Dexron—1968 GM, used with higher horsepower engines.

• CJ—1977 Ford, used with automatic overdrive transmissions.

• 11—1977 Ford, used with Ford C5 transmission.

• Dexron II-D—current fluid for GM and some Chrysler and American Motors products.

The ATF is the means by which engine force and motion are transmitted to properly operate the transmission clutches, bands, servos, and valves. The ATF also cools and lubricates the various parts of the transmission, and makes a seal between moving parts. The clutches and bands with their friction coatings alone could not function with out ATF; they would seize because of the tremendous heat of friction that would be quickly generated. The ATF provides, together with these friction coatings, the required frictional characteristics that will produce the desired slip-lockup of clutches and bands.

The ATF also transmits the engine torque to the torque converter and in turn to the clutches, bands, and gears. Tremendous heat is generated by this process and must be absorbed and dissipated to the atmosphere by the fluid in order to prevent overheating and subsequent damaging oxidation of the fluid.

ATF level changes with temperature and as a result of the varying needs of clutches and bands in different gear arrangements. Normal operating temperatures for transmission fluid are in the range of 175 to 185 degrees Fahrenheit. Use of air conditioning, stop- and-go traffic conditions, pulling heavy trailers, or rocking the car from forward to re verse repeatedly can cause overheating. Rocking a car can cause temperatures within the ATF to rise to 300 degrees Fahrenheit and beyond. If temperatures continue to rise, friction materials on clutches and bands can be destroyed. Avoid rocking a car with an automatic transmission; use another means to free up the car.

Time, temperature, overloading, and overuse take their toll on the transmission and fluid. With time, a buildup of burned friction materials from clutches and bands, and particles from cracked seals can foul the ATF. It’s imperative to check the level and condition of the ATF periodically, especially under high-mileage operation. Check every 2 weeks; once a week if towing.

Check the ATF level at operating temperature, with the vehicle level, parking brake on, and gear selector lever in the factory-recommended position. Refer to the shop or owner’s manual for interpretation of the fluid level markings found on the transmission dipstick. A low fluid level results in insufficient pressure to operate the clutches and bands. This causes slippage of the friction materials and overheating. A high fluid level will cause churning and foaming of the ATF. Foaming air is trapped in the ATF and is carried into the hydraulic control system. This, too, will cause clutch and band slippage and subsequent overheating.

The appearance of the ATF should be inspected on a clean, white cloth. Put a few drops on the fingers first. The ATF should feel smooth and slippery. Smell the fluid. If there is a burnt smell, the transmission might need servicing. Normally the ATF is pink in color. The fluid can be a light amber color but should not be a brown or dark color. Look for metallic particles or friction materials from clutches and bands. There shouldn’t be any. A milky fluid indicates a coolant leak in the ATF via the fluid cooler in the radiator. It should be serviced immediately. Also check for any dark brown varnish deposits.

SUMMARY OF RECOMMENDATIONS

• Change transmission fluid and filter, and clean the pan every 25,000 miles with the recommended fluid. Do this about every 10,000 miles if towing a heavy load.

• Check and adjust the bands to specification at every fluid change.

• Use factory-recommended fluid only. Never substitute and never use engine oil in an automatic transmission.

• Maintain fluid at specified level. Never overfill. Check every 2 weeks or sooner.

• Never rock a car with an automatic transmission. Always shift casually, never suddenly from a forward gear to a reverse gear, and vice versa.

• Keep engine idle speed within specified limits. Check monthly.

MECHANIC’S TIPS

• Check and adjust the shift linkage and throttle linkage to specification at least once a year.

• Check and adjust the vacuum modulator system at least once a year.

• Check the exhaust gas recirculation system (EGR) at least once a year.

• Install after-market transmission oil cooler if doing heavy towing to ensure longer automatic transmission life.

• Servicing a transmission is many times less expensive than overhauling one. Most people never think of their transmission until it doesn’t work.

• Never use dirty containers to store transmission fluid. Never use cans of transmission fluid that had been opened previously.

• When adding fluid to the automatic transmission, be sure the funnel is clean. Otherwise, you might be pouring in trouble instead of prolonging the life of your transmission.

• Use a lint-free rag to wipe the ATF dipstick. Lint will do more harm than dirt to the transmission.

Prev: Grease Lubrication Next: Wear of Tires, Hoses, Belts, and Other Rubber Parts

Home top

of page