“Change the oil and grease it” are instructions a mechanic hears many times during a week. Oil changes and grease jobs are undoubtedly two of the most common maintenance items performed on cars.

WHAT IS IT?

Grease is essentially a combination of a base mineral lubricating oil, as discussed in Section 3, and a thickening agent, such as a metallic soap. The many different types of greases are classified according to the soap base used (Table 4-1).

Table 4-1. Greases.

Metallic Soap Base |

Structure |

Operating Temperature |

Operating Load |

Application |

Calcium (lime) soap Sodium (soda) soap Aluminum soap Lithium soap Barium soap |

Smooth Fibrous Salve-like Smooth Short fibers |

160° F Max 300° F Max 180° F Max 300° F Max 350° F Max |

Moderate Wide range Moderate Moderate Wide Range |

Wide speed ranges Low temperature Multipurpose |

Synthetic grease is composed of the same types of metallic soaps, as stated above, but contains synthetic hydrocarbons instead of the usual base mineral oil. Synthetic greases are used in industry because of their ability to operate under a wide range of temperature.

Greases, just like lubricating oils, are available with additives. Additives, such as oxidation inhibitors and extreme-pressure additives are common. Filler materials such as mica, lead, zinc, carbon black, or graphite can be added to greases to enhance their lubricating ability. Normally, fillers are used to best advantage with extremely heavy loads or intermittent motion.

Classification is also made according to the application method. The National Lubricating Grease Institute (NLGI) has assigned NLGI consistency numbers to greases. This classification is shown in Table 2, along with methods of application.

Table 2. NLGI Classification.

NLGI No. |

Consistency |

Application Method |

0 1 2 3 4 5 6 |

Semifluid Very soft Soft Light cup grease Medium cup grease Heavy cup grease Block grease |

Bush or gun Pin-type cup or gun Pressure gun or pressure system Pressure gun or hand Hand, cut to fit |

The calcium soap-base grease listed in Table 4-1 is made by forming an emulsion of oil, soap, and water. Dehydration or loss of the water can occur in service or during long storage, especially when high temperatures are encountered. Excessive working of the grease also tends to cause dehydration. For these reasons, the calcium soap-base grease is recommended where renewal of the grease is periodic (where new grease displaces the old grease), where working of the grease is not excessive, and where water is present. This grease might typically be used in steering linkages or suspension parts.

In sodium soap-base grease, water is not required to form the grease emulsion. It has a high melting point (400 degrees Fahrenheit), is soluble in water, and can withstand excessive working. This grease is used in high-temperature environments and where service is continuous, such as in roller bearings.

WHAT DOES IT DO?

In some applications, lubricating oils such as engine oil cannot be used because of their tendency to flow. Greases successfully overcome this difficulty. The metallic soaps mentioned above serve as the thickeners that act to keep the oil in place. Some of these thickeners have a lubricating quality of their own. However, it is actually the oil that is slowly released or bled from the grease that provides the bulk of the lubricating quality of the grease. When the oil has been depleted to 50% of the total weight of the grease, the lubricating quality of the grease is unreliable. This is one reason, along with the entrapment of dirt, that grease needs to be renewed periodically.

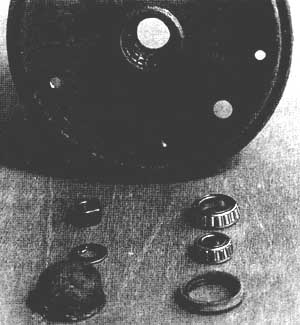

In order to replenish this lost lubricating oil, bearings are supplied with an extra amount of grease in a reservoir or cavity close to the rolling element of the bearing. In a front wheel bearing assembly (Fig. 4-1), the hub cavity serves as this reservoir. Typical wheel bearing repacking instructions will include directions to put a glob of grease in the hub cavity. Care must be taken not to fill this cavity too full. Filling the cavity flush with both bearing races is the recommended limit. Excessive packing causes overheating, churning, and aerating, not to mention slippage of grease past the bearing seal and onto the brake lining. Follow the manufacturer’s recommendations for application.

Fig. 1 Front wheel bearing assembly.

WHERE IS IT USED?

The front wheel bearings (on rear-wheel drive cars), the steering linkages, and the suspension parts are the major items that need periodic re-greasing. Other parts include door, trunk, and hood hinges and latches, window slides, and various linkages and cables.

Wheel Bearings

Use only a specially formulated, fresh, clean wheel bearing grease for the front wheel bearings. Some manufacturers do not recommend using a fibrous-type grease. If so, follow their recommendation for grease type and NLGI classification. In the absence of a manufacturer’s recommendation, we recommend using a good-quality sodium-, lithium-, or barium-based grease with an NLGI classification of 3. Remember to select one specially formulated for wheel bearings. Further, we recommend re-greasing the front wheel bearings at the manufacturer’s recommended interval or at every other oil change (every 6,000 miles), whichever is sooner.

Steering Linkages/Suspension Parts

These parts are not designed to experience high speed, intermittent loads, or high temperatures. They are exposed more than wheel bearings to water, ice, and snow, so take care to select an insoluble grease. Again, as for wheel bearings, follow the manufacturer’s recommendations as to type. In the absence of other recommendations, use either the calcium- or aluminum-based grease of NLGI Nos. 2-4. Be sure the grease fittings are clean before re-greasing. Perform this maintenance at the manufacturer’s recommended interval or at every oil change (every 3,000 miles), whichever is sooner.

Universal Joints

All rear-wheel drive cars employ drive shafts that connect the transmission to the rear differential gears via two, and sometimes three, universal joints or U-joints. Some U- joints are lubricated for life at the factory and need no periodic lubrication. Others need to be lubricated periodically. You can tell if periodic lubrication of the U-joints is necessary by inspecting the U-joints for evidence of a grease fitting. If a grease fitting exists, then the U-joints must be re-greased periodically. Follow the manufacturer’s recommendations or re-grease every other oil change (every 6,000 miles), whichever is sooner. In the absence of a recommendation of grease type, use a sodium or barium grease of NLGI No. 3 or 4.

WHITE GREASE

White grease is a light, lithium-based grease that is used to lubricate hinges, latches, linkages, and cables. It is creamy in color and texture. It will not wash away or dry out, and it also protects against rust and corrosion. It usually is bought in a small tube with a screw cap. To apply, simply squeeze the tube.

Lubricate door, hood, and trunk hinges and latches with white grease twice a year. Remember to clean the old grease completely before applying the new. It can also be used to lubricate cables and linkages such as those found on carburetors. Lubricate cables and linkages at their connection or termination points, and where they run through the fire wall or turn round a pulley. If your car has a standard transmission with the clutch activated by a clutch cable, follow this recommendation: use white grease at the termination points, but use a light grease with a graphite filler at the places the clutch cable rounds a pulley. The graphite particles will intersperse with the cable strands at these flexure points and provide marvelous lubrication.

MANUAL TRANSMISSION/REAR AXLE/STEERING GEAR BOX LUBRICANT

The manual transmission, the rear axle, and the steering gear are included in this section because these components use very viscous oils as lubricants. These oils are not greases, but the subject matter fits here.

Check the level of these lubricants at least twice a year, more often ii any heavy or long-term towing is done. Lubricant levels should be maintained at the level of the threaded plug used to contain the lubricant. In no case should the lubricant level be more than ¼ to ½ inch below the threaded hole. If the lubricant level is low, add the manufacturer’s specified type only. This is usually an SAE-80 or -90 multipurpose gear lubricant. For limited-slip axles a special lubricant with additives is required. Add lubricant with a gear lubricant syringe.

Change these lubricants yearly. Manual transmission lubricant can be changed by drawing out as much of the old lubricant as possible with a lubricant syringe before refilling with fresh lubricant. Rear axle lubricant change can be performed in the same manner. Look for a drain plug on the rear axle differential case, however, before proceeding with the syringe. If the case has a drain plug, drain the fluid by removing the plug. Refill by reinstalling the drain plug and adding the proper amount of fresh lubricant with the syringe. Follow the same procedure for the steering gear box.

SUMMARY OF RECOMMENDATIONS

• Clean and grease wheel bearings every 6,000 miles. Use the factory- recommended grease type. If no recommendation is available, use a quality sodium-, lithium- or barium-based grease of NLGI No. 3 that is specially formulated for wheel bearings.

• Re-grease the steering linkages and suspension parts every 3,000 miles with the factory-recommended type grease. If no recommendation is available, use a calcium- or aluminum-based grease of NLGI Nos. 2-4.

• Lube the U-joints (if they are the lubeable type) every 6,000 miles with the factory- recommended grease. If no recommendation is available, use a sodium or barium grease of NLGI No. 3 or 4.

• Lubricate all door, hood, and trunk binges and latches with white grease twice a year.

MECHANIC’S TIPS

• Refer to the shop manual when performing a grease job to be sure to locate all the applicable grease fittings.

• Don’t mix grease types. Mixing two types of grease will impair the performance.

• Inspect the old grease and transmission, axle, or steering gear lubricant for presence of any dirt or metal chips or filings.

• Grease the car when the temperature of the fittings is above freezing. Joints will not accept grease when they are cold.

• Always follow the factory-recommended methods when performing lube service.

• Check for other lubrication areas in the shop manual and perform at those recommended intervals or sooner. If your plan is to perform them sooner, consider doing them twice as often as recommended in the shop manual.

• The recommendations made in this section all boil down to one thing: if you get serious about lubrication of suspension and drive train components, you’re bound to save a lot of money and aggravation. Tie-rod ends, ball joints, center links, and idler arms are not cheap when it comes time to replace them. Most of these repairs need to be done in a repair shop because of the special tools required to do the job right.

• Wheel bearings, universal joints, and axle bearings that fail due to lack of lubrication not only cost plenty to repair but are often the cause of accidents. Wheels may lock up, causing loss of control of the vehicle, or drive shafts may fall out from under the car and jamb into the pavement or hit the car following you.

• Lubricate connection and termination points of linkages and cables twice a year with white grease. In the case of shift or clutch linkages, use a multipurpose molybdenum grease.

• Lubricate clutch cables, if applicable, twice a year with a light grease containing a graphite filler. Do this in the area where the cable rounds a pulley or goes through the fire wall.

• Check lubricant levels of the manual transmission, the rear axle, and the steering gear box at every oil change. Change these lubricants once a year with the factory- recommended types.

MORE MECHANICS TIPS

• If hinges and linkages don’t free up or respond to grease lubrication, try some penetrating oil to clean out old grease. Then lube with clean grease.

• Keeping your suspension parts lubricated and in good working order can save on tire wear and many times wear on the driver. It’s no fun having to fight to keep your car on the road because of a worn-out front end. Again, consider the safety aspects of maintaining your car.

• Add only enough grease to a suspension joint to swell the rubber seal. Too much grease could break the seal, which must then be replaced. Joints that are not sealed should be lubricated until fresh grease appears at the joint edge.

• In cars designed with front-wheel drive, the axle drive or differential is located in the same housing as the manual transmission. These two components share the same lubricant. Check the lubricant level in the same manner as rear-wheel drive cars. If the front-wheel drive car has an automatic transmission, the two components will have separate lubricants and fill holes. Follow the recommendations in the shop manual.

Prev: Oil Lubrication Next: Automatic

Transmissions

Home top

of page