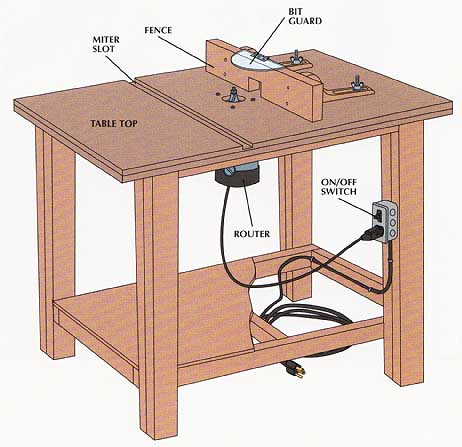

Easy and inexpensive to build, a router table transforms your router into a stationary tool for shaping edges and cutting grooves. The arrangement has advantages over hand-held routing. Feeding stock into the tool gives you greater control over the operation. Also, certain large router bits can be used only on a table-mounted router. The table shown below feature an ample top, an adjustable fence, a storage shelf, and a conveniently located on/off switch.

Design and Size: A typical table measures 25 inches by 40 inches, but you can vary the size to suit your needs. To ensure the table top is perfectly flat and even, prepare it by gluing together two sheets of 1/2-inch medium-density fiberboard (MDF), which is flatter and more stable than plywood. You can cover the table top with plastic laminate for a smoother surface; sheathe the underside too so the top won’t warp.

SAFETY TIPS: Wear goggles when nailing or when operating a power tool.

Tools:

- Hammer

- Screwdriver

- Tape measure

- Circular saw

- Electric drill and assorted bits

- Router

- Awl

- Saber saw

- Jointer

MATERIALS:

- Fiberboard (1/2”)

- 2 x 4s

- Plywood (1/2”)

- Wood glue

- Wood screws (3/4”, 2½”, 3” No. 8)

- Machine screws ( No. 8)

- Common nails (1½”)

- Angle irons (2”)

- Carriage bolts (3/8” x 3”), washers, and wing nuts

- Polycarbonate sheet

- Butt hinge

- Switch-receptacle with electric cord

A router table holds a router upside down with its bit protruding from a hole in the table top. The tool is screwed by its base to the underside of the table top. For the base, adapt the backboard-bench design shown earlier.

A miter slot routed across the top to one side of the bit allows a workpiece to be guided by a miter gauge for cross-grain routing. Make the slot the same width as your table saw’s gauge. Combined with a clear plastic guard that offers protection from the bit, a fence is used for routing with the grain. The fence’s slotted supports, with wing nuts that hold them in place, allow for quick adjustment of the fence.

A switched receptacle on one of the table legs saves the user from having to reach under the table for the router switch. The tool is plugged into the receptacle with its switch left on so it can be turned on and off with the receptacle’s switch.

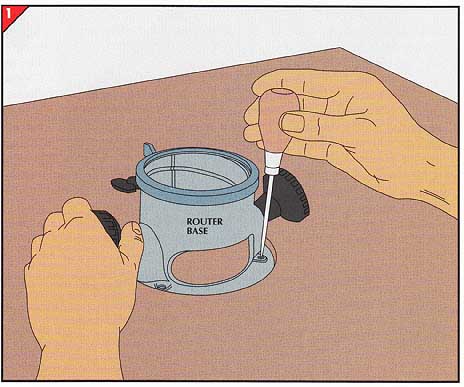

• Position the router on the underside of the table top and outline its base with a pencil.

• Rout a 1/4-inch-deep recess within the outline. Separate the router body from its base, unscrew the thin plate under the base, and set the base in the recess.

• With an awl, mark the recess through the screw holes in the base. Drill a hole for the screws at each mark and countersink them into the top surface of the table.

• With a spade bit or hole saw larger in diameter than your largest router bit, bore through the center of the recess.

• Set the router base in the recess, and fasten it to the table top with 7/8- inch No. 8 machine screws.

• Secure the top to the table base with 2-inch angle irons and 3/4-inch wood screws.

• Attach the router body to the base.

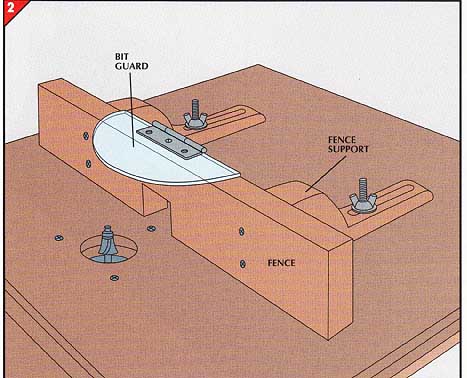

• Cut the fence and supports from 2-by-4s. With a saber saw, cut the supports to shape—wide at one end and narrow at the other—and cut 4- inch slots in the narrow end.

• Run the face of the fence across a jointer to flatten it.

• Cut a notch from the fence’s bottom edge to accommodate your largest bit.

• Drill countersunk pilot holes, then secure the fence to the supports with 3-inch No. 8 wood screws.

• Attach a clear semicircular piece of polycarbonate as a bit guard to the fence with a butt hinge so it can be raised out of the way if necessary.

• Set the fence assembly on the table about 1 inch from the bit opening. Drill a 3/8-inch hole into the table top through the center of each slot. Fasten the fence to the table with 3-inch-long 3/8-inch carriage bolts, washers, and wing nuts.

Next: Portable Shop

Accessories

Prev: Adding Accessories

to Power Tools