AMAZON multi-meters discounts AMAZON oscilloscope discounts

Learning Goals:

- • Describe the purpose of push-button speed selection of wound rotor motors.

- • Describe what happens during acceleration and deceleration of a motor used with a push-button speed selector control.

- • Connect wound rotor motors and push-button speed selector controls.

- • Recommend troubleshooting solutions for wound rotor problems.

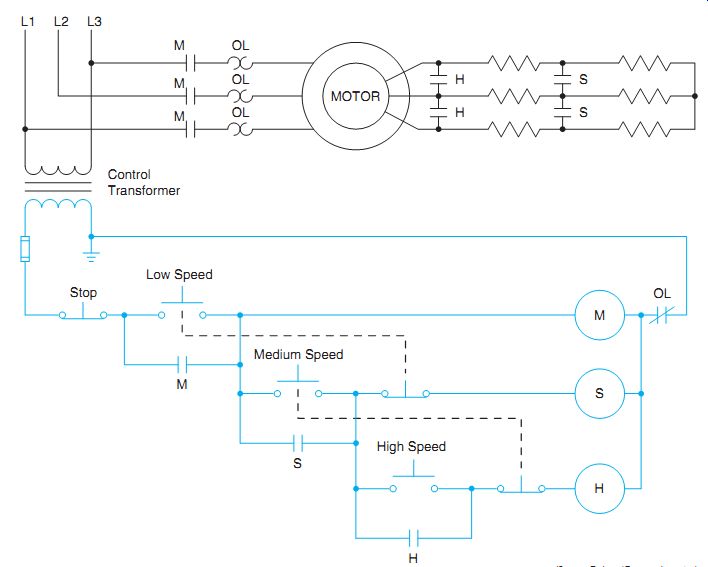

Magnetic controllers for wound rotor motors consist of (1) a magnetic starter that connects the primary or stator winding to the power line and (2) one or more accelerating contactors that cut out steps of resistance in the secondary or rotor circuit. The number of accelerating contactors depends on the desired number of speeds for the motor. Enough steps of speed are used to ensure a smooth acceleration and to keep the inrush or starting current within practical limits. The circuit shown in ill. 1 permits three steps of speed. The motor must be started in low speed and progress to second speed and then to high speed. If the motor is operating in high speed, a slower speed can be selected by pushing the appropriate speed push button.

ill. 1 Push-button speed selection for a wound rotor motor.

The motor is started by pressing the low speed push button and energizing coil M, causing power to be supplied to the motor's stator winding through load contacts M. The motor starts slowly with full resistance in the secondary circuit. When the second, or medium-speed, push button is pressed, contactor S energizes and closes the two S load contacts. This shorts the first bank of resistors out of the circuit and the motor accelerates to a higher speed. When the high speed push button is pressed, contactor H energizes and shorts all the resistance out of the rotor circuit and the motor accelerates to its highest speed.

If it's desirable to go from high to medium speed, pressing the medium-speed push button causes the normally closed medium-speed push button to open and de-energize contactor coil H, causing the H load contacts to open and one bank of resistors to be connected back in the rotor circuit. This additional resistance in the rotor circuit will cause the motor to slow down. A similar change can be made from medium to low by pressing the low-speed push button. The speed can also be changed from medium to low or high to low by pressing the low-speed push button.

This method of push-button speed selection is achieved by a relatively simple, inexpensive control installation. The resistors should have a high enough power rating to operate at any speed.

A disadvantage of this method is that the motor and the driven machine can be accelerated without allowing sufficient time between steps for the rotor to gain its maximum speed for each step of acceleration. The desired time delay can be achieved by adding compelling relays to the circuit to prevent too rapid an acceleration.

QUIZ:

1. Can the motor in ill. 1 be started in medium or high speed? Why?

2. Must the stop button be pressed between speeds on acceleration or deceleration? Why?

3. When the motor is being accelerated, must each speed push button be closed in succession? Why?

4. Is it possible to transfer from high speed to low speed without pressing the medium push button? Why?

5. Do all contactors remain energized when the motor is in high speed?

6. Acceleration resistors cannot be used for continuous duty. Why is this true and what may happen if an attempt is made to use them for continuous duty?

7. Draw a line diagram of a three-speed acceleration control that uses compelling timing relays to prevent too rapid an acceleration.