AMAZON multi-meters discounts AMAZON oscilloscope discounts

GOALS:

• Describe the general operation of electric brakes, both AC operated and DC operated.

• State the advantages of DC shunt wound brakes over AC-operated brakes.

• Describe the function of typical braking circuits for hoists and cranes.

• Connect motors and braking controllers.

• Recommend troubleshooting solutions for electric brake problems.

Many modern industrial processes require very powerful motors running at increased speeds.

These motors must frequently be stopped in a shorter time than can be obtained by disconnecting the power from the motor. When machines require one or more motors and more precise control, and there is less time available to wait for the machines to coast to a standstill, then it's even more important to provide faster stopping methods.

Since the early 1900s, electric brakes have been in use. These are also known as magnetic brakes, friction brakes, and mechanical brakes.

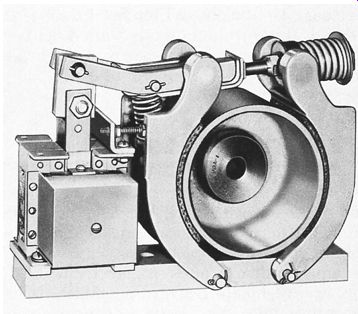

An electric brake consists of two friction surfaces, or shoes, which can be made to bear on a wheel on the motor shaft, Ill. 1. Spring tension holds the shoes on the wheel. Braking is achieved because of the friction between the shoes and the wheel. A solenoid mechanism is used to release the shoes.

ill. 1 Solenoid brake used on machine tools, conveyors, small hoists, and similar devices.

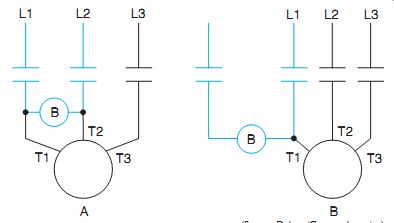

ill. 2 AC brake coil connections for across-the-line starting. Control

relays and contactors also are used to control magnetic brakes.

In a magnetically operated brake, the shoes are held in a released position by a magnet as long as the magnet coil is energized. However, if a pilot device interrupts the power, or there is a power failure, then the brake shoes are applied instantly to provide a fast, positive stop.

The coil leads of an AC magnetic brake are normally connected directly to the motor terminals, Ill. 2. If a reduced-voltage starting method is used, the brake coil should be connected to receive full voltage.

Magnetic brakes provide a smooth braking action. This feature makes them suitable for high-inertia loads. Because these brakes apply and remove the braking pressure smoothly in either direction, they are often used on cranes, hoists, elevators, and other machinery where it's desirable to limit the shock of braking.

This brake is operated by a vertically mounted torque motor. When power is applied to the brake torque motor, the shaft of the motor turns and lifts the operating lever of a ball jack to release the brake. When the brake is fully re leased, the torque motor is stalled across the line. When power is released from the brake, a heavy compression spring counteracts the jack lever so that the brake is applied quickly.

MAGNETIC DISC BRAKES

Disc brakes can generally be installed wherever shoe brakes are used. Disc brakes can also be installed where appearance and available space prohibit the use of shoe brakes.

Magnetic disc brakes are used on machine tools, cranes, hoists, conveyors, printing presses, saw mills, index mechanisms, overhead doors, and other installations. The control adjustments of the torque and wear of disc brakes are similar to those for shoe brakes. A disc brake is a self-enclosed unit that's bolted directly to the end bell of the motor. (This end bell operates on the motor shaft.) The braking action consists of pressure released by a solenoid and applied by a spring on the sides of a disc or discs.

DC MAGNETIC BRAKES

The construction of DC magnetic brakes is similar to that of AC shoe brakes. For DC magnetic brakes, however, the operating coils are shunt wound for across-the-line connections and series wound for connecting in series with DC motor armatures.

Shunt-wound brakes pick up at approximately 80 percent of the rated voltage and drop out about 60 percent. Series-wound brakes pick up (release) at about 40 percent of the full-load current of the motor and drop out (set) when the current reaches 10 percent of the full-load value.

The brake linings for DC magnetic brakes are similar to those for AC brakes. The linings are made of molded or woven asbestos with high friction resistance. They are bonded or riveted to steel backplates. Brakes range in size from approximately 1 inch to 30 inches in diameter. Large-diameter shunt-wound brakes are available with a relay and protective resistor to permit operation at high speed. Brakes with smaller diameters pick up and drop out quickly without this added feature. The large-diameter, high-speed brakes release quickly. When the armature closes, the protective resistor is inserted in the circuit. This action reduces the holding current to a low value and keeps the coil cooler.

As a result, the brake sets quickly. High-speed brakes are suitable for any duty. They can be operated on alternating current if a rectifier unit's added.

The operation of DC magnetic brakes may be sluggish due to the induction present, unless the manufacturer has attempted to overcome it in order to speed the brake operation. The following list gives advantages of the use of DC brakes for shunt-wound operation (as compared with AC brakes).

- Laminated magnets or plungers are not used.

- Magnet and armature are cast of steel.

- No destructive hammer blow.

- Fast release and fast set.

- No AC chatter.

- Short armature movement.

- No coil burnout due to shoe wear, which affects the air gap.

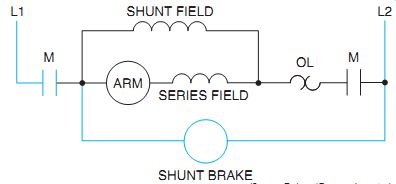

Ill. 3 shows the connection of a DC brake in a circuit that does not allow armature regeneration through the brake coil. As a result, the brake is prevented from setting.

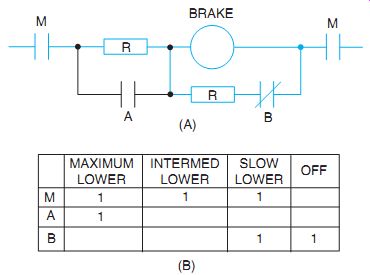

Ill. 4(A) shows a shunt brake control circuit. (This circuit's a small portion of a crane hoist elementary diagram.) The target table in Ill. 4(B) lists the contacts that are closed for different crane-lowering operations. Note how the brake is weakened by the use of resistors in series and in parallel.

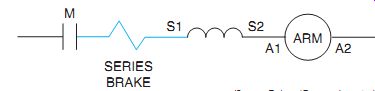

Series-wound brakes generally are used with series motors, Ill. 5, and must have the same full-load current rating as the motor. The brakes must be properly sized for their loads also. Series-wound brakes may be used for heavy hoist applications and for many metal processing applications, such as steel mill drives and conveyors.

ill. 3 DC shunt brake connections with motor connections.

ill. 4 Varying friction braking.

ill. 5 Series brake connected with series motor.

QUIZ:

1. Why are magnetic brakes used?

2. How do electric brakes operate?

3. When an AC reduced voltage starter is used, how should the electric brakes be wired for release?

4. Why should protective resistors be provided on coils for high-speed shunt brakes?

5. In Ill. 4,which contacts are closed when the brake coil receives full voltage?

6. What precautions must be taken when matching a series-wound brake to a motor?

7. How are electric brakes adjusted in general?

8. What may cause a de-energized brake to slip under load with maximum spring tension?