Home

Articles

Forum

Glossary

Books

Sitemap

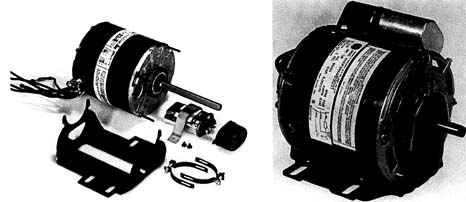

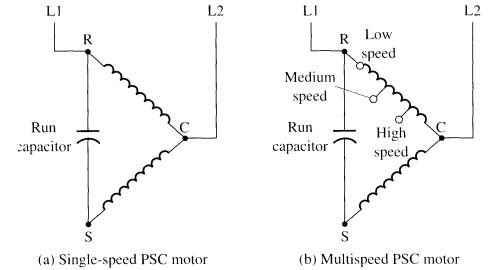

The permanent split-capacitor (PSC) motor uses only a run capacitor to provide the phase shift required to start the motor. Fig. 1 shows examples of PSC motors, and Fig. 2 shows two diagrams of the PSC motor. In the diagrams note that the run capacitor is connected between the run and start windings and no disconnecting switch or relay is required to dc-energize the start winding from the applied voltage when the motor has started. Also note that the run capacitor is oval shaped. The run capacitor has a metal case, which allows it to dissipate extra heat that is built up in the capacitor since it remains in the circuit at all times.

Buy Permanent Split-Capacitor Motors at Global Industrial - Shop Over 75,000 Products Online for all your Industrial Needs!

Above: Fig. 1: Examples of permanent split-capacitor (PSC) motors. Notice the

run capacitor mounted on the second motor.

Above: Fig. 2: (a) Electrical diagram of a PSC motor. (b) Electrical diagram

of a multi-speed PSC motor.

When voltage is applied to the motor, current will flow through the run winding to the common terminal. At this same time current will flow through the run capacitor to the start winding. When the current flows through the run capacitor. it will provide a phase shift that is large enough to start the motor. As the rotors speed increases, a counter EMF will he produced in the start winding that will limit current through it to less than 1 A when the motor reaches full speed. The small amount of current in the start winding when the motor is operating at full speed is small enough so that it won't cause the start winding to overheat.

When the motor shaft sees an increase in its load, it will slow down slightly. The decrease in the rotor’s rpm causes a decrease in the counter EMF. which makes a larger potential difference between it and the applied voltage. The larger potential difference causes an increase in the current in the start winding, which will cause an increase in rotor torque that increases the rotor’s rpm.

above: A permanent split-capacitor-motor 5-inch

This characteristic allows the PSC motor to operate with a constant speed under varying load conditions without using any mechanical devices. The PSC motor is generally used for applications such as small hermetic compressors. blade fan loads, and other loads that require constant speed.

More examples...

above: LEESON fan and blower duty motor. Uses a permanent-split-capacitor

(that "hump" on top).

above: LEESON Reversing motor. Uses Permanent split capacitor design (those three humps on top are capacitors).

Above: Example by A.O. Smith 733A, 5-5/8" Enclosed Fan/Blower Motor

115/208-230 Volts 1140 RPM 1/2 HP

Sold by: globalindustrial (web link)

Hertz: 60

Phase: 1

Overload: Automatic

Mounting: Mounting kit

Frame: 48

Product Specifications

AMPS --

BEARING TYPE Ball

BRAND A.O. Smith

DIAMETER INCHES 5-5/8

FRAME 48

HORSEPOWER 1/2

LENGTH LESS SHAFT INCHES --

MANUFACTURERS PART NUMBER 733A

ROTATION Reversible

VOLTAGE 115/208-230

MOUNT TYPE Resilient Base

ENCLOSURE TYPE Totally Enclosed

RPM 1140

SPEEDS 1

SHAFT TYPE Single

SHAFT LENGTH INCHES 4-1/2

SHAFT DIMENSION INCHES 1/2 x 4-1/2

OVERLOAD Automatic

SERVICE FACTOR 1.00

SHAFT DIAMETER INCHES 1/2

References: