AMAZON multi-meters discounts AMAZON oscilloscope discounts

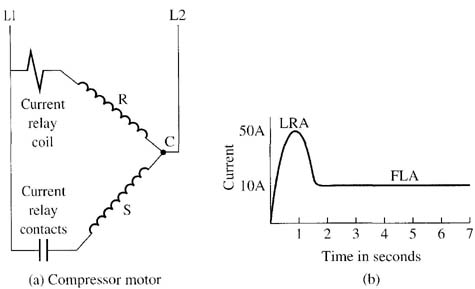

From Fig. 1b notice that when voltage is applied to the compressor, the run winding will pull locked-rotor amperage (LRA) of up to 40 A. Since the coil of the current relay is in series with the run winding, it will also see this large current, which will be strong enough to pull the current relay’s contacts closed. When the contacts close, it will provide a path for voltage to reach the start winding. This voltage will also pass through the start capacitor, which causes a phase shift in the magnetic field in the start winding and the torque will be strong enough to start the compressor motor even though it's under 70-80 psi of pressure.

Above: Fig 1.

The current relay has a return spring connected to its contacts that tries to pull them open. After the motor starts and picks up speed, the rotor will produce enough counter EMF to allow the full-load current ( FLA) to drop substantially. When the motor’s current drops to the FLA level of 3 to 4 A, the spring will pull the contacts open. This drop in current from LRA to FLA occurs in 1 to 2 seconds as the motor reaches full speed. When the contacts open, the start capacitor and start winding are removed from the circuit and their current drops to zero. Since the run winding continues to be energized, it will draw FLA and the motor will continue to run. A graph of the locked rotor current and full-load current is also shown in Fig. 2b. Note that LRA only exists for several seconds while the rotor is coming up to speed. This current is strong enough to pull the current relay’s contacts closed for the few seconds the motor requires to start.

Above: Fig 2.

Since the current relay is mounted on the outside of the compressor, it can easily be replaced if it becomes faulty. It can also be tested easily by checking voltage from L2 to the S terminal of the motor during the time the motor is starting. If no voltage is present at terminal S during start, the start capacitor should be removed from the circuit and an attempt made to restart the motor. Allow the motor to try to start for only a few seconds during this test because continued LRA current will damage the motor.

If terminal S on the motor receives voltage when the capacitor is removed, one can assume that the capacitor is open. If the terminal still does not receive voltage, the current relay is faulty and should be replaced.