AMAZON multi-meters discounts AMAZON oscilloscope discounts

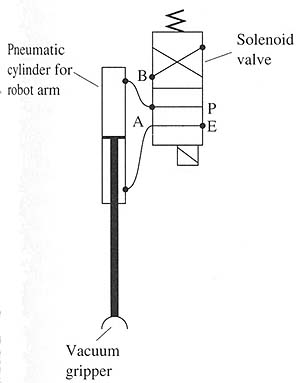

Solenoids are used in a wide variety of applications. Simple applications include energizing a valve to allow fluid such as water or solvents to flow. A more widely used application includes control of air for use in pneumatic cylinders or control of oil for hydraulic cylinders. For example, a pneumatic cylinder can be used to move machine tools into place for cutting and drilling applications, or a pneumatic cylinder can be used for one or more axes on a robot. Ill. 1 shows an example of a solenoid valve that's used to control the extension and retraction of a pneumatic cylinder for a robot. The cylinder controls the up-and-down action of the robot for pick and place operation. When the cylinder is extended, the vacuum cup on the end of the rod is down on a conveyor to pick up a part. When the cylinder is retracted, it picks the part up and the robot moves from the conveyor to a machining fixture where the cylinder is extended again to drop the part into the fixture.

Above: Ill. 1: An air cylinder connected to a solenoid valve. The air

cylinder is part of a robot arm that uses a vacuum cup to pick up parts.

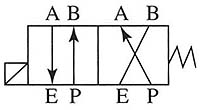

The solenoid valve has four ports that are labeled P (pressure), E (exhaust), A, and B. Notice the diagram symbol for the valve shows two boxes with the ports identified in one. It's important to understand the physical valve has four ports identified as P, E, A, and B. The symbol for the valve shows the valve body two times to indicate the position of the valve passages when the coil for the valve is energized and when it's de-energized:

In the diagram of the valve, the ports shown in the box near the coil indicate the position of the valve when the coil is energized. In this condition, the pressure port (P) is connected to the B port, which allows air to fill the cylinder and causes the rod to extend. It's important to understand that the front port on the cylinder is connected to the A port, which is connected to the exhaust port (E) when the valve is energized. This allows a passage for the air in the front part of the cylinder to escape so the valve rod can move forward.

The diagram on the side of the valve near the spring symbol shows the position of the valve passages when the valve is de-energized. When the coil is de-energized, the spring moves the valve spool to a position where the pressure port (P) is connected to the A port and the exhaust port E is connected to the B port. This allows air pressure to enter the front of the cylinder and causes the rod to retract. The rear port of the cylinder is connected to the B port on the valve, which allows air to exhaust and the rod to retract.