AMAZON multi-meters discounts AMAZON oscilloscope discounts

GOALS:

- Describe the differences between analog and digital inputs.

- Discuss precautions that should be taken when using analog inputs.

- Describe the operation of a differential amplifier.

Some facts:

- The pressure sensor produces 1 to 5 volts at 4-20mA.

- Resistance in the lines can cause problems.

- The current must be the same in a series circuit.

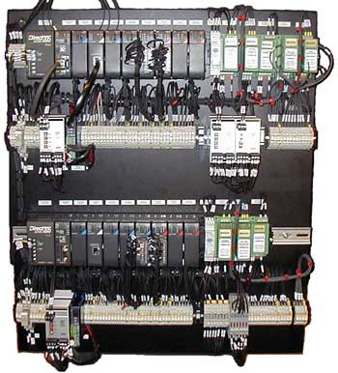

above: PLC used in railroad apps, such as traction control.

Many of the programmable controllers found in industry are designed to accept analog as well as digital inputs. Analog means continuously varying. These inputs are designed to sense voltage, current, speed, pressure, temperature, humidity, etc. When an analog input is used, a special module mounts on the I/O Rack of the PLC. An analog sensor may be designed to operate between a range of settings, such as 50 to 300 C_, or 0 to 100 psi. These sensors are used to indicate between a range of values instead of merely operating in an on or off mode. An analog pressure sensor designed to indicate pressures between 0 and 100 psi would have to indicate when the pressure was 30 psi, 50 psi, or 80 psi.

It would not just indicate whether the pressure had or had not reached 100 psi. A pressure sensor of this type can be constructed in several ways. One of the most common methods is to let the pressure sensor operate a current generator which produces currents between 4 - 20 milliamperes. It’s desirable for the sensor to produce a certain amount of current instead of a certain amount of voltage because it eliminates the problem of voltage drop on lines. For example, assume a pressure sensor is designed to sense pressures between 0 and 100 psi. Also assume that the sensor produces a voltage output of 1 volt when the pressure is 0 psi and a volt age of 5 volts when the pressure is 100 psi. Since this is an analog sensor, when the pressure is 50 psi, the sensor should produce a voltage of 3 volts. This sensor is connected to the analog input of a programmable controller. The analog input has a sense resistance of 250 ohms. If the wires between the sensor and the input of the programmable controller are short enough (so that there is almost no wire resistance), the circuit will operate without a problem. Because the sense resistor in the input of the programmable controller is the only resistance in the circuit, all of the output volt age of the pressure sensor will appear across it. If the pressure sensor produces a 3 volt output, 3 volts will appear across the sense resistor.

If the pressure sensor is located some distance away from the programmable controller, however, the resistance of the two wires running between the pressure sensor and the sense resistor can cause inaccurate readings.

Assume that the pressure sensor is located far enough from the programmable controller so that the two conductors have a total resistance of 50 ohms: the total resistance of the circuit is now 300 ohms (250 +50 =300). If the pressure sensor produces an output voltage of 3 volts when the pressure reaches 50 psi, the current flow in the circuit will be 0.010 ampere (3/300 = 0.010). Since there is a current flow of 0.010 through the 250 ohms sense resistor, a voltage of 2.5 volts will appear across it. This is substantially less than the 3 volts being produced by the pressure sensor.

If the pressure sensor is designed to operate a current generator with an output of 4 to 20 milliamperes, the resistance of the wires won’t cause an inaccurate reading at the sense resistor. Since the sense resistor and the resistance of the wire between the pressure sensor and the programmable controller form a series circuit, the current must be the same at the point in the circuit. If the pressure sensor produces an output current of 4 milliamperes when the pressure is 0 psi and a current of 20 milliamperes when the pressure is 100 psi, at 50 psi it will produce a current of 12 milliamperes. When a current of 12 milliamperes flows through the 250 sense resistor, a voltage of 3 volts will be dropped across it. Because the pressure sensor produces a certain amount of current instead of a certain amount of voltage with a change in pressure, the amount of wire resistance between the pressure sensor and programmable controller is of no concern.

The pressure sensor produces one to five volts.

Resistance in the lines can cause problems.

The current must be the same in a series circuit.

Installation

Most analog sensors can produce only very weak signals--0 to 10 volts or 4 to 20 milliamperes are common. In an industrial environment where intense magnetic fields and large voltage spikes abound, it’s easy to lose the input signal in the electrical noise. For this reason, special precautions should be taken when in stalling the signal wiring between the sensor and the input module. These precautions are particularly important when using analog inputs, but they should also be followed when using digital inputs.

Keep Wire Runs Short

Try to keep wire runs as short as possible. A long wire run has more surface area of wire to pick up stray electrical noise.

Shielded cable. POWER LINE SIGNAL CABLE INSULATION SHIELD GROUND WIRE

CONDUCTORS

Signal cable crosses power line at right angle.

All grounds are not equal.

Differential ampl ifier detects difference in signal level.

INPUT FROM SENSOR; OUTPUT

Plan the Route of the Signal Cable

Before starting, plan how the signal cable should be installed. Never run signal wire in the same conduit with power wiring. Try to run signal wiring as far away from power wiring as possible. When it’s necessary to cross power wiring, install the signal cable so that it crosses at a right angle.

Use Shielded Cable

Shielded cable is used for the installation of signal wiring. One of the most common types uses twisted wires with a Mylar foil shield. The ground wire must be grounded if the shielding is to operate properly. This type of shielded cable can provide a noise reduction ratio of about 30,000:1.

Another type of signal cable uses a twisted pair of signal wires surrounded by a braided shield. This type of cable provides a noise reduction of about 300:1.

Common coaxial cable should be avoided. This cable consists of a single conductor surrounded by a braided shield. This type of cable offers very poor noise reduction.

Grounding

Ground is generally thought of as being electrically neutral, or zero at all points. However, this may not be the case in practical application. It’s not uncommon to find that different pieces of equipment have ground levels that are several volts apart.

To overcome this problem, large cable is some times used to tie the two pieces of equipment together. This forces them to exist at the same potential. This method is sometimes referred to as the brute-force method.

Where the brute-force method is not practical, the shield of the signal cable is grounded at only one end. The preferred method is generally to ground the shield at the sensor.

The Differential Amplifier

An electronic device that is often used to help overcome the problem of induced noise is the differential amplifier. This device detects the voltage difference between the pair of signal wires and amplifies this difference. Since the induced noise level should be the same in both conductors, the ampl ifier will ignore the noise. E.g, assume an analog sensor is producing a 50 millivolt signal. This signal is applied to the input module, but induced noise is at a level of 5 volts.

In this case, the noise level is 100 times greater than the signal level. The induced noise level, however, is the same for both of the input conductors. Therefore, the differential ampl ifier ignores the 5 volt noise and ampl ifies only the voltage difference, which is 50millivolts.

QUIZ:

- 1. Explain the difference between digital inputs and analog inputs.

- 2. Why should signal wire runs be kept as short as possible?

- 3. When signal wiring must cross power wiring, how should the wires be crossed?

- 4. Why is shielded wire used for signal runs?

- 5. What is the brute-force method of grounding?

- 6. Explain the operation of the differential amplifier.