AMAZON multi-meters discounts AMAZON oscilloscope discounts

7. Installation of Cables

After having made the correct selection of cable to meet load requirements and other system characteristics, it is important that cables be installed and maintained correctly. A good understanding of local conditions, installation crews, and maintenance personnel is essential to assure that the selected cable system will operate satisfactorily. Many times cable insulation is damaged or weakened during installation by applying the incorrect pulling tensions. Designs of conduit systems not only should minimize the number of conduit bends and distances between manholes but also should specify the pulling tensions.

The inspection personnel should ensure that installation crews do not exceed these values during installations. It is also important that correct bending radius be maintained in order to avoid unnecessary stress points. Once a correct installation is made, routine inspection, testing, and maintenance should be carried out on a regular basis to chart the gradual deterioration and upkeep of the cable system. Cable systems are the arteries of the electric power distribution system and carry the energy required for the successful operation of a plant. Following is a brief discussion on cable installation and maintenance.

There are several types of cable systems available for carrying electrical energy in a given distribution system. The selection of a particular system may be influenced by local conditions, existing company policies, or past experience.

No set standards or established guidelines can be given for the selection of a particular system. Following is a general discussion of the various types of installations, bending data, and pulling tensions that, combined with sound engineering judgment, will be helpful in selecting a system for a particular installation.

7.1 Outdoor Installations

Cable can be installed underground or overhead. Today most cable is installed underground in conduit banks or direct burial, even though the trend for outdoor overhead installation is becoming popular. The underground installation of cables in nonmetallic ducts will result in smaller impedance than for cables in metallic ducts. Since conduits may become flooded, only cable insulations approved for this purpose should be installed in ducts.

Cable failures in underground ducts are difficult to locate and repair.

Therefore, maintenance personnel should be trained and equipped with correct equipment to troubleshoot cable faults and make repairs.

Several types of cable construction are available for direct-burial service.

Cable selected for direct-burial service should have excellent mechanical strength in order to withstand rough environmental surroundings. Cables without jackets should be avoided for direct-burial service.

Low- and medium-voltage aerial cable lashed to a supporting steel messenger cable is becoming popular for overhead installations because of its many advantages, such as low reactance, adaptability, better appearance, and voltage regulation. Another type of overhead installation that is gaining popularity is interlocked armor installed in racks or cable trays because of advantages such as flexibility, ease of installation, and good mechanical and chemical protection.

7.2 Indoor Installations

The conventional installation of indoor cables has been in conduit (FIG. 7a). However, interlocked armor cable is gaining popularity recently, especially in industrial plants. This cable can be installed overhead in racks or cable trays (FIG. 7b), thus eliminating the expensive conduit systems. The racks bonded together provide the ground circuit similar to the conduit system.

Because of this cable being installed in open air, it has higher current rating. An overall jacket of PVC is available for this cable for installations where corrosive atmosphere may be present.

7.3 Bending Data

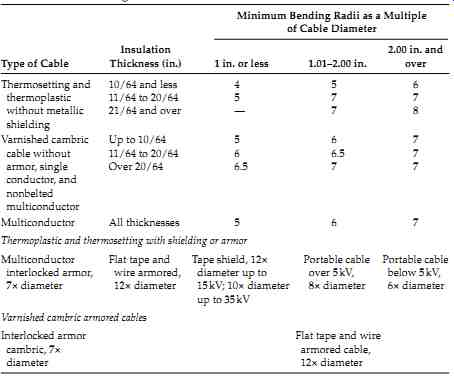

The ICEA recommended values of minimum bending radii for rubber and rubber-like compounds and varnished cambric cables are given in TABLE 3.

As mentioned before, it is important to install cables without sharp bends to minimize stress points. The ICEA recommended bending data do not apply to conduits in which cables may be pulled under tension. In cases of conduit bends, larger radius bend should be required.

7.4 Pulling Tensions

Since cables can be damaged by applying excessive pulling tension or by sharp bends in poorly constructed duct banks, the following are some of the cautions that should be considered to minimize damage to cables during installation.

1. Do not exceed the required fill as set by the NEC.

2. Calculate the jam ratio for the selected cable and conduit sizes.

3. Avoid sharp bends of the cable during pulling.

4. Use adequate lubrication to avoid friction. (Use the correct kind of lubricant.)

5. Check end seals for intactness after installation.

6. In rack-type installation, use rollers to prevent cable from dragging on the rack.

In duct and conduit runs, the tension for a straight pull can be calculated by the formula

TLwf =

where T is the pulling weight L is the length to feet pulled w is the weight of cable (lb/ft) f is the friction coefficient, approximately = 0.5 To pull cables in conduits and ducts, the cables can be gripped directly by a pulling eye or basket-weave pulling grip. The basket-weave grip is usually used for relatively light pulls, whereas pulling eye is used for heavier pulls.

The following tension limitations apply when pulling cables:

Direct pull of conductor: When pulling force is applied directly to the conductor, the maximum pull should not exceed 0.008 lb/circular mil area of cross section for copper 0.008 for hard-drawn, 0.006-0.008 for three-fourth hard-drawn, 0.003-0.004 for one-half hard-drawn, 0.002-0.004 for soft aluminum and 0.75 for hard-drawn aluminum.

Grip over lead sheath: When a grip is applied over lead-sheathed cables, the pulling force shall be limited to 1500 psi of sheath cross section.

Grip over nonmetallic sheath: When a grip is applied over a nonmetallic sheathed cable, the pulling force should not be over 1000 lb provided it does not exceed the force calculated in a direct pull of conductor.

Pulling around bends: The pulling force around bends in conduit should not exceed 300 times the radius of the bend in feet.

TABLE 3 Recommended Bending Data for Cable

8. Maintenance of Cables

Visual inspection of the cable, conduit, manholes, and so on, and electrical maintenance testing are the major maintenance procedures for cable systems.

Visual inspection

Visual inspection can be made on energized cables, but if cables are to be touched or moved they should be de-energized. Cables in vaults, substations rooms, manholes, and at other locations should be inspected for the following on a yearly basis:

1. Physical damage, sharp bends, and excessive tension

2. Oil leaks, soft spots, and insulation swelling

3. Poor ground connections, metallic-sheath bonding deterioration, corroded cable supports, and continuity of main grounding system

4. Cracked jackets of nonleaded cables

5. Damage to i reproofing

6. Tracking or corona

7. Soft spots in terminations and splices

8. Inspect the manhole for spalling concrete and standing water

9. Potheads should be inspected for oil or compound leaks (dirt and grime should be cleaned off and connections checked for tightness)

Aerial cables should be inspected for mechanical damage caused by vibration or deterioration of support and suspension system. Inspection should be made of cables for insulation abrasion and cable being bent or pinched.

---