AMAZON multi-meters discounts AMAZON oscilloscope discounts

There are management, economic, and technical considerations, along with other requirements that need to be understood in order to develop an effective maintenance program. Let us review these items from the viewpoint of developing an effective and comprehensive maintenance program. The main parts of the maintenance program can be classified into maintenance management considerations, technical requirements, and those items that should be included in the EPM (electrical preventive maintenance) program.

__4.1 Maintenance Management Considerations

The design of any maintenance program must meet the ultimate goals of plant management. Maintenance is like an insurance policy: it has no direct payback, yet it is a cost that adds to the cost of the final product. However, one must hasten to say that it has inherent paybacks. It is generally observed that management resists the investment in a maintenance program even though they realize the need for good maintenance.

In view of this, it is up to electrical personnel to show management how a properly planned electrical maintenance and testing program is justifiable.

The planning of EPM programs should then include the advantages of a well-planned maintenance along with cost data for lost production due to equipment failure versus cost of budgeted PM. Any maintenance program should prove that it is cost effective and minimizes equipment failure. The planning of the program should include considerations for proper test equipment, tools, trained personnel to carry out maintenance tasks, and time required to perform inspections, tests, and maintenance routines. Also, consideration should be given to record keeping systems, which can range from fully computerized to manual file systems. To set up an EPM and test pro gram, the following steps may be undertaken:

Determine the factors that will form the basis of the maintenance program, such as the necessity for continuous production, management policy on budgeting for planned maintenance versus replacement of equipment, and the like.

Survey and consolidate data on equipment breakdowns and cost of lost production. Make an analysis of the cost data to convince management of the benefits of planned maintenance.

Establish electrical maintenance priorities. These consist of on-line production sequence, most important to least important equipment, weighing the reliability of the equipment, and other factors.

Establish the best maintenance techniques. This involves selecting the best maintenance method and personnel for the various types of equipment and systems.

Schedule and implement the program. Monitor its benefits and costs.

Analyze program functions periodically for improvement of the program.

After the program has been set up, it is essential that it consist of elements that will prove it to be a success such as responsibilities, inspection, scheduling, work orders, and record keeping.

__4.1.1 Responsibilities

The responsibilities of the maintenance organization should be clearly defined by organization charts with functional work statements for each unit. The functional work statements must be established by management as a matter of policy. Every other department must be informed of the responsibilities assigned to maintenance organizations. The effectiveness of the maintenance departments will depend upon how well they are organized and how well personnel are utilized.

__4.1.2 Inspection

Inspection is the key to the success of any maintenance program. Sufficient time should be allocated for inspection to verify the condition of new and installed equipment. The purpose of inspection is to provide advance warning as to the condition of the equipment under investigation. When inspection is performed on definite cycles by qualified people, impending deterioration can be detected in advance so that repair or replacement can be made before failure of the equipment occurs.

__4.1.3 Scheduling

To perform maintenance, a definite schedule of work to be performed must be established. Maintenance schedules must be based upon minimum downtime for the various operating segments. The schedule for inspection, routine maintenance, and other work may vary for different equipment and will depend upon many factors. These factors can be age of equipment, frequency of service, hours of operation, environmental conditions, damage due to abuse, and safety requirements. Frequency of scheduling of all tasks should be adjusted as data on various equipment are recorded and analyzed to provide a balance between cost of maintenance and replacement cost of the equipment.

__4.1.4 Work Orders

Work orders are job requests that need action for completion. Work orders can be established for all inspection service and other work on equipment in terms of routines. Any of these routines should include information on when such work is to be performed, where it is to be performed, and exactly what has to be done. These routines can be generated by a computer-based maintenance system. The routines should include all the pertinent information concerning the equipment.

__4.1.5 Record Keeping

The success of a planned maintenance program depends upon the impetus given by top management and the interest of the maintenance personnel in the program. To have an effective program, it is imperative that maintenance and test inventory data on all equipment should be complete and readily available throughout the service life of the equipment. To that end, record keeping is very important. All forms and reports should be organized to provide ready accessibility to data when needed and to flag down problem areas. Such data may also be used over the years to analyze trends for equipment deterioration. If data are not recorded and maintained properly, the whole purpose of planned maintenance is lost.

__4.2 Technical Requirements

Technical requirements can be stated as follows:

• Survey of plant equipment

• Listing of plant equipment in the order of critical importance

• Plan to perform EPM on a regular frequency

• Development of instructions and procedures for the EPM program

__4.2.1 Survey of Plant Equipment

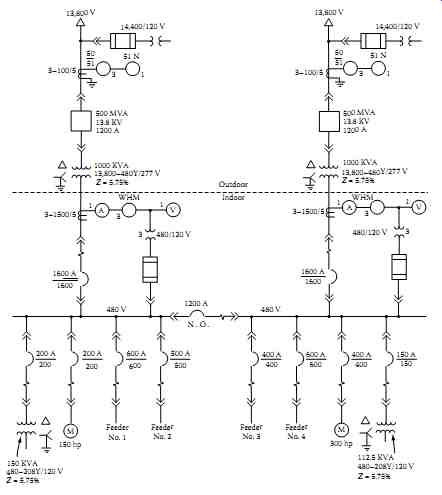

FIG. 4 Typical one-line diagram of a power distribution system.

To perform an effective EPM program, it is necessary to have accurate data about the electrical power system. This may include one-line diagrams, short-circuit coordination study, wiring and control diagrams, and other data that can be used as a reference point for future maintenance and testing.

The purpose of these diagrams is to document and serve as an official record of equipment and circuit installation. The National Electrical Manufacturer's Association (NEMA) has established standards for diagram symbols, device designations, and electrical symbols. The types of diagrams and drawings in common use are the following:

Process or flow diagram: A conceptual diagram of the functional interrelationship of subsystems in pictorial form.

Block diagram: A group of interconnected blocks, each of which represents a device or subsystem.

One-line (single-line) diagram: It shows, by means of single lines and graphic symbols, the flow of electrical power or the course of electrical circuits and how they are connected. In this diagram, physical relationships are usually disregarded. A typical one-line diagram is shown in FIG. 4.

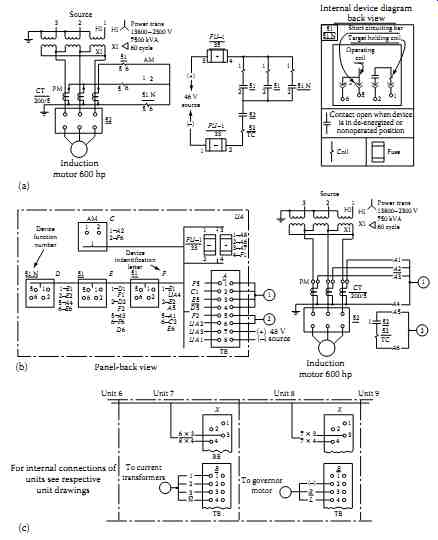

Schematic (elementary) diagram: It shows all circuits and device elements of the equipment. This diagram emphasizes the device elements and their functions, and it is always drawn with all devices shown in de-energized mode. A typical elementary diagram is shown in FIG. 5a.

FIG. 5 Typical electrical (a) elementary control, (b) connection, and

(c) interconnection diagrams.

Control sequence (truth-table) diagram: A description of the contact positions, or connections, that are made for each position of control action or device.

Wiring diagram (connection diagram): It locates and identifies electrical devices, terminals, and interconnecting wires in an assembly. This diagram may show interconnecting wiring by lines or terminal designations. A typical wiring diagram is shown in FIG. 5b.

Interconnection diagram: It shows only the external connections between controllers and associated equipment or between various housing units of an assembly of switchgear apparatus as shown in FIG. 5c.

Circuit layout and routing diagram: They show the physical layout of the facility and equipment and how the circuit to the various equipment is run.

Short-circuit coordination study: An electrical power system data, diagrams, and drawings are needed during maintenance and testing of electrical equipment. This may involve information and data relating to protective devices and relays. Such data are usually found in a short-circuit coordination study and usually encompass all the short-circuit values available in the power system, relays, and trip device settings. Normally, this study is performed during the construction and commissioning phase of the facility. It would be much more desirable to perform this engineering study as part of the initial facility design, and then validate it during the construction phase to assure that equipment and values specified have been met. When accepting the facility, this study data should be used as a benchmark, and any changes that may have been made during construction in the system should be incorporated to update the study for future references.

System diagrams: In addition to other data assembled, system diagrams will generally be needed for large systems. Such diagrams may consist of the following:

- Control and monitoring system

- Lighting system

- Ventilation system

- Heating and air conditioning system

- Emergency system

- Other systems

All the system diagrams may interface with one another, such as electrical diagrams, fire and security diagrams, emergency power, hydraulic, pneumatic, and/or mechanical systems. Therefore, it is important to know how these inter faces work and how they can be coordinated in the maintenance program.

__4.2.2 Listing of Plant Equipment in the Order of Critical Importance

Electrical power system equipment, like any other plant equipment, is vital to the operation of the plant or facility. Failure of the power system may be considered a serious threat to people and property. The listing may be difficult to accomplish because the criticalness of any piece of equipment will vary for each plant or facility. Therefore, a team to mutually identify and list the critical equipment (electrical and other) vital to the operation of a facility may be necessary. The team should consist of representatives from each area of expertise involved in the operation of the plant. All the critical equipment and/or systems should be identified on the drawings. The maintenance department should understand each of these systems, equipment, and/or their functions and how they may affect or interface with other systems. The more knowledgeable the maintenance members are about their system, the better job they will perform in their duties.

__4.2.3 Plan to Perform EPM on Regular Frequency

Several factors should be considered in establishing the frequency with which equipment is to be maintained:

• Environmental conditions

• Load conditions

• Duty requirements

• Critical nature of the equipment

The purpose of the maintenance schedule is to establish the condition of the equipment and determine what work will be required before its next scheduled maintenance. Usually, manufacturers' service manuals specify recommended frequency of maintenance and/or inspection. These time intervals are based upon standard operating conditions and environments.

If these standard conditions change for the equipment, then the frequency should be modified accordingly. However, once the frequency of scheduled maintenance is established, this schedule should be adhered to for at least several maintenance cycles. The schedule should be adjusted if the equipment begins to experience unexpected failures. The frequency in this case can be reduced by as much as 50%. On the other hand, if the equipment does not require maintenance for more than two inspections, the period of frequency for that equipment can be increased by as much as 50%. Adjustment should be continued until the optimum interval is found. Generally, the test frequency can vary from 6 months to 3 years.

__4.2.4 Development of Instruction and Procedures for the EPM Program

The final technical function in developing an EPM program involves establishment of instructions, procedures, and methods to ensure that the equipment and system components operate without failure. The maintenance department should have fully developed procedures and instructions for thoroughly servicing all equipment and components. In addition, the maintenance department should also develop shutdown procedures, safeguards, interlocking of equipment, alarms, and methods of recording data (forms) and reporting unusual conditions to the proper authority. The maintenance records should be further utilized to evaluate results and as an indicator of possible modifications or changes in the maintenance program. In other words, the recorded information should be used as historical data and for feedback to modify the maintenance program.

__4.3 What Should Be Included in the EPM Program

The EPM and testing program should encompass the following activities:

• EPM and testing

• Electrical repairs

• Analysis of failures

• Trending of maintenance and testing data

• To have an effective and efficient operation, it is essential to carry out these four activities.

__4.3.1 EPM and Testing

This activity involves inspection, cleaning and adjustment, and testing of equipment to ensure trouble-free operation until its next scheduled maintenance. PM and testing also allow the prediction of impending failure of a particular piece of equipment so that plans can be made to replace it without catastrophic results. The information on testing can be obtained from several different sources such as manufacturer's manuals, published literature on specific equipment, and industry standards. The relevant industry standards are: the Insulated Cable Engineering Association (ICEA), NFPA, Institute of Electrical and Electronic Engineers (IEEE), American National Standard Institute (ANSI), NEMA, NETA, Insurance Company Manuals (ICMs), and others, depending on the equipment to be tested.

__4.3.2 Electrical Repairs

The repair of electrical equipment and related machinery associated with plant production is the fundamental requirement of good maintenance pro grams. The maintenance should be performed economically and expeditiously. The basic objective of the maintenance program should be to avoid unexpected breakdowns of equipment. Furthermore, when breakdowns occur, spare parts should be on hand to make the necessary repairs. The maintenance personnel should be properly trained to perform the repairs promptly and correctly in order to minimize the downtime of the equipment.

__4.3.3 Analysis of Failures

The failure of electrical equipment should be analyzed to assess reasons for its breakdown. Unless the cause is obvious, the equipment quality may be questioned. Reliability can be built into the equipment, but it requires upkeep to retain it. The tendency to ignore regular maintenance and testing generally prevails over regularly scheduled maintenance because regular maintenance may be considered unnecessary and too expensive. Therefore, the best designed and built equipment may break down through lack of attention.

Every failure should be analyzed for its cause so that corrective measures can be implemented to prevent similar breakdowns.

__4.3.4 Trending of Maintenance and Testing Data

Systematic trending of maintenance and testing data (see Sections 3.5) can alert the maintenance staff of degrading equipment. This allows the maintenance staff to monitor such equipment more closely or take corrective actions to avert a catastrophic failure.

__4.3.5 Computerized Maintenance Management System

It is essential to have a CMMS for implementing an effective maintenance program. In the past, the maintenance data were manually recorded and managed. It was time consuming and difficult to record data and perform trend analysis of the maintenance test results. Today, most maintenance tasks can be automated with the use of commercially available CMMS programs and a desktop or a laptop computer. The job of maintaining and managing maintenance and test data has become much easier compared to the past. A CMMS is essential for improving performance, analyzing data for key trends and anomalies, forecasting reliability issues, and in making forward-looking decisions that deliver improved bottom-line results.

A comprehensive CMMS program can incorporate all of the elements discussed, and make the electrical maintenance department an effective organization. Typical key functions of CMMS include the following:

- Work orders-scheduling jobs, assigning personnel, reserving materials, and recording costs.

- PM-keeping track of PM inspections, tests, and jobs, including step by-step instructions or checklists, lists of materials required, and other pertinent details.

- Asset management-recording data on equipment including specifications, nameplate information, purchase date, maintenance history, inspection and test data, and so on.

- Inventory control-management of spare parts, tools, and other materials.

- Critical equipment listing and inventory-list of critical equipment vital to the operation of the facility.

- Root cause analysis of failures-analysis of failures and their causes so that corrective measures can be implemented to prevent similar failures.

- Advanced reporting and analytics-creating customized reports and analyses that can be used to forecast likely problems in time to prevent them.

There are number of vendors that offer CMMS for the management of electrical maintenance and testing data and reporting such as Megger "PowerDB," Service Automation Technologies "EPower Forms," and Optima SMS. For example, PowerDB is a powerful software package for entry and management of acceptance (start-up) and maintenance test data, storage and reporting. The system allows the user to define data forms for different equipment types. When testing equipment, these forms are used to facilitate data entry, on-screen data presentation, and report printing. Equipment is organized in an organization scheme of up to i ve levels. This software is designed to work as the Equipment Tree. The Equipment Tree levels are labeled as customer, user, plant, substation, and position. Data entry and reporting for one or more pieces of equipment are organized into jobs.

PowerDB stores information in a database. Subsets of the database may be made for field-testing. Results, changes, and additions to the subset may be merged with the master database. All types of test results can be entered and stored into the software for generating formal reports and a permanent historical record. The PowerDB CMMS program is designed to record and manage the maintenance and test data for the many of the electrical equipment including the following: batteries, cables, circuit breakers, coordination data, disconnects, generators and motors, power transformers, insulation fluids, load-break switches, motor control centers (MCCs), relays, PF tests, switchboards, transfer switches, watt-hour meters transducers, ground fault tests; ground mat/grid tests; instrument transformers, and so on.

The user interface for viewing or recalling information is also the actual test or inspection entry form. Various forms for each type of apparatus allow input of inspection and electrical test data. Over 200 standard tests forms currently exist in PowerDB, and customized forms can be generated using a built-in forms editor. Archived test results can be trended and compared with newly entered information for quick analysis of equipment condition.

Forms include embedded equation calculations as well as functional scripts for operating electrical and electronic field test sets. This capability allows for automated testing and capturing of test results into the database. Customer and contract information is quickly sorted and searched. Opening a specific record shows detailed information about the job, such as type of service, order date, sales contact, and invoice information. Job information and related test results can be transferred between field-use databases and a master database. Job and device productivity reports track the time spent on testing and evaluation of equipment. Test data entry screens and printed forms are identical allowing intuitive operation. Entire test documentation packages consisting of test reports, comment and deficiency summaries, table of contents, and field service reports are created easily.