AMAZON multi-meters discounts AMAZON oscilloscope discounts

.Limited speed control can be achieved in the split-phase induction motor. Control of the slip is accomplished by varying the magnitude of the voltage applied to the stator. However, the speed must not be made so low that the centrifugal switch allows the starting winding to be energized during normal operation. Controlling the speed by varying the frequency of the power supply enables higher speeds to be reached than if the rotor slip were controlled. However, the same low-speed limitation exists because of the centrifugal switch. Clever implementation of electronic control and logic circuits can circumvent limitations such as those described above. For example, a tachometer or stroboscopic speed sensor could actuate logic circuitry so that the starting winding would not be energized when the motor was slowed down from a higher operating speed ( you would have to bring out extra leads from the centrifugal switch in order to make such a modification in a conventional motor).

-- --

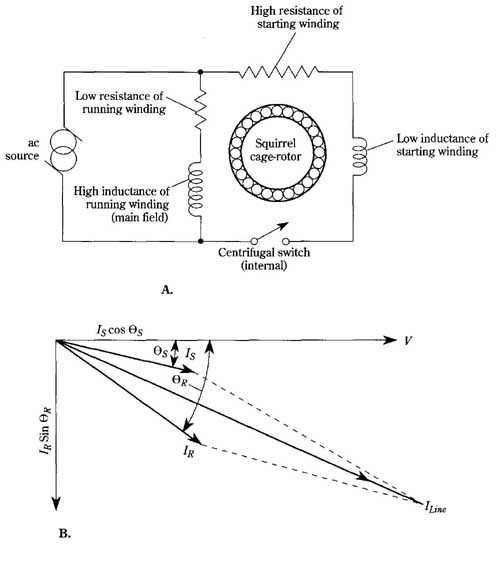

A. Equivalent circuit. B. Initial phase relationship during starting interval. I_s is the current in the starting winding, and I_R is the current in the running winding.

FIG. 7 The resistance-start, split-phase motor.

-- --

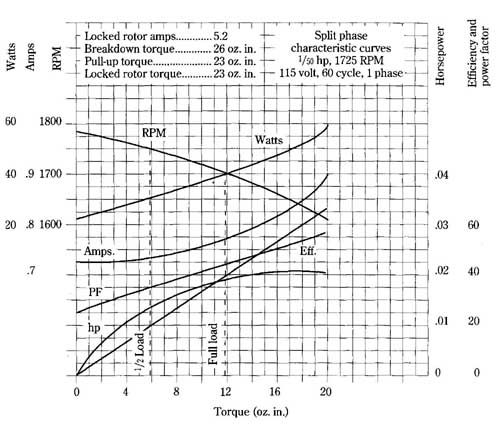

FIG. 8 Characteristics of a split-phase induction motor.

In general, loads that are primarily inertial in nature tend to be better suited to slip control of speed than loads that are essentially frictional. Fans, blowers, and fly wheels exemplify loads with high inertial components. The frequency-control method is often an excellent way to control the speed of induction motors, regard less of the type of load. However, as the frequency is changed, it’s generally necessary to also change the applied voltage in direct proportion to the frequency. The split-phase motor can be reversed by transposing the two leads of either the starting winding or the main field (running) winding.

There are split-phase motors in which the auxiliary winding is designed so that it’s always connected in parallel with the main field winding. There is thus no need for the centrifugal switch. However, it’s not easy to incorporate a very high starting torque when this simplification is used. To distinguish between these two types of split-phase induction motors, the one with the centrifugal switch is referred to as a resistance-start type.