AMAZON multi-meters discounts AMAZON oscilloscope discounts

LEARNING GOALS:

- • state basic safety rules.

- • describe the effects of electric current on the body.

- • discuss the origin and responsibilities of OSHA.

- • discuss material safety data sheets.

- • discuss lock out and tag out procedures.

- • discuss types of protective clothing.

- • explain how to properly place a straight ladder against a structure.

- • discuss different types of scaffolds.

- • discuss classes of fires.

- • discuss ground fault circuit interrupters.

- • discuss the importance of grounding.

GLOSSARY OF SAFETY TERMS

- artificial respiration a method of providing oxygen to a person unable to breath on his or her own

- confined space a space that has limited entrances or exits

- CPR an acronym for cardiopulmonary resuscitation

- de-energized circuit a circuit that has been disconnected from the power supply

- disconnect to turn off or remove power from a circuit egress an entrance or exit into a structure

- energized circuit a circuit connected to the power supply; a voltage or potential exists between conductors

- fibrillation a condition in which the heart starts to quiver and stops its pumping action

- fire retardant clothing made from a specially treated material that resists ignition;

- many industries require electricians to wear this type of clothing

- horseplay playing practical jokes or exhibiting adolescent behavior in an inappropriate place

- idiot proofing designing a piece of equipment so it cannot be misused by an experienced person

- lock out and tag out a procedure to prevent a circuit from being energized accidentally

- meter an instrument used to test for some electrical quantity such as voltage, current, or resistance milliamperes one milliampere equals 1/1000 of an amp (0.001)

- MSDS an acronym for material safety data sheets

- OSHA an acronym for Occupational Safety and Health Administration

- scaffold a platform for working in high places, generally designed so it can be taken apart and transported to a different job site or area

Safety is the job of each individual. You should be concerned not only with your own safety, but with the safety of others around you. This is especially true for persons employed in the electrical field.

Some general rules should be followed when working with electrical equipment or circuits.

GENERAL SAFETY RULES:

NEVER WORK ON AN ENERGIZED CIRCUIT IF THE POWER CAN BE DISCONNECTED

When possible, use the following three-step check to make certain that power is turned off:

1 Test the meter on a known live circuit to make sure the meter is operating.

2 Test the circuit that is to become the de-energized circuit with the meter.

3 Test the meter on the known live circuit again to make certain the meter is still operating.

Install a warning tag at the point of disconnection so people won’t restore power to the circuit.

If possible, use a lock to prevent anyone from turning the power back on.

THINK

Of all the rules concerning safety, this one is probably the most important. No amount of safeguarding or idiot proofing a piece of equipment can protect a person as well as taking time to think before acting. Many technicians have been killed by supposedly "dead" circuits. Don’t depend on circuit breakers, fuses, or someone else to open a circuit. Test it yourself before you touch it. If you are working on high voltage equipment, use insulated gloves and meter probes to measure the voltage being tested. Think before you touch something that could cost you your life.

AVOID HORSEPLAY

Jokes and horseplay have a time and place, but not when someone is working on an electric circuit or a piece of moving machinery. Don’t be the cause of someone being injured or killed and don’t let someone else be the cause of your being injured or killed.

DO NOT WORK ALONE

This is especially true when working in a hazardous location or on a live circuit. Have someone with you who can turn off the power or give artificial respiration and/or CPR. Possible effects of several electrical shocks is breathing difficulties and causing the heart to go into fibrillation.

WORK WITH ONE HAND WHEN POSSIBLE

The worst kind of electrical shock occurs when the current path is from one hand to the other, which permits the current to pass directly through the heart. A person can survive a severe shock between the hand and foot that would cause death if the current path was from one hand to the other.

LEARN FIRST AID

Anyone working on electrical equipment, especially those working with voltages greater than 50 volts, should make an effort to learn first aid.

A knowledge of first aid, especially CPR, might save your own or someone else's life.

EFFECTS OF ELECTRIC CURRENT ON THE BODY

Most people have heard that it's not the voltage that kills, but the current. This is true, but don’t be mislead into thinking voltage cannot harm you.

Voltage is the force that pushes the current though the circuit. It can be compared to the pressure that pushes water through a pipe. The more pressure available, the greater the volume of water flowing through the pipe. Students often ask how much current will flow through the body at a particular voltage. There is no easy answer to this question.

The amount of current that can flow at a particular voltage is determined by the resistance of the cur rent path. Different people have different resistances. A body has less resistance on a hot day when sweating, because salt water is a very good conductor. What one eats and drinks for lunch can have an effect on the body's resistance as can the length of the current path. Is the current path between two hands or from one hand to one foot? All of these factors affect body resistance.

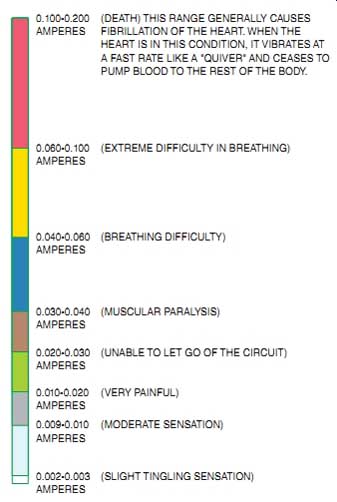

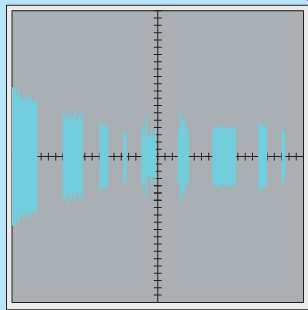

The chart ( Fig. 1) illustrates the effects of different amounts of current on the body. This chart is general-some people may have less tolerance to electricity and others may have a greater tolerance.

A current of 2 to 3 milliamperes (0.002 to 0.003 amp) usually causes a slight tingling sensation, which increases as current increases and becomes very noticeable at about 10 (0.010 amp) milliamperes. The tingling sensation is very painful at about 20 milliamperes. Currents between 20 and 30 milliamperes cause a person to seize the line and be unable to let go of the circuit. Currents between 30 and 40 milliamperes cause muscular paralysis, and those between 40 and 60 milliamperes cause breathing difficulty. When the current increases to about 100 milliamperes, breathing is extremely difficult. Currents from 100 to 200 milliamperes generally cause death because the heart usually goes into fibrillation, a condition in which the heart begins to "quiver" and the pumping action stops.

Currents above 200 milliamperes cause the heart to squeeze shut. When the current is removed, the heart usually returns to a normal pumping action.

This is the operating principle of a defibrillator.

The voltage considered to be the most dangerous to work with is 120 volts, because that generally causes a current flow of between 100 and 200 milliamperes through most people's bodies. Large amounts of current can cause severe electrical burns that are often very serious because they occur on the inside of the body. The exterior of the body may not look seriously burned, but the inside may be severely burned.

===

(DEATH) THIS RANGE GENERALLY CAUSES FIBRILLATION OF THE HEART. WHEN THE HEART IS IN THIS CONDITION, IT VIBRATES AT A FAST RATE LIKE A "QUIVER" AND CEASES TO PUMP BLOOD TO THE REST OF THE BODY.

- 0.100-0.200 AMPERES

- 0.060-0.100 AMPERES

- 0.040-0.060 AMPERES

- 0.030-0.040 AMPERES

- 0.020-0.030 AMPERES

- 0.010-0.020 AMPERES

- 0.009-0.010 AMPERES

- 0.002-0.003 AMPERES

(EXTREME DIFFICULTY IN BREATHING) (BREATHING DIFFICULTY) (MUSCULAR PARALYSIS) (UNABLE TO LET GO OF THE CIRCUIT) (VERY PAINFUL) (MODERATE SENSATION) (SLIGHT TINGLING SENSATION)

Above: Fig. 1 The effects of electric current on the body.

===

OSHA

OSHA is an acronym for Occupational Safety and Health Administration, U.S. Department of Labor.

Created by congress in 1971, its mission is to ensure safe and healthful workplaces in the United States.

Since its creation, workplace fatalities have been cut in half, and occupational injury and illness rates have declined by 40%. Enforcement of OHSA regulations is the responsibility of the Secretary of Labor.

OSHA standards cover many areas, such as the handling of hazardous materials, fall protection, protective clothing, and hearing and eye protection. Part 1910 subpart S deals mainly with the regulations concerning electrical safety. These regulations are available in books and can be accessed at the OSHA website on the Internet at www.osha.org.

HAZARD MATERIALS

It may become necessary to deal with some type of hazardous material. A hazardous material or sub stance is any substance which exposure to may result in adverse effects on the health or safety of employees. Hazardous materials may be chemical, biological, or nuclear. OSHA sets standards for dealing with many types of hazardous materials.

The required response is determined by the type of hazard associated with the material. Hazardous materials are required to be listed as such. Much information concerning hazardous materials is generally found on Material Safety Data Sheets (MSDS). (A sample MSDS is included at the end of the Section.) If you are working in an area that contains hazardous substances, always read any information concerning the handling of the material and any safety precautions that should be observed. Waiting until a problem exists in not the time to start looking for information on what to do. Some hazardous materials require a HAZMAT (Hazardous Materials Response Team) to handle any problems. A HAZMAT means any group of employees designated by the employer that are expected to handle and control an actual or potential leak or spill of a hazardous material. They are expected to work in close proximity to the material. A HAZMAT team is not a fire brigade and a fire brigade may not necessarily be a HAZMAT team. A HAZMAT team may be part of a fire brigade or fire department.

EMPLOYER RESPONSIBILITIES

Section 5(a)1 of the occupational safety and health act basically states that each employer must furnish each of his employees a place of employment that is free of recognized hazards that are likely to cause death or serious injury. This places the responsibility for compliance on the employer. The employer must identify hazards or potential hazards within the work site and eliminate them, control them, or provide the employee with suitable protection from them. It’s the employee's responsibility to follow the safety procedures set up by the employer.

To help facilitate these safety standards and procedures, OSHA requires that an employer have a competent person oversee implementation and enforcement of these standards and procedures. This person must be able to recognize unsafe or dangerous conditions and have the authority to correct or eliminate them. He also has the authority to stop work or shut down a job site until safety regulations are met.

MSDS

MSDS stands for material safety data sheets, which are provided with many products. They generally warn users of any hazards associated with the product. They outline the physical and chemical properties of the product, list precautions that should be taken when using the product, list any potential health hazards, storage consideration, flammability, reactivity, and in some instances radioactivity. They sometimes list the name, address, and telephone number of the manufacturer, MSDS date, and emergency telephone numbers, and usually provide information on first aid procedures to use if the product is swallowed or comes in contact with the skin. Material safety data sheets can be found on many home pro ducts such as cleaning products, insecticides, and flammable liquids.

ALCOHOL AND DRUGS

The use of alcohol and drugs has no place on a construction site. It’s not only dangerous to users and those who work around them, it also costs industry millions of dollars a year. Alcohol and drug abusers kill thousands of people on the high ways each year, and are just as dangerous on a work site as they are behind the wheel of a vehicle.

Many industries have instituted testing policies to screen for alcohol and drugs. A person who tests positive generally receives a warning the first time and is fired the second time.

TRENCHES

It’s often necessary to dig trenches to bury conduit.

Under some conditions, these trenches can be deep enough to bury a person if a cave-in should occur.

Safety regulations for the shoring of trenches is found in OSHA Standard 1926 Subpart P App C titled "Timber Shoring for Trenches." These procedures and regulations are federally mandated and must be followed. Some general safety rules should be followed also:

1 Don't walk close to trenches unless it’s necessary.

This can cause the dirt to loosen and increase the possibility of a cave-in.

2 Don't jump over trenches if it’s possible to walk around them.

3 Place barricades around trenches ( Fig. 2).

4 Use ladders to enter and exit trenches.

===

Above: Fig. 2 Place a barricade around a trench and use a ladder to

enter and exit the trench.

Above: Fig. 3 A confined space is any space having a limited means

of egress.

====

CONFINED SPACES

Confined spaces have a limited means of egress ( Fig. 3). They can be very hazardous workplaces, often containing atmospheres that are extremely harmful or deadly. Confined spaces are very difficult to ventilate because of their limited openings. It’s often necessary for a workman to wear special clothing and use a separate air supply to work there.

OSHA Section 12: "Confined Space Hazards," lists rules and regulations for working in a confined space.

In addition, many industries have written procedures that must be followed when working in confined spaces. Some general rules include the following:

1 Have a person stationed outside the confined space to watch the person or persons working inside. The outside person should stay in voice or visual contact with the inside workers at all times.

He should check air sample readings, and monitor oxygen and explosive gas levels.

2 The outside person should never enter the space, even in an emergency, but should contact the proper emergency personnel. If he or she should enter the space and become incapacitated, there would be no one available to call for help.

3 Use only electrical equipment and tools that are approved for the atmosphere found inside the confined area. It may be necessary to obtain a burning permit to operate tools that have open brushes and that spark when they are operated.

4 As a general rule, a person working in a confined space should wear a harness with a lanyard that extends to the outside person, so the outside per son could pull him or her to safety if necessary.

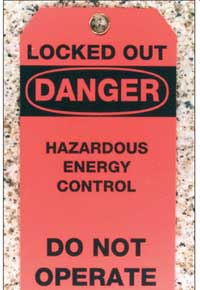

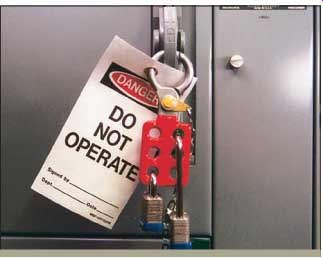

Above: Fig. 4 Safety tag used to tag-out equipment.

Above: Fig. 5 The equipment can be locked out by several different

people.

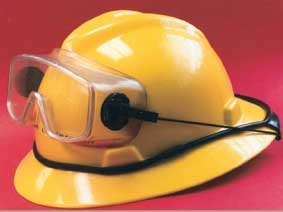

Above: Fig. 6 Typical electrician's hard hat with attached safety goggles.

Above: Fig. 7 Safety glasses provide side protection.

LOCK OUT AND TAG OUT PROCEDURES

Lock out and tag out procedures are generally employed to prevent someone from energizing a piece of equipment by mistake. This could apply to switches, circuit breakers, or valves. Most industries have their own internal policies and procedures. Some require that a tag similar to the one shown in Fig. 4 be placed on the piece of equipment being serviced; some also require that the equipment be locked out with a padlock.

The person performing the work places the lock on the equipment and keeps the key in his or her pos session. A device that permits the use of multiple padlocks and a safety tag is shown in Fig. 5.

This is used when more than one person is working on the same piece of equipment. Violating lock and tag out procedures is considered an extremely serious offense in most industries and often results in immediate termination of employment. As a general rule, there are no first time warnings.

PROTECTIVE CLOTHING

Maintenance and construction workers alike are usually required to wear certain articles of protective clothing, dictated by the environment of the work area and the job being performed.

HEAD PROTECTION

Some type of head protection is required on almost any construction site or in any industrial location.

A typical electrician's hard hat, made of non conductive plastic, is shown in Fig. 6. It has a pair of safety goggles attached that can be used when desired or necessary.

EYE PROTECTION

Eye protection is another piece of safety gear required on almost all construction sites and industrial locations. Eye protection can come in different forms ranging from the goggles shown in Fig. 6 to the safety glasses with side shields shown in Fig. 7. Common safety glasses may or may not be prescription glasses, but almost all provide side protection ( Fig. 7). Sometimes a full face shield may be required.

HEARING PROTECTION

Section III Chapt. 5 of the OSHA Technical Manual includes requirements concerning hearing protection. The need for hearing protection is based on the ambient sound level of the construction site or the industrial location. It’s not unusual for workers to be required to wear some type of hearing protection when working in certain areas, usually in the form of ear plugs or ear muffs.

FIRE RETARDANT CLOTHING

Special clothing made of fire retardant material is required in some areas, generally certain industries as opposed to new construction sites. Fire retardant clothes are often required for maintenance personnel who work with high power sources such as transformer installations and motor control centers. An arc-flash in a motor control center can easily catch a person's clothes on fire. The typical motor control center can produce enough energy during an arc-flash to kill a person 30 feet away.

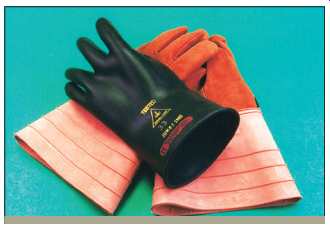

GLOVES

Another common article of safety clothing is gloves. Electricians often wear leather gloves with rubber inserts when it’s necessary to work on energized circuits ( Fig. 8). These gloves are usually rated for a certain amount of voltage. They should be inspected for holes or tears before they are used.

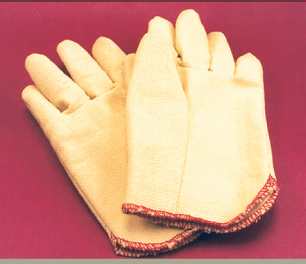

Kevlar gloves ( Fig. 9) help protect against cuts when stripping cable with a sharp blade.

Above: Fig. 8 Leather gloves with rubber inserts.

Above: Fig. 9 Kevlar gloves protect against cuts.

SAFETY HARNESS

Safety harnesses provide protection from falling.

They buckle around the upper body with leg, shoulder, and chest straps, and the back has a heavy metal D-ring ( Fig. 10). A section of rope approximately 6 feet in length, called a lanyard, is attached to the D-ring and secured to a stable structure above the worker. If the worker falls, the lanyard limits the distance he can drop. A safety harness should be worn.

1 when working more than 6 feet above the ground or floor.

2 when working near a hole or drop-off.

3 when working on high scaffolding

A safety harness is shown in Figure 11 (below).

===

SHOULDER STRAPS CHEST STRAP LEG STRAPS D-RING LANYARD

Above: Fig. 10 Typical safety harness.

===

Above: Fig. 11 Safety harness.

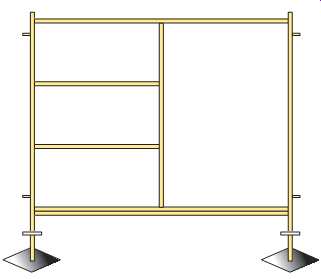

Above: Fig. 12 Typical section of scaffolding.

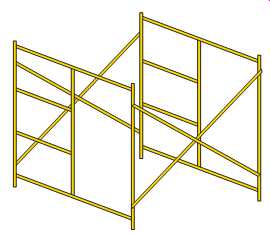

Above: Fig. 13 X braces connect scaffolding sections together.

LADDERS AND SCAFFOLDS

It’s often necessary to work in an elevated location. When this is the case, ladders or scaffolds are employed. Scaffolds generally provide the safest elevated working platforms. They are commonly assembled on the job site from standard sections ( Fig. 12). The bottom sections usually contain adjustable feet that can be used to level the section.

Two end sections are connected by X braces that form a rigid work platform ( Fig. 13). Sections of scaffolding are stacked on top of each other to reach the desired height.

ROLLING SCAFFOLDS

Rolling scaffolds are used in areas that contain level floors, such as inside a building. The major difference between a rolling scaffold and those discussed previously is that it’s equipped with wheels on the bottom section that permit it to be moved from one position to another. The wheels usually contain a mechanism that permits them to be locked after the scaffold is rolled to the desired location.

Above: Fig. 14 Straight ladder.

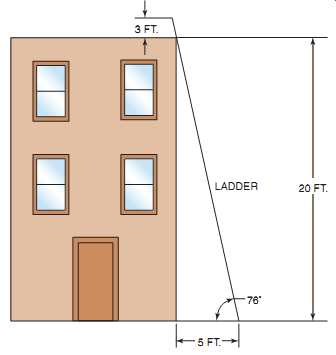

Above: Fig. 15 A ladder should be placed at an angle of approximately 76°.

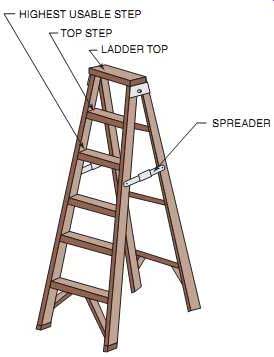

Above: Fig. 16 Typical step ladder. HIGHEST USABLE STEP TOP STEP; LADDER TOP; SPREADER

HANGING OR SUSPENDED SCAFFOLDS

Hanging or suspended scaffolds are suspended by cables from a support structure. They are generally used on the sides of buildings to raise and lower workers by using hand cranks or electric motors.

LADDERS

Ladders can be divided into two main types, straight and step. Straight ladders are constructed by placing rungs between two parallel rails ( Fig. 14).

They generally contain safety feet on one end that helps prevent the ladder from slipping. Ladders used for electrical work are usually wood or fiberglass; aluminum ladders are avoided because they conduct electricity. Regardless of the type of ladder used, you should check its load capacity before using it.

This information is found on the side of the ladder. Load capacities of 200 lbs., 250 lbs., and 300 lbs. are common. Don’t use a ladder that does not have enough load capacity to support your weight plus the weight of your tools and the weight of any object you are taking up the ladder with you.

Straight ladders should be placed against the side of a building or other structure at an angle of approximately 76° (Fig. 15). This can be accomplished by moving the base of the ladder away from the structure a distance equal to one-fourth the height of the ladder. If the ladder is 20 feet high, it should be placed 5 feet from the base of the structure. If the ladder is to provide access to the top of the structure, it should extend 3 feet above the structure.

STEP LADDERS

Step ladders are self-supporting, constructed of two sections hinged at the top ( Fig. 16). The front section has two rails and steps; the rear portion two rails and braces. Like straight ladders, step ladders are designed to withstand a certain load capacity. Always check the load capacity before using a ladder. As a general rule, ladder manufacturers recommend that the top step not be used because of the danger of becoming unbalanced and falling. Many people mistakenly think the top step is the top of the ladder, but it’s actually the last step before the ladder top.

FIRES

For a fire to burn it must have three things: fuel, heat, and oxygen. Fuel is anything that can burn, including materials such as wood, paper, cloth, combustible dusts, and even some metals. Different materials require different amounts of heat for combustion to take place. If the temperature of any material is below its combustion temperature, it won’t burn. Oxygen must be present for combustion to take place. If a fire is denied oxygen, it will extinguish.

Fires are divided into four classes: A, B, C, and D.

Class A fires involve common combustible materials such as wood or paper. They are often extinguished by lowering the temperature of the fuel below the combustion temperature. Class A fire extinguishers often use water to extinguish a fire.

A fire extinguisher listed as class A only should never be used on an electrical fire.

Class B fires involve fuels such as grease, combustible liquids, or gases. A class B fire extinguisher generally employs carbon dioxide (CO2), which greatly lowers the temperature of the fuel and deprives the fire of oxygen. Carbon dioxide extinguishers are often used on electrical fires, because they don’t destroy surrounding equipment by coating it with a dry powder.

Class C fires involve energized electrical equipment. A class C fire extinguisher usually uses a dry powder to smother the fire. Many fire extinguishers can be used on multiple types of fires; For example, an extinguisher labeled ABC could be used on any of the three classes of fire. The important thing to remember is never to use an extinguisher on a fire for which it’s not rated. Using a class A extinguisher filled with water on an electrical fire could be fatal.

Class D fires consist of burning metal. Spraying water on some burning metals actually can cause the fire to increase. Class D extinguishers place a powder on top of the burning metal that forms a crust to cut off the oxygen supply to the metal.

Some metals cannot be extinguished by placing powder on them, in which case, the powder should be used to help prevent the fire from spreading to other combustible materials.

GROUND FAULT CIRCUIT INTERRUPTERS

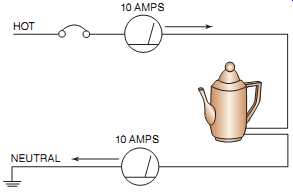

Ground fault circuit interrupters (GFCI) are used to prevent people from being electrocuted. They work by sensing the amount of current flow on both the ungrounded (hot) and grounded (neutral) conductors supplying power to a device. In theory, the amount of current in both conductors should be equal, but opposite in polarity ( Fig. 17). In this example, a current of 10 amperes flows in both the hot and neutral conductors.

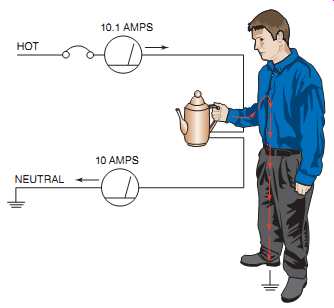

A ground fault occurs when a path to ground, other than the intended path, is established ( Fig. 18). Assume that a person comes in contact with a defective electrical appliance. If the person is grounded, a current path can be established through the person's body. In the example shown in Figure 18, it’s assumed that a current of 0.1 amps is flowing through the person. This means that the hot conductor now has a current of 10.1 amps, but the neutral conductor has a current of only 10 amps. The GFCI is designed to detect this current difference to protect personnel by opening the circuit when it detects a current difference of approximately 5 milliamperes (0.005 amps). Section 210.8 of the National Electrical Code lists places where ground fault protection is required in dwellings.

===

HOT 10 AMPS NEUTRAL 10 AMPS

Above: Fig. 17 The current in both the hot and neutral conductors should

be the same but flowing in opposite directions.

===

HOT 10.1 AMPS NEUTRAL 10 AMPS

Above: Fig. 18 A ground fault occurs when

a path to ground other than the intended path is established.

===

Above: Fig. 19 Ground fault circuit breaker.

===

Above: Fig. 20 Ground fault receptacle.

===

GFCI DEVICES

Several devices can be used to provide ground fault protection, including the ground fault circuit breaker ( Fig. 19). The circuit breaker provides ground fault protection for an entire circuit, so any device connected to the circuit is ground fault protected.

A second method of protection, ground fault receptacles ( Fig. 20), provide protection at the point of attachment. They have some advantages over the GFCI circuit breaker. They can be connected so that they protect only the devices connected to them and don’t protect any other outlets on the same circuit, or they can be connected so they provide protection to other outlets. Another advantage is that, since they are located at the point of attachment for the device, there is no stray capacitance loss between the panel box and the equipment being protected.

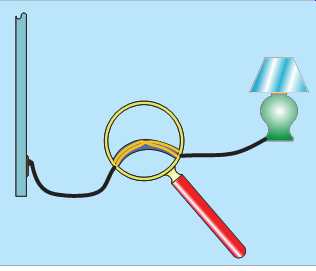

Long wire runs often cause nuisance tripping of GFCI circuit breakers. A third ground fault protective device is the GFCI extension cord ( Fig. 21). It can be connected into any standard electrical outlet, and any devices connected to it are then ground fault protected.

Above: Fig. 21 Ground fault extension.

Above: Fig. 22 Parallel arc-faults are caused by two conductors touching.

ARC-FAULT CIRCUIT INTERRUPTERS

Arc-fault circuit interrupters (AFCI) are similar to ground fault circuit interrupters in that they are designed to protect people from a particular hazard.

Where the ground fault circuit interrupter is designed to protect against electrocution, the arc-fault circuit interrupter is intended to protect against fire. Studies have shown that one third of electrical-related fires are caused by an arc-fault condition. At present, the National Electrical Code requires that arc-fault circuit interrupters be used on all 120 volt, single-phase, 15 and 20 ampere circuits installed in dwelling units supplying power to family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sun rooms, recreation rooms, closets, hallways, and similar rooms or areas.

An arc-fault is a plasma flame that can develop temperatures in excess of 6,000 °C or 10,832 °F.

Arc-faults occur when an intermittent gap between two conductors or a conductor and ground permits current to "jump" between the two conductive surfaces. There are two basic types of arc-faults, the parallel and the series.

PARALLEL ARC-FAULTS

Parallel arc-faults are caused by two conductors becoming shorted together, ( Fig. 22). A prime example of this situation is when the insulation of a lamp cord or extension cord has become damaged and permits the two conductors to short together.

The current in this type of fault is limited by the resistance of the conductors in the circuit. The current in this type of fault is generally much higher than the rated current of a typical thermo/magnetic circuit breaker. A continuous short will usually cause the circuit breaker to trip almost immediately because it will activate the magnetic part of the circuit breaker, but an intermittent short may take some time to heat the thermal part of the circuit breaker enough to cause it to trip open. Thermal/magnetic circuit breakers are generally effective in protecting against this type of arc-fault, but cords with small sized conductors, such as lamp cords and small extension cords, can add enough resistance to the circuit to permit the condition to exist long enough to produce sufficient heat to start a fire.

Parallel arc-faults can be more hazardous than series arc-faults (discussed in the next section) because they generate a greater amount of heat, often causing hot metal to be ejected into combustible material. Parallel arc-faults, however, generally produce peak currents that are well above the normal current rating of a circuit breaker. This permits the electronic circuits in the arc-fault circuit interrupter to detect the peak currents very quickly and trip the breaker in a fraction of a second.

===

TO HIGH WATTAGE LOAD LOOSE CONNECTION Above: Fig. 23 Series arc-faults age generally caused by bad connections.

====

Above: Fig. 24 Switch damaged by a loose connection.

===

SERIES ARC-FAULTS

Series arc-faults are generally caused by loose connections. A loose screw on an outlet terminal, or an improperly made wire-nut connection are prime examples of this problem. They are called "series arc-faults" because the circuit contains some type of current-limiting resistance connected in series with the arc ( Fig. 23). Although the amount of electrical energy converted into heat is less than that of a parallel arc-fault, series arc-faults can be more dangerous. Because the current is limited by a load, it’s kept below the thermal and magnetic trip rating of a common thermo/magnetic circuit breaker. Since the peak arc current is never greater than the normal steady current flow, series arcing is more difficult to detect than parallel arcing. A switch damaged by a loose connection is shown in ( Fig. 24).

When the current of an arc remains below the normal range of a common thermo/magnetic circuit breaker, it cannot provide protection. If a hair-dryer, For example, normally has a current draw of 12 amperes, but the wall outlet has a loose screw at one terminal so that the circuit makes connection only one half of the time, the average circuit current is 6 amperes. This is well below the trip rating of a common circuit breaker.

A 6-ampere arc, however, can produce a tremendous amount of heat in a small area.

Above: Fig. 25 Current spike produced by turning a light on or off.

Above: Fig. 26 Waveform produced by typical arc-fault.

ARC-FAULT DETECTION

There are conditions where arcing in an electric circuit is normal, such as:

• Turning a light switch on or off.

• Switching of a motor relay.

• Plugging in an appliance that is already turned on.

• Changing a light bulb with the power turned on.

• The arcs caused by motors that contain a commutator and brushes.

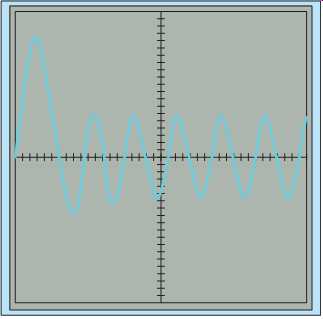

The arc-fault circuit interrupter is designed to distinguish between normally occurring arcs and an arc fault. An arc caused by a toggle switch being used to turn a light on or off will produce a current spike of short duration, as shown in ( Fig. 25). An arc-fault, however, is an intermittent connection and will generally produce current spikes of various magnitudes and lengths of time ( Fig. 26). In order for an arc-fault circuit interrupter to determine the difference between a normally occurring arc and an arc-fault, a microprocessor and other related electronic components are employed. The AFCI contains current and temperature sensors, as well as a microprocessor and non-volatile (retains its information when power is switched off) memory.

The current and temperature sensors permit the AFCI to operate as a normal circuit breaker in the event of a circuit overload or short circuit.

The microprocessor continuously monitors the cur rent and compares the waveform to information stored in the memory. The microprocessor is monitoring the current for the magnitude, duration, and length of time between pulses, not for a particular waveform. For this reason, there are some appliances that can produce waveforms similar to that of an arc-fault and may cause the AFCI to trip.

Appliances containing motors that employ the use of brushes and a commutator, such as vacuum cleaners and hand drills, will produce a similar waveform.

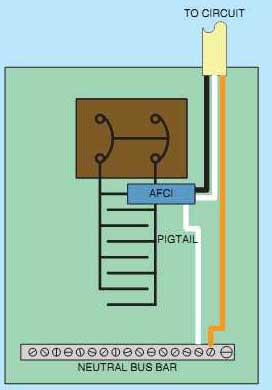

CONNECTING AN ARC-FAULT CIRCUIT INTERRUPTER

Above: Fig. 27 Arc-fault circuit breaker.

Above: Fig. 28 The arc-fault interrupter connects in the same manner

as a ground-fault interrupter. AFCI TO CIRCUIT PIGTAIL NEUTRAL BUS BAR

The AFCI is connected in the same manner as a ground fault circuit breaker. The AFCI contains a white pigtail ( Fig. 27) that is connected to the neutral bus bar in the panel box. Both the neutral and the hot or ungrounded conductors of the branch circuit are connected to the arc-fault circuit breaker. The circuit breaker contains a silver-colored and a brass-colored screw. The neutral or white wire of the branch circuit is inserted under the silver screw and the black wire is inserted under the brass screw ( Fig. 28).

A rocker switch located on the front of the AFCI permits the breaker to be tested for both short and arc condition. In addition to the manual test switch, the microprocessor performs a self-test about once every 10 minutes.

GROUNDING

Grounding is one the most important safety considerations in the electrical field. Grounding provides a low resistance path to ground to prevent conductive objects from existing at a high potential. Many electrical appliances are provided with a three-wire cord.

The third prong is connected to the case of the appliance and forces the case to exist at ground potential. If an ungrounded conductor comes in con tact with the case, the grounding conductors conduct the current directly to ground. The third prong on a plug should never be cut off or defeated. Grounding requirements are far too numerous to list in this Section, but Section 250 of the National Electrical Code (NEC) covers the requirements for the grounding of electrical systems.

SUMMARY:

• Never work on an energized circuit if the power can be disconnected.

• The most important rule of safety is to think.

• Avoid horseplay.

• Don’t work alone.

• Work with one hand when possible.

• Learn first aid and CPR.

• A current of 100 to 200 milliamperes passing through the heart generally causes death.

• The mission of OSHA is to ensure safe and healthy workplaces in the United States.

• Avoid using alcohol and drugs in the workplace.

• Don't walk close to trenches unless it’s necessary.

• Don't jump over trenches if it’s possible to walk around them.

• Place barricades around trenches.

• Use ladders to enter and exit trenches.

• When working in confined spaces, an outside person should keep in constant contact with people inside the space.

• Lock out and tag out procedures are used to prevent someone from energizing a circuit by mistake.

• Scaffolds generally provide the safest elevated working platforms.

• The bottom of a straight ladder should be placed at a distance from the wall that is equal to one fourth the height of the ladder.

• Fires can be divided into four classes: class A is common items such as wood and paper; class B is grease, liquids, and gases; class C is energized electrical equipment; and class D is metals.

• Ground fault circuit interrupters are used to protect people from electrical shock.

• GFCI protectors open the circuit when approximately 5 milliamperes of ground fault current is sensed.

• Section 250 of the NEC lists requirements for grounding electrical systems.

• Arc-fault circuit interrupters sense the presence of an electrical arc.

• Arc-fault circuit interrupters employ the use of a microprocessor to identify the characteristic waveform of an arc-fault.

• Arc-faults can produce temperatures in excess of 6000 °C.

QUIZ:

1. What is the most important rule of electrical safety?

2. Why should a person work with only one hand when possible?

3. What range of electric current generally causes death?

4. What is fibrillation of the heart?

5. What is the operating principle of a defibrillator?

6. Who is responsible for enforcing OSHA regulations?

7. What is the mission of OSHA?

8. What is an MSDS?

9. A padlock is used to lock out a piece of equipment. Who should have the key?

10. A ladder is used to reach the top of a building 16 feet tall. What distance should the bottom of the ladder be placed from the side of the building?

11. What is a ground fault?

12. What is the approximate current at which a ground fault detector will open the circuit?

13. Name three devices used to provide ground fault protection.

14. What type of fire is class B?

15. What section of the National Electrical Code covers grounding?

16. What is an arc-fault?

17. Name two types of arc-faults.

18. Of the two types of arc-faults, which is probably the most dangerous and why?

19. What device is used to determine the difference between normal arcing that occurs when a switch is opened and an arc-fault?

20. How often does an arc-fault circuit breaker perform a test to ensure that the device is operating properly?