AMAZON multi-meters discounts AMAZON oscilloscope discounts

.

OVERVIEW:

1 Underground System Designs

2 Conductor

3 Insulation

4 Medium- and High-Voltage Power Cables

5 Shield Bonding Practice

6 Installation Practice

7 System Protection Devices

8 Common Calculations Used with Cable

Aesthetics is primarily the major reason for installing power cables underground, providing open views of the landscape free of poles and wires. One could also argue that underground lines are more reliable than overhead lines as they are not susceptible to weather and tree caused outages, common to overhead power lines. This is particularly true of temporary outages caused by wind, which represents approximately 80% of all outages occurring on overhead systems. However, underground lines are susceptible to being damaged by excavations (reason behind "call before digging" locating programs implemented by many states in the United States). The time required to repair a damaged underground line may be considerably longer than an overhead line. Underground lines are typically 10 times more expensive to install than overhead lines. The ampacity, current carrying capacity, of an underground line is less than an equivalent sized overhead line. Underground lines require a higher degree of planning than over head, because it’s costly to add or change facilities in an existing system. Underground cables don’t have an infinite life, because the dielectric insulation is subjected to aging; therefore, systems should be designed with future replacement or repair as a consideration.

========

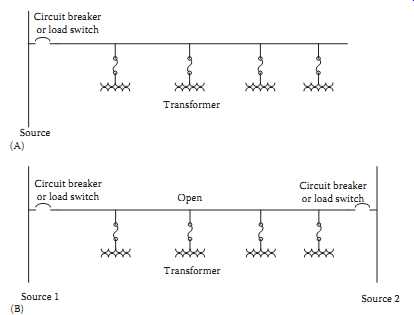

Source Circuit breaker or load switch

Transformer Source 1

(A)

(B)

Source 2 Circuit breaker or load switch

Circuit breaker or load switch Transformer Open

Above: Fig. 1 (A) Radial system and (B) looped system.

========

1 Underground System Designs

There are two types of underground systems ( FIG. 1).

1. Radial-Where the transformers are served from a single source.

2. Looped-Where the transformers are capable of being served from one of two sources. During normal operation an open is located at one of the transformers, usually the midpoint.

A radial system has the lowest initial cost, because a looped system requires the additional facilities to the second source. Outage restoration on a radial system requires either a cable repair or replacement, whereas on a looped system, switching to the alternate source is all that is required.

Underground cable can be directly buried in earth, which is the lowest initial cost, allows splicing at the point of failure as a repair option and allows for maximum ampacity. Cables may also be installed in conduit, which is an additional cost, requires replacement of a complete section as the repair option, reduces the ampacity, because the conduit wall and surrounding air are additional thermal resistances, but provides protection to the cable.

Underground power cables have three classifications.

1. Low voltage-Limited to 2 kV. Primarily used as service cables

2. Medium voltage-2-46 kV. Primarily used to supply distribution transformers

3. High voltage-Above 46 kV. Primarily used to supply substation transformers

American Standards Testing Material (ASTM), Insulated Cable Engineering Association (ICEA), National Electrical Manufacturing Association (NEMA), and Association of Edison Illuminating Companies (AEIC) have published standards for the various types of power cables.

2 Conductor

Common among all classes in function is the central conductor, the purpose of which is to conduct power (current and voltage) to serve a load. The metals of choice are either copper or aluminum. This central conductor may be composed of a single element (solid) or composed of multiple elements (stranded), on the basis of a geometric progression of 6, 12, 18, etc., of individual strands for each layer.

Each layer is helically applied in the opposite direction of the underlying layer.

There are three common types of stranding available.

1. Concentric round

2. Compressed round (97% of the diameter of concentric)

3. Compact round (90%-91% of the diameter of concentric)

Note: Some types of connectors may be suitable for stranded types 1 and 2 but not type 3 for the same size.

To improve manufacturing, 19 wire combination unilay stranding (helically applied in one direction one operation) has become popular in low-voltage applications, where some of the outer strands are of a smaller diameter, but the same outside diameter as compressed round is retained. Another stranding method which retains the same overall diameter is single input wire (SIW) compressed, which can be used to produce a wide range of conductors using a smaller range of the individual strands.

Conductors used at transmission voltages may have exotic stranding to reduce the voltage stress.

Cables requiring greater flexibility such as portable power cable utilize very fine strands with a rope type stranding.

Typical sizes for power conductors are #6 American wire gage (AWG) through 1000 kcmil. One cmil is defined as the area of a circle having a diameter of 1 mile (0.0001 in.). Solid conductors are usually limited to a maximum of #1/0 because of flexibility.

The metal type and size determines the ampacity and losses (I2 R). Copper having a higher intrinsic conductivity will have a greater ampacity and lower resistance than an equivalent size aluminum conductor. Aluminum 1350 alloy medium hardness is typical for power cable use.

3 Insulation

In order to install power cables underground, the conductor must be insulated. For low-voltage applications, a layer of insulation is extruded onto the conductor. Many types of insulation compounds have been used from natural or synthetic rubber, polyvinyl chloride (PVC), high molecular weight polyethylene (HMWPE), and cross-linked polyethylene (XLPE) to name a few. Although each insulation type has various characteristics, operating temperature and durability are probably the most important. XLPE is probably the most widely used insulation for low-voltage cables. XLPE is a thermoset plastic with its hydrocarbon molecular chains cross-linked. Cross-linking is a curing process, which occurs under heat and pressure, or as used for low-voltage cables, moisture and allows an operating temperature of 90°C.

Multiple layer cable insulation composed of a softer compound under a harder compound, a single layer harder insulation, or a self-healing insulation are used to address protection of the conductor, typically for direct buried low-voltage power cables.

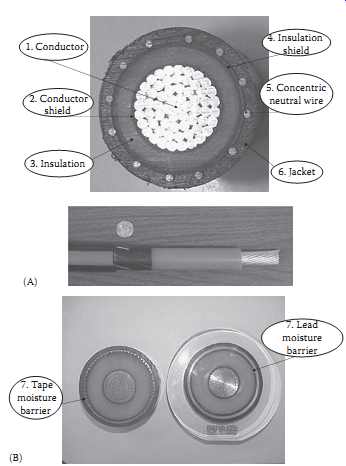

Above: Fig. 2 (A) Medium-voltage cable components and (B) high-voltage cable

components.

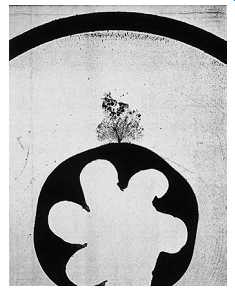

Above: Fig. 3 Tree in XLPE.

4 Medium- and High-Voltage Power Cables

Medium- and high-voltage power cables, in addition to being insulated, are shielded to contain and evenly distribute the electric field within the insulation.

The components and function of a medium- and high-voltage cable are as follows ( FIG. 2A and B):

1. The center conductor-Metallic path to carry power.

2. The conductor shield-A semiconducting layer placed over the conductor to provide a smooth conducting cylinder around the conductor. Typical of today's cables, this layer is a semiconducting plastic, polymer with a carbon filler, extruded directly over the conductor. This layer represents a very smooth surface, which, because of direct contact with the conductor, is elevated to the applied voltage on the conductor.

3. The insulation-A high dielectric material to isolate the conductor. The two basic types used today are XLPE or ethylene propylene rubber (EPR). Because of an aging effect known as treeing ( FIG. 3), on the basis of its visual appearance, caused by moisture in the presence of an electric field, a modified version of XLPE designated tree retardant (TRXLPE) has replaced the use of XLPE for medium-voltage applications. High-voltage transmission cables still utilize XLPE, but they usually have a moisture barrier. TRXLPE is a very low loss dielectric that is reasonably flexible and has an operating temperature limit of 90°C or 105°C depending on type. TRXLPE because it’s cross-linked, does not melt at high operating temperatures but softens. EPR is a rubber-based insulation having higher losses than TRXLPE and is very flexible and has an operating temperature limit of 105°C. EPR does not melt or soften as much as TRXLPE at high operating temperatures, because of its high filler content.

4. The insulation shield-A semiconducting layer to provide a smooth cylinder around the out side surface of the insulation. Typical shield compound is a polymer with a carbon filler that is extruded directly over the insulation. This layer, for medium-voltage applications, is not fully bonded to the insulation (strippable) to allow relatively easy removal for the installation of cable accessories. Transmission cables have this layer bonded to the insulation, which requires shaving tools to remove.

5. The metallic shield-A metallic layer, which may be composed of wires, tapes, or corrugated tube.

This shield is connected to the ground, which keeps the insulation shield at ground potential and provides a return path for fault current. Medium-voltage cables can utilize the metallic shield as the neutral return conductor if sized accordingly. Typical metallic shield sizing criteria:

a. Equal in ampacity to the central conductor for one phase applications.

b. One-third the ampacity for three-phase applications.

c. Fault duty for three-phase feeders and transmission applications.

6. Overall jacket-A plastic layer applied over the metallic shield for physical protection. This polymer layer may be extruded as a loose tube or directly over the metallic shield (encapsulated).

Although both provide physical protection, the encapsulated jacket removes the space present in a loose tube design, which may allow longitudinal water migration. The typical compound used for jackets is linear low density polyethylene (LLDPE), because of its ruggedness and relatively low water vapor transmission rate. Jackets can be specified insulating (most common) or semiconducting (when jointly buried and randomly laid with communication cables).

7. Moisture barrier-A sealed metallic barrier applied either over or under the overall jacket.

Typically used for transmission cables, this barrier may be a sealed tape, corrugated tube, or lead sheath.

Cable components 1-4 comprise the cable core, which in cross-section, is a capacitor with the conductor shield and insulation shield making up the plates on each side of a dielectric. These plates evenly distribute the electric field radially in all directions within the insulation; however, until the metallic shield is added and effectively grounded, the insulation shield is subject to capacitive charging and presents a shock hazard. To be considered effectively grounded, the National Electrical Safety Code (NESC) requires a minimum of four ground connections per mile of line or eight grounds per mile when jointly buried with communication cables for insulating jackets. Semiconducting jackets are considered grounded when in contact with earth.

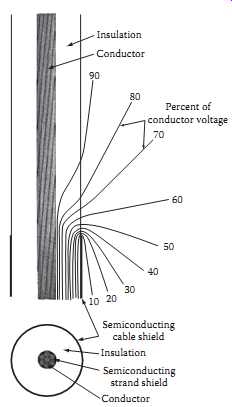

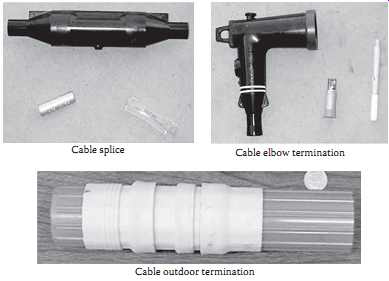

Because medium- and high-voltage cables are shielded, special methods are required to connect them to devices or other cables. Since the insulation shield is conductive and effectively grounded, it must be carefully removed a specific distance from the conductor end, on the basis of the operating volt age. Once the insulation shield has been removed, the electric field will no longer be contained within the insulation and the highest electrical stress will be concentrated at the end of the insulation shield ( FIG. 4). Premolded, cold or heat shrink, or special tapes are applied at this location to control this stress, allowing the cable to be connected to various devices ( FIG. 5).

===

Insulation Conductor

Percent of conductor voltage Semiconducting cable shield Semiconducting strand shield Conductor Insulation

Above: Fig. 4 Voltage distribution in the insulation with the cable shield

removed.

===

Cable splice Cable elbow termination Cable outdoor termination

Above: Fig.

5 Cable accessories.

===

Above: Fig. 6 (A) Multigrounded shield, (B) single point grounded shield,

and (C) cross-bonding shields.

====

5 Shield Bonding Practice

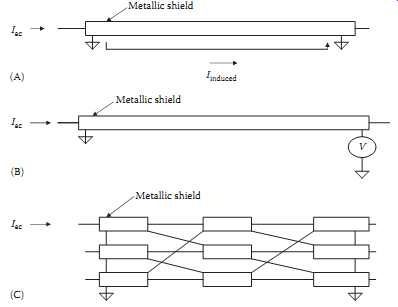

Generally, the metallic shields on distribution circuits are grounded at every device. Transmission circuits, however, may use one of the following configurations.

Multiple ground connections (multigrounded) ( FIG. 6A): The metallic shield will carry an induced current because they surround the alternating current in the central conductor. This circulating current results in an I^2 R heating loss, which adversely affects the ampacity of the cable.

Single point grounded ( FIG. 6B): The metallic shield is grounded at a single point and no current can flow in the metallic shield because there is no closed circuit. This configuration allows the maxi mum ampacity rating for the cable; however, a voltage will be present on the open end, which may be a hazard. This voltage is dependent on the cable spacing, current, and cable length.

Cross-bonding ( FIG. 6C): The three-phase circuit is divided into three equal segments. The metallic shield between each segment is connected to an adjacent phase using insulated conductor.

Splices at these segments must interrupt the insulation shield to be effective.

6 Installation Practice

When cables are directly buried in earth, the trench bottom may require bedding sand or select back fill free from rocks that could damage the cable over time. When the cable is installed in conduit, the pulling tension must be limited so as not to damage the conductor, insulation, or shields. Typical value when using a wire basket grip is 3000 lbs. When the cable is pulled around a bend, the pulling tension results in a side-wall bearing force against the inside surface of the elbow. This force must be limited to avoid crushing the cable components. Cables also have a minimum bending radius limit that prevents distortion of the cable components.

7 System Protection Devices

Two types of protecting devices are used on cable systems.

1. Overcurrent-Fuses or circuit breakers. These devices isolate the cable from its source, preventing the flow of damaging levels of current during an overload, or remove a faulted cable from the system allowing restoration of the unfaulted parts.

2. Overvoltage-Surge arrester. This device prevents damaging overvoltages caused by lightning or switching surges from entering the cable by clamping the voltage to a level tolerated by the cable insulation.

8 Common Calculations Used with Cable

- Inductance

- Inductive reactance

- Capacitance

- Charging current

- Ampacity

- Voltage drop