Introduction

A functional workshop has three fundamental requirements: a complement of tools, sufficient lighting, and enough electricity to power both. Once you have selected the portable and stationary tools suited to your needs and have laid them out efficiently, you’ll need to route electrical power through the shop—both to serve the tools and shed light on the work at hand.

Equipping the Shop with Portable Tools

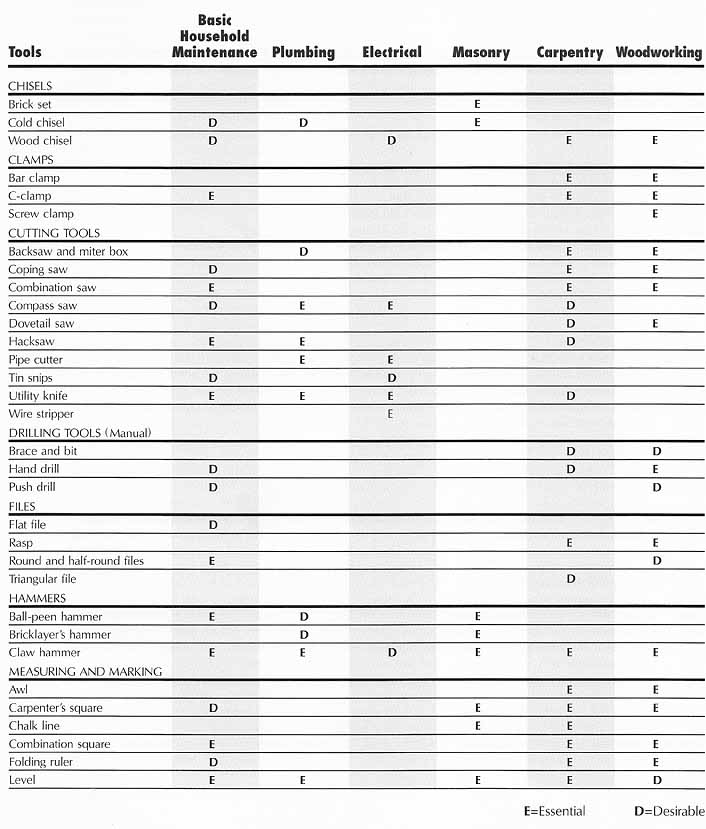

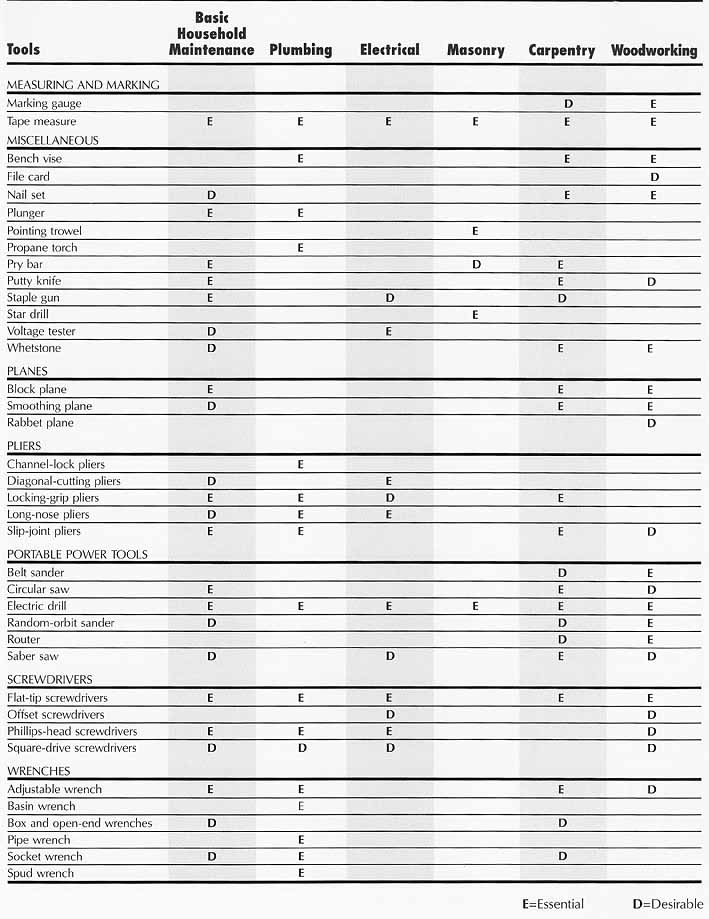

One of the first tasks in preparing a workshop for action is to take an inventory of the tools you have, and decide what additional ones you require (see chart).

Choosing Tools: The key to selecting tools is quality—each type requires certain features to perform properly (below and opposite). Look for reputable brand names. Before buying, check performance tests in do-it-yourself and consumer web sites and magazines (e.g., Consumer Reports), so you can confine your search to tools that have been given high ratings. Inspect the item before buying it. Quality products have a solid feel and a finely worked finish. Although such tools are seldom available at bargain-basement prices, they are designed to provide decades of service.

Buying Tools: To guard against impulse purchases of items you are unlikely to ever need, draw up a purchase plan and stick to it; or, simply wait until you actually need a tool, then buy the best-quality model you can afford. Watch for sales, but con firm that the price includes the normal warranty. To save money, buy tools in sets—screwdrivers, chisels, and wrenches, for example, are less expensive when purchased this way, although your initial investment will be higher than for a smaller number of individual items. Don’t exclude garage sales and country auctions, where you may be able to find rock-bottom prices, but examine the merchandise with care.

Chisels. Four wood chisels with blades ranging in width from 1/4 to 1 inch suffice for most jobs. Look for high-impact plastic handles and a washer between the blade and the handle to act as a shock absorber. For chopping mortises, you will need a set of firmer chisels. For metal work, choose a cold chisel with a flat 1/2-inch blade. For splitting bricks, buy a brick set.

Clamps. There are dozens of clamp designs for securing workpieces and tools, each type suited to a particular purpose, but a collection of C-clamps can see you through most jobs. Useful additions include wood en screw clamps. Because their jaws can be adjusted to a wide range of angles, they are more versatile than C-clamps. Bar clamps are essential for securing large projects, and web clamps wrap around odd-shaped pieces like chairs. Quick clamps, with their one fixed jaw and one sliding jaw, and spring clamps are easy to use.

Files and rasps. Designed to trim metal and wood, the basic half-round file is 10 inches long, with rows of coarse bladelike ridges on the rounded side and criss-crossed, or “double-cut,” ridges on the flat side. A patternmaker’s cabinet rasp has irregularly placed teeth that make the tool easy to control when shaping wood. More specialized files and rasps include flat, round, and triangular types for trimming odd-shaped work. Two helpful accessories are a wood or plastic handle that can be switched from file to file as needed, and a stiff-wire brush—called a file card—for cleaning shavings from file teeth.

Handsaws. For most carpentry projects, a combination saw for cut ting both with and across the grain is most practical. Look for a polished blade to reduce friction as it passes through wood. Make sure the teeth are sharp and uniform in shape and size, and that the handle feels comfortable and solid. Other useful saws include the backsaw, which is used in a miter box for angled cuts, and the coping saw and the compass saw for cutting curves.

Manual drilling tools. The “egg-beater” drill is ideal for boring holes up to inch in diameter; choose one with metal rather than plastic gears. A push drill with a ratchet mechanism bores pi lot holes for screws and small holes in delicate work. The brace-and-bit type can drive bits that are too large for most 3/8-inch electric drills. Buy one with a reversible ratchet for work in tight areas.

Hammers. A curved-claw hammer excels at pulling nails, but a straight-claw hammer is more useful for prying boards apart. The tempered head of a ball-peen hammer is meant for striking cold chisels and other metal tools. The best heads are made of drop- forged steel, seamless, and highly polished. Buy a weight that suits the job and feels comfortable; for general carpentry, a 16-ounce model is the most common. Finish work calls for a lighter hammer, while a heavier one is needed for rough construction.

Measuring and marking tools. A flexible steel measuring tape in a sturdy case is invaluable. Buy a tape marked in both incremental and cumulative feet and inches, and with 16-inch intervals highlighted to help locate stud positions. A 6-foot folding extension ruler with a brass inset that slides out for measuring inside dimensions is handy. Levels should feature metal bodies or metal edges and replaceable vials. A marking gauge is useful for scribing lines along the edge of a board.

Screwdrivers. Every tool collection needs at least four common sizes of flat-tip screwdrivers, and two sizes of Phillips screwdrivers. You may want to add screwdrivers for square-drive screws. Ensure that the tip and shaft are made of chrome-vanadium steel. A plastic handle with a rubber cover makes the best shock insulator for electrical work. You’ll also find a collection of screwdriver bits for use in a variable-speed drill.

Wrench and sockets. The most versatile wrench is the 10-inch adjustable wrench with smooth jaws. Buy one made of drop-forged steel with a chrome finish. If you plan on doing even a modest amount of mechanical work, you will need a set of fixed-width wrenches. Open-end wrenches slip around nuts and bolt-heads from the side, while box wrenches fit over nuts and bolts and are especially suited to hexagonal nuts and bolt-heads. Combination wrenches combine the two types, but separate sets of open-end and box wrenches may be more convenient, especially when two wrenches of the same size are needed at one time. Socket wrenches, driven by handles with ratchet mechanisms, speed the task of tightening bolts and facilitate working in tight spots. A good basic set has a 3/8-inch wide drive post and hexagonal sockets. Buy metric-standard wrenches if you will work on foreign bicycles or cars.

Hand planes. The block plane, for trimming end grain, and the smoothing plane, for shaving with the grain, are the two essential planing tools. Choose models with flat soles and high-quality steel blades. The best-quality planes have adjustment mechanisms that hold their positions and allow exact control over the amount of wood to be shaved. For keeping the blades razor-sharp, you’ll need a 4000x whetstone and a honing guide.

Pliers. A pair of 8-inch slip-joint pliers is needed for bending and gripping. Diagonal-cutting pliers snip wire and small nails. A pair of locking-grip pliers can be adjusted to clamp onto an object, serving as a wrench. Long-nose pliers can reach into recessed areas and are especially handy for making terminal loops on electrical wires. Look for those made of chrome-plated steel with strong joints and plastic-coated handles.

Portable power tools. Small power tools, such as a 3/8-inch electric drill and a 7¼-inch circular saw, have become an indispensable part of most workshops. Other useful electric tools include a saber saw, a router, and belt and random-orbit sanders. When purchasing portable power tools, buy items of at least medium quality. Check for plastic double- insulated bodies, heavy-duty power cords, and permanently lubricated bearings. Models with variable-speed control are convenient. Drills, circular saws, and screwdrivers are available in handy cord less versions as well.

THE RIGHT TOOL FOR THE JOB

The chart below and opposite rates the suitability of a wide range of hand and power tools in six categories of projects. To determine whether you are likely to need a tool, check whether it is deemed essential “E” or desirable “D” in the appropriate category. Keep in mind that these ratings are not the last word in tool selection. Certain projects straddle two or more categories, and no two jobs are ever exactly the same.

Next: Stationary

Power Tools

Prev: Soundproofing the Shop