AMAZON multi-meters discounts AMAZON oscilloscope discounts

The transport of generator-produced electric energy to loads. An electric power transmission system interconnects generators and loads and generally provides multiple paths among them. Multiple paths in crease system reliability because the failure of one line does not cause a system failure. Most transmission lines operate with three-phase alternating current (ac). The standard frequency in North America is 60 Hz; in Europe , 50 Hz. The three-phase system has three sets of phase conductors. Long-distance energy transmission occasionally uses high-voltage direct-current (dc) lines.

The electric power system can be divided into the distribution, sub-transmission, and transmission systems. With operating voltages less than 34.5 kV, the distribution system carries energy from the local substation to individual households, using both overhead and underground lines. With operating voltages of 69-138 kV, the sub-transmission system distributes energy within an entire district and regularly uses overhead lines. With operating voltage exceeding 230 kV, the transmission system interconnects generating stations and large substations located close to load centers by using overhead lines.

Overhead alternating-current transmission. Overhead transmission lines distribute the majority of the electric energy in the system. A typical high-voltage line has three phase conductors to carry the current and transport the energy, and two grounded shield conductors to protect the line from direct lightning strikes. The usually bare conductors are insulated from the supporting towers by insulators attached to grounded towers or poles. Lower-voltage lines use post insulators, while the high- voltage lines are built with insulator chains or long-rod composite insulators. The normal distance between the supporting towers is a few hundred feet.

Transmission lines use ACSR (aluminum cable, steel rein forced) and ACAR (aluminum cable, alloy reinforced) conductors. In an ACSR conductor, a stranded steel core carries the mechanical load, and layers of stranded aluminum surrounding the core carry the current. An ACAR conductor is a stranded cable made of an aluminum alloy with low resistance and high mechanical strength. ACSR conductors are usually used for high- voltage lines, and ACAR conductors for subtransmission and distribution lines. Ultrahigh-voltage (UHV) and extra-high-voltage (EHV) lines use bundle conductors. Each phase of the line is built with two, three, or four conductors connected in parallel and separated by about 1.5 ft (0.5 m). Bundle conductors re duce corona discharge.

Transmission lines are subject to environmental adversities, including wide variations of temperature, high winds, and ice and snow deposits. Typically designed to withstand environmental stresses occurring once every 50—100 years, lines are intended to operate safely in adverse conditions.

Variable weather affects line operation. Extreme weather reduces corona inception voltage, leading to an increase in audible noise, radio noise, and telephone interference. Load variation requires regulation of line voltage. A short circuit generates large currents, overheating conductors and producing permanent damage.

The power that a line can transport is limited by the line’s electrical parameters. Voltage drop is the most important factor for distribution lines; where the line is supplied from only one end, the permitted voltage drop is about 5%.

Conductor temperature must be lower than the temperature which causes permanent elongation. A typical maximum steady- state value for ACSR is 212°F (100°C), but in an emergency temperatures 10—20% higher are allowed for a short period of time (10 mm to 1 h).

Corona discharge is generated when the electric field at the surface of the conductor becomes larger than the breakdown strength of the air. The oscillatory nature of the discharge generates high-frequency, short-duration current pulses, the source of corona-generated radio and television interference. Surface irregularities such as water droplets cause local field concentration, enhancing corona generation. Thus, during bad weather, corona discharge is more intense and losses are much greater. Corona discharge also generates audible noise with two components: a broad-band, high-frequency component, which produces crack-ling and hissing, and a 120-Hz pure tone.

Transmission-line conductors are surrounded by an electric field which decreases as distance from the line increases, and depends on line voltage and geometry. At ground level, this field induces current and voltage in grounded bodies, causes corona in grounded objects, and can induce fuel ignition. Utilities limit the electric field at the perimeter of right-of-ways to about 1000 V/m. An ac magnetic field around the transmission line also decreases with distance from the line.

Lightning strikes produce high voltages and traveling waves on transmission lines, causing insulator flashovers and interruption of operation. Steel-grounded shield conductors at the tops of the towers significantly reduce, but do not eliminate, the probability of direct lightning strikes to phase conductors.

The operation of circuit breakers causes switching surges that can result in interruption of inductive current, energization of lines with trapped charges, and single-phase ground fault. Modern circuit breakers, operating in two steps, reduce switching surges to 1.5 - 2 times the 60-Hz voltage. See CIRCUIT BREAKER.

Line current induces a disturbing voltage in telephone lines running parallel to transmission lines. Because the induced volt age depends on the mutual inductance between the two lines, disturbance can be reduced by increasing the distance between the lines and shielding the telephone lines.

Underground power transmission. Most cities use underground cables to distribute electrical energy. These cables virtually eliminate negative environmental effects and reduce electrocution hazards. However, they entail significantly higher construction costs.

Underground cables are divided into two categories: distribution cables (less than 69 kV) and high-voltage power-transmission cables (69 - 500 kV).

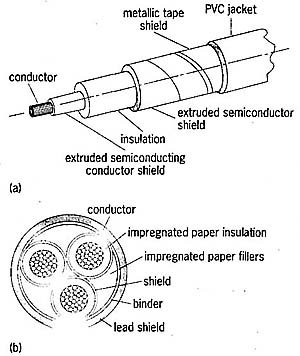

Extruded solid dielectric cables dominate in the 15 - 33-ky urban distribution system. In a typical arrangement (fig. a), the stranded copper or aluminum conductor is shielded by a semiconductor layer, which reduces the electric stress on the conductor’s surface. Oil-impregnated paper-insulated distribution cables are used for higher voltages and in older installations (fig. b).

Above: Underground distribution cables. (a) Extruded solid dielectric

cable. (b) Three-phase, oil-impregnated paper-insulated cable.

Cable temperatures vary with load changes, and cyclic thermal expansion and contraction may produce voids in the cable. High voltage initiates corona in the voids, gradually destroying cable insulation. Low-pressure oil-filled cable construction reduces void formation. A single-phase concentric cable has a hollow conductor with a central oil channel. Three-phase cables have three oil channels located in the filler.

Submarine cables. High-voltage cables are frequently used for crossing large bodies of water. Water provides natural cooling, and pressure reduces the possibility of void formation. A typical submarine cable has cross-linked polyethylene insulation, and corrosion-resistant aluminum alloy wire armoring that provides tensile strength and permits installation in deep water.