above: A line/load reactor from GE.

Three-phase harmonic-compensated line or load reactors allow one to "clean up" the voltage being sent to the motor from a VFD (Variable-Frequency Drive). Harmonic compensation maximizes the reactor's benefit to the VFD input circuit, while PWM / IGBT protection maximizes their performance in the drive output circuit. A purer voltage to both the VFD and the motor means:

- Improved Motor Drive System Reliability

- Reduced Motor Drive System Downtime

- Improved True Power Factor

- Virtual Elimination of Inverter Nuisance Tripping

- Attenuation of Input Current Harmonics

- Extended Motor Life

- Reduced Motor Peak Voltage

- Reduced Motor dv/dt Spikes

- Reduced Motor Temperature

- Reduced Motor Noise

Difference between "line" and "load" reactors:

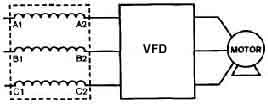

Line reactors are used the "line side" or input of a variable frequency drive (i.e. where three-phase voltage comes into the VFD). The following schematic shows a line-reactor installation in a VFD system:

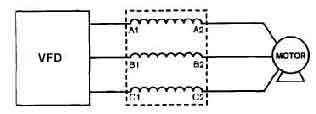

Load reactors are used on the "load" side of variable frequency drive (between the drive and the motor). Load reactors are a new, more effective reactor technology and are ideal for harmonic compensation. The following schematic shows a load-reactor installation in a VFD system:

About Harmonics

Harmonics, or multiple frequencies of the original, are always present

on the supply and com from many different types of equipment connected

to the supply. Some harmonics are introduced by iron cored components

such as motors and transformers, but by far the greatest source

of harmonics are electronic rectifiers as found in inverters and switched-mode

power supplies.