ENGINE COOLING

Power produced at the crankshaft is called gross horsepower. Accessories that rob power include the alternator (charging system), air conditioning, cool ant pump, cooling fan, power steering pump, and smog pump. Combined, these absorb about 25% of the power available at the crankshaft. The power remaining to be used is called net horsepower.

Power is also lost through friction in the driveline (transmission and differential) and due to wind resistance, increased vehicle weight, tires, and weather.

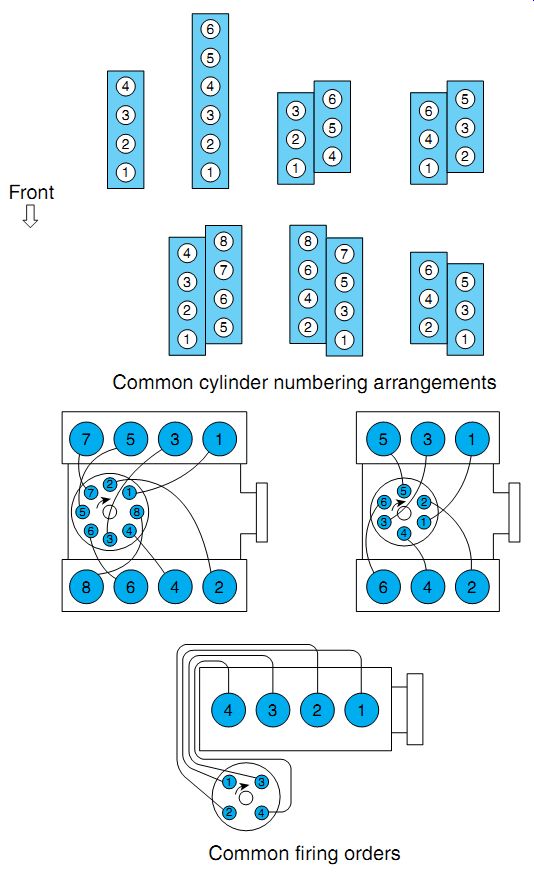

Fig 1.39 Several different cylinder numberings and firing orders. Common

firing orders. Common cylinder numbering arrangements.

In a spark ignition engine, only about one third of the energy of the burning fuel is converted to work at the crankshaft. The remainder is wasted as heat; half of it goes out the exhaust and the other half is carried off through the cooling sys tem and by air contact with the metal castings.

Automotive engines use liquid cooling systems.

Air cooled engines are found in lawnmowers, motorcycles, and some older automobiles.

Liquid cooled engines have water jackets to cool the areas around all cylinders and throughout the cylinder head, especially around the valve seats.

Coolant is pumped throughout by a coolant pump, commonly called a water pump. A thermostat regulates the flow of coolant between the engine and radiator to maintain a specified temperature.

Freezing and boiling protection is provided by a mixture of water and coolant in a concentration of about 50% water and 50% coolant. One of coolant's important jobs is to inhibit rust and electrolysis, which cause corrosion. The bimetal engine, found in some of today's cars and trucks, combines iron cylinder blocks and aluminum cylinder heads.

These two dissimilar metals promote electrolysis, or the creation of an electrical current. Electrolysis causes much faster deterioration of metals.

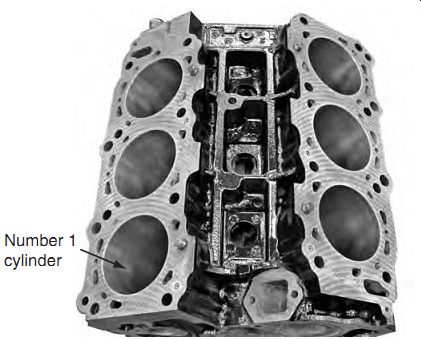

Fig 1.40 The number 1 cylinder is the closest to the front of the engine

on almost all V-type engines. Number 1 cylinder

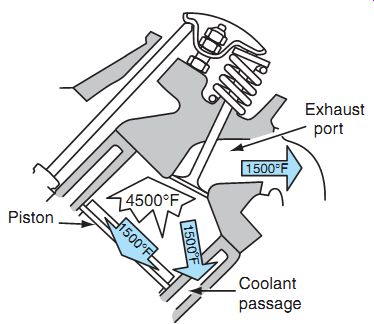

Fig 1.41 One-third of the heat energy produced is converted to work. The

other two-thirds go to the cooling system, exhaust, and metal castings.

Exhaust port 1500°F 1500 F ° Coolant passage Piston 4500°F 1500°F

CLASSIC ENGINE--The V-type engine uses a two-barrel intake manifold. On most V8s each barrel serves four cylinders. In theory, the V8 is actually two four cylinder engines operating together and a V6 is two three cylinder engines. An in-line engine with more than four cylinders would require fuel injection or multiple carburetors to distribute fuel more efficiently. Intake manifolds are covered in detail.

CLASSIC ENGINE--On a few older engines, the number 1 cylinder was positioned behind the front cylinder in the opposite cylinder bank. These include Ford's Y-block engines from the mid-1950s to mid-1960s as well as Ford and Mercury L-head engines and some older Pontiacs.

CLASSIC ENGINE--Until emission requirements curtailed their use, air cooled automobile engines were produced in vehicles like Volkswagen, Porsche, and Corvair. Air cooled engines operate at higher temperatures than liquid cooled engines. Higher running temperatures result in increased NOx (oxides of nitrogen) emissions (a major component in photochemical smog).

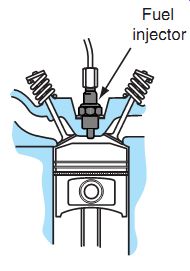

Fig 1.42 A diesel engine has a timed, high-pressure fuel injector to control

the point of ignition. Fuel injector

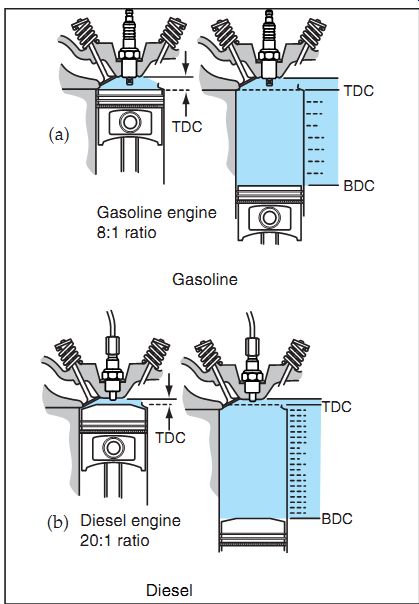

Fig 1.43 Comparison of gasoline and diesel compression ratios.

SPARK and COMPRESSION IGNITION

Although this text does not deal specifically with diesel engines, most of the automobile engine information included here applies to light-duty diesel engines found in some passenger cars and light trucks. Diesel-cycle and Otto-cycle engines share the same basic principles of operation. The difference is in the way the fuels are introduced to the cylinder and ignited. The gasoline engine is called a spark ignition (SI) engine.

Diesel Engine

The diesel engine was invented by Rudolf Diesel in 1892 in Germany. Diesel engines, which can be either two stroke or four stroke cycle, are used extensively in heavy equipment and were not used in automobiles until the 1930s. In operation and appearance, the diesel engine is very similar to the gasoline engine.

A diesel is a compression ignition (CI) engine. It does not use a spark to ignite the fuel. Diesel engines use fuel injectors. When air is compressed in the cylinder and high-pressure fuel is injected into it, the fuel ignites. Whereas gasoline engine compression ratios most often range between 8:1 and 10:1, diesel compression ratios range from 15:1 to 22:1. When air is compressed, it heats up. In a diesel engine the temperature of the compressed air can be approximately 1000°F. An air-fuel mixture will explode if it’s compressed too much, so the diesel engine compresses only air. Diesel fuel does not burn at room temperature; its autoignition temperature is 410°F (210°C). However, when diesel fuel is injected into the cylinder at the exact moment when ignition is desired, it burns easily in the hot environment of the compressed air.

Diesels use different types of injections, all of which must have injector pressure that is very high so it can overcome the cylinder pressures reached during the compression stroke. Older diesel engines had mechanical injectors operated by a camshaft.

Later engines used a precision fuel distributor and individual injectors. The most recent diesel engines use high-pressure, direct injection similar to gasoline direct injection described earlier.

Diesel engines can run at very lean mixtures at idle and are generally about one-third more efficient on fuel, although they produce less power than a gasoline engine. In gasoline engines the amount of air entering the engine is changed to control speed and power. In a diesel, the amount of air remains the same while the fuel mixture is changed to control speed and power. The mixture can be as rich as 20:1 under load and as lean as about 80:1 at idle.

Problems with older diesel engines were their high particulate emissions (soot) and the high temperature of combustion, which produces high levels of NOx emissions. Diesels also have starting problems in cold weather and require more frequent oil changes and other maintenance.

Modern diesel engines have been mandated to have exhaust emissions that are nearly free of particulates. Engine manufacturers have been able to accomplish this using computerized engine controls with altered engine designs. Common rail direct injection diesels first appeared in the mid-1990s.

A tube or passage called a common rail connects the fuel injectors with diesel fuel under very high pressure of nearly 20,000 psi (1360 BAR). The fuel system injects a small amount of high-pressure fuel before and after the main fuel charge. High pressure in the common rail thoroughly atomizes the diesel fuel, mixing it with air. This results in less unburned fuel and cleaner exhaust gas. Electronic piezoelectric injectors precisely control the fuel. Direct injection engines have lower emissions, are very responsive, and get better fuel economy than the old diesel engines.

Two Stroke Cycle

Two stroke engines have been used for years in diesel engines, outboards engines, chainsaws, and motorcycles. Other than a basic explanation of their operation, two stroke engines are not covered in this text. Future automobile engines might use the two stroke cycle because it has several advantages. A two stroke engine can be made smaller and lighter than a four stroke engine of comparable displacement.

Theoretically, a two stroke engine only requires half of the displacement of a four stroke engine.

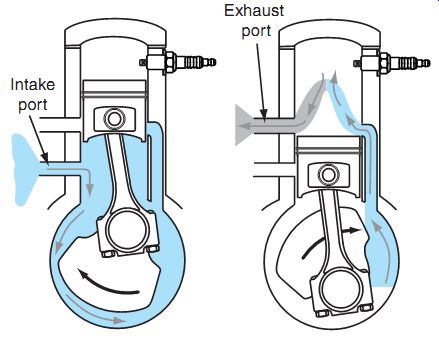

A two stroke engine has a power stroke every crankshaft revolution. The two stroke cycle begins with the piston at TDC on the power stroke. The cylinder has intake and exhaust ports, which are openings in the side of the cylinder. As the piston reaches the bottom of the power stroke, the exhaust port is opened to release exhaust gases. Shortly after the exhaust port opens, the intake port opens to force the air-fuel mixture to enter the cylinder. This action also helps to push the exhaust out. As the piston moves up on its compression stroke, both the intake and exhaust ports are covered.

Most nonautomotive two stroke engines use a mixture of oil and gasoline for lubrication. The oil and fuel mixture lubricates the lower end (crankshaft and bearings) as it flows through the crankcase on its way to the cylinder. New direct injected two stroke engines use fuel injectors to put fuel into the combustion chamber. Air is pushed into the cylinder using a supercharger. The crank case is pressure-lubricated in these engines just like in four stroke engines.

Fig 1.44 Two stroke cycle engine operation. Intake port; Exhaust port

NOTE: The sprocket or gear on the crankshaft has half as many teeth on it as the cam sprocket or gear. This is because the camshaft turns 360° (one turn) during one four stroke cycle, whereas the crankshaft turns 720° (two turns).

NOTE: An engine running at 3000 rpm has to open and close a valve 25 times per second! Each spark plug must also fire at this same speed.

PUTTING IT ALL TOGETHER

• Most of today's cars and light trucks are powered by Otto-cycle engines. During one four stroke cycle, the intake, compression, power, and exhaust strokes are completed. This action takes 720°, or two crankshaft revolutions.

• In a simple one cylinder engine, the reciprocating (up-and-down) motion of the piston is changed to usable rotary motion by the connecting rod and crankshaft. A flywheel gives momentum to the crankshaft between power strokes. Valves control the engine's intake and exhaust.

• Cylinders are arranged in-line, in a V, or opposed to each other. The most popular automotive engines have four, six, or eight cylinders.

• The camshaft controls the opening and closing of the valves and, thus, the way that the engine breathes. Different cam grinds provide better low-speed or better high-speed operation.

• The camshaft is driven by a chain, a belt, or gears.

• Cylinder rows, called banks, are determined from the flywheel end of the engine. A complete engine assembly including the heads is called a long block; without heads it’s called a short block.

• The crankcase houses the crankshaft and bearings. It’s enclosed by the oil pan. The crankshaft has a flywheel on one end and a vibration damper or pulley on the other end. The part that the bearing rides against is called the main or rod bearing journal. Crankpins on four cylinders are offset from each other by 180°, in-line six cylinders by 120°, and V8s by 90°.

• Engine sizes are described by their cylinder displacement, usually in liters. Engine breathing determines the power that the engine develops.

• Camshafts are located either in the block (push rod engine) or above the cylinder head (OHC). Pushrods are often found in V-type engines, whereas in-line engines are most often of the overhead cam design.

• Most crankshafts turn counterclockwise when viewed from the flywheel end of the engine.

Engine cylinders are fired in one of several firing orders. Pairs of pistons that go up and down together but fire 360° from each other are called companions.

• Most engines have liquid cooling systems that use coolant to prevent rust and corrosion and provide additional protection against freezing and boiling.

HIGH-PERFORMANCE ENGINE TIP

Top fuel dragster engines reach the upper end of their rev range somewhere between 7000 and 9000 rpm. Some Formula One engines approach 20,000 rpm. These are four stroke cycle engines, so the pistons must stop and start during every revolution of the crankshaft. At 18,000 rpm, each valve will have to open and close 150 times per second!

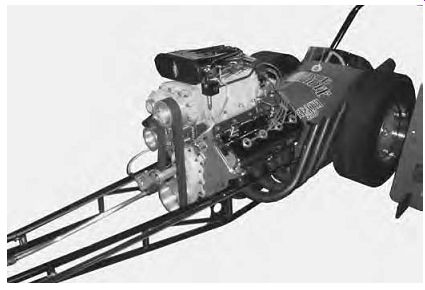

CLASSIC ENGINE---This vintage dragster engine is a "hemi." Note the spark plug cable terminations at the center of the cylinder heads, indicating the hemispheric combustion chamber design. The first automotive production hemi was a 180 HP model, introduced by Chrysler in 1951. By 1956, the Chrysler 300-B hemi had 340 HP. Hemi engines were popular in stock car racing and drag racing throughout the 1950s, 1960s, and 1970s. The four engine dragster shown has wedge cylinder heads.

Fig 1.45 This vintage four engine dragster has wedge cylinder heads.

Fig 1.46 A vintage dragster with a hemi engine.

TERMINOLOGY:

BDC bimetal engine blowby companion cylinders compression ratio displacement firing order lower end TDC transverse engine

EXAM:

1. What is the movement of the piston from top dead center (TDC) to bottom dead center (BDC) called?

2. What is the ratio called that compares the volume of the air space above the piston at TDC and BDC?

3. The crankshaft turns _____ as the camshaft.

a. half as fast

b. twice as fast

4. Where would an L-head engine be found today?

5. What does OHC mean?

6. How many times in 1 second will a valve open in an engine running at 6000 rpm?

7. What are four other names for a core plug?

8. What is a complete engine assembly called?

9. List three functions that a flywheel performs.

10. Do all engines use a vibration damper?

11. How many degrees are rod journals offset on the following engines?

V8s _____ °

in-line sixes _____ °

in-line four cylinders _____°

12. What type of engine is a compression ignition engine?

13. What are the normal ranges of compression ratios for the following?

Otto-cycle engine ______:1

diesel-cycle _______:1

14. In a four stroke, four cylinder engine, how many degrees must the crankshaft turn before the next cylinder in the firing order is fired?

15. What causes ignition to occur in a diesel engine?

SAMPLE ASE TEST:

1. Technician A says that the Otto-cycle gasoline engine has four strokes per cycle. Technician B says that the crankshaft makes four revolutions during the four stroke cycle. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

2. Technician A says that the purpose of the flywheel is to control the twisting of the crankshaft.

Technician B says that the purpose of the vibration damper is to help provide a continuous flow of power. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

3. Technician A says that an in-line six cylinder engine is usually longer and heavier than a V8 engine of the same displacement. Technician B says that there are twice as many teeth on the crankshaft sprocket as there are on the camshaft sprocket. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

4. An eight-cylinder engine has a 1 8 4 3 6 5 7 2 firing order. Technician A says that cylinder number 3 is cylinder number 1's companion.

Technician B says that cylinder number 5 is cylinder number 8's companion. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

5. A six cylinder engine has a 1 5 3 6 2 4 firing order. Technician A says that after cylinder number 1 begins its intake stroke, the crankshaft will have to travel 240° before cylinder number 3 begins its intake stroke. Technician B says that when cylinders number 3 and 4 are at TDC, cylinders number 5 and 2 are at BDC. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

6. Technician A says that diesel engines have compression ratios that are about twice as high as those found in gas engines. Technician B says that diesel engines require less maintenance than gasoline engines. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

7. Technician A says that "blowby" consists of gases that leak past the valves. Technician B says that blowby reduces the pressure in the crankcase. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

8. Technician A says that the intake and exhaust valves are both closed during most of the power stroke. Technician B says that the intake and exhaust valves are both closed during most of the compression stroke. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

9. Two technicians are discussing the part installed on the front of the crankshaft to control its twisting. Technician A says that it’s called a harmonic balancer. Technician B says that it’s called a vibration damper. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

10. Technician A says that the crankshaft turns 720° during one four stroke cycle. Technician B says that the camshaft turns 360° during one four stroke cycle. Who is right?

a. Technician A only

b. Technician B only

c. Both A and B

d. Neither A nor B

Next:

Prev.: Basics of Engine Operation (part 2)

Home Article Index top of page