LEARNING GOALS:

- Explain the principles of internal combustion engine operation.

- Identify internal combustion engine parts by name.

- Explain various engine classifications and systems.

INTRODUCTION:

Most of today's automobiles and light trucks are powered by a spark-ignited four stroke reciprocating engine. The first engine of this type was built in 1876 by Nicolaus Otto in Germany. Thus, it was named the Otto-cycle engine. Compared to previous internal combustion engine designs using the same amount of fuel, Otto's four stroke engine weighed less, ran much faster, and required less cylinder displacement to produce the same horse power. A few years later, this engine design powered a motorcycle and then a horseless carriage. Other engine designs in limited use in modern autos include the rotary (Wankel), two stroke, and compression ignition (diesel) engines.

In a spark-ignited internal combustion engine, a precise mixture of air and fuel is compressed in a cylinder. The fuel must be of a type that vaporizes easily (such as gasoline, methanol, or ethanol) or a flammable gas (such as propane or natural gas). When the compressed air-fuel mixture is burned, it pushes a piston down in a cylinder. This action turns a crankshaft, which powers the car.

CLASSIC ENGINE---Although Nicolaus Otto has been credited with the invention of the four stroke internal combustion engine in 1876, the French inventor Alphonse Beau de Rochas developed the concept 14 years earlier in 1862. He applied for a patent but did not pay the required taxes so the French government did not validate his patent.

SIMPLE ENGINE

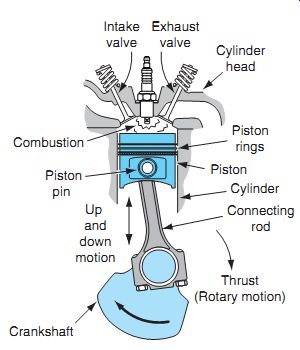

A simple reciprocating engine has a cylinder, a piston, a connecting rod, and a crankshaft. The cylinder can be compared to a cannon and the round piston can be compared to a cannonball. The end of the cylinder is sealed with a cylinder head. The piston, which is sealed to the cylinder wall by piston rings, is connected to the crankshaft by a connecting rod and a piston pin (also called a wrist pin).

This arrangement allows the piston to return to the top of the cylinder, making continuous rotary motion of the crankshaft possible. Because of the powerful impulses on the piston as the fuel is burned in the cylinder, a heavy flywheel is bolted to the rear of the crankshaft. The weight of the flywheel blends the power impulses together into one continuous motion of the crankshaft.

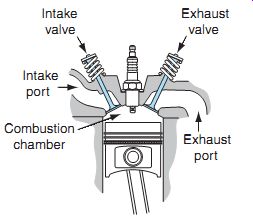

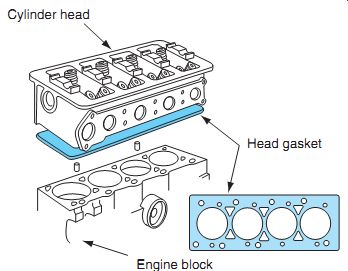

The cylinder head has one combustion chamber for each cylinder. An intake valve port allows a mixture of air and fuel to flow into the cylinder, and an exhaust valve port allows the burned gases to flow out. Each port is sealed off by a poppet style valve. The head is sealed to the cylinder block with a head gasket. The opening of the valves is controlled by the camshaft.

Fig 1.1 A piston forces a crankshaft to turn. Crankshaft; Thrust (Rotary

motion); Piston; Combustion; Cylinder head; Exhaust valve; Piston rings;

Intake valve; Piston pin; Up and down motion; Connecting rod; Cylinder

Fig 1.2 A flywheel is installed at the end of the crankshaft. This is a Buick

opposed engine from the early 1900s.

Fig 1.3 Valves seal off the valve ports. Intake valve Exhaust valve Intake

port Combustion chamber; Exhaust port

Fig 1.4 A head gasket seals the head to the block. Cylinder head Engine block;

Head gasket

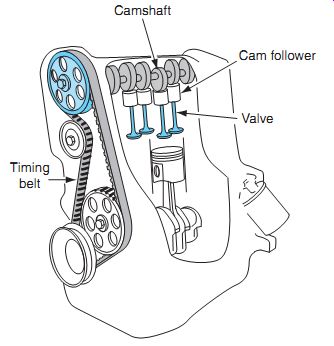

Fig 1.5 The opening of the valves is controlled by the camshaft. Camshaft;

Cam follower; Timing belt; Valve

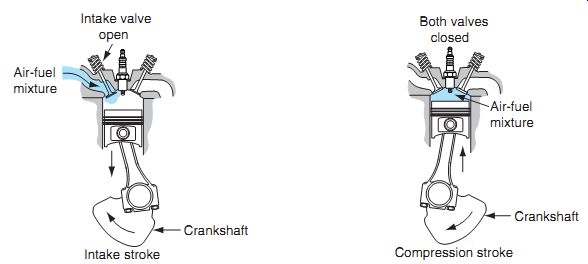

Fig 1.6 The air-fuel mixture is drawn into the cylinder. Intake valve open

Intake stroke; Air-fuel mixture; Crankshaft

Fig 1.7 The air-fuel mixture is compressed. Both valves closed; Compression stroke; Air-fuel mixture; Crankshaft

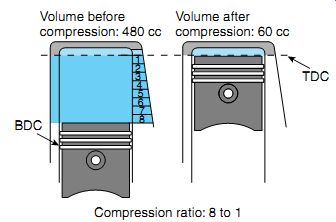

Fig 1.8 Compression ratio is a comparison of the volume of the air space

above the piston at BDC and at TDC. In this example the compression ratio is 8:1. Compression ratio: 8 to 1 Volume before compression: 480 cc Volume after

compression: 60 cc

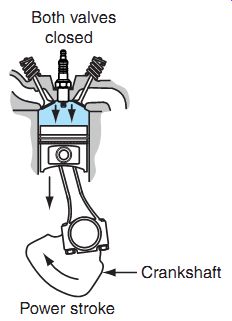

Fig 1.10 The air-fuel mixture ignites, pushing the piston down. Both valves

closed Power stroke; Crankshaft

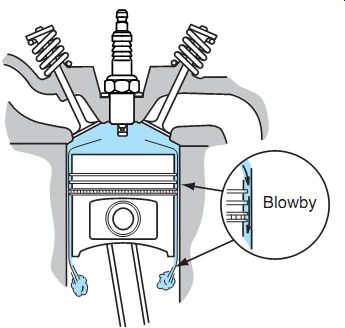

Fig 1.11 Leakage of gases past the ring is known as blowby.

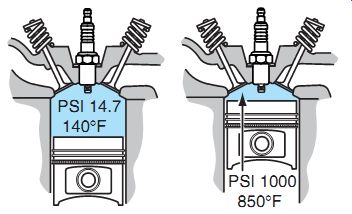

Fig 1.9 The air-fuel mixture heats up as it’s compressed.

OPERATION of 4-STROKE ENGINE

A stroke is the movement of the piston from TDC (top dead center) to BDC (bottom dead center), or from BDC to TDC. There are four strokes in one four stroke cycle of the engine. They are called the intake stroke, compression stroke, power stroke, and exhaust stroke.

• Intake Stroke. Gasoline won’t burn unless it’s mixed with the correct amount of air. It’s very explosive when 1 part is mixed with about 15 parts of air. Shortly before the piston reaches TDC, the intake valve begins to open. As the crankshaft turns, it pulls the rod and piston down in the cylinder toward BDC. This action creates a low-pressure void that is filled by atmospheric air pressure and fuel through the open intake valve. About 10,000 gallons of air is drawn in for every 1 gallon of fuel supplied by the fuel system. The ideal mixture (called stoichiometric) for the combined purposes of engine performance, emission control, and fuel economy is about 14.7:1 (at sea level).

Older vehicles had carburetors and newer vehicles manufactured since the mid-1980s have fuel injection systems with computer controls.

The computer monitors the oxygen content in the vehicle's exhaust and then adjusts the fuel supply to provide the correct amount of fuel and air for each intake stroke.

As the crankshaft continues to turn, the piston begins to move back up in the cylinder and the intake valve closes.

• Compression Stroke. The piston moves up in the cylinder, compressing the air-fuel mixture. If you light a puddle of gasoline on fire in open air it does not produce power. If it’s confined in a cylinder, however, usable power can be produced. Compressing the mixture of air and fuel into a smaller area makes it easier to burn. The compression stroke begins at BDC after the intake stroke is completed. As the piston moves toward TDC, both of the valves are closed as the mixture is compressed to about 1/8 of the volume it occupied when the piston was at BDC. In this case, the compression ratio is said to be 8:1. If the mixture is compressed to 1/12 its original volume, the compression ratio is then 12:1.

• Power Stroke. As the piston approaches TDC on its compression stroke, the compressed air-fuel mixture becomes very explosive. When the ignition system generates a spark at the spark plug, the fuel ignites. The air-fuel mixture burns, but it must not explode. As the mixture burns it expands, forcing the piston to move down in the cylinder until it reaches BDC. The action of the piston turns the crankshaft to power the car. The power stroke is sometimes called the expansion stroke.

Some leakage of gases past the rings occurs during the power stroke. This leakage, called blowby, causes pressure in the crankcase.

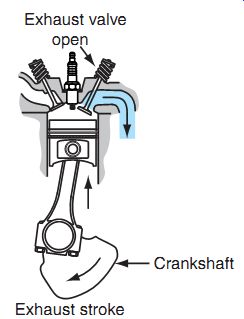

• Exhaust Stroke. As the piston nears BDC on the power stroke, the exhaust valve opens, allowing the spent gases to escape. Because the burning gases are still expanding, they are forced out through the open exhaust valve. As the crank shaft continues to turn past BDC, the piston moves up in the cylinder, helping to push the remaining exhaust gases out through the open exhaust valve. A few degrees after the piston passes TDC, the exhaust valve closes.

The entire four stroke cycle repeats itself, starting again as the piston moves down on the intake stroke.

The four stroke cycle is considerably more complicated than this simple explanation. When the engine is running, the timing of the opening and closing of the valves actually determines when each stroke effectively begins. Valve timing is discussed in much greater detail.

Fig 1.12 The exhaust valve opens and exhaust gases escape as the piston comes

up. Exhaust valve open; Exhaust stroke; Crankshaft

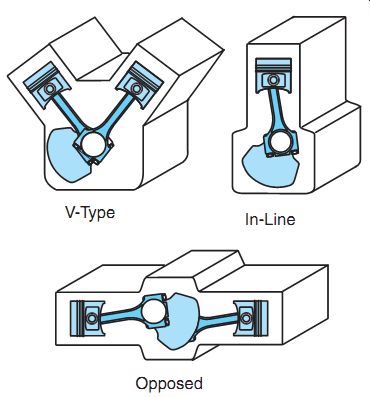

Fig 1.13 Cylinder arrangements. V-Type In-Line Opposed

CLASSIC ENGINE--- In the first half of the 20th century, before the jet age, airplane engines had cylinders arranged in a radial arrangement.

The V arrangement is popular with designers when an engine has more than four cylinders because this design can be considerably shorter in length. A completely assembled V-type engine typically weighs less than an in-line engine with the same number of cylinders.

V-type engines have connecting rods from two cylinders on opposite sides of the engine that share one crankpin. This allows the engine block to have fewer supports for the crank shaft main bearings. An in-line six cylinder engine might have seven main bearings; a V6 block is shorter and will typically have only four main bearings, whereas a V8 block will usually have five main bearings.

CLASSIC ENGINE--- A V-type engine uses a carburetor more efficiently than an in-line engine. This is because the intake manifold runner lengths are more equal.

In-line six and V6 engines.

Fig 1.14 A radial engine from a vintage airplane.

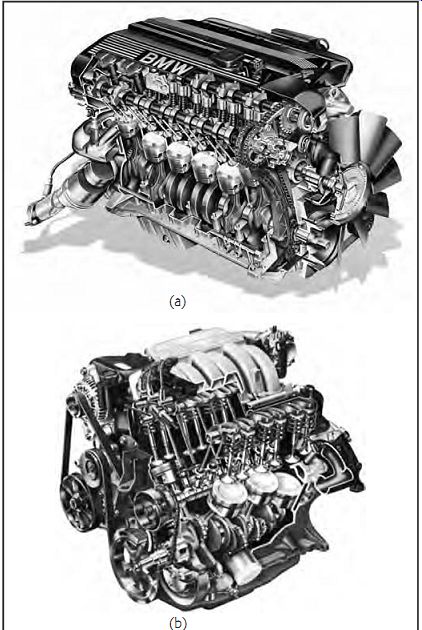

Fig 1.15 (a) Section view of an in-line six cylinder engine. (BMW) (b) Section view of a V6 engine.

CYLINDER ARRANGEMENT

Automobile and light truck engines have three, four, five, six, eight, or more cylinders.

Cylinders are arranged in one of three ways: in line, in a "V" arrangement, or opposed to each other.

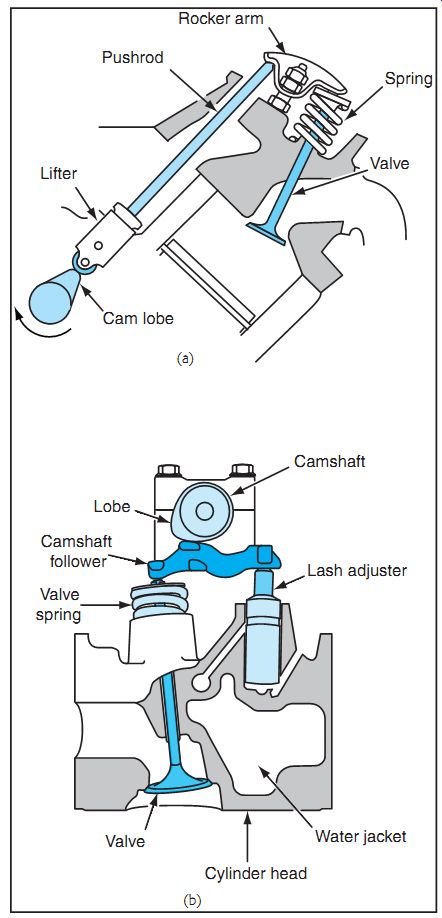

VALVETRAIN

One complete four stroke cycle requires the crankshaft to rotate two times. Two 360° crankshaft revolutions means the crankshaft travels a total of 720° to complete one cycle. During these two revolutions, each cylinder's intake and exhaust valves open once. The valves are opened by the camshaft, commonly called the "cam," which is considered the "heart" of the engine. The cam has lobes that are off-center and push against the valvetrain parts, causing the valves to open at precise times.

The camshaft controls the rate at which the engine breathes. Its design can be for best operation at maximum power and high speed, or for fuel economy and best low-speed operation. A production engine is an engine produced at the factory.

Production engines are a compromise between these two concerns, and this is the reason many late model vehicles use variable valve timing. --- deals with different "cam grinds" and variable valve timing in detail.

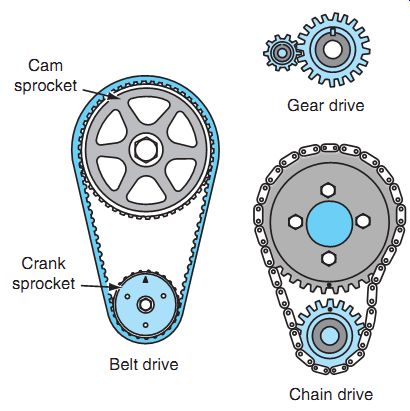

Camshafts can be located either in the block or in an overhead cam cylinder head. One or more camshafts are driven via crankshaft rotation using one of several combinations, including gears or sprockets and chains or belts. The crank must turn twice for every one turn of the cam, so there are half as many teeth on the crank drive as there are on the cam drive.

Fig 1.16 A cam lobe forces the valve open. (a) The cam-in-block design uses

pushrods to open valves. (b) In the overhead cam design, the camshaft is located

in the cylinder head. Lifter Cam lobe Pushrod Valve Rocker; arm Spring (a)

Camshaft Lobe Camshaft follower; Valve spring, Valve, Lash adjuster; Cylinder

head; Water jacket (b)

Fig 1.17 There are half as many teeth on the crank drive as there are on

the cam drive. Chain drive, Gear drive, Belt drive, Cam sprocket, Crank sprocket

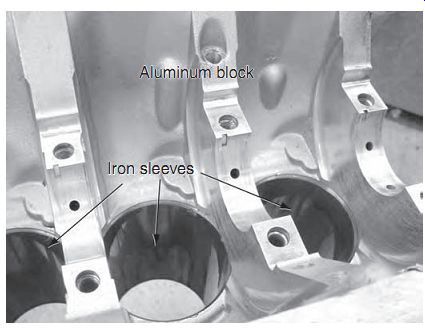

Fig 1.18 An aluminum block with cast iron sleeves.

Fig 1.19 Sand casting cores.

CYLINDER BLOCK

The cylinder block is an intricate casting that includes oil galleries as well as jackets for coolant, which are commonly called water jackets. Cylinder blocks are made of cast iron or aluminum, cast into a sand mold called a core. Many engine blocks today are made of aluminum, cast around iron cylinder bore liners called sleeves. This allows for the weight savings provided by aluminum, coupled with the durability and trueness of cast iron in the cylinder bore area. Some aluminum blocks don’t have iron sleeves because aluminum cylinder wall surfaces can be made very hard.

There are different casting processes for engine parts. In the sand casting process, the core is suspended in a container with a liner that will provide the shape for the outside surface of the engine block. The core is supported at several points around the outside of the core box, which leaves core holes in the finished block. The sand casting process uses binders to hold the grains of sand together. When molten iron or aluminum is poured into the core box, the heat of the casting process cooks the sand. When the casting cools, the sand breaks up. The casting is shaken out and any remaining sand is washed away through the core holes, leaving the finished casting.

In another casting process, lost foam casting (LFC), foam is "lost" or burned up during the pour.

General Motors first experimented with LFC in 1982 and since then has refined the process for use in casting blocks, heads, and crankshafts. Saturn used this process since its beginning in 1990. With conventional sand casting, oil galleries must be machined in the block casting. With LFC, the oil galleries and coolant passages can be cast into the part.

Foam also provides a more accurate casting com pared to sand casting. The completed casting is smoother in appearance and there are no parting lines. More intricate castings are possible because the pattern does not need to be removed as was the case with sand castings.

The LFC pattern is made of expendable poly styrene beads, otherwise known as Styrofoam. Pat terns are made by injecting the beads into a die and then superheating them with steam to bond them together and form the finished mold. The foam pat tern is coated with a refractory coating, which smoothes the surface of the pattern. Gates and risers are attached to the pattern to allow for the pouring and venting of the molten metal. Unlike the conventional sand casting process, which uses binders to hold the sand together, LFC uses dry, unbonded sand that is poured around and into the internal passages in the pattern. The sand is vibrated and compacted to thoroughly fill the voids around the pattern. During the pour, the molten metal replaces the pattern as it vaporizes. When the finished casting has cooled and become solid, the unbonded sand is dumped out. It can be reused, unlike conventional casting sand, which requires disposal.

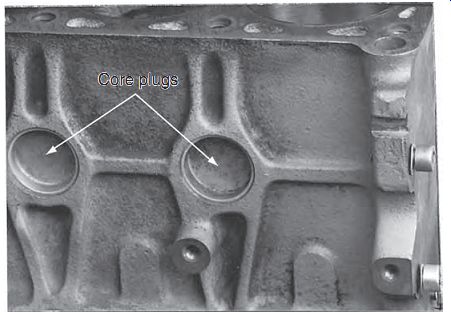

Fig 1.20 Core plugs.

The core holes are closed off with core plugs. Core plugs are usually made of steel or brass, although rubber and copper expandable plugs are available, too. Brass core plugs are superior because they don’t rust. Brass plugs are not used in new cars because of their extra cost and because new engines are filled with coolant, which prevents rust. Core plugs are sometimes referred to as expansion plugs, welsh plugs, freeze plugs, or soft plugs.

On V-type blocks, cylinders are cast in two rows called left and right banks.

NOTE: The location of the left and right banks is determined when viewing from the transmission end of the engine.

V8 blocks are cast with the cylinder banks separated by a 90° angle. V6 blocks have either 60° or 90° between banks. There are also unusual engine designs, such as Volkswagen's V6, which has 15° between banks.

There are big block and small block engine designs.

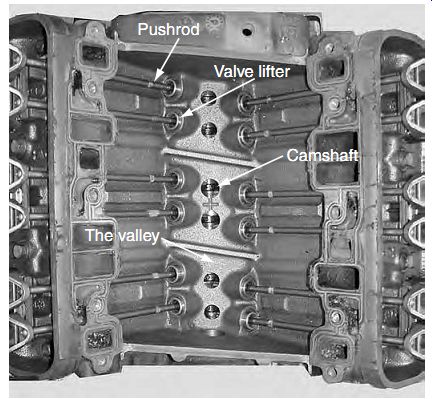

Smaller, lighter blocks are more popular in passenger cars because of their fuel efficiency. Some intake manifolds cover the area between the heads known as the valley, whereas others use covers and a separate intake plenum.

A complete block assembly with the entire valve train (cylinder heads and related parts) included is called a long block.

Fig 1.21 The area between the heads of a V-type engine is known as the valley.

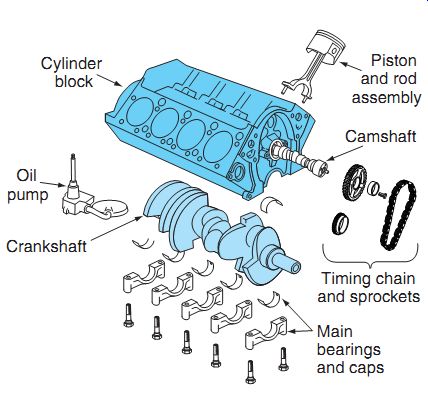

Fig 1.22 Exploded view of a short block for a cam-in-block engine. Cylinder

block; Piston and rod assembly Camshaft; Crankshaft; Main bearings and caps;

Oil pump; Timing chain and sprockets

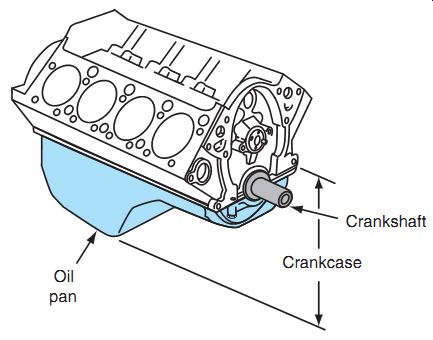

Fig 1.23 The oil pan encloses the crankcase. Crankshaft; Oil pan; Crankcase

Short Block and Long Block

The cylinder block assembly (without the heads installed) is called a short block. The short block includes the crankshaft, piston and rod assembly, and all bearings. On pushrod engines, the camshaft, timing sprockets, and timing chain are also part of the short block.

The lower area of the cylinder block surrounded by the oil pan is called the crankcase because the crankshaft is located there. Main bearing bore holes are precisely align-bored in the lower end of the block to provide a mounting place for the main bearings and crankshaft. Main bearing caps are removable, but they must be replaced in exactly the same location. At the factory, the camshaft bore holes, cylinder bores, cylinder head mounting surface, all threaded holes, and all gasket surfaces are machined automatically and in perfect alignment to each other. During rebuilding, the technician or machinist's job is to maintain the original alignment.

The following lists typical components common to both short and long blocks:

• Oil Pan. The oil pan is a stamped sheet metal or cast aluminum part that encloses the crankcase. It provides a reservoir where the engine oil is cooled as air passes across its surface. Oil pans are some times damaged when driving or during engine removal and replacement. Sometimes a sheet metal oil pan can be bent enough so that the crankshaft comes in contact with it.

After a rebuild, the resulting noise can cause a great deal of worry when the engine is first started.

• Flywheel. Mounted on the rear of the crankshaft is a flywheel or flexplate. The weight of the fly wheel helps carry the crankshaft beyond BDC after the power stroke and smoothes out the power impulses of multiple cylinders. A fly wheel is used with a standard transmission. It also provides a surface for the clutch to work upon. When the vehicle is equipped with an automatic transmission, a torque converter and flexplate are used. A ring gear on…

• Crankshaft. The crankshaft is made of either cast iron or forged steel. Its bearing surfaces for the main and rod bearings are called journals. The main bearing journals are those that run down the centerline of the crankshaft, in line between the front and rear journals. Oil galleries provide lubrication to the main bearing journals through oil holes in the main bearings. Holes are drilled in the crankshaft, from the main bearing journals to the connecting rod bearing journals, to provide the rod bearings with pressurized lubrication.

Rod journals, also called crankpins, are offset 90° on V8s, 180° on four cylinders, and 120° on six cylinders. Some V6s have offset crank pins; the circumference of the flywheel or flexplate provides a gear drive for the starter motor. Ring gears on flywheels and flexplates are sometimes damaged by faulty starter motors. Replacement of a flywheel ring gear or a flexplate is a relatively easy job while the engine is out of the vehicle.

• Vibration Damper. The vibration damper, also called a harmonic balancer, is mounted on the front of the crankshaft on V-type and in-line six cylinder engines. The power impulses on the pistons cause the crankshaft to twist and untwist in much the same manner as a tuning fork vibrates. The damper dampens out these torsional vibrations, which could result in a broken crankshaft if allowed to continue. Most 4-cylinder engines don’t require a damper and use only a pulley.

Fig 1.24 Crankshaft rod journals are offset 180° for four cylinders, 120°

for six cylinders, and 90° for eight cylinders. 4-cylinder crank pins V8 crank

pins; In-line six crank pins; V6 splayed crankshaft crank pins.

Next: Basics of Engine Operation (part 2)

Prev.: Ultimate Guide to Automotive Engine Technology--Index

Home Article Index top of page