As the spark plug fires, it ignites the air-fuel mixture delivered from the intake manifold during the power stroke of the engine. Ignition of the air-fuel mixture causes it to very rapidly oxidize (burn) and expand, forcing the piston downward in the cylinder. The air-fuel mixture inside the cylinder burns at temperatures approaching 4600 degrees Fahrenheit, Each firing in the cylinder does not produce that much heat because the volume of the air-fuel mixture is low. However, continued firing by four, six, or eight cylinders many times during a minute does create a rapid heat build-up.

Some of the heat produced (about 25%) is used to expand the burning air-fuel mixture. This, of course, is what drives the car as the expanding gas mixture forces the piston downward, turning the crankshaft. The balance of the heat does not do any useful work. It is passed out of the exhaust system and heats the engine oil and engine parts. The part of the heat that does not pass through the exhaust system—about 35% of the heat produced—would very quickly vaporize the lubricating oil in the cylinders and seize the engine if it were not removed from the engine. It is the job of the cooling system to remove this waste heat.

TYPES

There are two types of cooling systems in use with modern passenger cars: air and liquid. With the exception of a few imported models (and the Corvair), the great majority of car engines are liquid cooled, and these are the types of engines we shall concentrate on here.

Liquid cooling is accomplished by circulating a mixture of water and antifreeze through the passages of the water jacket inside the engine. There the heat is absorbed by the liquid mixture, which is pumped to the radiator where the cooling air flows through the radiator fins and removes the heat. The coolant liquid is circulated through the engine, hoses, and radiator by the water pump. The water pump is driven by a rubber V-belt from the crankshaft pulley and is normally located at the front of the engine.

The portions of the engine that need the most cooling are the cylinder walls and other sliding surfaces. In addition, the exhaust valves, which must handle high-temperature exhaust gases, are cooled to prevent combustion knock or overheating. In order for the piston to continue reciprocating, the cylinder walls must have a thin lubricant film for the piston rings to ride upon without cooling. High cylinder wall temperatures would quickly destroy or vaporize this oil film, causing rapid seizure of the piston rings and piston to the cylinder wall.

COMPONENTS

The major components of the cooling system are the radiator, the overflow recovery tank, the pressure cap, hoses, the thermostat, the fan, the water pump, the cylinder block passages or water jacket, the heater core, and the liquid coolant mix (antifreeze mix).

Radiator, Overflow Tank, and Pressure Cap

In the cooling system there are two primary ways heat transfer is accomplished. One is between the cooling fluid and the cylinder walls, the other between the radiator and outside air and the cooling fluid.

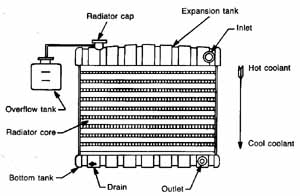

Fig. 1. Downflow radiator (engine side view).

The radiator is a heat-transfer device. It receives heat from the hot engine coolant and transfers it to the atmosphere via the cool air moving through the radiator core (Fig. 1). The radiator core is made up of water tubes and connecting fins. The hot coolant flows through the water tubes from the expansion tank at the top of the radiator to the bottom tank in the radiator. As it flows downward it loses its heat through the walls of the water tubes to the fins connected to the tubes. The rate of heat transfer to the air from the fins is proportional to the surface area of the fins. To a limit, the more fins a radiator core has, the more heat it can transfer. That is why the radiator core is jammed with so much fin material.

In order to keep the heat transfer rate efficiently high, air flow around the fins and through the core must not be impeded. Clean dead insects and any road debris from the radiator core whenever you notice it. Inspect the radiator monthly. Straighten any bent fins because these will also impede air flow.

Most cars with automatic transmissions are equipped with oil coolers to cool the automatic transmission fluid. The transmission oil cooler is another, smaller, finned radiator located within the larger engine radiator. It is placed in the outlet or bottom tank of the engine radiator. The automatic transmission cooler gives up its heat to the antifreeze mix inside the radiator which, in turn, loses heat to the outside air.

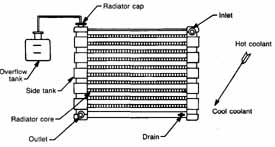

Not all radiators are the downflow type described above. Downflow radiators are used on smaller engines. Another type of radiator is the crossflow type used on larger V-8 engines. It is more efficient than the downflow type and can usually be made compact enough to fit under low, sleek, hood designs. In this type of radiator, hot coolant enters the radiator at an upper right or left corner and exits at a diagonal lower corner. If there is an automatic transmission cooler, it will be located in the cooler on the exit side of the radiator (Fig. 2).

Fig. 2. Crossflow radiator (engine side view).

Most car radiators are made of brass because brass will resist rust and corrosion much better than steel. Normally, radiators give little problem, but they will corrode after a time if not properly maintained. Antifreeze contains anti-corrosion additives to forestall corrosion, but these additives wear out eventually and need to be replaced. It is therefore necessary to flush the cooling system periodically and refill with fresh antifreeze mix. Do this every 12,000 miles. Some radiators are made of aluminum. Be sure to use antifreeze formulated for use in these radiators.

The other major radiator problem is clogging. Clogging normally occurs in the small- diameter water tubes inside the radiator. It can be caused by an accumulation of rust and corrosion scale that blocks these small holes. Periodic flushing and use of fresh antifreeze will help solve this. Clogging can also be caused by build-up of gum, sludge, and varnish deposits that are carried away from inside the engine through internal leakage of oil or burnt fuel into the cooling system. This type of clogging is rare. Suspect internal leaks where there is a gradual loss of coolant and no evidence of external leaks. Normally, internal leakage will lead to antifreeze fouling of the oil, and antifreeze leakage and burning into the cylinder, which can quickly ruin the engine. Internal leaks can be caused by a cracked intake manifold, blown head gasket, warped head, or cracked cylinder head or engine block. Repairs need to be made immediately if you suspect internal leakage.

In almost all modem cars there will be an overflow tank connected to the top of the radiator by a rubber hose. The hose is usually connected to the radiator right under the pressure cap (see Fig. 1). As the coolant expands from absorption of the engine heat, it forces its way past the pressure cap via a valve, through the connecting hose, and into the overflow tank. In older cars that used water instead of antifreeze as the coolant, this overflow tank wasn’t necessary. Overflow simply passed through an overflow hose and spilled to the ground. Clean the overflow tank whenever it looks dirty. The overflow tank is also used to give a quick indication of coolant inventory in the cooling system. If the overflow tank is empty, it is time to check the fluid level in the radiator.

Antifreeze expands five times more than water for the same volume and the same amount of heat absorbed. Overflow was, therefore, rare with water coolant systems. However, because antifreeze expands so much more than water, we need to provide the overflow tank to capture what would otherwise be lost coolant.

When the engine is shut off, the antifreeze gradually cools and contracts and any overflow is drawn back into the radiator by a siphon action. Markings on the side of the translucent overflow tank will indicate the antifreeze liquid levels for engine hot and engine normal or shut off. Add antifreeze mix to keep the level at normal at all times. Check this level weekly. Under normal conditions no coolant is lost. Also, check for sediment or scum in the overflow tank because this can lead to potential clogging of the radiator.

Aside from preserving antifreeze, the overflow tank eliminates air bubbles in the cooling system because, in effect, a cooling system with an overflow tank is a closed system. Coolant without air bubbles will absorb heat (and lose it) much better than cool ant with air bubbles.

In any heat transfer system, heat is transferred at a greater rate when the temperature of the heat absorber and the temperature of the heat generator are further apart and the system is pressurized. In the case of the car, the hotter the coolant, the faster heat is transferred from the radiator to the cooling airflow through it. And anyone who has ever done any food canning knows that to raise the temperature of the food being canned you need to heat it in a pressure cooker. That’s just what the radiator cap is used for. It does the same job as the lid on the pressure cooker. It raises the temperature of the antifreeze mix by pressurizing the cooling system from between 13 to 16 pounds per square inch. The pressure cap also seals the system so that air bubbles cannot leak into it. Thus, the pressurized and sealed cooling system transfers heat very efficiently from the engine.

The pressure cap also does double duty as the pressure relief valve for the cooling system. Any excessive overpressure of the cooling system causes the pressure relief valve of the cap to lift off its seat in the filler neck of the radiator, uncovering the opening into the overflow tube. Passage of the hot, over-pressurized coolant into the overflow tank causes the coolant to expand and reduce in pressure. When the pressure of the cooling system drops to the pressure rating of the radiator cap, the pressure relief valve closes, sealing the system again.

Check the condition of the radiator cap every 12 months. Clean the seals at this time. If the seals are cracked or hardened, replace the cap. You can have the cap tested for pressure capacity by having the spring tested at a service station. Replace a cap with a weak spring.

Remember to work on the cooling system with the engine off and cooled down.

Water Pump

Fig. 3. Water pump.

Engine coolant is circulated through the cooling system by the water pump, more appropriately called the coolant pump. The water pump is a centrifugal pump (Fig. 3). Engine coolant flows into the center or eye of the impeller of the pump. It travels along the ever-widening vanes of the impeller, where its energy or head is changed from velocity energy to pressure energy. The centrifugal force at the tips of the impeller flings the coolant out of the pump and into the cylinder block.

When the engine is cold the thermostat is closed, causing flow from the engine block to recirculate through the water pump rather than flowing to the radiator. This helps the coolant to warm up quickly and prevents unnecessary cooling of the engine when it’s cold, typically at start-up. Cold engines are very inefficient. When the engine warms to a preset temperature, the thermostat opens, allowing hot coolant to flow through the radiator for cooling. The cooled liquid then flows from the outlet of the radiator to the inlet of the water pump for another cycle through the engine.

Water pumps are fairly simple creatures. There is not a whole lot you can do to lengthen the life of a water pump. Be sure the coolant is kept clean and fresh. Abrasive dirt can cause premature failure of the internal seals with subsequent bearing failure of the pump. Assure that the coolant is fresh, because its anticorrosion additives protect the water pump. Maintain the V-belt that drives the pump at the specified tension. A V-belt that is adjusted too tight will cause premature pump bearing failure. A loose or worn V-belt will cause slipping and will not drive the water pump fast enough—which may, in turn, cause the engine to overheat. If the pump is driven by two belts, replace both at the same time even if only one is worn or cracked. If only one belt is replaced, all the force is put on the new belt and it will wear rapidly. When both belts are replaced, each will carry half the force. Check belt tension every month.

A water pump that is noisy or rattles is on its last leg. The bearings are worn and loose, which causes the noise. Also, any noticeable leakage of coolant—beyond a few drops through the weep hole in the bottom of the water pump—can point to internal seal failure. Either of these conditions is reason to replace the water pump.

Fans

The purpose of the fan is to pull cooling air through the radiator core. It has little, if any, direct cooling effect on the engine by itself. At idle and slow speeds the fan aids in the cooling effect of the radiator. At speeds above 35 to 40 mph, the air flowing through the radiator caused by the motion of the car provides all the cool air that is needed.

All engine fans have from four to eight blades. The blades are made of metal or plastic, and unless damaged by road debris, are maintenance-free. Sometimes the blades are spaced unevenly around the hub in an effort to reduce fan noise. Another way to reduce noise and to save on engine power is to use flexible blade fans. The pitch or twist of this type of blade changes as the speed of the fan increases. This results in each blade taking a smaller “bite” of air per revolution, saving engine power and reducing noise.

There are three types of radiator fans: direct drive, clutch type, and electric. Most engines use fans of either direct drive or clutch drive. They are mounted on the water pump shaft and receive their motive force from the V-belt and pulley arrangement that powers the water pump. Direct-drive fans can have either rigid or flexible blades.

Clutch-drive fans are usually used on cars equipped with air conditioning. The clutch drive fan is driven only when it is needed to keep the engine from overheating, thereby reducing noise and saving engine power. When the temperature of the air flowing through the radiator core rises, the heat causes a clutch mechanism mounted at the front of the fan to gradually engage the fan to the water pump shaft. When the air temperature becomes cooler, the clutch mechanism disengages the fan from the water pump shaft, and causes the fan to coast. Clutch fans can also have either rigid or flexible blades.

Electric fans are used on cars with transverse-mounted engines and on some engines with radiators offset to one side. Electric fans are powered by an electric motor that is controlled by a thermostatic switch. The switch turns the fan on only when additional cooling air is needed and turns the fan off if sufficient air flow through the radiator exists, in order to reduce noise and save engine power. Electric fans have rigid blades only.

Most modern cars have a shroud mounted around the fan. It is not a safety device and should not be counted upon to prevent a loose fan blade from causing damage or injury if it flies off the hub. The shroud is there to improve fan performance by acting like a wind tunnel. All air pulled by the fan must pass through the radiator core, because the shroud prevents it from going anywhere else. Thus, an increase in efficiency of the fan is realized.

Keeping the fan blades, the shroud, and the clutch face (if so equipped) clean is all you can do to maintain the fan. No periodic maintenance of the clutch mechanism on clutch drive fans is recommended. Fan blades that are cracked or bent are a serious safety hazard. Replace them as soon as possible. Inspect the fan every month for dam age and only with the engine off.

Thermostat

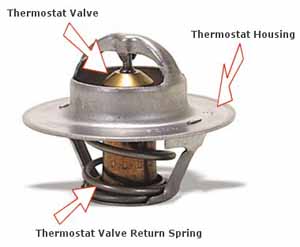

Fig. 4. Thermostat.

As stated above, the thermostat controls the direction of coolant flow, whether through the radiator and engine block or through the block only, depending on coolant temperature. The thermostat is a temperature-controlled valve placed between the cylinder head and the top inlet of the radiator (Fig. 4). As the temperature of the coolant rises, tiny copper-impregnated wax pellets inside the thermostat housing begin to melt and expand. As they expand they begin forcing a piston rod out of the thermostat housing, gradually lowering a valve and allowing more and more coolant flow to the radiator. When all the pellets are melted, the valve is fully opened and almost all coolant flow is to the radiator via the upper inlet radiator hose. In this open position, heat can be removed from the engine by way of increased flow to the radiator.

At start-up, engine heat should be conserved as much as possible to allow the engine to warm up quickly. This reduces the build-up of moisture, sludge, and acids. In addition, higher engine temperatures improve engine efficiency. The thermostat is normally closed at start-up.

Thermostats are sold in different temperature ranges. The temperature rating of the thermostat is the temperature it is designed to open at, allowing flow of the coolant to the radiator. Most common ratings are 180, 195 and 205 degrees Fahrenheit. Thermostats are fully open at about 20 degrees Fahrenheit above these temperatures. For example, for the 180-degree thermostat, it is fully open at 200-degrees. The shop manual or owner’s manual will tell you what temperature range of thermostat to use. Modem cars have thermostats for year-round use. No changing to a hot thermostat in winter and a cooler one in summer is needed or recommended.

Thermostats normally last for years. No periodic maintenance is necessary. Overheating and corrosion are enemies of thermostats. Checking the condition of the thermostat every year can help to avoid future problems. Your shop manual will tell you how to perform tests that reveal thermostat condition. Also, keeping the antifreeze fresh helps to prolong thermostat life by providing potent anticorrosion additives.

If the car overheats, takes forever to warm up, or if the passenger compartment heater does not warm up, the thermostat might be malfunctioning. Check the thermostat according to the tests in the shop manual. If it is defective, throw it away. Thermostats can’t be repaired. Replace it with the correct temperature range thermostat recommended for your car.

Water Jacket

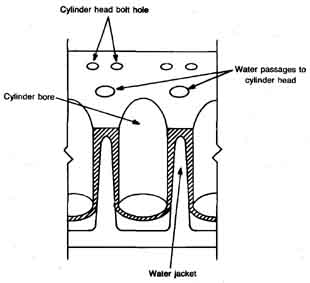

We’ve alluded to the water jacket of the engine in the above discussion without really defining it. Water jackets are molded into the cylinder block and cylinder head during the foundry casting process. They are merely open or hollow spaces between the outer walls of the cylinders, the inside of the cylinder block, and throughout the cylinder head. They are designed to keep the cylinders cool by providing space for the engine coolant to flow through. Keeping the antifreeze fresh will help prevent corrosion in the water jacket (Fig. 5).

Fig. 5. Engine water jacket.

Antifreeze

Antifreeze is the substance that makes the engine run cool. Years ago, tap water with a rust preventive additive was used as the engine coolant for most engines. This created a problem in cold weather, however, because it had to be drained to prevent freezing.

To prevent water from freezing and subsequent engine or radiator damage, antifreeze is mixed with the water in all modern cars.

Antifreeze is an alcohol-based liquid called ethylene glycol. Its heat transfer characteristics are only slightly different from those of water. It is normally mixed half and half with water and recommended for year-round use. In addition, it is formulated with rust inhibitor additives to prevent rust and corrosion, and foam inhibitors to reduce air entrapment and foaming since air does not conduct heat as well as the liquid coolant. Also, a red, green, or yellow dye is added to serve as a leak detector. Some antifreeze formulations contain tiny plastic beads or inorganic fibers that plug small leaks in the cooling system.

Here are a few do’s and don’t’s in regard to antifreeze. First, never add only plain water to the cooling system. The antifreeze can become so diluted that it will boil long before it should. Temperature indicator lights are calibrated to function for properly mixed antifreeze solutions only. The temperature indicator light will not come on until well above the boiling point of water. The engine can be overheating on a weak antifreeze mixture and you wouldn’t be aware of it before engine damage occurs.

If your engine or cooling system has aluminum parts, add only antifreeze that is formulated for compatibility with this metal. Not all commercial antifreeze is safe for use with aluminum.

As stated earlier, use a 50/50 mix of water and antifreeze in the cooling system and change it every 12,000 miles. A 50/50 mix freezes at -34 degrees Fahrenheit and boils at 266 degrees Fahrenheit, which is adequate for most climates. In extreme cold weather, a 64% concentration of antifreeze will lower the freezing point of the mixture to —84 degrees. Don’t add antifreeze beyond 64% concentration, because the freezing point will start to rise again to only —9 degrees for a 100% concentration of antifreeze.

Keep the same mixture of water and antifreeze in the engine year-round. The engine needs the corrosion protection all year long, even in sunny Florida.

Don’t mix any additives with the antifreeze mixture. If you suspect the antifreeze to be weak, flush it out of the cooling system and refill with fresh 50/50 mix. Weak antifreeze will look tan or rust in color. If you change the antifreeze mixture following our recommendation, you should never get to that point.

Years ago, water pumps had bearings that required a water pump lubricant to be mixed with the coolant. Modern cars use sealed bearings to support the impeller shaft in the pump. These bearings never need lubrication. Unless your shop manual directs the use of a water pump lubricant, don ‘4 add it to the coolant.

Never use a methanol- or ethanol-based antifreeze in the cooling system. A 50/50 mixture of methanol and water boils at only 180 degrees Fahrenheit long before the temperature warning light comes on. Normal coolant temperature can be as high as 250 degrees Fahrenheit or more. You must, therefore, use the 50/50 ethylene glycol and water mix in a pressurized system for complete protection.

Test the antifreeze mixture every three months with an antifreeze tester. If the tester indicates that the antifreeze is weak, better flush the system and replace the coolant with a fresh mixture as soon as practical.

Perform a complete cooling system check according to the instructions in the shop manual every 25,000 miles or two years. In the fall of each year inspect for leaks. When working around the cooling system, remember that antifreeze is poisonous. Don’t get it in your mouth or on your skin or in your eyes.

AIR CONDITIONING

More than half of the cars sold in the United States are equipped with air conditioning. Typical cooling or refrigeration capacity is 20,000 BTU/hour. This refrigeration capacity allows the passenger compartment temperature to be lowered by 25 to 30 degrees Fahrenheit with the car moving at 30 mph. Air conditioning is another heat transfer process similar, although more complicated, than the cooling system heat transfer process.

Theory

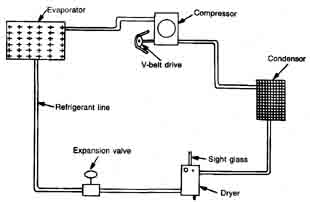

In a passenger car air conditioning system, the working fluid is usually Freon-12 (Fig. 6). The Freon-12 flows through a radiator-like device called an evaporator. As it does so, it picks up heat from the hot air flowing across the evaporator inside the car. As the Freon-12 heats up it vaporizes to a gas and flows to a belt-driven, clutch-activated compressor. The compressor pressurizes the gas, causing its temperature to rise.

From the compressor, the hot, pressurized Freon-12 gas flows to another radiator like device called a condenser. The condenser is usually mounted in front of the engine radiator. In the condenser, the Freon-12 gas loses heat to the cool air flowing through the condenser fins and condenses back into a liquid. The liquid Freon-12 then flows to a storage tank, sometimes called a dryer. Any water in the Freon-12 is removed by the dryer to prevent formation of corrosive hydrochloric acid.

The Freon-12 flows next to the expansion valve. In the expansion valve the Freon-12 is expanded from a relatively cool, high-pressure liquid to a much colder, low-pressure gas. This process (actually boiling of the Freon-12) requires heat to work. The heat is supplied by the hot air from inside the car passenger compartment. As the Freon-12 absorbs heat, it cools the fins in the evaporator, allowing the hot air from the car to transfer its heat to the fins. Cooled air flows back into the passenger compartment, and the cycle starts over again.

In addition to cooling the passenger compartment air, the air conditioning system will also dehumidify the air. This is done as water vapor in the humid air condenses inside the evaporator and is drained beneath the car. Sometimes a small puddle of water forms under the car from this drainage. This is a normal occurrence. In very humid air this condensed moisture might freeze and block the cooling fins of the evaporator. To prevent this, the suction throttling value (shown in Fig. 6) keeps the condensed water vapor out of the evaporator by pulling it back into the low pressure line, where it will eventually be removed from the system by the dryer.

Fig. 6. Air conditioning system.

Most air conditioning systems in modern cars are combined with the heating, defrosting, and ventilating systems. These systems normally share common ductwork. Thus, the proper type of air (heated, air conditioned, etc.) is directed through the ductwork, depending on the setting of the mode switch on the control panel. The air is directed by flapper doors that direct the proper amount of air through the ductwork to the appropriate outlet vents inside the car. Your shop manual will locate these doors and explain their operation.

Problems

The day you need the air conditioning the most could be the day it lets you down. Air conditioning problems can usually be traced to low refrigerant level, a loose compressor drive belt, a blown fuse or relay, a system leak, or flapper door troubles. Besides the compressor, the controls and flapper doors are the only moving parts of the system.

A sight glass is used in some systems to determine the amount of refrigerant in the system. If the glass is clear it indicates either a fully charged or empty system. If the system provides cool air, you can assume it is charged. If you see a few bubbles through the sight glass, the system might need to be charged. A foamy appearance in the sight glass indicates the system is just about empty and needs to be fully charged. Be especially alarmed if you notice a cloudy appearance through the sight glass. This most likely indicates that the drying chemical—called a desiccant—in the dryer is disintegrating and is being drawn through the system. Have the system serviced as soon as possible.

If the system needs a charge, have it serviced by a mechanic certified in air conditioning. You can buy a do-it-yourself recharge kit from an auto store, but we advise against this. Low refrigerant levels usually mean the system has a leak. To find a leak, a repairman uses a specially designed propane torch whose flame changes color in the presence of Freon-12 vapors. Fixing leaks, is an involved service best left to the pros, but finding leaks can be just plain hazardous. Freon-12 (or any other type Freon) is transformed into phosgene gas by the torch flame. This is commonly called mustard gas, and is deadly. Handling the Freon-12 poses another danger: if, while recharging, the Freon-12 blows back and gets in your eyes, you could be permanently blinded. Do not attempt this type of service yourself.

You can check the operation of the compressor and its clutch very simply. Start the car with the air conditioner off. Have someone turn the air conditioning on as you watch the clutch on the compressor. If the clutch does not engage, service is needed.

Preventive Maintenance

Run the air conditioner a few minutes every month both summer and winter. This causes the Freon-12 refrigerant to circulate throughout the system and helps keep all the seals in the various components lubricated. Lubricated seals won’t crack or dry out, and will help prevent refrigerant loss.

Check the condition of and adjust the compressor V-belt every month. Replace cracked, glazed, or frayed belts. Adjust the belt with a tension gauge according to factory specifications.

Check the level and condition of the refrigerant every month. If your system doesn’t have a sight glass check the system pressure instead at the low-pressure side port. Consult the shop manual for pressure readings that indicate whether recharging is necessary.

Clean the outside of the condenser in much the same manner you clean the engine radiator. Remove bugs and other debris from between the condenser fins, being careful not to bend any of the fins. Straighten them if they are bent. Clean the condenser monthly.

Check the operation of the flapper doors twice a year. Make sure all the controls are working properly at this time by checking the connection of all vacuum lines to the controls.

Test and tune up the system every two years, yearly if you live in a hot climate. Remember that most repairs should be left to a certified air conditioning mechanic. If you live in a colder climate, consider removing the compressor drive belt in the winter if it doesn’t operate other equipment. Even with the air conditioning load off the belt, the belt will turn the compressor clutch, resulting in a slight loss of engine efficiency.

SUMMARY OF RECOMMENDATIONS

• Inspect and clean the cooling system radiator monthly.

• Flush the cooling system every 12,000 miles and refill with fresh antifreeze mix. Test the coolant every three month with an antifreeze tester.

• Check the coolant level weekly. Check for signs of scum or sediment in the overflow tank.

• Check the radiator cap every 12 months. Consider replacing the cap every 100,000 miles regardless of condition.

• Check the water pump V-belt condition and tension monthly.

• Inspect the fan blades monthly for cracks or bending.

• Don’t add rust inhibitor to antifreeze. Certain types may contaminate the antifreeze mix by reacting adversely with antirust compounds already in the antifreeze.

• Never use a methanol or ethanol based antifreeze.

• Run the air conditioner a few minutes every month year-round to keep seals lubricated.

• Check monthly the condition and tension of the air conditioning compressor V belt, the refrigerant level, and clean the condenser.

• Check the operation of the air conditioning flapper doors and controls twice a year.

MECHANIC’S TIPS

• When replacing cooling system drive belts, consider replacing all the belts at the same time. Chances are they are all worn.

• Never remove a thermostat to prevent engine overheating. Find the cause of the overheating condition and solve it. Use a new gasket when replacing the thermostat.

• Never add plain water to the cooling system’. Use only the proper water/antifreeze mix year-round.

• Leave air conditioning system charging to your mechanic.

• Consider removing the air conditioning compressor belt in the winter to increase gas mileage.

Prev: Car Body Care

Next: When Trouble Strikes

Home top

of page