Section: Bed in closed position; Folding doors

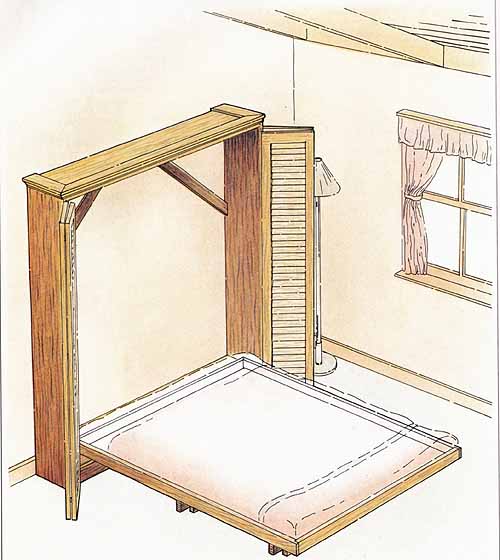

When your guest bedroom has to serve double duty as a den, recreation room, or library, you will probably want to hide the bed when it’s not in use.

This large cabinet is specially de signed to store a bed (the dimensions given are for a standard double mat tress), but it can be adapted for other uses. It would work well for hiding a model-train setup, for instance. What ever its use, this cabinet should be anchored to the wall, making a back panel optional. If you do include a back panel, it will be necessary to join two sections of plywood together in order to make a single piece that is large enough.

As shown, the cabinet is built of solid wood, lumber-core plywood, and purchased doors. Pine is the logical choice for the solid parts be cause it is widely available arid relatively inexpensive. It can be finished nicely, but if you are adept at veneering, you can give this large cabinet a more elegant look by applying veneer to the exposed sides and edges. Use hardwood-veneer plywood for the door panels and solid-hardwood molding at the top.

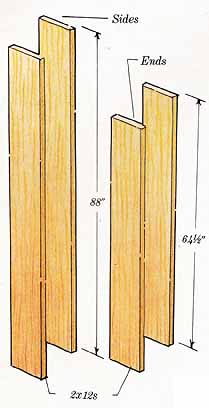

Cabinet box

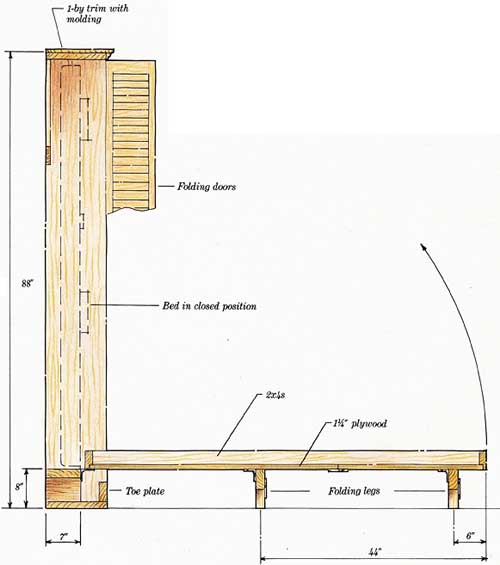

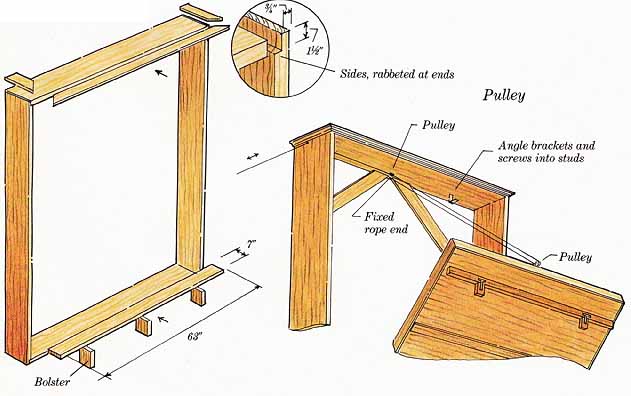

Using select 2 by 12 pine, cut sides 88 inches long and top and bottom pieces 64½ inches long. These dimensions allow a 3-inch clearance on each side of mattress-box assembly. The 3-inch spaces are necessary so that mattress box clears doors when they are in the folded-back position. Determine exactly how much space will be required by the doors and hinges you select and build the case accordingly. Even if doors fold completely out of the way, allow 1 inch on each side, to be safe. Cut rabbets at ends of side pieces and, if installing a back panel, along back edges. Glue and nail main case together.

Build a support shelf into bottom of main case using 2-by material 63 inches long, ripped to 7 inches wide. Attach top of support shelf 8 inches above outside bottom of case. Add 3 bolsters (see illustration) also cut from 2-by material.

Trim top of case with 3 glued-on pieces of mitered 1-by material. Overhang pieces 1 inch at sides and front, and skirt pieces with molding, mitered at the corners.

Lowering mechanism

Manufactured fold-up beds in cabinets utilize a spring mechanism to facilitate raising and lowering the mattress platform. These mechanisms can be purchased with or without the bed base.

In this version, the bed can be raised and lowered with a pulley, making it easier to both pull the bed down and push it back up. If you use the pulley system, install let-in braces at top of case. Make braces from 1 by 3 or 1 by 4 material.

Finish the case and set it into position. Use L brackets to secure case to wall, driving screws into studs.

Cabinet construction

Pulley: Sides, rabbeted at ends, Angle brackets and screws into

studs

Mattress box

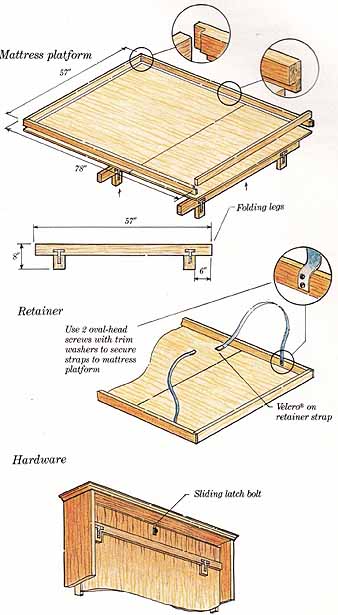

The mattress box consists of a 55½- by 76½ inch platform of 3 lumber- core plywood (2 pieces joined with a 55½ inch length of 1 by 4) nested into a frame of select-grade 2 by 4s.

Cut side pieces 78 inches long and end pieces 55’/2 inches long. Rabbet ends of side pieces as well as bottom inside edge of all 4 pieces. Screw and glue rails together, and nail and glue bottom platform in place.

Using select-grade 2 by 4s, make folding-leg assemblies to dimensions shown on the illustration. Hinge these assemblies to bottom of mattress plat form. Place 1 folding leg 6 inches from the foot of the bed; the other, 44 inches. Apply finish to assembly, let it dry, then hinge box to case using three 3-inch hinges.

Finishing the cabinet

Louvered shutter doors are a good choice on a bed cabinet because they allow air circulation when cabinet is closed; use the bifold type. If doors are a bit short (80-inch-long ones will be), set in a toe plate across bottom of case.

Install a sliding bolt to keep mat tress in the stowed position.

Attach four 1-inch-wide nylon webbing straps. Screw webbing to inside of mattress box rails using 2 oval-head screws and finish washers per strap. These straps hold mattress and bedding in place when bed is in the stowed position. Attach patches of Velcro® or sew D rings to strap ends.

Mattress platform; Retainer; Hardware

Prev.: Computer

Center

Next: Slide- or TV-,

Computer-Monitor Projector Cabinet

Full guide: How to Plan & Build Bookcases, Cabinets & Shelves

Product

Catalog